When did steel bikes peak?

#151

Senior Member

Join Date: Jul 2014

Posts: 1,490

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 1083 Post(s)

Liked 686 Times

in

440 Posts

Trek was still hand-building lugged steel frames in Wisconsin until 1992, if that's any measure. But I'll go with mid-80's to mid-90's being the "golden age" of chromoly steel. There were many fine steel bikes produced well into the late 90's also, though most of them were TIG welded. Ultimately it's all about the builder, not the the time frame. Because steel has become the "elite" frame material in favor of the much cheaper aluminum, any modern steel framebuilder is probably putting out a very fine product.

Last edited by Jeff Neese; 08-12-15 at 10:21 PM.

#152

Senior Member

Join Date: Sep 2010

Location: NE Indiana

Posts: 8,687

Bikes: 2020 Masi Giramondo 700c; 2013 Lynskey Peloton; 1992 Giant Rincon; 1989 Dawes needs parts; 1985 Trek 660; 1985 Fuji Club; 1984 Schwinn Voyager; 1984 Miyata 612; 1977 Raleigh Competition GS

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 1126 Post(s)

Liked 253 Times

in

204 Posts

When I took my first tour of the Trek factory in '90, when lugged steel, tig-welded aluminum and bonded carbon/aluminum were all produced in-house, the steel brazers were the highest-paid factory workers. Because reliable, quality brazing requires far more experience and honed technique than tig welding, or bonding. Pre-brazing prep, getting the temperature just right, heating the lugs properly to maintain the proper temperature and allow the brass/silver to flow correctly, working not too fast and not too slow, getting full brass/silver penetration without gaps, without overheating or cold-brazing---can't be learned in an afternoon. And in fact, "how one brazes the lug" matters a lot more than what kind of steel is used.

Many of the tig welders were hired right out of trade school. They didn't need bicycle framebuilding experience, all they needed was the certificate showing they could weld.

"Leave it at that."

.

Many of the tig welders were hired right out of trade school. They didn't need bicycle framebuilding experience, all they needed was the certificate showing they could weld.

"Leave it at that."

.

#153

Senior Member

Join Date: Jul 2014

Posts: 1,490

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 1083 Post(s)

Liked 686 Times

in

440 Posts

One question would be how do you define "best"? Any good chromoly frame will (should) last a lifetime. Differences in ride and handling will be more a function of which frame you're talking about. There is a difference between my 1992 Trek 930 (lugged) and my 1993 Rockhopper (TIG welded) but not much, and it's because they have slightly different dimensions and are set up for different types of riding. Neither is "better".

Having said that, they are both WAY better than my Schwinn Continental was (45 years ago), and I don't think we need to explain why.

Having said that, they are both WAY better than my Schwinn Continental was (45 years ago), and I don't think we need to explain why.

#154

Senior Member

This was 25 years ago, so I'm in the world of IIRC. Trek was still building lugged steel frames in Waterloo then, the move to tig'd steel was a couple of years away. The lugged steel frames were not 100% machine built. The main frame lugs/joints were machine brazed. The human brazers did all the cable/casing stops/guides and seatstay/chainstay bridges.

Trek paid brazers more than welders because brazing required a more highly-developed skill set, and Trek still needed skilled brazers even when the lugs were machine-brazed.

FWIW, IMHO all the compromises they made for high-volume machine brazing, like using brass i/o silver, thicker tubes, thicker lugs, one-piece head tube/lug assemblies, socketed seat lugs and dropouts, all made for heavier, less-lively and less-elegant frames. Automating brazing might have eliminated some human inefficiencies and variability, but it did not result in a nicer, better-riding frame.

Trek paid brazers more than welders because brazing required a more highly-developed skill set, and Trek still needed skilled brazers even when the lugs were machine-brazed.

FWIW, IMHO all the compromises they made for high-volume machine brazing, like using brass i/o silver, thicker tubes, thicker lugs, one-piece head tube/lug assemblies, socketed seat lugs and dropouts, all made for heavier, less-lively and less-elegant frames. Automating brazing might have eliminated some human inefficiencies and variability, but it did not result in a nicer, better-riding frame.

Actually Trek stopped doing hand brazed silver lugged frames in 85 and went with a automatic robotic system that brass brazed without any human intervention...So in reality machines were able to make lugged steel bike frames...I find it strange you claim to went on a tour there yet claim they were doing it by hand in 1990...Perhaps you can explain what you saw more thoroughly.

__________________

Fuggedaboutit!

Fuggedaboutit!

#155

Decrepit Member

One question would be how do you define "best"? Any good chromoly frame will (should) last a lifetime. Differences in ride and handling will be more a function of which frame you're talking about. There is a difference between my 1992 Trek 930 (lugged) and my 1993 Rockhopper (TIG welded) but not much, and it's because they have slightly different dimensions and are set up for different types of riding. Neither is "better".

Having said that, they are both WAY better than my Schwinn Continental was (45 years ago), and I don't think we need to explain why.

Having said that, they are both WAY better than my Schwinn Continental was (45 years ago), and I don't think we need to explain why.

So I'd say the newer high strength alloys offer significant advantages over chromoly, but you're correct in saying a properly cared for chromoly frame should last a lifetime.

References:

Reynolds 525 (AISI 4130 Cromoly) Reynolds 525

Ultimate Tensile Strength (UTS) 700 - 900 MPa

Yield Strength (YS) 600 - 750 MPa

Reynolds 853 Reynolds 853

Ultimate Tensile Strength (UTS) 1,250 - 1,400 MPa

Yield Strength (YS) 1,000 - 1,150 MPa

Reynolds 953 Stainless Steel Reynolds 953

Ultimate Tensile Strength (UTS) 1,750 - 2,050 MPa

Yield Strength (YS) 1,450 - 1,650MPa

#157

Senior Member

Join Date: Sep 2010

Location: NE Indiana

Posts: 8,687

Bikes: 2020 Masi Giramondo 700c; 2013 Lynskey Peloton; 1992 Giant Rincon; 1989 Dawes needs parts; 1985 Trek 660; 1985 Fuji Club; 1984 Schwinn Voyager; 1984 Miyata 612; 1977 Raleigh Competition GS

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 1126 Post(s)

Liked 253 Times

in

204 Posts

Actually Trek stopped doing hand brazed silver lugged frames in 85 and went with a automatic robotic system that brass brazed without any human intervention except for the pushing of buttons to operate the robotics. So in reality machines were able to make lugged steel bike frames, were they better than handbuilt? I don't think so but some probably think so. I find it strange you claim to went on a tour there yet claim they were doing it by hand in 1990, see: Vintage Trek - Steel Road Bike Timeline, Trek Bicycle Corporation Scan down to 1985. Perhaps you can explain what you saw more thoroughly.

"Trek replaces the automatic brazers with a robotic system that assembles, aligns and brazes in a single pass."

So that sentence makes it sound like Trek had automatic brazers for awhile but humans assembled and aligned the frame, then switched to robotic system that did it all. Is the Vintage Trek site incorrect? Here's where I would ask to backup your claims but obviously you can't, just like I can't backup my claim that Greg Lemond doped because it's hearsay from people that I knew who knew him.

#158

Senior Member

Join Date: Jul 2014

Posts: 1,490

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 1083 Post(s)

Liked 686 Times

in

440 Posts

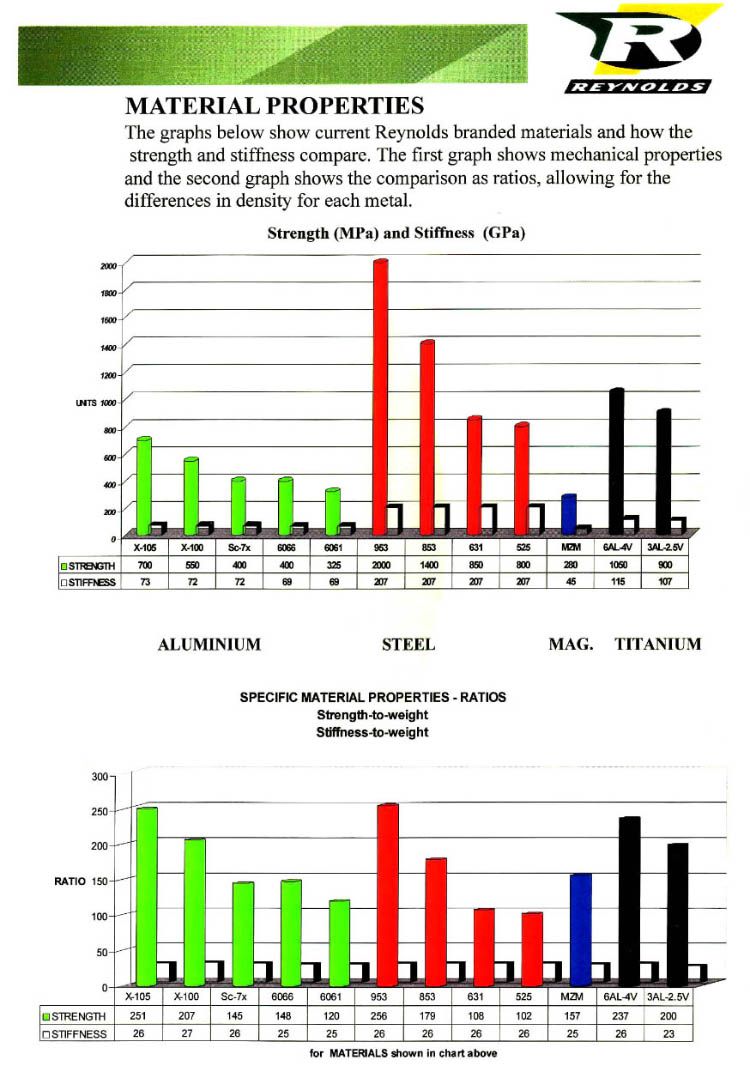

Jeff, steel alloys have come a long way since basic 4130 chromoly. Some of the new high strength air-hardening steels have more than twice the ultimate tensile strength and yield strength of chromoly, so the tubing can be drawn with much thinner walls and are therefore significantly lighter without compromising structural integrity. Oversize tubing diameters restore the stiffness lost by drawing the tubing with thinner walls. Stainless high strength alloys have the additional advantage of not requiring paint - which adds weight and is subject to scraping and chipping - to prevent corrosion.

So I'd say the newer high strength alloys offer significant advantages over chromoly, but you're correct in saying a properly cared for chromoly frame should last a lifetime.

References:

Reynolds 525 (AISI 4130 Cromoly) Reynolds 525

Ultimate Tensile Strength (UTS) 700 - 900 MPa

Yield Strength (YS) 600 - 750 MPa

Reynolds 853 Reynolds 853

Ultimate Tensile Strength (UTS) 1,250 - 1,400 MPa

Yield Strength (YS) 1,000 - 1,150 MPa

Reynolds 953 Stainless Steel Reynolds 953

Ultimate Tensile Strength (UTS) 1,750 - 2,050 MPa

Yield Strength (YS) 1,450 - 1,650MPa

So I'd say the newer high strength alloys offer significant advantages over chromoly, but you're correct in saying a properly cared for chromoly frame should last a lifetime.

References:

Reynolds 525 (AISI 4130 Cromoly) Reynolds 525

Ultimate Tensile Strength (UTS) 700 - 900 MPa

Yield Strength (YS) 600 - 750 MPa

Reynolds 853 Reynolds 853

Ultimate Tensile Strength (UTS) 1,250 - 1,400 MPa

Yield Strength (YS) 1,000 - 1,150 MPa

Reynolds 953 Stainless Steel Reynolds 953

Ultimate Tensile Strength (UTS) 1,750 - 2,050 MPa

Yield Strength (YS) 1,450 - 1,650MPa

Regardless, I think you quickly get to a point of diminishing returns. A well-made 4130 frame, double-butted, either lugged or TIG welded, will put you in the ball park and improvements are incremental from there. You can change wheels and tires and get more of a difference sometimes, than you'd feel with a "higher end" steel frame. Just my opinion and experience.

By the way, here are those same numbers for aluminum. Strength-wise, there's no comparison. And lifespan - no comparison. Also ride and handling - no comparison. Even a mass-produced 4130 chromoly frame is better than the best aluminum frame. The exception is racing or other competition where most of those factors don't matter and you're ONLY optimizing for weight. Again, my opinion. The only downside to steel is cost.

6061-T6

Ultimate Tensile Strength 310 MPa

Yield Strength 276 MPa

7000 series

Ultimate Tensile Strength 572 MPa

Tensile Yield Strength 503 MPa

#159

Senior Member

Stan, of course you're right. There are differences between "generic" 4130 and some of the more exotic (and rarely used) alloys. I would contend though that there are other factors that make more of a difference than the type of chromoly. You mentioned tube diameter/wall thickness. That goes hand in hand with the way the tubes are butted. "Custom butted" tubing is a real thing that makes a difference, compared to off-the-shelf standard double butted tubing.

Regardless, I think you quickly get to a point of diminishing returns. A well-made 4130 frame, double-butted, either lugged or TIG welded, will put you in the ball park and improvements are incremental from there. You can change wheels and tires and get more of a difference sometimes, than you'd feel with a "higher end" steel frame. Just my opinion and experience.

By the way, here are those same numbers for aluminum. Strength-wise, there's no comparison. And lifespan - no comparison. Also ride and handling - no comparison. Even a mass-produced 4130 chromoly frame is better than the best aluminum frame. The exception is racing or other competition where most of those factors don't matter and you're ONLY optimizing for weight. Again, my opinion. The only downside to steel is cost.

6061-T6

Ultimate Tensile Strength 310 MPa

Yield Strength 276 MPa

7000 series

Ultimate Tensile Strength 572 MPa

Tensile Yield Strength 503 MPa

Regardless, I think you quickly get to a point of diminishing returns. A well-made 4130 frame, double-butted, either lugged or TIG welded, will put you in the ball park and improvements are incremental from there. You can change wheels and tires and get more of a difference sometimes, than you'd feel with a "higher end" steel frame. Just my opinion and experience.

By the way, here are those same numbers for aluminum. Strength-wise, there's no comparison. And lifespan - no comparison. Also ride and handling - no comparison. Even a mass-produced 4130 chromoly frame is better than the best aluminum frame. The exception is racing or other competition where most of those factors don't matter and you're ONLY optimizing for weight. Again, my opinion. The only downside to steel is cost.

6061-T6

Ultimate Tensile Strength 310 MPa

Yield Strength 276 MPa

7000 series

Ultimate Tensile Strength 572 MPa

Tensile Yield Strength 503 MPa

Specialized Bicycle Components

#160

aka Tom Reingold

Join Date: Jan 2009

Location: New York, NY, and High Falls, NY, USA

Posts: 40,503

Bikes: 1962 Rudge Sports, 1971 Raleigh Super Course, 1971 Raleigh Pro Track, 1974 Raleigh International, 1975 Viscount Fixie, 1982 McLean, 1996 Lemond (Ti), 2002 Burley Zydeco tandem

Mentioned: 511 Post(s)

Tagged: 0 Thread(s)

Quoted: 7348 Post(s)

Liked 2,470 Times

in

1,435 Posts

Yes, now that it's gotten back on topic.

Even a badly cared for frame tends to last a lifetime. I know frames do sometimes fail from rust, but it's very rare. I've worked as a bike mechanic, so I've probably worked on thousands of bikes. I have never seen a frame fail from rust. As I said, I know it happens, but my sample size is large, and I haven't seen it happen once.

Even a badly cared for frame tends to last a lifetime. I know frames do sometimes fail from rust, but it's very rare. I've worked as a bike mechanic, so I've probably worked on thousands of bikes. I have never seen a frame fail from rust. As I said, I know it happens, but my sample size is large, and I haven't seen it happen once.

__________________

Tom Reingold, tom@noglider.com

New York City and High Falls, NY

Blogs: The Experienced Cyclist; noglider's ride blog

“When man invented the bicycle he reached the peak of his attainments.” — Elizabeth West, US author

Please email me rather than PM'ing me. Thanks.

Tom Reingold, tom@noglider.com

New York City and High Falls, NY

Blogs: The Experienced Cyclist; noglider's ride blog

“When man invented the bicycle he reached the peak of his attainments.” — Elizabeth West, US author

Please email me rather than PM'ing me. Thanks.

#161

curmudgineer

Join Date: Dec 2009

Location: Chicago SW burbs

Posts: 4,417

Bikes: 2 many 2 fit here

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 263 Post(s)

Liked 112 Times

in

70 Posts

By the way, here are those same numbers for aluminum. Strength-wise, there's no comparison. And lifespan - no comparison. Also ride and handling - no comparison. Even a mass-produced 4130 chromoly frame is better than the best aluminum frame. The exception is racing or other competition where most of those factors don't matter and you're ONLY optimizing for weight. Again, my opinion. The only downside to steel is cost.

6061-T6

Ultimate Tensile Strength 310 MPa

Yield Strength 276 MPa

7000 series

Ultimate Tensile Strength 572 MPa

Tensile Yield Strength 503 MPa

6061-T6

Ultimate Tensile Strength 310 MPa

Yield Strength 276 MPa

7000 series

Ultimate Tensile Strength 572 MPa

Tensile Yield Strength 503 MPa

When you get into structures and loading cases more complex than a wire in tension, it gets much more complicated. Typically, the advantage of a higher specific strength material increases as the structure becomes more complex, but fatigue properties can throw a wrench into the works., i.e., if fatigue is a consideration. Space (and perhaps other) constraints can also offset the advantage of higher specific strength, e.g., if the material density is relatively low. Materials with high specific strength but low stiffness tend to disqualify themselves as well, when stiffness (as is frequently the case) is quite important alongside strength.

Last edited by old's'cool; 08-13-15 at 09:17 PM. Reason: brackets

#162

Decrepit Member

No argument with your data as presented, but your data are incomplete. We also need to consider specific strength, i.e., the strength-to-weight ratio. This is most easily understood as the length of a wire made of a given material capable of supporting its own vertical hanging weight, and is a simple ratio of the material strength [force/unit area] divided by (the material density [mass/unit volume] * acceleration [distance/time^2]).

When you get into structures and loading cases more complex than a wire in tension, it gets much more complicated. Typically, the advantage of a higher specific strength material increases as the structure becomes more complex, but fatigue properties can throw a wrench into the works., i.e., if fatigue is a consideration. Space (and perhaps other) constraints can also offset the advantage of higher specific strength, e.g., if the material density is relatively low. Materials with high specific strength but low stiffness tend to disqualify themselves as well, when stiffness (as is frequently the case) is quite important alongside strength.

When you get into structures and loading cases more complex than a wire in tension, it gets much more complicated. Typically, the advantage of a higher specific strength material increases as the structure becomes more complex, but fatigue properties can throw a wrench into the works., i.e., if fatigue is a consideration. Space (and perhaps other) constraints can also offset the advantage of higher specific strength, e.g., if the material density is relatively low. Materials with high specific strength but low stiffness tend to disqualify themselves as well, when stiffness (as is frequently the case) is quite important alongside strength.

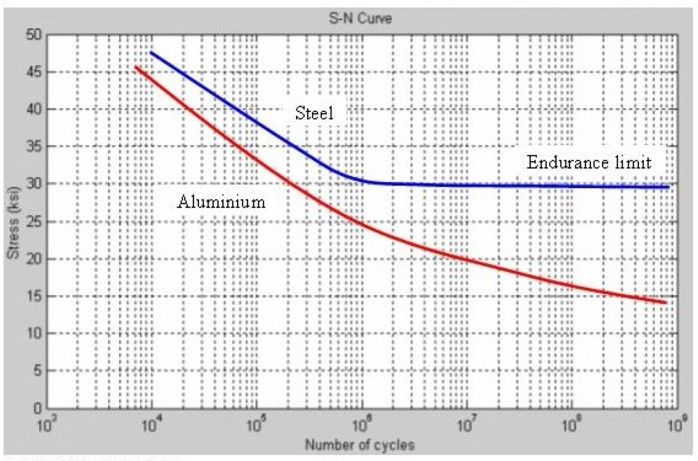

Since aluminum alloys have no fatigue limit, aluminum structures subject to cyclic stresses like the stresses imposed on bicycle frames are typically overbuilt to provide a reasonable lifetime before fatigue failure. Because aluminum lacks fatigue limit, even small amplitude stress cycles will ultimately result in failure over time. Steel, OTOH, has a fatigue limit and a virtually unlimited number of stress cycles with amplitudes below that limit will not result in fatigue failure.

Strength-to-weight ratio of aluminum alloys compared to steel alloys is illustrated in the bottom graph in this Reynolds graphic. Aluminum is less dense (lighter for a given volume of material) than steel, but steel is stronger.

#163

Senior Member

Join Date: Apr 2009

Location: Boulder County, CO

Posts: 1,511

Bikes: '92 22" Cannondale M2000, '92 Cannondale R1000 Tandem, another modern Canndondale tandem, Two Holy Grail '86 Cannondale ST800s 27" (68.5cm) Touring bike w/Superbe Pro components and Phil Wood hubs. A bunch of other 27" ST frames & bikes.

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 110 Post(s)

Likes: 0

Liked 4 Times

in

4 Posts

As has already been amply demonstrated, very little of what you're saying has any merit. And most of what you're saying seems to show you have very little understanding of the underlying technology.

When I took my first tour of the Trek factory in '90, when lugged steel, tig-welded aluminum and bonded carbon/aluminum were all produced in-house, the steel brazers were the highest-paid factory workers. Because reliable, quality brazing requires far more experience and honed technique than tig welding, or bonding. Pre-brazing prep, getting the temperature just right, heating the lugs properly to maintain the proper temperature and allow the brass/silver to flow correctly, working not too fast and not too slow, getting full brass/silver penetration without gaps, without overheating or cold-brazing---can't be learned in an afternoon. And in fact, "how one brazes the lug" matters a lot more than what kind of steel is used.

Many of the tig welders were hired right out of trade school. They didn't need bicycle framebuilding experience, all they needed was the certificate showing they could weld.

The bonded carbon/aluminum frame workers were the lowest paid, because all they had to do was slather pre-mixed epoxy onto the joints with little brushes. The cast lugs, with cast-in alignment ribs, combined with hydraulic jigs, took care of all alignment issues. Brushing on enough epoxy for it to smush out when the tube is pressed into place requires very little precision or experience. Whether aluminum, aluminium/carbon hybrid or all-carbon, tubes and lugs were machine-built at very low cost, and assembly was fast and cheap.

Whether the carbon frame is made from bonded sub-assemblies, or pops out of a mold, it is pretty inexpensive to produce. Gluing joints is easy, laying prepreg is easy, learning to clack the keys that control the mold-making machines or presses doesn't take years of experience. You can search for higher-priced prepreg if you want to justify a $5,000 frameset, and the engineering input is more intensive, but the material costs and labor are relatively cheap.

"Leave it at that."

Lastly, forgive my strong language, but your conclusions about comparative ride quality and the possible perceptions for "any objective person that has spent time in the saddle" is pure poppycock.

When I took my first tour of the Trek factory in '90, when lugged steel, tig-welded aluminum and bonded carbon/aluminum were all produced in-house, the steel brazers were the highest-paid factory workers. Because reliable, quality brazing requires far more experience and honed technique than tig welding, or bonding. Pre-brazing prep, getting the temperature just right, heating the lugs properly to maintain the proper temperature and allow the brass/silver to flow correctly, working not too fast and not too slow, getting full brass/silver penetration without gaps, without overheating or cold-brazing---can't be learned in an afternoon. And in fact, "how one brazes the lug" matters a lot more than what kind of steel is used.

Many of the tig welders were hired right out of trade school. They didn't need bicycle framebuilding experience, all they needed was the certificate showing they could weld.

The bonded carbon/aluminum frame workers were the lowest paid, because all they had to do was slather pre-mixed epoxy onto the joints with little brushes. The cast lugs, with cast-in alignment ribs, combined with hydraulic jigs, took care of all alignment issues. Brushing on enough epoxy for it to smush out when the tube is pressed into place requires very little precision or experience. Whether aluminum, aluminium/carbon hybrid or all-carbon, tubes and lugs were machine-built at very low cost, and assembly was fast and cheap.

Whether the carbon frame is made from bonded sub-assemblies, or pops out of a mold, it is pretty inexpensive to produce. Gluing joints is easy, laying prepreg is easy, learning to clack the keys that control the mold-making machines or presses doesn't take years of experience. You can search for higher-priced prepreg if you want to justify a $5,000 frameset, and the engineering input is more intensive, but the material costs and labor are relatively cheap.

"Leave it at that."

Lastly, forgive my strong language, but your conclusions about comparative ride quality and the possible perceptions for "any objective person that has spent time in the saddle" is pure poppycock.

Too funny. Mark Nobilette tells a story that when a bunch of frame builders, including himself, were building high-end road frames for GT in Longmont, CO that they weren't getting paid squat. Many of the GT frames went out the door with lugs we would have been embarrassed to to have brazed. He still thinks these were great GT frames, but only if the lugs were actually redone. He wasn't getting paid enough to teach these other "master frame builders" how to actually do it correctly, and most of these experience frame builders didn't seem to have a clue in his book.

I think its funny that your anecdotal story doesn't reconcile with reality. There was NO MONEY in lugged steel frames for Trek in 1990, compared to their aluminum and emerging carbon bikes. They even had those weird bonded aluminum and carbon tubes, remember those? Yet you are representing that the highest paid factory workers in the plant were brazing steel for lugged bikes. Not the techs laying up the high-end expensive carbon bikes. Not the impossible to get experienced aluminum welders (before the feed system and current controller technology advanced) that were required to deal with the challenges that aluminum presents, but people brazing steel. Not the guys in the paint booths. So Trek was paying employees building steel bikes that did NOT represent a significant market for Trek at that point in time, more than all their other workers? For a skill that if properly taught a person can become competent at in mere days and anyone can learn? Got it.

Here's a hint. Even to build Rivendell's Waterford and Nobilette don't get much. Its just not a valuable and marketable skill. No one gets rich building steel bikes. There are a thousand frame builders, and its not a rare skill set, and even for the best frame builders there just isn't a lot of money in it.

You want to see some talent go look at what Black Sheep fabricates. You can't begin to compare the skill set needed to weld up exotic metals to simply brazing steel. Every hipster and their cousin has started a steel bike company. There is no barrier to entry in terms of skill level, equipment cost, or experience.

When was the last time you read a post from someone actually honestly acknowledging that their "dream build" Independent, Sycip, Rivendell, or Gunnar didn't meet their expectations? You'll never read those posts. To actually come to terms with that requires a level of inventory and honesty that a cult member in the "steel is real" cult will never reach. What you do see is an awful awful lot of custom high-end steel bikes being sold on the secondary market in absolutely pristine condition. I wonder why that is?

#164

Fat Guy on a Little Bike

Join Date: Jun 2008

Location: Philadelphia, PA

Posts: 15,944

Bikes: Two wheeled ones

Mentioned: 42 Post(s)

Tagged: 0 Thread(s)

Quoted: 1254 Post(s)

Liked 345 Times

in

174 Posts

Stan, of course you're right. There are differences between "generic" 4130 and some of the more exotic (and rarely used) alloys. I would contend though that there are other factors that make more of a difference than the type of chromoly. You mentioned tube diameter/wall thickness. That goes hand in hand with the way the tubes are butted. "Custom butted" tubing is a real thing that makes a difference, compared to off-the-shelf standard double butted tubing.

Regardless, I think you quickly get to a point of diminishing returns. A well-made 4130 frame, double-butted, either lugged or TIG welded, will put you in the ball park and improvements are incremental from there. You can change wheels and tires and get more of a difference sometimes, than you'd feel with a "higher end" steel frame. Just my opinion and experience.

By the way, here are those same numbers for aluminum. Strength-wise, there's no comparison. And lifespan - no comparison. Also ride and handling - no comparison. Even a mass-produced 4130 chromoly frame is better than the best aluminum frame. The exception is racing or other competition where most of those factors don't matter and you're ONLY optimizing for weight. Again, my opinion. The only downside to steel is cost.

6061-T6

Ultimate Tensile Strength 310 MPa

Yield Strength 276 MPa

7000 series

Ultimate Tensile Strength 572 MPa

Tensile Yield Strength 503 MPa

Regardless, I think you quickly get to a point of diminishing returns. A well-made 4130 frame, double-butted, either lugged or TIG welded, will put you in the ball park and improvements are incremental from there. You can change wheels and tires and get more of a difference sometimes, than you'd feel with a "higher end" steel frame. Just my opinion and experience.

By the way, here are those same numbers for aluminum. Strength-wise, there's no comparison. And lifespan - no comparison. Also ride and handling - no comparison. Even a mass-produced 4130 chromoly frame is better than the best aluminum frame. The exception is racing or other competition where most of those factors don't matter and you're ONLY optimizing for weight. Again, my opinion. The only downside to steel is cost.

6061-T6

Ultimate Tensile Strength 310 MPa

Yield Strength 276 MPa

7000 series

Ultimate Tensile Strength 572 MPa

Tensile Yield Strength 503 MPa

The difference in builders is more significant than material differences. I'd rather have an aluminum bike designed by a quality builder than a high quality steel bike built by a sloppy one. Even the stiffest Cannondale is preferable to a bike boom Raliegh international built after a few beers.

#165

Senior Member

Join Date: Apr 2009

Location: Boulder County, CO

Posts: 1,511

Bikes: '92 22" Cannondale M2000, '92 Cannondale R1000 Tandem, another modern Canndondale tandem, Two Holy Grail '86 Cannondale ST800s 27" (68.5cm) Touring bike w/Superbe Pro components and Phil Wood hubs. A bunch of other 27" ST frames & bikes.

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 110 Post(s)

Likes: 0

Liked 4 Times

in

4 Posts

Trek was still hand-building lugged steel frames in Wisconsin until 1992, if that's any measure. But I'll go with mid-80's to mid-90's being the "golden age" of chromoly steel. There were many fine steel bikes produced well into the late 90's also, though most of them were TIG welded. Ultimately it's all about the builder, not the the time frame. Because steel has become the "elite" frame material in favor of the much cheaper aluminum, any modern steel framebuilder is probably putting out a very fine product.

I think some very very nice steel frames had some very poor paint jobs. Interestingly, I think at some point when EPA regs changed paint quality actually went down a bit. I think early 80s stuff looked spectacular, but as a rule not every great steel frame had a great paint job.

To be fair some of the most hideous paint jobs I've ever seen were on Cannondales. The weird free form graphics just look so bad, in my mind. Then again some of the best paint jobs I've ever seen were on Klein or Colnagos. There are some 'nagos where the paint job just goes too far for me, but many of them are drop dead gorgeous.

I think Bike Snob is an idiot, for the most part I love Klein and Colnago paint:

Bike Snob NYC: Color Me Nauseous: Cycling's Worst Paint Jobs

So for me the peak would be when steel was really advancing the technology to make up ground with Klein & Cannondale. The Colnago Master with the shaped steel tubing, the crazy but great paint, and the history. So count me in for a peak of '86 to the early 90s.

#166

Senior Member

Join Date: Apr 2009

Location: Boulder County, CO

Posts: 1,511

Bikes: '92 22" Cannondale M2000, '92 Cannondale R1000 Tandem, another modern Canndondale tandem, Two Holy Grail '86 Cannondale ST800s 27" (68.5cm) Touring bike w/Superbe Pro components and Phil Wood hubs. A bunch of other 27" ST frames & bikes.

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 110 Post(s)

Likes: 0

Liked 4 Times

in

4 Posts

The difference in builders is more significant than material differences. I'd rather have an aluminum bike designed by a quality builder than a high quality steel bike built by a sloppy one. Even the stiffest Cannondale is preferable to a bike boom Raliegh international built after a few beers.

#167

Senior Member

I worked for Trek internationally from '90-'99, and visited/toured the US factories several times during those 9 years. I probably toured Waterloo 4-5 times, Whitewater only once. I've related what I myself saw and was told during those factory tours. I could "backup my claims" by searching for photographs/notes I took, or getting corroboration from other Trekkies who were in a position to know or see the same things. But I don't need to "backup my claims" to you or anybody else. Whether you believe me or not has no effect on the reality of what I saw.

If you care that much, check with the website owner, see if you can get in touch with former Trekkies. Go ahead chase that voodoo down.

If you care that much, check with the website owner, see if you can get in touch with former Trekkies. Go ahead chase that voodoo down.

I wasn't there, but that's not what the vintage Trek site says; it says this in the 1985 section if the history:

"Trek replaces the automatic brazers with a robotic system that assembles, aligns and brazes in a single pass."

So that sentence makes it sound like Trek had automatic brazers for awhile but humans assembled and aligned the frame, then switched to robotic system that did it all. Is the Vintage Trek site incorrect? Here's where I would ask to backup your claims but obviously you can't, just like I can't backup my claim that Greg Lemond doped because it's hearsay from people that I knew who knew him.

"Trek replaces the automatic brazers with a robotic system that assembles, aligns and brazes in a single pass."

So that sentence makes it sound like Trek had automatic brazers for awhile but humans assembled and aligned the frame, then switched to robotic system that did it all. Is the Vintage Trek site incorrect? Here's where I would ask to backup your claims but obviously you can't, just like I can't backup my claim that Greg Lemond doped because it's hearsay from people that I knew who knew him.

__________________

Fuggedaboutit!

Fuggedaboutit!

#168

Senior Member

Join Date: Apr 2009

Location: Boulder County, CO

Posts: 1,511

Bikes: '92 22" Cannondale M2000, '92 Cannondale R1000 Tandem, another modern Canndondale tandem, Two Holy Grail '86 Cannondale ST800s 27" (68.5cm) Touring bike w/Superbe Pro components and Phil Wood hubs. A bunch of other 27" ST frames & bikes.

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 110 Post(s)

Likes: 0

Liked 4 Times

in

4 Posts

Actually Trek stopped doing hand brazed silver lugged frames in 85 and went with a automatic robotic system that brass brazed without any human intervention except for the pushing of buttons to operate the robotics. So in reality machines were able to make lugged steel bike frames, were they better than handbuilt? I don't think so but some probably think so. I find it strange you claim to went on a tour there yet claim they were doing it by hand in 1990, see: Vintage Trek - Steel Road Bike Timeline, Trek Bicycle Corporation Scan down to 1985. Perhaps you can explain what you saw more thoroughly.

#169

Senior Member

Join Date: Apr 2009

Location: Boulder County, CO

Posts: 1,511

Bikes: '92 22" Cannondale M2000, '92 Cannondale R1000 Tandem, another modern Canndondale tandem, Two Holy Grail '86 Cannondale ST800s 27" (68.5cm) Touring bike w/Superbe Pro components and Phil Wood hubs. A bunch of other 27" ST frames & bikes.

Mentioned: 8 Post(s)

Tagged: 0 Thread(s)

Quoted: 110 Post(s)

Likes: 0

Liked 4 Times

in

4 Posts

What do you guys think of Ox Platinum compared to more vintage tube sets? I gave away my 68cm Curtlo OxPlatinum with a Record 10-speed triple/long cage build.

I'm curious what other people think of that tube set compared to other stuff, whether it is "better" and more advanced that some of the legendary vintage stuff. What modern tube sets would make you think about replacing your favorite vintage bikes with something modern, if you think steel hasn't peaked. Which in terms of developing innovative new engineered tube sets I don't think steel has peaked. I just think its been overshot by other materials. So I think steel will continue to get better, but other materials are now on a different performance curve.

I'm curious what other people think of that tube set compared to other stuff, whether it is "better" and more advanced that some of the legendary vintage stuff. What modern tube sets would make you think about replacing your favorite vintage bikes with something modern, if you think steel hasn't peaked. Which in terms of developing innovative new engineered tube sets I don't think steel has peaked. I just think its been overshot by other materials. So I think steel will continue to get better, but other materials are now on a different performance curve.

#170

Senior Member

Too funny +1.

You're saying that anybody can learn brazing in an afternoon/coupla days, easy peasy, yet Mark Nobilette worked with experienced frame builders who weren't doing it correctly. If it's so easy, how could so many experienced builders be doing it wrong? What you seem to be saying is that it's easy to learn how to braze badly, but difficult to learn to do it well.

You're saying nobody's getting rich building steel bikes. Who's getting rich building aluminum bikes? If Builder A is barely breaking even building/selling a $3k steel frame and Builder B is richly profitable building/selling a $3k aluminum frame, doesn't that say the aluminum frame is cheaper and easier to build? Where else does profit come from but cheaper materials and lower production costs/time? Brazing/steel is simple, but nobody can make money at it, while welding/aluminum is difficult, but profits are high?

It's a sad fact that just about nobody makes money in the bike biz. Underpaid brazers, underpaid welders, underpaid mechanics, underpaid salesfolk. Your anecdotal stories of poor brazers and emerging steel hipster builders are all pretty meaningless.

Trek's 1990 US-made steel bikes were all lugged, and represented a large share of the model mix. 930/950/970/990 ATBs, 720/750/790 hybrids, 330/420/520 road. I sold a lot of them, especially the ATBs and Hybrids, and they were profitable. The market was shifting, and for the '94 model year Trek dropped brazed steel and bonded aluminum for tig welding to cut costs, lower frame weights and increase mfr flexibility.

The veep told me the brazers were paid the highest hourly wage on the factory floor. There were no high-tech workers laying up carbon frames in 1990. Trek bought carbon tubes from an outside supplier and bonded them to cast aluminum lugs. Assembly was no more advanced than a grade-schooler brushing paste onto macaroni and paper. There weren't any welders in 1990, since all the frames were either brazed or bonded. When tig'd production started for the '94 model year, I was told most of the welders were being hired fresh out of tech/vocational school.

As for steel cults, I'll give you a yawn and a whatevs. Hang out where plenty of folks ride high-end steel and you'll find plenty of folks deciding their dream steel isn't good enough any more, or they need a new frame for 'cross or gravel or some other niche. Check out the classifieds on The Paceline and you'll see more high-end carbon being sold than high-end steel. You won't find much high-end aluminum, though, since nobody rides expensive aluminum any more.

You're saying that anybody can learn brazing in an afternoon/coupla days, easy peasy, yet Mark Nobilette worked with experienced frame builders who weren't doing it correctly. If it's so easy, how could so many experienced builders be doing it wrong? What you seem to be saying is that it's easy to learn how to braze badly, but difficult to learn to do it well.

You're saying nobody's getting rich building steel bikes. Who's getting rich building aluminum bikes? If Builder A is barely breaking even building/selling a $3k steel frame and Builder B is richly profitable building/selling a $3k aluminum frame, doesn't that say the aluminum frame is cheaper and easier to build? Where else does profit come from but cheaper materials and lower production costs/time? Brazing/steel is simple, but nobody can make money at it, while welding/aluminum is difficult, but profits are high?

It's a sad fact that just about nobody makes money in the bike biz. Underpaid brazers, underpaid welders, underpaid mechanics, underpaid salesfolk. Your anecdotal stories of poor brazers and emerging steel hipster builders are all pretty meaningless.

Trek's 1990 US-made steel bikes were all lugged, and represented a large share of the model mix. 930/950/970/990 ATBs, 720/750/790 hybrids, 330/420/520 road. I sold a lot of them, especially the ATBs and Hybrids, and they were profitable. The market was shifting, and for the '94 model year Trek dropped brazed steel and bonded aluminum for tig welding to cut costs, lower frame weights and increase mfr flexibility.

The veep told me the brazers were paid the highest hourly wage on the factory floor. There were no high-tech workers laying up carbon frames in 1990. Trek bought carbon tubes from an outside supplier and bonded them to cast aluminum lugs. Assembly was no more advanced than a grade-schooler brushing paste onto macaroni and paper. There weren't any welders in 1990, since all the frames were either brazed or bonded. When tig'd production started for the '94 model year, I was told most of the welders were being hired fresh out of tech/vocational school.

As for steel cults, I'll give you a yawn and a whatevs. Hang out where plenty of folks ride high-end steel and you'll find plenty of folks deciding their dream steel isn't good enough any more, or they need a new frame for 'cross or gravel or some other niche. Check out the classifieds on The Paceline and you'll see more high-end carbon being sold than high-end steel. You won't find much high-end aluminum, though, since nobody rides expensive aluminum any more.

Too funny. Mark Nobilette tells a story that when a bunch of frame builders, including himself, were building high-end road frames for GT in Longmont, CO that they weren't getting paid squat. Many of the GT frames went out the door with lugs we would have been embarrassed to to have brazed. He still thinks these were great GT frames, but only if the lugs were actually redone. He wasn't getting paid enough to teach these other "master frame builders" how to actually do it correctly, and most of these experience frame builders didn't seem to have a clue in his book.

I think its funny that your anecdotal story doesn't reconcile with reality. There was NO MONEY in lugged steel frames for Trek in 1990, compared to their aluminum and emerging carbon bikes. They even had those weird bonded aluminum and carbon tubes, remember those? Yet you are representing that the highest paid factory workers in the plant were brazing steel for lugged bikes. Not the techs laying up the high-end expensive carbon bikes. Not the impossible to get experienced aluminum welders (before the feed system and current controller technology advanced) that were required to deal with the challenges that aluminum presents, but people brazing steel. Not the guys in the paint booths. So Trek was paying employees building steel bikes that did NOT represent a significant market for Trek at that point in time, more than all their other workers? For a skill that if properly taught a person can become competent at in mere days and anyone can learn? Got it.

Here's a hint. Even to build Rivendell's Waterford and Nobilette don't get much. Its just not a valuable and marketable skill. No one gets rich building steel bikes. There are a thousand frame builders, and its not a rare skill set, and even for the best frame builders there just isn't a lot of money in it.

You want to see some talent go look at what Black Sheep fabricates. You can't begin to compare the skill set needed to weld up exotic metals to simply brazing steel. Every hipster and their cousin has started a steel bike company. There is no barrier to entry in terms of skill level, equipment cost, or experience.

When was the last time you read a post from someone actually honestly acknowledging that their "dream build" Independent, Sycip, Rivendell, or Gunnar didn't meet their expectations? You'll never read those posts. To actually come to terms with that requires a level of inventory and honesty that a cult member in the "steel is real" cult will never reach. What you do see is an awful awful lot of custom high-end steel bikes being sold on the secondary market in absolutely pristine condition. I wonder why that is?

I think its funny that your anecdotal story doesn't reconcile with reality. There was NO MONEY in lugged steel frames for Trek in 1990, compared to their aluminum and emerging carbon bikes. They even had those weird bonded aluminum and carbon tubes, remember those? Yet you are representing that the highest paid factory workers in the plant were brazing steel for lugged bikes. Not the techs laying up the high-end expensive carbon bikes. Not the impossible to get experienced aluminum welders (before the feed system and current controller technology advanced) that were required to deal with the challenges that aluminum presents, but people brazing steel. Not the guys in the paint booths. So Trek was paying employees building steel bikes that did NOT represent a significant market for Trek at that point in time, more than all their other workers? For a skill that if properly taught a person can become competent at in mere days and anyone can learn? Got it.

Here's a hint. Even to build Rivendell's Waterford and Nobilette don't get much. Its just not a valuable and marketable skill. No one gets rich building steel bikes. There are a thousand frame builders, and its not a rare skill set, and even for the best frame builders there just isn't a lot of money in it.

You want to see some talent go look at what Black Sheep fabricates. You can't begin to compare the skill set needed to weld up exotic metals to simply brazing steel. Every hipster and their cousin has started a steel bike company. There is no barrier to entry in terms of skill level, equipment cost, or experience.

When was the last time you read a post from someone actually honestly acknowledging that their "dream build" Independent, Sycip, Rivendell, or Gunnar didn't meet their expectations? You'll never read those posts. To actually come to terms with that requires a level of inventory and honesty that a cult member in the "steel is real" cult will never reach. What you do see is an awful awful lot of custom high-end steel bikes being sold on the secondary market in absolutely pristine condition. I wonder why that is?

__________________

Fuggedaboutit!

Fuggedaboutit!

#171

Senior Member

Join Date: Jul 2014

Posts: 1,490

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 1083 Post(s)

Liked 686 Times

in

440 Posts

Oh, I dunno. I'm guessing this aluminum bike is better than a generic 4130 chromoly frame beyond just some weight savings:

Specialized Bicycle Components

Specialized Bicycle Components

Last edited by Jeff Neese; 08-14-15 at 06:18 AM.

#172

Fat Guy on a Little Bike

Join Date: Jun 2008

Location: Philadelphia, PA

Posts: 15,944

Bikes: Two wheeled ones

Mentioned: 42 Post(s)

Tagged: 0 Thread(s)

Quoted: 1254 Post(s)

Liked 345 Times

in

174 Posts

I worked for Trek internationally from '90-'99, and visited/toured the US factories several times during those 9 years. I probably toured Waterloo 4-5 times, Whitewater only once. I've related what I myself saw and was told during those factory tours. I could "backup my claims" by searching for photographs/notes I took, or getting corroboration from other Trekkies who were in a position to know or see the same things. But I don't need to "backup my claims" to you or anybody else. Whether you believe me or not has no effect on the reality of what I saw.

If you care that much, check with the website owner, see if you can get in touch with former Trekkies. Go ahead chase that voodoo down.

If you care that much, check with the website owner, see if you can get in touch with former Trekkies. Go ahead chase that voodoo down.

#173

Senior Member

As for steel cults, I'll give you a yawn and a whatevs. Hang out where plenty of folks ride high-end steel and you'll find plenty of folks deciding their dream steel isn't good enough any more, or they need a new frame for 'cross or gravel or some other niche. Check out the classifieds on The Paceline and you'll see more high-end carbon being sold than high-end steel. You won't find much high-end aluminum, though, since nobody rides expensive aluminum any more.

My order of preference: Ti > Steel > Aluminum > CF

(but all my bikes are Steel since I'm too cheap to buy Ti...I previously owned carbon fiber).

#174

Senior Member

Join Date: Sep 2010

Location: NE Indiana

Posts: 8,687

Bikes: 2020 Masi Giramondo 700c; 2013 Lynskey Peloton; 1992 Giant Rincon; 1989 Dawes needs parts; 1985 Trek 660; 1985 Fuji Club; 1984 Schwinn Voyager; 1984 Miyata 612; 1977 Raleigh Competition GS

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 1126 Post(s)

Liked 253 Times

in

204 Posts

#175

Senior Member

Join Date: Sep 2010

Location: NE Indiana

Posts: 8,687

Bikes: 2020 Masi Giramondo 700c; 2013 Lynskey Peloton; 1992 Giant Rincon; 1989 Dawes needs parts; 1985 Trek 660; 1985 Fuji Club; 1984 Schwinn Voyager; 1984 Miyata 612; 1977 Raleigh Competition GS

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 1126 Post(s)

Liked 253 Times

in

204 Posts

They do exist though. Not many, but there are people who actually seek out high-end aluminum. Surely a small market. I posted that link to the $8000 Specialized Allez aluminum bike. I have a Cat3 racer friend who rides an Allez. Another person I know loves his CAAD10. And Co-Motion's top-of-the-line race bike is aluminum (Co-Motion Ristretto).

My order of preference: Ti > Steel > Aluminum > CF

(but all my bikes are Steel since I'm too cheap to buy Ti...I previously owned carbon fiber).

My order of preference: Ti > Steel > Aluminum > CF

(but all my bikes are Steel since I'm too cheap to buy Ti...I previously owned carbon fiber).

By the way you can afford TI, Bikes Direct has them (Motobecane) at very low cost and are very highly reviewed; see this road bike: https://www.bikesdirect.com/products/...hamp_ti_10.htm

Or this cross bike: https://www.bikesdirect.com/products/...pro_ti_xiv.htm