What Do You Like Least & Why?

#101

Senior Member

I'll echo tight fitting tires or rims, whatever causes the tire to not go on, as well as the hub preload adjustment. It's almost impossible to get it "juuuust right".

I also hate when I have to adjust the seat post binder on a C&V bike. I posted about this the other day. Lately my record with those things is like 50/50 on if it'll break or not. I guess due to the previous owner over tightening.

I also hate when I have to adjust the seat post binder on a C&V bike. I posted about this the other day. Lately my record with those things is like 50/50 on if it'll break or not. I guess due to the previous owner over tightening.

#102

All Campy All The Time

Join Date: Nov 2013

Location: Richmond, Virginia

Posts: 1,417

Bikes: Listed in my signature.

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 177 Post(s)

Liked 114 Times

in

63 Posts

Good one! They already have the factory and the machine, and it's no secret how good cones are made. Why not just make good cones?

__________________

My C&V Bikes:

1972 Bottecchia Professional, 1972 Legnano Olympiade Record,

1982 Colnago Super, 1987 Bottecchia Team C-Record,

1988 Pinarello Montello, 1990 Masi Nuova Strada Super Record,

1995 Bianchi Campione d'Italia, 1995 DeBernardi Thron

My C&V Bikes:

1972 Bottecchia Professional, 1972 Legnano Olympiade Record,

1982 Colnago Super, 1987 Bottecchia Team C-Record,

1988 Pinarello Montello, 1990 Masi Nuova Strada Super Record,

1995 Bianchi Campione d'Italia, 1995 DeBernardi Thron

#103

aka Tom Reingold

Join Date: Jan 2009

Location: New York, NY, and High Falls, NY, USA

Posts: 40,502

Bikes: 1962 Rudge Sports, 1971 Raleigh Super Course, 1971 Raleigh Pro Track, 1974 Raleigh International, 1975 Viscount Fixie, 1982 McLean, 1996 Lemond (Ti), 2002 Burley Zydeco tandem

Mentioned: 511 Post(s)

Tagged: 0 Thread(s)

Quoted: 7348 Post(s)

Liked 2,463 Times

in

1,433 Posts

I don't like to be interrupted when I'm working on a project, whether working on a car, RC boat build, machine shop job, house repair, yard work, or bike maintenance. Fercrissakes, can't you see I'm in the middle of something here? Do I have a sign on my back or what?

I'm with @fender1 on cable housing being the worst. It's not that I mind finishing the ends. I dislike measuring and installing them. To me, installing cables seems to take as long as the rest of the bike.

I'm also with @TimmyT that bacon is lousy. I don't like it in any context. I know I'm weird that way. But I do love truing wheels. I could do it all day. In fact, a hundred years ago or so, I had a job where I trued wheels almost all day.

__________________

Tom Reingold, tom@noglider.com

New York City and High Falls, NY

Blogs: The Experienced Cyclist; noglider's ride blog

“When man invented the bicycle he reached the peak of his attainments.” — Elizabeth West, US author

Please email me rather than PM'ing me. Thanks.

Tom Reingold, tom@noglider.com

New York City and High Falls, NY

Blogs: The Experienced Cyclist; noglider's ride blog

“When man invented the bicycle he reached the peak of his attainments.” — Elizabeth West, US author

Please email me rather than PM'ing me. Thanks.

#104

Banned.

Join Date: Jul 2009

Location: PAZ

Posts: 12,294

Mentioned: 255 Post(s)

Tagged: 0 Thread(s)

Quoted: 2588 Post(s)

Liked 4,824 Times

in

1,709 Posts

I don't know what I was thinking in my earlier post. The worst is not being able to find what I need. This morning it was, first, a cantilever brake hanger, and, second, my trusty Park chain breaker. I tell myself I'm getting organized.

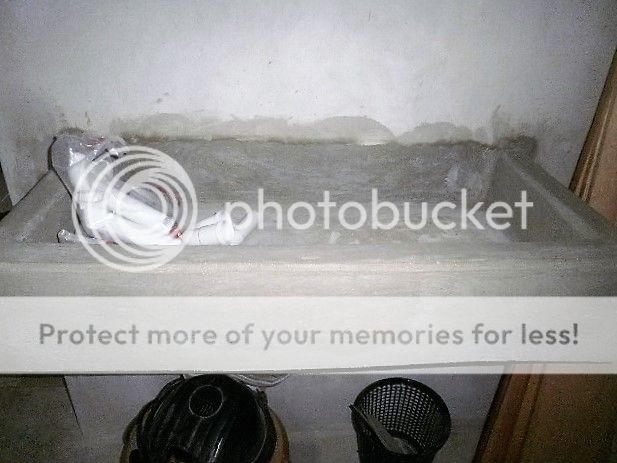

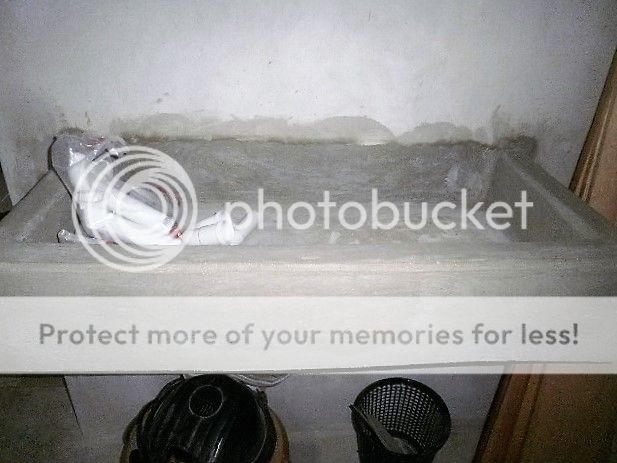

And, as promised, the sink custom built for finding holes in innertubes:

And, as promised, the sink custom built for finding holes in innertubes:

DD

#106

Ride, Wrench, Swap, Race

Join Date: Jan 2010

Location: Northern California

Posts: 9,193

Bikes: Cheltenham-Pedersen racer, Boulder F/S Paris-Roubaix, Varsity racer, '52 Christophe, '62 Continental, '92 Merckx, '75 Limongi, '76 Presto, '72 Gitane SC, '71 Schwinn SS, etc.

Mentioned: 132 Post(s)

Tagged: 0 Thread(s)

Quoted: 1565 Post(s)

Liked 1,295 Times

in

865 Posts

I finally took the pluge and rebuilt my new '73 Super Course bb last night, entertaining as usual!

Drive side cotter came out with the home-made press, took a lot of wrench torque on the poor iron casting but out it came, still straight!

The left arm cotter resisted budging, right up to where I could see the precious original cotter was bending!

So I stopped right there, took the bike outside into the cold, and blasted the knuckle of the crankarm for several minutes with the propane torch, with the press still in place and pushing hard.

I cycled the heat three times, re-torqueing the press slightly further each time only a tenth of a turn. Getting this original cotter out still usable would be a huge victory!!!

Then I applied one final full half-turn, the yielding still seemingly indistinguishable from that caused by the bending cotter, and I then removed the press to inspect the progress. I could see a line where the cotter seemed to have exited the arm by perhaps a half-millimeter, so I went back, re-installed the press and just tightened away, and the cotter at one point suddenly started moving more freely. Whew! That was a close one.

Then it was on to the bb, and the original (stamped Phillips, 2/73) spindle was found to be in new condition, so I repacked with new GR25 balls and waterproof grease.

Needless to say, this ordeal ate up the better part of my evening, but I was happy to get it all back together with the original cotters.

Btw, I didn't heat the end of the crankarm over about 300F, judging by the lack of any smoke that such efforts occasionally issue forth, so no harm done, no discoloration or weakening, etc.

The torch saved the day. May I never have to rebuild this one again.

Last edited by dddd; 11-30-15 at 03:33 PM.

#107

Ride, Wrench, Swap, Race

Join Date: Jan 2010

Location: Northern California

Posts: 9,193

Bikes: Cheltenham-Pedersen racer, Boulder F/S Paris-Roubaix, Varsity racer, '52 Christophe, '62 Continental, '92 Merckx, '75 Limongi, '76 Presto, '72 Gitane SC, '71 Schwinn SS, etc.

Mentioned: 132 Post(s)

Tagged: 0 Thread(s)

Quoted: 1565 Post(s)

Liked 1,295 Times

in

865 Posts

[QUOTE=SJX426;18348600]

...Nearly all of the frustrations listed so far are overcome with repetition and seeing them as challenges to improve the process. I like accomplishments from my work, weather it is a build or a ride. For those who prefer riding over wrenching, I don't think my statement about repetition applies...

QUOTE]

Rule to live by. ^^^

Even applies to my approach to finding haphazardly-stored or lost bits, there is a process to be developed, most of it mental.

I once found a micro-sized bearing ball from an SPD pedal that I was rebuilding. By tenacity, I ruled out all possibilities, finally discovered it had hit the concrete, bounced up, then fell/dropped into the edge of the wall of an open corrugated cardboard box. Yes, it was found to have fallen down the length of a corrugation tunnel, and was retrieved.

By embracing the challenge...

...Nearly all of the frustrations listed so far are overcome with repetition and seeing them as challenges to improve the process. I like accomplishments from my work, weather it is a build or a ride. For those who prefer riding over wrenching, I don't think my statement about repetition applies...

QUOTE]

Rule to live by. ^^^

Even applies to my approach to finding haphazardly-stored or lost bits, there is a process to be developed, most of it mental.

I once found a micro-sized bearing ball from an SPD pedal that I was rebuilding. By tenacity, I ruled out all possibilities, finally discovered it had hit the concrete, bounced up, then fell/dropped into the edge of the wall of an open corrugated cardboard box. Yes, it was found to have fallen down the length of a corrugation tunnel, and was retrieved.

By embracing the challenge...

#108

Ride, Wrench, Swap, Race

Join Date: Jan 2010

Location: Northern California

Posts: 9,193

Bikes: Cheltenham-Pedersen racer, Boulder F/S Paris-Roubaix, Varsity racer, '52 Christophe, '62 Continental, '92 Merckx, '75 Limongi, '76 Presto, '72 Gitane SC, '71 Schwinn SS, etc.

Mentioned: 132 Post(s)

Tagged: 0 Thread(s)

Quoted: 1565 Post(s)

Liked 1,295 Times

in

865 Posts

I just had to chime in here.

Before de-torqueing quite to the point of damage, and after applying the penetrant, take a 3/4" wooden dowel and use as a drift punch with a good-sized hammer.

Apply blows around the periphery of the cap, which momentarily un-loads and thus un-sticks the threading!

I've done this maybe 50 times and only the plastic caps have incurred any further grief, when they break.

Last edited by dddd; 11-30-15 at 04:16 PM.

#109

aka Tom Reingold

Join Date: Jan 2009

Location: New York, NY, and High Falls, NY, USA

Posts: 40,502

Bikes: 1962 Rudge Sports, 1971 Raleigh Super Course, 1971 Raleigh Pro Track, 1974 Raleigh International, 1975 Viscount Fixie, 1982 McLean, 1996 Lemond (Ti), 2002 Burley Zydeco tandem

Mentioned: 511 Post(s)

Tagged: 0 Thread(s)

Quoted: 7348 Post(s)

Liked 2,463 Times

in

1,433 Posts

I hate cotters, too, but I don't deal with them often any more, so I'm good.

__________________

Tom Reingold, tom@noglider.com

New York City and High Falls, NY

Blogs: The Experienced Cyclist; noglider's ride blog

“When man invented the bicycle he reached the peak of his attainments.” — Elizabeth West, US author

Please email me rather than PM'ing me. Thanks.

Tom Reingold, tom@noglider.com

New York City and High Falls, NY

Blogs: The Experienced Cyclist; noglider's ride blog

“When man invented the bicycle he reached the peak of his attainments.” — Elizabeth West, US author

Please email me rather than PM'ing me. Thanks.

#110

Ride, Wrench, Swap, Race

Join Date: Jan 2010

Location: Northern California

Posts: 9,193

Bikes: Cheltenham-Pedersen racer, Boulder F/S Paris-Roubaix, Varsity racer, '52 Christophe, '62 Continental, '92 Merckx, '75 Limongi, '76 Presto, '72 Gitane SC, '71 Schwinn SS, etc.

Mentioned: 132 Post(s)

Tagged: 0 Thread(s)

Quoted: 1565 Post(s)

Liked 1,295 Times

in

865 Posts

This is a pretty positive and helpful place over all. I enjoy the finding, rebuilding and riding of bikes and enjoy giving rebuilt ones to friends and family etc. That said, there is one thing about this process I dislike above all others, cutting & filing cable housing. I don't know why I dislike it so much but I do. Stuck post, stuck stem frozen spoke nipples? No problem. Cutting and filing shiffter & brake cable housing makes me irritated.It always seems to take longer than it should, The edges still seem sharp to me, even after filing. The housing cutters often times don't make a clean cut and extend the whole miserable process. Completely irrational, I know. What's your thing?

As far as spiral housing, I nearly always make two cuts, the first attempts to get cleanly between two coils, the second involves rotating the housing so the nipper makes the end more flat, with the opening clear for the cable.

Some cutters make doing this easier than others, it's the shape of the blades.

Then there are the longitudinal wires in shift housing. These always are used with ferrules, which always have a plastic insert to allow some embedment of the wires, which enables a more-even support so that each wire sees a similar level of compressive stress.

The wire's sharp ends allow the ferrules to work as intended!

Any kind of sander, stone or abrasive wheel is going to massively contaminate the inside of the housing with abrasive dust of the type that necessitates the periodic replacement of housings on a well-maintained bike. If the dust gets in, it must be removed before installing.

Many of today's better housings are pre-lubricated with a non-thickening silicon-based lube, which would of course need to be flushed out in order to flush any dust out, so I don't use any sort of abrasive grinding any more these days.

And I used to use a Dremel cut-off wheel in the very early days, but man what a time-consuming mess it seemed to be. Like it was specifically meant to melt and contaminate at the same time, and as it wasted ten minutes!

I did use linesman pliers for a long, long time, and so lucky for me that I had a decent pair with good edge alignment and really hard metal.

The jaws of the cutters that I like best look like this:

#111

Abuse Magnet

Join Date: Jun 2012

Location: Colorado

Posts: 1,869

Bikes: '91 Mtn Tek Vertical, '74 Raleigh Sports, '72 Raleigh Twenty, '84 Univega Gran Turismo, '09 Surly Karate Monkey, '92 Burley Rock-n-Roll, '86 Miyata 310, '76 Raleigh Shopper

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 151 Post(s)

Liked 174 Times

in

88 Posts

I hate adjusting SIS rear derailleurs. I can never get it right.

#112

Senior Member

Join Date: Nov 2012

Posts: 693

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 3 Post(s)

Likes: 0

Liked 15 Times

in

2 Posts

The only thing that really gets to me is the 'thing' I can't fix, for what ever reason.

For a while it seemed to be 90's era Trek's with bottom bracket cups to rusty to allow for removal.

Now, at the moment it is freewheels/hubs that cannot be repaired. But when working with old, often neglected bikes, that's all part of it I suppose.

Occasionally I find something that I am unable to repair because I don't have the right tool. That makes me angry and usually embarrasses me if the bike owner is standing there watching.

There is immense satisfaction in working with my hands. When I can repair something for someone or bring life back to an old bike someone previously decided had no value, I am especially satisfied.

Not being able to complete the repair or not having the tool undermines all of that.

For a while it seemed to be 90's era Trek's with bottom bracket cups to rusty to allow for removal.

Now, at the moment it is freewheels/hubs that cannot be repaired. But when working with old, often neglected bikes, that's all part of it I suppose.

Occasionally I find something that I am unable to repair because I don't have the right tool. That makes me angry and usually embarrasses me if the bike owner is standing there watching.

There is immense satisfaction in working with my hands. When I can repair something for someone or bring life back to an old bike someone previously decided had no value, I am especially satisfied.

Not being able to complete the repair or not having the tool undermines all of that.

#113

Death fork? Naaaah!!

I'm with @fender1 on cable housing being the worst. It's not that I mind finishing the ends. I dislike measuring and installing them. To me, installing cables seems to take as long as the rest of the bike.

Top

__________________

You know it's going to be a good day when the stem and seatpost come right out.

(looking for a picture and not seeing it? Thank the Photobucket fiasco.PM me and I'll link it up.)

You know it's going to be a good day when the stem and seatpost come right out.

(looking for a picture and not seeing it? Thank the Photobucket fiasco.PM me and I'll link it up.)

#114

Ride, Wrench, Swap, Race

Join Date: Jan 2010

Location: Northern California

Posts: 9,193

Bikes: Cheltenham-Pedersen racer, Boulder F/S Paris-Roubaix, Varsity racer, '52 Christophe, '62 Continental, '92 Merckx, '75 Limongi, '76 Presto, '72 Gitane SC, '71 Schwinn SS, etc.

Mentioned: 132 Post(s)

Tagged: 0 Thread(s)

Quoted: 1565 Post(s)

Liked 1,295 Times

in

865 Posts

I sometimes allow cabling to take up near the lions share of the build time, but that is when using recycled cable/housing that needs to be measured (must be long enough to start with) and cleaned (inside housings and outside cables).

From there, I turn the bars full left, then right, to see where a too-short condition exists with housing that is test-fitted in place. I try for minimum lengths, but with non-aero brake levers the loops need to be aesthetically right and not interfere with the rider's hands.

This stuff requires much more time if you don't do it often. Don't sweat having to take extra time, it builds the learning curve.

On vintage builds where I am trying to squeeze in a wider 6 or 7-speed freewheel, I might similarly kill a lot of time trying to determine how short that the right-side axle spacing can be and still allow chain clearance and swift shifting to the smallest cog. This allows for a stronger axle and wheel when everything is optimized from the beginning.

Vintage-bike cabling can take extra time when modern housing necessitates using properly-sized (ID and OD) ferrules. Sometimes I have to search for just the right size of stepped ferrule, or search for a housing liner that fits in a vintage housing and still accommodates the inner wire without interference.

I keep bundles of varied lengths of used housing around for doing test-fits for the shortest practical housing lengths, and using shorter ones often reduce the flex in the cabling noticeably. Old rear derailers often require only a few short inches of housing, but often I see bikes with perhaps twice the needed length there, to the detriment of shifting accuracy.

What I kind of hate about certain older bikes is odd-sized cable housing stop ID's, where finding a proper-fitting ferrule might be particularly difficult.

Last edited by dddd; 11-30-15 at 09:47 PM.

#115

Senior Member

Join Date: Aug 2009

Location: Berkeley, CA

Posts: 7,241

Bikes: '72 Cilo Pacer, '72 Gitane Gran Tourisme, '72 Peugeot PX10, '73 Speedwell Ti, '74 Peugeot UE-8, '75 Peugeot PR-10L, '80 Colnago Super, '85 De Rosa Pro, '86 Look Equipe 753, '86 Look KG86, '89 Parkpre Team, '90 Parkpre Team MTB, '90 Merlin

Mentioned: 87 Post(s)

Tagged: 0 Thread(s)

Quoted: 832 Post(s)

Liked 2,124 Times

in

554 Posts

Rust.

No, bike thieves. They're the worst.

I don't mind cutting cables. While a dremel or clippers and grinding stone get the job done quickly, I find it more often than not creates a sharp edge on the inside of the housing. I've gone back to a metal file for finishing housings. Less heat to melt the lining and a smoother inner edge to the metal coil. Holding the end of the housing in a pair of good needle-nose pliers while running it across a flat metal file on a bench takes some of the work out of the operation. I object to cable drag far more than the extra effort of finishing housing.

No, bike thieves. They're the worst.

I don't mind cutting cables. While a dremel or clippers and grinding stone get the job done quickly, I find it more often than not creates a sharp edge on the inside of the housing. I've gone back to a metal file for finishing housings. Less heat to melt the lining and a smoother inner edge to the metal coil. Holding the end of the housing in a pair of good needle-nose pliers while running it across a flat metal file on a bench takes some of the work out of the operation. I object to cable drag far more than the extra effort of finishing housing.

Thread

Thread Starter

Forum

Replies

Last Post

Shahmatt

Bicycle Mechanics

9

05-14-14 07:58 PM