Bad ISIS splines on FSA crank- and almuminum carnage- anyone else see this?

#1

Two wheels, two skis...

Thread Starter

Join Date: Mar 2006

Location: Dudley, MA

Posts: 647

Bikes: Tarmac SL4, Lemond Victoire, Titus Motolite

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 10 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Bad ISIS splines on FSA crank- and almuminum carnage- anyone else see this?

So I was all happy because I got a good deal on the 2007 FSA SL-K compact road crank Nashbar was selling. I've been wanting a compact double for a while, and my PT girlfriend kept telling me I needed it to be easier on my knees. It came UPS on Monday and I was installing it today. The mega something BB when in fine after I sprung for the $20 outboard bearing tool. The shell width matched perfect. I was happy. Oh, for anyone that doesn't know, the SL-K has a spindle attached to the drive side crank, like the new Shimano cranks, and a hollow BB with the bearings on the outside of BB shell.

Here's the crank from FSA's website:

https://road.fullspeedahead.com/fly.a...xid=53&pid=292

I got the right O-rings and washers where they were supposed to be, and slid the spindle through the BB. I was excited because it was taking really no time. The only real work to do was to push the non drive crank arm onto the ISIS splines on the spindle. Here's a picture of the crank pieces so you know what I'm talking about in case you're lost:

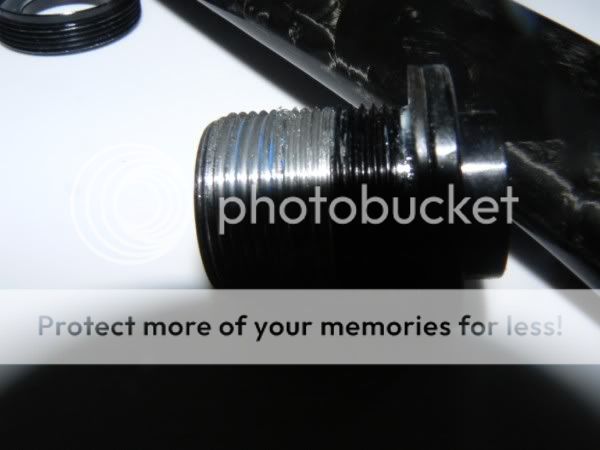

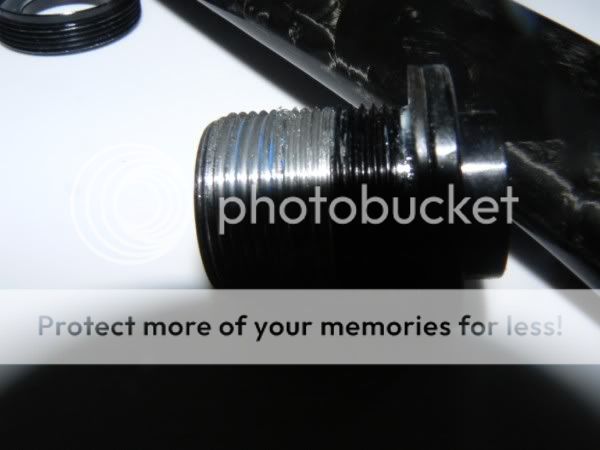

I'm making progress, but the progress begins to slow and the bolt starts offering lots of resistance. I've had tight ISIS splines before so I didn't think much of it. Soon they became unnervingly tight. My bud shows up on his bike to go riding and lends a hand. We put a little cheater bar on it, make more progress and it becomes way too tight. My 8 mm allen wrench is bending. Not a good sign. I pull the crank bolt out and it looks like this:

Notice how there was paint on those threads. When I pulled it out, it was full of aluminum shavings. Here's some of the carnage, sorry it's out of focus:

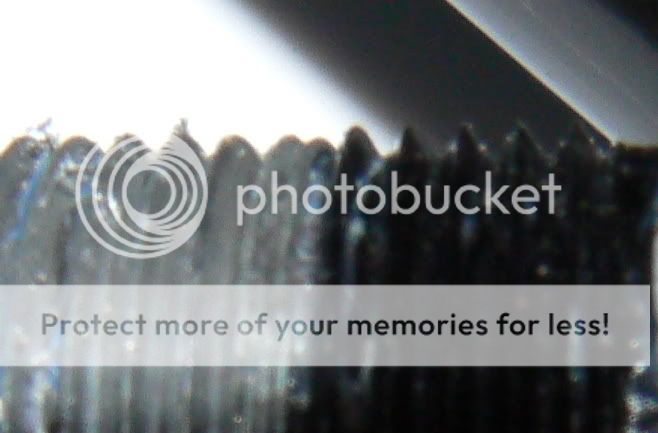

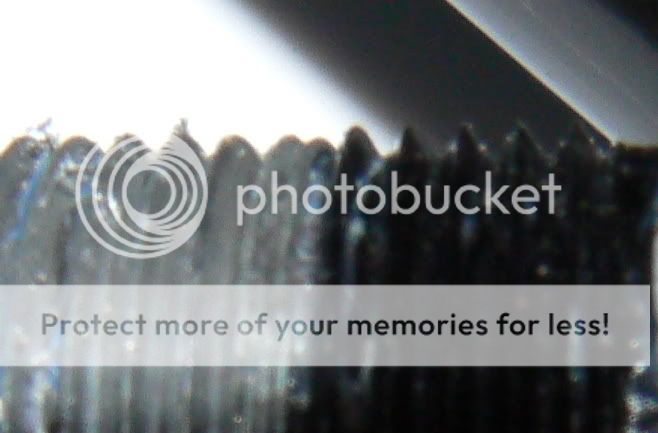

Had I cross threaded it? Doubtful... it went four threads deep by hand right away. I was dumbfounded, as was my friend. The above pictures shows exactly where the threads failed. We had begun to cut threads of our own. How exciting! The threads on the crank spindle were not as bad, being some sort of steel, probably from a diecasting? It seemed unlikely either of the threads were cut wrong. I couldn't get my crank puller in the threads, so I threaded the mangled bolt back in and used the self extracting feature. I inspected the spindle and low and behold found some funny marks in the splines:

Whatever material that is seemed fairly hard. It had to be, because it was able to do this to the splines in the crank arm:

Yeah. Neat huh?

I was able to get a replacement from Nashbar after a quick word with the fine people at FSA, and found out they don't deal directly with consumers.

I can't figure how exactly the splines could be so out of tolerance. My friend thought at first it was more likely for the female splines to be off, but I didn't think so, because where they deformed was probably just a round bit that machined out that material. I really think the male splines are either die cast or forged, and somehow, they either didn't bang em hard enough or something went afoul in the casting. Either way, not good.

Anyone else seen this on FSA cranks or any other ISIS cranks?

Here's the crank from FSA's website:

https://road.fullspeedahead.com/fly.a...xid=53&pid=292

I got the right O-rings and washers where they were supposed to be, and slid the spindle through the BB. I was excited because it was taking really no time. The only real work to do was to push the non drive crank arm onto the ISIS splines on the spindle. Here's a picture of the crank pieces so you know what I'm talking about in case you're lost:

I'm making progress, but the progress begins to slow and the bolt starts offering lots of resistance. I've had tight ISIS splines before so I didn't think much of it. Soon they became unnervingly tight. My bud shows up on his bike to go riding and lends a hand. We put a little cheater bar on it, make more progress and it becomes way too tight. My 8 mm allen wrench is bending. Not a good sign. I pull the crank bolt out and it looks like this:

Notice how there was paint on those threads. When I pulled it out, it was full of aluminum shavings. Here's some of the carnage, sorry it's out of focus:

Had I cross threaded it? Doubtful... it went four threads deep by hand right away. I was dumbfounded, as was my friend. The above pictures shows exactly where the threads failed. We had begun to cut threads of our own. How exciting! The threads on the crank spindle were not as bad, being some sort of steel, probably from a diecasting? It seemed unlikely either of the threads were cut wrong. I couldn't get my crank puller in the threads, so I threaded the mangled bolt back in and used the self extracting feature. I inspected the spindle and low and behold found some funny marks in the splines:

Whatever material that is seemed fairly hard. It had to be, because it was able to do this to the splines in the crank arm:

Yeah. Neat huh?

I was able to get a replacement from Nashbar after a quick word with the fine people at FSA, and found out they don't deal directly with consumers.

I can't figure how exactly the splines could be so out of tolerance. My friend thought at first it was more likely for the female splines to be off, but I didn't think so, because where they deformed was probably just a round bit that machined out that material. I really think the male splines are either die cast or forged, and somehow, they either didn't bang em hard enough or something went afoul in the casting. Either way, not good.

Anyone else seen this on FSA cranks or any other ISIS cranks?

#2

Junior Member

Join Date: Feb 2007

Location: PHILA

Posts: 14

Bikes: GF Sugar Novara Buzz Schwinn Stingray Schwinn World Wport

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Never seen this exactly, I'm not sure how you installed it, but the splines should be well greased before mating the spindle to the crank arm. Its super important to make sure the crank arms are mating properly before you begin to apply torque. Also it is crucial to properly torque these crankarms I have personally seen them fall off of several bikes. The proper procedure is to torque the arm to the specified value at which time you should feel the bolt bottom out, if you do not feel this remove the arm and repeat.

best of luck

best of luck

#3

Two wheels, two skis...

Thread Starter

Join Date: Mar 2006

Location: Dudley, MA

Posts: 647

Bikes: Tarmac SL4, Lemond Victoire, Titus Motolite

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 10 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

There was grease on the splines, but I wiped it all off to take pictures.

Doesn't matter though, grease or no grease wouldn't do something like that. It wasn't even on the whole way, there was probably still an 1/8" gap left. There's no physical way it can go on crooked. Even if there was a physical way for it to be crooked, then I would've seen symmetrical deformation. It was all on two or three adjacent splines. I don't think there's any other explanation other than parts were made out of tolerance.

I agree with you that torque and alignment are crucial on square taper setups, but ISIS is nearly fully idiot proof. Just look at the way the splines are cut...

Hmm... I wonder if FSA is ISO 9000...

Doesn't matter though, grease or no grease wouldn't do something like that. It wasn't even on the whole way, there was probably still an 1/8" gap left. There's no physical way it can go on crooked. Even if there was a physical way for it to be crooked, then I would've seen symmetrical deformation. It was all on two or three adjacent splines. I don't think there's any other explanation other than parts were made out of tolerance.

I agree with you that torque and alignment are crucial on square taper setups, but ISIS is nearly fully idiot proof. Just look at the way the splines are cut...

Hmm... I wonder if FSA is ISO 9000...

#4

Senior Member

Join Date: Aug 2005

Location: Pittsburgh, PA

Posts: 33,656

Bikes: '96 Litespeed Catalyst, '05 Litespeed Firenze, '06 Litespeed Tuscany, '20 Surly Midnight Special, All are 3x10. It is hilly around here!

Mentioned: 39 Post(s)

Tagged: 0 Thread(s)

Quoted: 2026 Post(s)

Likes: 0

Liked 1,096 Times

in

742 Posts

I don't think that's what you did but it can be done.

#6

Two wheels, two skis...

Thread Starter

Join Date: Mar 2006

Location: Dudley, MA

Posts: 647

Bikes: Tarmac SL4, Lemond Victoire, Titus Motolite

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 10 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Yeah.... I think I'm still of the opinion it would take incompetency beyond my level of comprehension to f up the installation of an ISIS crank. Compare how deep the splines are cut to the depth of the deformation I induced in the crank splines. And that was only on two or three splines. Now imagine the amount of cold deformation that would be required to install that crank arm uniformly misaligned. I don't know if a tool exists to apply that much torque. To do what I did required using a 10" cheater on an 8 mm allen key and standing on the crank arm.

Now of course, the minimum amount of torque to get a properly manufactured ISIS crank installed fully is obviously important, but a little over torque, as long as you understand those bolts are a soft aluminum, is not a huge issue. Someone that has terrible feel for that kind of thing I'd recommend a torque wrench to but otherwise, it's probably a waste of time. Torque wrenches are pretty darn imprecise as it is.

Now of course, the minimum amount of torque to get a properly manufactured ISIS crank installed fully is obviously important, but a little over torque, as long as you understand those bolts are a soft aluminum, is not a huge issue. Someone that has terrible feel for that kind of thing I'd recommend a torque wrench to but otherwise, it's probably a waste of time. Torque wrenches are pretty darn imprecise as it is.

#7

Two wheels, two skis...

Thread Starter

Join Date: Mar 2006

Location: Dudley, MA

Posts: 647

Bikes: Tarmac SL4, Lemond Victoire, Titus Motolite

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 10 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

#8

Two wheels, two skis...

Thread Starter

Join Date: Mar 2006

Location: Dudley, MA

Posts: 647

Bikes: Tarmac SL4, Lemond Victoire, Titus Motolite

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 10 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Ok, never mind, they're definitely not ISIS splines. But that's not really the point. I don't think calling them ISIS splines is what cause the issue.