Question about a wheel the LBS built for me - should I be concerned?

#1

Senior Member

Thread Starter

Join Date: Jan 2011

Location: Utah

Posts: 781

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 27 Post(s)

Likes: 0

Liked 7 Times

in

4 Posts

Question about a wheel the LBS built for me - should I be concerned?

Hello,

I hate to have to even ask this, because I like these guys; they have been good to me. But I'm afraid this might not be right.

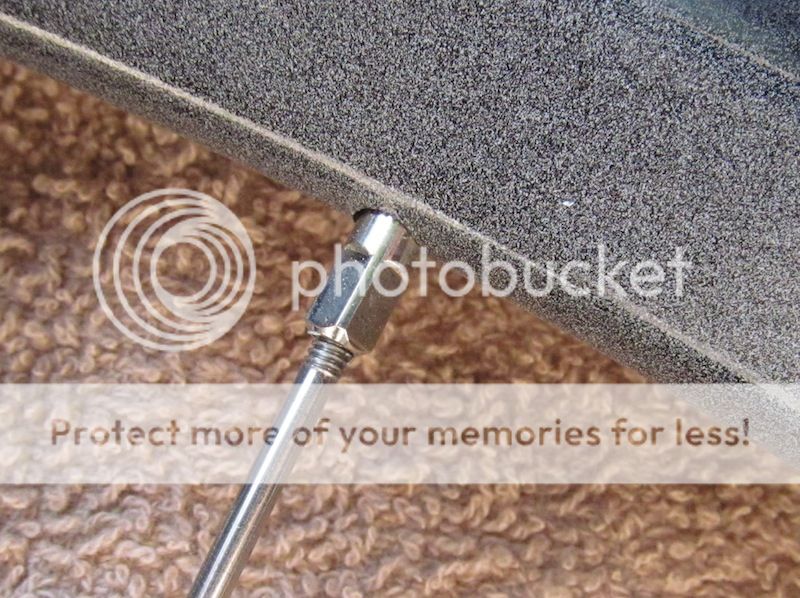

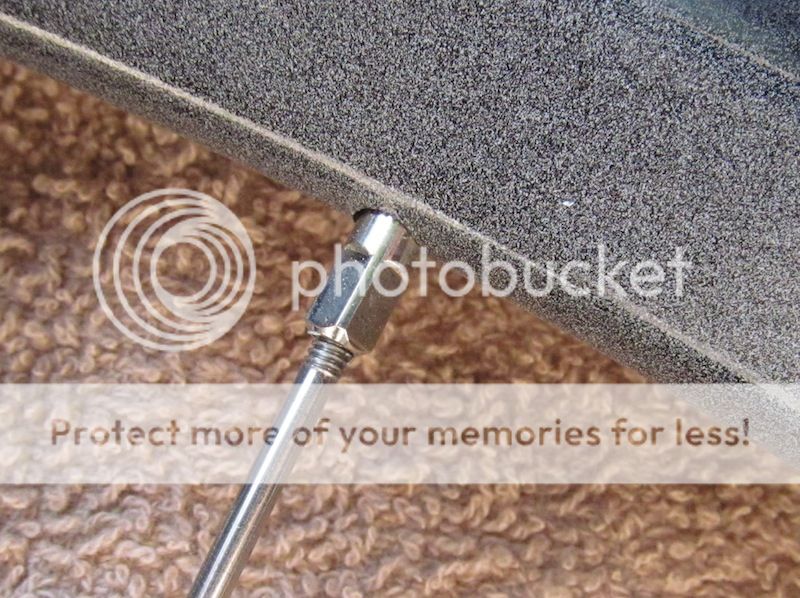

Deore 32h rear hub, straight-gauge spokes, Velocity Dyad rim. Every other NDS spoke (so -- every 4th spoke, 8 total) has spoke thread showing. I have looked down into the nipples, but it's hard to tell how much of the thread is actually engaged.

In your opinion, is this a problem, or is it within the bounds of reasonable variation? I don't care about the look but I do care that this wheel has a long, trouble-free life.

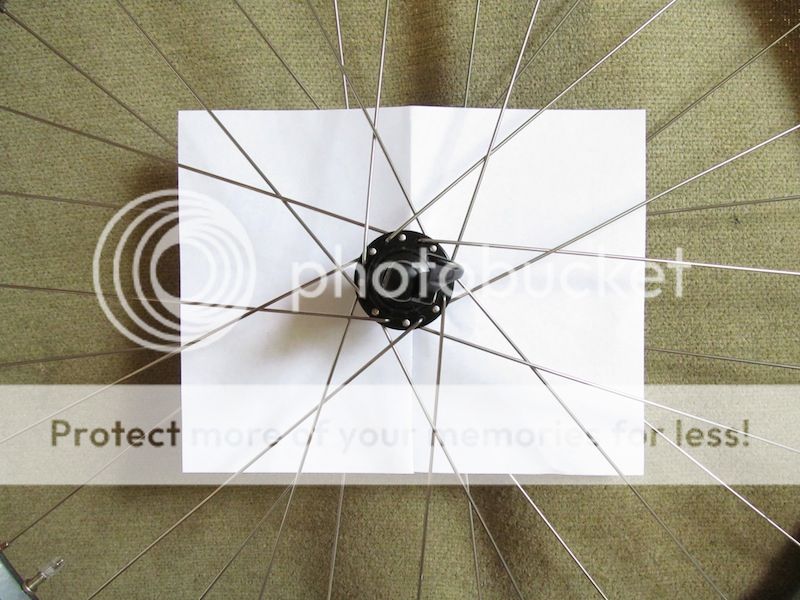

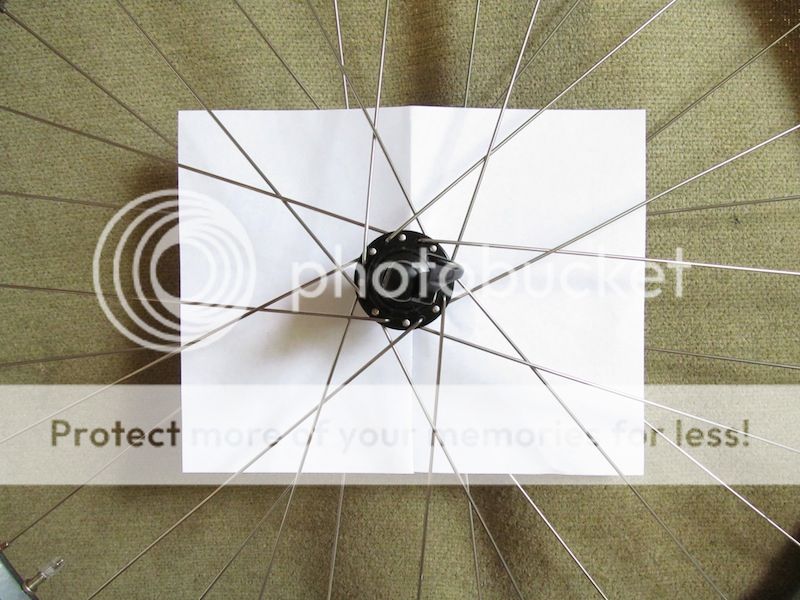

Some of the 8 have a bit less of the threaded area showing, and some have this much:

Thanks so much.

I hate to have to even ask this, because I like these guys; they have been good to me. But I'm afraid this might not be right.

Deore 32h rear hub, straight-gauge spokes, Velocity Dyad rim. Every other NDS spoke (so -- every 4th spoke, 8 total) has spoke thread showing. I have looked down into the nipples, but it's hard to tell how much of the thread is actually engaged.

In your opinion, is this a problem, or is it within the bounds of reasonable variation? I don't care about the look but I do care that this wheel has a long, trouble-free life.

Some of the 8 have a bit less of the threaded area showing, and some have this much:

Thanks so much.

#3

Senior Member

Join Date: Apr 2010

Location: Mountain View, CA USA and Golden, CO USA

Posts: 6,341

Bikes: 97 Litespeed, 50-39-30x13-26 10 cogs, Campagnolo Ultrashift, retroreflective rims on SON28/PowerTap hubs

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 550 Post(s)

Liked 325 Times

in

226 Posts

They laced the non-drive side incorrectly.

Alloy nipples would break because the short spokes (due to incorrect position) are loading the nipples with threads showing in tension (pulling beneath the spoke bed bed) instead of in compression like a nut (pulling on the nipple above the spoke). Brass nipples are more likely to be fine, although I've never bothered to compare the shear strength of a stainless steel spoke and a brass nipple.

Last edited by Drew Eckhardt; 08-08-12 at 04:23 PM.

#5

Senior Member

Join Date: Apr 2006

Location: Sioux Falls

Posts: 223

Bikes: Bianchi Road bike, Nashbar Ultegra triple cyclocross, Raleigh full XT hybrid, lugged steel Schwinn, Full rigid Diamondback MTB

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

I had a set of XT/Rhyno Lites with less thread showing. After less than a year the barrel seperated from the head of a couple nipples.

Remove the rim strip or tape and inspect how far the spokes go into the nipples. If the spokes aren't long enough to get to the heads of the nipples, take the wheel back to the LBS.

Remove the rim strip or tape and inspect how far the spokes go into the nipples. If the spokes aren't long enough to get to the heads of the nipples, take the wheel back to the LBS.

#6

Senior Member

Join Date: Dec 2007

Location: San Jose, California

Posts: 3,504

Bikes: 2001 Tommasini Sintesi w/ Campagnolo Daytona 10 Speed

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 145 Post(s)

Likes: 0

Liked 35 Times

in

30 Posts

Once the spoke ends end up more than 1mm below the screwdriver flats of the nipples, nipple head and barrel separation starts to factor as a risk. The lower you go, the more the risk.

One the ends of the spokes are such that they aren't penetrating the rim wall at all - it's not a question of "if", it's a question of when.

Nipples are nipples, not spoke extenders.

=8-)

One the ends of the spokes are such that they aren't penetrating the rim wall at all - it's not a question of "if", it's a question of when.

Nipples are nipples, not spoke extenders.

=8-)

__________________

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

#8

Senior Member

Join Date: May 2008

Location: Zang's Spur, CO

Posts: 9,083

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 3375 Post(s)

Liked 5,514 Times

in

2,857 Posts

Yikes!

This is where I normally post the cross-sectional nipple drawing that just annoys the hell out of Mr Rabbit.

This is where I normally post the cross-sectional nipple drawing that just annoys the hell out of Mr Rabbit.

#9

Senior Member

Join Date: Dec 2007

Location: San Jose, California

Posts: 3,504

Bikes: 2001 Tommasini Sintesi w/ Campagnolo Daytona 10 Speed

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 145 Post(s)

Likes: 0

Liked 35 Times

in

30 Posts

Go for it...

A newbie here needs lessons in uploading and posting attachments anyway...

It's for a good cause.

=8-)

A newbie here needs lessons in uploading and posting attachments anyway...

It's for a good cause.

=8-)

__________________

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

#10

Senior Member

Thread Starter

Join Date: Jan 2011

Location: Utah

Posts: 781

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 27 Post(s)

Likes: 0

Liked 7 Times

in

4 Posts

Sorry to be slow to get back here, and thanks so much for the information. Seems like a clear answer. Yeah, I don't think these 8 spokes make it to the head of the nipples.

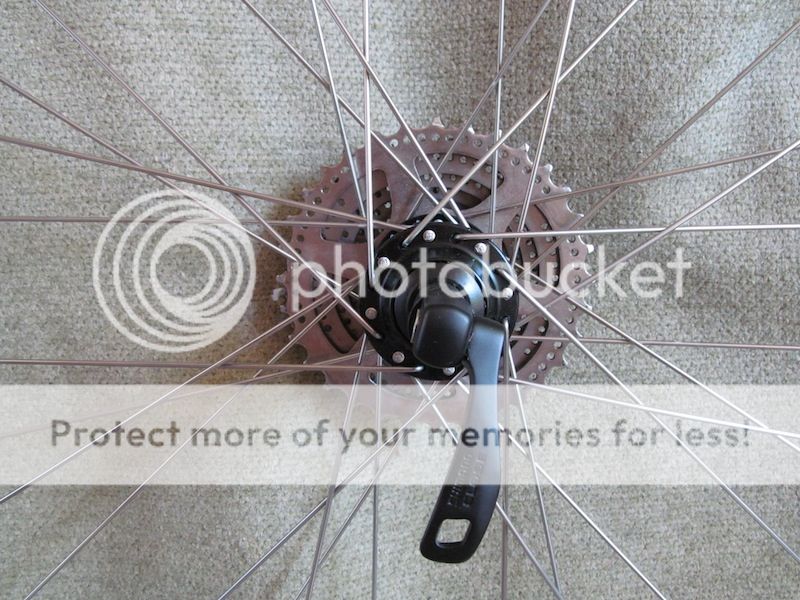

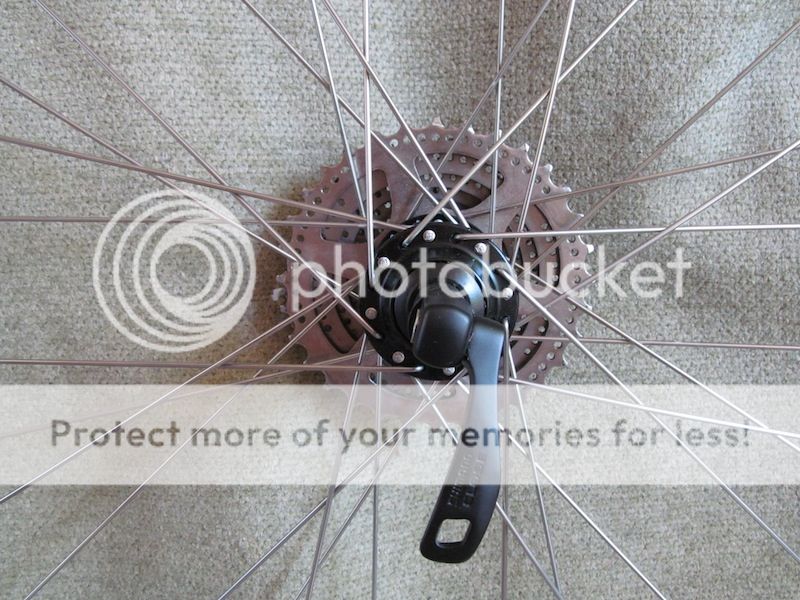

Here are a couple photos of the lacing. Are these helpful? Is there an error visible?

Here are a couple photos of the lacing. Are these helpful? Is there an error visible?

#11

Senior Member

Join Date: Dec 2007

Location: San Jose, California

Posts: 3,504

Bikes: 2001 Tommasini Sintesi w/ Campagnolo Daytona 10 Speed

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 145 Post(s)

Likes: 0

Liked 35 Times

in

30 Posts

It's not a lacing error...it's simply spokes that are too short...

I'm betting this LBS in question doesn't have a Phil Wood, Morizumi or Kowa spoke machine - i.e., they're always trying to make do with boxed spokes on hand as-is.

If that is the case, you really should have a chat with them and encourage them to:

1. Get a spoke machine.

2. Purchase 15g and 14g spokes in bulk in lengths of 310mm

3. Purchase 2.0/1.8/2.0 and 2.0/1.7./2.0 double butted spokes in bulk in lengths of 310mm, 280mm and 250mm with 45mm ends.

4. Save the boxed spokes for bladed and triple butted stuff.

=8-)

Spoke machines practically pay for themselves in a matter of just a few years...

=8-)

I'm betting this LBS in question doesn't have a Phil Wood, Morizumi or Kowa spoke machine - i.e., they're always trying to make do with boxed spokes on hand as-is.

If that is the case, you really should have a chat with them and encourage them to:

1. Get a spoke machine.

2. Purchase 15g and 14g spokes in bulk in lengths of 310mm

3. Purchase 2.0/1.8/2.0 and 2.0/1.7./2.0 double butted spokes in bulk in lengths of 310mm, 280mm and 250mm with 45mm ends.

4. Save the boxed spokes for bladed and triple butted stuff.

=8-)

Spoke machines practically pay for themselves in a matter of just a few years...

=8-)

__________________

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

#12

Senior Member

Join Date: May 2008

Location: Zang's Spur, CO

Posts: 9,083

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 3375 Post(s)

Liked 5,514 Times

in

2,857 Posts

Drawing illustrating the problem with spokes too short:

Drawing which corrects minor geometry error in former drawing:

Drawing which corrects minor geometry error in former drawing:

#13

Senior Member

Join Date: Jan 2012

Location: Ithaca, NY

Posts: 4,852

Bikes: Click on the #YOLO

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 26 Post(s)

Likes: 0

Liked 12 Times

in

12 Posts

No, it is a lacing issue, take a look at the third spoke crossing on the NDS (the interwoven one furthest from the flange), then eyeball a triangle from there to the head of the spoke in the flange, see how that isosceles triangle is canted to be side? The whole NDS is one spoke hole off clockwise.

To fix this, you'd have to unlace the NDS one spoke at a time and move the spoke to the next hole to the left if you're looking at the wheel from the same angle that the second set of pictures is taken. That's why the threads are off.

The shop owes you a new wheel, don't settle for a fix on this one unless they're giving you sme serious percentage back. This is one of the most common newbie mistakes you can make lacing a wheel, and completely unacceptable from a "professional" mechanic.

To fix this, you'd have to unlace the NDS one spoke at a time and move the spoke to the next hole to the left if you're looking at the wheel from the same angle that the second set of pictures is taken. That's why the threads are off.

The shop owes you a new wheel, don't settle for a fix on this one unless they're giving you sme serious percentage back. This is one of the most common newbie mistakes you can make lacing a wheel, and completely unacceptable from a "professional" mechanic.

#14

Friendship is Magic

Join Date: Nov 2010

Location: Sacramento, CA

Posts: 22,984

Bikes: old ones

Mentioned: 304 Post(s)

Tagged: 0 Thread(s)

Quoted: 26419 Post(s)

Liked 10,380 Times

in

7,208 Posts

usually, if there is a lacing error, it is easily seen when you look at

the spoke crossings.....the mistake will be a crossing higher or lower

than the other spoke pairs......

It's a little confusing visually from your pictures, because some of back

side spokes in your photo appear to be in the same plane as the front

side, but I think the pattern looks OK. they probably just calculated the

length wrong, or worse yet, did not have the right length in stock and

just kinda pushed it out the door...more likely since you state every other

spoke on the non drive side.

The picture that will tell you for certain if you have a problem is with

the tires and rim strips removed, looking down into the spoke nipples

of the ones you can see threads exposed. I think, like the others,

you have a reasonable complaint here. You can tell pretty easily if

the non drive spokes are all the same length by pulling out one of each

of the right ones and short ones.....but then you'd have to retrue the

wheel. They might be willing to do it, though.

Certainly, I'd not build a wheel like that for anyone.

Sometimes, if a builder is distracted, he can mix the two sides accidentally,

(drive and non drive). Since the drive side spokes are slightly shorter, if

that happened here it would have a similar result to what you describe.

(i.e. the last set of spokes inserted into the non drive side were shorter

than the first set.........thus every other spoke has threads showing.)

the spoke crossings.....the mistake will be a crossing higher or lower

than the other spoke pairs......

It's a little confusing visually from your pictures, because some of back

side spokes in your photo appear to be in the same plane as the front

side, but I think the pattern looks OK. they probably just calculated the

length wrong, or worse yet, did not have the right length in stock and

just kinda pushed it out the door...more likely since you state every other

spoke on the non drive side.

The picture that will tell you for certain if you have a problem is with

the tires and rim strips removed, looking down into the spoke nipples

of the ones you can see threads exposed. I think, like the others,

you have a reasonable complaint here. You can tell pretty easily if

the non drive spokes are all the same length by pulling out one of each

of the right ones and short ones.....but then you'd have to retrue the

wheel. They might be willing to do it, though.

Certainly, I'd not build a wheel like that for anyone.

Sometimes, if a builder is distracted, he can mix the two sides accidentally,

(drive and non drive). Since the drive side spokes are slightly shorter, if

that happened here it would have a similar result to what you describe.

(i.e. the last set of spokes inserted into the non drive side were shorter

than the first set.........thus every other spoke has threads showing.)

__________________

#15

Senior Member

Join Date: Dec 2007

Location: San Jose, California

Posts: 3,504

Bikes: 2001 Tommasini Sintesi w/ Campagnolo Daytona 10 Speed

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 145 Post(s)

Likes: 0

Liked 35 Times

in

30 Posts

OP:

Take two more photos...

(Having a hard time seeing what IthaDan is seeing...)

1. For both, on center...

2. Whole wheel - but with with camera higher up so we can see a little more of the far flange while looking at the near flange.

3. Up close - but once again, with camera higher up and angled in so we can see a little more of the far flange while looking at the near flange.

=8-)

Take two more photos...

(Having a hard time seeing what IthaDan is seeing...)

1. For both, on center...

2. Whole wheel - but with with camera higher up so we can see a little more of the far flange while looking at the near flange.

3. Up close - but once again, with camera higher up and angled in so we can see a little more of the far flange while looking at the near flange.

=8-)

__________________

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

#16

Senior Member

Join Date: Jan 2012

Location: Ithaca, NY

Posts: 4,852

Bikes: Click on the #YOLO

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 26 Post(s)

Likes: 0

Liked 12 Times

in

12 Posts

Now that im looking again, I think I'm off on this. Couple amazingly flat light, an iPad and too much caffeine and you get post #14. I thought I saw something in the location of the crosses and the offset of the spoke holes in the flange.

#17

Senior Member

Join Date: Jan 2007

Location: Alexandria, VA

Posts: 2,174

Bikes: 2007 Pergoretti Marcelo

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Lacing looks ok to me. I just think the LBS used spokes that were too short. What I find odd is that this occurs on every 4th NDS spoke. I would have expected *all* NDS spokes to be too short since they should all be the same length. 3alarmer I think has it right that the build just was not well organized and mixed up some DS with NDS spokes. Then again, I haven't built that many wheels.

#18

Senior Member

Thread Starter

Join Date: Jan 2011

Location: Utah

Posts: 781

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 27 Post(s)

Likes: 0

Liked 7 Times

in

4 Posts

Thanks again all. So it sounds like the lacing is probably fine, but for additional info here are the photos Mr. Rabbit requested, plus one that might also be helpful.

So assuming the problem is wrong-length spokes, if they re-build with 8 proper spokes everything should be fine, right? No other issues would have been caused? I haven't put many miles on the wheel yet.

So assuming the problem is wrong-length spokes, if they re-build with 8 proper spokes everything should be fine, right? No other issues would have been caused? I haven't put many miles on the wheel yet.

#19

Friendship is Magic

Join Date: Nov 2010

Location: Sacramento, CA

Posts: 22,984

Bikes: old ones

Mentioned: 304 Post(s)

Tagged: 0 Thread(s)

Quoted: 26419 Post(s)

Liked 10,380 Times

in

7,208 Posts

Thanks again all. So it sounds like the lacing is probably fine, but for additional info here are the photos Mr. Rabbit requested, plus one that might also be helpful.

So assuming the problem is wrong-length spokes, if they re-build with 8 proper spokes everything should be fine, right? No other issues would have been caused? I haven't put many miles on the wheel yet.

So assuming the problem is wrong-length spokes, if they re-build with 8 proper spokes everything should be fine, right? No other issues would have been caused? I haven't put many miles on the wheel yet.

I need in a pile, and the exact number of non drive side spokes in another pile.

I then proceed to mark one or the other pile with a sharpie or something that

gives me a visual cue besides length.

When you insert the spokes, you do them 8 at a time in a 32 spoke wheel,

so if your guy uses a similar procedure to me (not everyone does), and I'm

correct in my guess that somewhere there was some confusion in the assembly

where he grabbed 8 from the wrong pile, it's also possible that there are 8

more that are too long on the drive side, which were just filed or ground off

after assembly.

This leaves them with fewer original rolled threads engaged in the nipples, but

probably is not a problem of the same magnitude as your short spokes.

Since they are going to have to pull some spokes to fix this anyway, see

if you can get them to pull a couple of the drive spokes as well to check,

just out of curiosity. All this is just guessing from afar, and could be complete

fantasy on my part.

__________________

#20

Senior Member

Join Date: Dec 2007

Location: San Jose, California

Posts: 3,504

Bikes: 2001 Tommasini Sintesi w/ Campagnolo Daytona 10 Speed

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 145 Post(s)

Likes: 0

Liked 35 Times

in

30 Posts

Lacing looks fine...

So it's either:

1. Too short spokes were used...

2. Or NDS and DS spokes got mixed up during lacing.

=8-)

So it's either:

1. Too short spokes were used...

2. Or NDS and DS spokes got mixed up during lacing.

=8-)

__________________

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

#21

Banned

If the spoke is not flush with the bottom of the slot in the nipple, have the job redone.

I had to create a shorter spoke from a long one, using a Hozan spoke thread rolling tool.

took more turns than ideal, so there were threads showing,

but i filed down extra length inside the rim, so, at least, it was not too short.

I had to create a shorter spoke from a long one, using a Hozan spoke thread rolling tool.

took more turns than ideal, so there were threads showing,

but i filed down extra length inside the rim, so, at least, it was not too short.

#22

Senior Member

When I construct a rear wheel, I lay out the exact number of drive side spokes

I need in a pile, and the exact number of non drive side spokes in another pile.

I then proceed to mark one or the other pile with a sharpie or something that

gives me a visual cue besides length.

When you insert the spokes, you do them 8 at a time in a 32 spoke wheel,

so if your guy uses a similar procedure to me (not everyone does), and I'm

correct in my guess that somewhere there was some confusion in the assembly

where he grabbed 8 from the wrong pile, it's also possible that there are 8

more that are too long on the drive side, which were just filed or ground off

after assembly.

This leaves them with fewer original rolled threads engaged in the nipples, but

probably is not a problem of the same magnitude as your short spokes.

Since they are going to have to pull some spokes to fix this anyway, see

if you can get them to pull a couple of the drive spokes as well to check,

just out of curiosity. All this is just guessing from afar, and could be complete

fantasy on my part.

I need in a pile, and the exact number of non drive side spokes in another pile.

I then proceed to mark one or the other pile with a sharpie or something that

gives me a visual cue besides length.

When you insert the spokes, you do them 8 at a time in a 32 spoke wheel,

so if your guy uses a similar procedure to me (not everyone does), and I'm

correct in my guess that somewhere there was some confusion in the assembly

where he grabbed 8 from the wrong pile, it's also possible that there are 8

more that are too long on the drive side, which were just filed or ground off

after assembly.

This leaves them with fewer original rolled threads engaged in the nipples, but

probably is not a problem of the same magnitude as your short spokes.

Since they are going to have to pull some spokes to fix this anyway, see

if you can get them to pull a couple of the drive spokes as well to check,

just out of curiosity. All this is just guessing from afar, and could be complete

fantasy on my part.

Now, I also see no way that the builder didn't realize he/she made a mistake at some point and the idea that they tried to let it slide tells me they needs to be fired and/or you need to find a different lbs.

#23

Senior Member

Join Date: Dec 2007

Location: San Jose, California

Posts: 3,504

Bikes: 2001 Tommasini Sintesi w/ Campagnolo Daytona 10 Speed

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 145 Post(s)

Likes: 0

Liked 35 Times

in

30 Posts

My first thought was that something like this happened as it explains why they are off in a pattern. If this is correct then the wheel absolutely needs to be rebuilt.

Now, I also see no way that the builder didn't realize he/she made a mistake at some point and the idea that they tried to let it slide tells me they needs to be fired and/or you need to find a different lbs.

Now, I also see no way that the builder didn't realize he/she made a mistake at some point and the idea that they tried to let it slide tells me they needs to be fired and/or you need to find a different lbs.

1. Visible threads.

2. Too short spokes.

3. Poor extrusion and/or bad joints.

Does make you wonder about that LBS...

=8-)

__________________

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

5000+ wheels built since 1984...

Disclaimer:

1. I do not claim to be an expert in bicycle mechanics despite my experience.

2. I like anyone will comment in other areas.

3. I do not own the preexisting concepts of DISH and ERD.

4. I will provide information as I always have to others that I believe will help them protect themselves from unscrupulous mechanics.

5. My all time favorite book is:

Kahane, Howard. Logic and Contemporary Rhetoric: The Use of Reason in Everyday Life

#24

Senior Member

Join Date: Jan 2012

Location: Spokane, WA

Posts: 2,243

Bikes: Specialized Sequoia Elite/Motobecane Fantom Cross Team Ti/'85 Trek 520

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 6 Post(s)

Likes: 0

Liked 3 Times

in

3 Posts

Thanks again all. So it sounds like the lacing is probably fine, but for additional info here are the photos Mr. Rabbit requested, plus one that might also be helpful.

So assuming the problem is wrong-length spokes, if they re-build with 8 proper spokes everything should be fine, right? No other issues would have been caused? I haven't put many miles on the wheel yet.

So assuming the problem is wrong-length spokes, if they re-build with 8 proper spokes everything should be fine, right? No other issues would have been caused? I haven't put many miles on the wheel yet.

Remove the tire, remove the tube, remove the rim tape/strip, then take a few pictures of the nipples looking at them from the inside. Make sure there is plenty of light so you could see how deep the rabbit holes are.

#25

Reeks of aged cotton duck

Join Date: Oct 2007

Location: Middle Georgia, USA

Posts: 1,176

Bikes: 2008 Kogswell PR mkII, 1976 Raleigh Professional, 1996 Serotta Atlanta, 1984 Trek 520, 1979 Raleigh Comp GS

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 5 Times

in

4 Posts

I don't know about the shops where you live, but the LBS's around here do not hire professional mechanics. I'm not just saying that to be dramatic... they really just hire whoever will work for what they want to pay. And that is normally a very young guy who doesn't want to work at a fast food joint. Often times the kids that they hire barely know anything about bikes.

Consequently, they usually screw things up when they try to build or repair wheels... but the customers normally know even less about what is going on. So the incompetent mechanic gets away without blame when a wheel pops spoke after spoke or refuses to stay true. The mechanics at our LBS would see those threads protruding from the nipple and think nothing of it.

I have an understanding with my LBS owner that he calls me for any special wheel builds or repairs that his customers want. In return I buy the parts from his shop. I've seen his guys butcher too many wheels to count.

Consequently, they usually screw things up when they try to build or repair wheels... but the customers normally know even less about what is going on. So the incompetent mechanic gets away without blame when a wheel pops spoke after spoke or refuses to stay true. The mechanics at our LBS would see those threads protruding from the nipple and think nothing of it.

I have an understanding with my LBS owner that he calls me for any special wheel builds or repairs that his customers want. In return I buy the parts from his shop. I've seen his guys butcher too many wheels to count.