Vintage 4X spoking question

#51

Senior Member

Join Date: Apr 2016

Posts: 1,245

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 505 Post(s)

Liked 437 Times

in

336 Posts

We had inherited some bladed spokes that were never going to get used, so I used them to build myself some wheels, cutting and threading them by hand. I'm glad they were only 28 spoke wheels, that was plenty.

Likes For grumpus:

#53

Senior Member

Join Date: Apr 2016

Posts: 1,245

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 505 Post(s)

Liked 437 Times

in

336 Posts

So, the wheels had "half twist" spoking. Meaning they twist a half turn at the cross and continue to thd rim. Ie. a pulling spoke would become a pushing spoke at the rim.

Me, "what gives?"

Marty winking, "I hate #$&%$s who insist on giving me the parts, and anyway they were way too long".

Me, "what gives?"

Marty winking, "I hate #$&%$s who insist on giving me the parts, and anyway they were way too long".

#54

Senior Member

Originally Posted by Duragrouch

(above) Zero-cross, does not necessarily mean zero-angle. Many bikes with very large diameter hub motors use 0X by necessity, but the spokes are not radial, but are angled. It is not the cross per se that allows transmission of torque from the hub to the wheel, but the spoke angle other than pure radial.

(above) Zero-cross, does not necessarily mean zero-angle. Many bikes with very large diameter hub motors use 0X by necessity, but the spokes are not radial, but are angled. It is not the cross per se that allows transmission of torque from the hub to the wheel, but the spoke angle other than pure radial.

So they're pulling spokes on one side and trailing spokes on the other? Interesting. I was only aware of that spiral spoking being used for show-off wheel builds.

Still, there are zero-cross, zero-angle rear wheels out there, presumably used in applications where the strength of the build might have been inadequate for bikes with motors and/or disc brakes.

Still, there are zero-cross, zero-angle rear wheels out there, presumably used in applications where the strength of the build might have been inadequate for bikes with motors and/or disc brakes.

#55

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,729

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,595 Times

in

1,438 Posts

So, those spokes do cross operationally, but it happens within the shell rather than beyond, where the spokes actually are.

By example if you want to consider torque implications on a typical 3x32h wheel, you'd measure the radius at a right angle to where the spoke would pass even though it ends before that.

If i were asked (though nobody ever would) to name the pattern, I'd call them by -X crosses, based on the number of skipped holes.

Last edited by FBinNY; 02-11-24 at 08:32 PM.

#56

Senior Member

When thinking about tension structures, you have to consider the line of action, rather than the actual part.

So, those spokes do cross operationally, but it happens within the shell rather than beyond, where the spokes actually are.

By example if you want to consider torque implications on a typical 3x32h wheel, you'd measure the radius at a right angle to where the spoke would pass even though it ends before that.

If i were asked (though nobody ever would) to name the pattern, I'd call them by -X crosses, based on the number of skipped holes.

So, those spokes do cross operationally, but it happens within the shell rather than beyond, where the spokes actually are.

By example if you want to consider torque implications on a typical 3x32h wheel, you'd measure the radius at a right angle to where the spoke would pass even though it ends before that.

If i were asked (though nobody ever would) to name the pattern, I'd call them by -X crosses, based on the number of skipped holes.

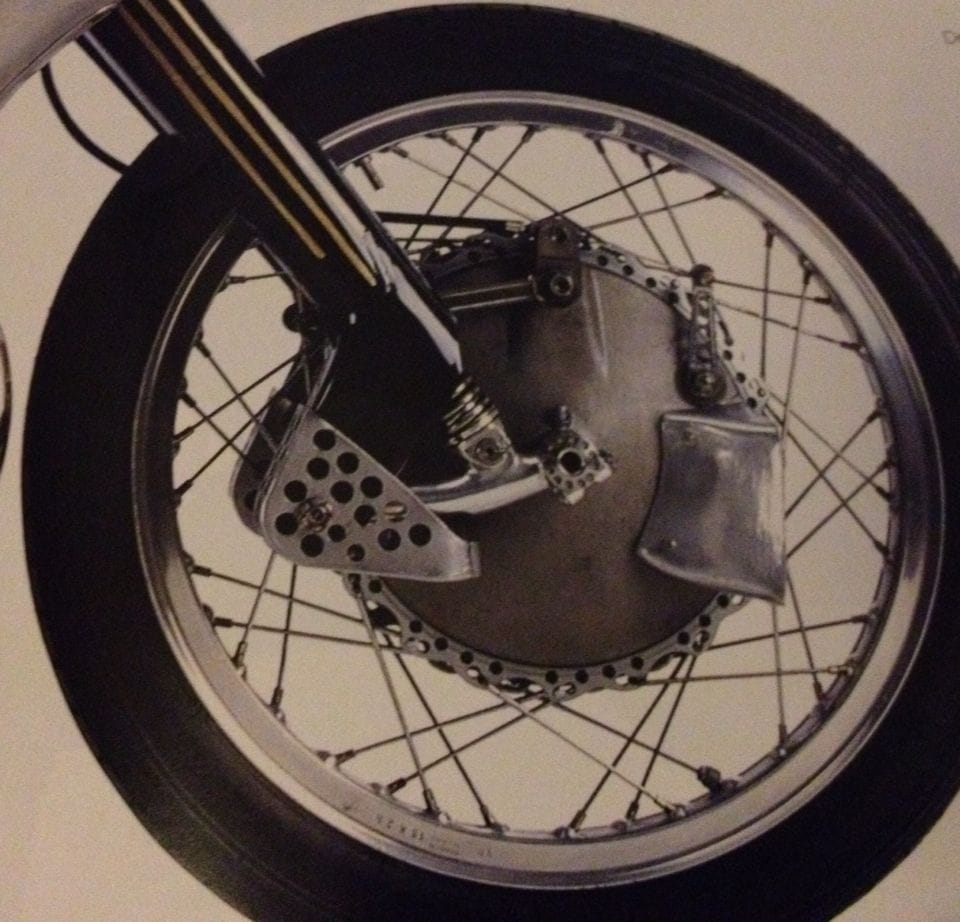

Actual physical crossed spokes are possible, with large hubs close to rim size, with the right rims with dimpled and aimed spoke holes:

Last edited by Duragrouch; 02-11-24 at 11:14 PM.

Likes For Duragrouch:

#57

Senior Member

Thread Starter

Join Date: Jan 2019

Location: Toledo Ohio

Posts: 1,497

Bikes: 1964 Huffy Sportsman, 1972 Fuji Newest, 1973 Schwinn Super Sport (3), 1982 Trek 412, 1983 Trek 700, 1989 Miyata 1000LT, 1991 Bianchi Boardwalk, plus others

Mentioned: 21 Post(s)

Tagged: 0 Thread(s)

Quoted: 583 Post(s)

Liked 700 Times

in

395 Posts

One comment I found interesting as relates to my original post is that 4x could be done with 2 different length spokes. Perhaps this was what the original builder did by accident on the NDS on my wheel.

#58

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,729

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,595 Times

in

1,438 Posts

As a simple example, imagine that your 3x wheel calls for 295mm spokes, which you don't have. Of course you can order them, but you're facing s deadline and can't wait.

If you have 297s and 293s, you can use them with all the long ones going one way and the short ones opposite. The wheel will come out fine with all spoke ending equally high in the nipples. The hub will be slightly twisted vs. the rim, but it won't be noticeable.

Way back in the early days of 32h, I was to build 32h track wheels for a sprinter. He was adamant that the non-tangent pattern wouldn’t handle the peak torques of sprinting as well, nor was going 36h an option.

I assured him I'd handle it, and built the rear with two lengths, so the pulling spokes were full tangent, and the others not. He was thrilled and had a great season. IMO another example of the placebo effect.

Likes For FBinNY:

Likes For grumpus:

#60

Senior Member

I would agree, thanks for that, I thought it was for strength. Thinking about it, if you ever had a wheel where spokes could be loaded in compression, crossed spokes might make them stronger, by reducing the unconstrained length of the spoke under compression. However, bicycle wheels, being designed for tension at all times, just varying between more tension and less tension, yes, I think you are right.

#61

Senior Member

Thread Starter

Join Date: Jan 2019

Location: Toledo Ohio

Posts: 1,497

Bikes: 1964 Huffy Sportsman, 1972 Fuji Newest, 1973 Schwinn Super Sport (3), 1982 Trek 412, 1983 Trek 700, 1989 Miyata 1000LT, 1991 Bianchi Boardwalk, plus others

Mentioned: 21 Post(s)

Tagged: 0 Thread(s)

Quoted: 583 Post(s)

Liked 700 Times

in

395 Posts

Kinda funny that a bike I’ve had sitting for nearly 3 years and I am tearing apart now also has 4 cross wheels. This one is from 1984 I believe. It is a Torpado Nuovo Sprint with low flange Miche hubs laced 4X to Ambrosia 19 rims. Spoking looks fine, but finding a two prong Regina freewheel tool is the problem now. That’s what makes it all interesting and keeps the mind occupied.

#62

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,729

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,595 Times

in

1,438 Posts

[QUOTE=Trakhak;23153644

.....Some of the older posters here will undoubtedly remember going to bike trade shows in the early '80's and visiting the Hi-E Engineering booth, where Harlan Meyer's latest wild designs would be on display.....[/QUOTE]

Harlan Meyers....brings back fond memories of a great era, and interesting people. Thanks for the trip down memory lane....

.....Some of the older posters here will undoubtedly remember going to bike trade shows in the early '80's and visiting the Hi-E Engineering booth, where Harlan Meyer's latest wild designs would be on display.....[/QUOTE]

Harlan Meyers....brings back fond memories of a great era, and interesting people. Thanks for the trip down memory lane....

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

Likes For FBinNY:

#63

Senior Member

Kinda funny that a bike I’ve had sitting for nearly 3 years and I am tearing apart now also has 4 cross wheels. This one is from 1984 I believe. It is a Torpado Nuovo Sprint with low flange Miche hubs laced 4X to Ambrosia 19 rims. Spoking looks fine, but finding a two prong Regina freewheel tool is the problem now. That’s what makes it all interesting and keeps the mind occupied.

#64

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,729

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5793 Post(s)

Liked 2,595 Times

in

1,438 Posts

Find two pieces of metal that match the freewheel slots. Clamp both in a good vise, at the correct spacing. Put freewheel over the metal parts. Turn wheel anti-clockwise to unscrew freewheel. I think in my toolbox is a two prong of some type that I altered at the bench grinder to fit another type.

Interestingly, Regina removers were the second tool I produced BITD, after cone wrenches. you won't find any to buy these days, but any mechanic who was working before the 90s will still have one tucked away.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#65

Senior Member

This is a good way to destroy a Regina or Everest freewheel. Removing these requires a solid purchase that absolutely shift, lift, or cam. It is necessary that you use the right remover, and clamp it down with the QR.

Interestingly, Regina removers were the second tool I produced BITD, after cone wrenches. you won't find any to buy these days, but any mechanic who was working before the 90s will still have one tucked away.

Interestingly, Regina removers were the second tool I produced BITD, after cone wrenches. you won't find any to buy these days, but any mechanic who was working before the 90s will still have one tucked away.

Spoke wrench, had just bought a new Cannondale and my old wrench didn't fit, Sunday, bike shop closed, had 24/7 access to machine shop at my college, whipped one out. 35 years later, still works great:

Likes For Duragrouch:

#66

Senior Member

Join Date: Jul 2005

Location: Boulder County, CO

Posts: 4,398

Bikes: '80 Masi Gran Criterium, '12 Trek Madone, early '60s Frejus track

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 514 Post(s)

Liked 451 Times

in

339 Posts

Any is a big word, so needs qualification, as in any wheel 36h or greater.

It's simple geometry. 4x 36h is full tangent. Likewise, 3x28, 2x24, and 1x12. You could do 4x32, but the spokes would leave the hole on a secant, passing inward before going out to the rim. It's possible, but annoying and pointless.

It's simple geometry. 4x 36h is full tangent. Likewise, 3x28, 2x24, and 1x12. You could do 4x32, but the spokes would leave the hole on a secant, passing inward before going out to the rim. It's possible, but annoying and pointless.