The advantages of threadless forks

#1

aka Tom Reingold

Thread Starter

Join Date: Jan 2009

Location: New York, NY, and High Falls, NY, USA

Posts: 40,498

Bikes: 1962 Rudge Sports, 1971 Raleigh Super Course, 1971 Raleigh Pro Track, 1974 Raleigh International, 1975 Viscount Fixie, 1982 McLean, 1996 Lemond (Ti), 2002 Burley Zydeco tandem

Mentioned: 511 Post(s)

Tagged: 0 Thread(s)

Quoted: 7346 Post(s)

Liked 2,453 Times

in

1,430 Posts

The advantages of threadless forks

Some have said they really feel the difference between a threaded fork and a threadless fork. The stem is attached much more firmly, so the fork/stem/handlebar assembly flexes less, which you can feel under heavy pedaling. I can easily believe this but I wonder how much the appreciation is a function of strength and rider mass. I'm down to 153 pounds (70 kg) and working on strength. I might build a little upper body mass but not much, I expect. I suspect fork type is not likely to be as big a deal for me as it is for bigger and stronger riders. (I'm a hair over 5'9" tall [176 cm], for what it's worth.)

Thoughts?

Thoughts?

__________________

Tom Reingold, tom@noglider.com

New York City and High Falls, NY

Blogs: The Experienced Cyclist; noglider's ride blog

“When man invented the bicycle he reached the peak of his attainments.” — Elizabeth West, US author

Please email me rather than PM'ing me. Thanks.

Tom Reingold, tom@noglider.com

New York City and High Falls, NY

Blogs: The Experienced Cyclist; noglider's ride blog

“When man invented the bicycle he reached the peak of his attainments.” — Elizabeth West, US author

Please email me rather than PM'ing me. Thanks.

#2

Senior Member

Join Date: Jul 2008

Location: Minas Ithil

Posts: 9,173

Mentioned: 66 Post(s)

Tagged: 0 Thread(s)

Quoted: 2432 Post(s)

Liked 638 Times

in

395 Posts

It's not that the stem is attached more "firmly", it's that a 1 1/8 steerer tube clamp diameter is much larger than a quill stem. Along with the fact most modern bars have a larger diameter. It also depends on how high you have a quill stem exposed from the steerer. But comparing my modern and vintage bikes by physically seeing how much I can move the bars, the difference isn't all that much. It certainly won't make a difference in anyone's speed. And another way to look at it if a quill setup flexes more it theoretically will ride smoother on rough roads. That's my idea, anyway.

#3

~>~

Although the threadless fork's stem choices are less elegant in appearance than the classic Cinelli 1A and cutting to fit the correct stack height is a one-shot-deal they make sense for me.

The 1 1/8" standard mated to a quality stem & bars makes for a really solid feeling front end on my Soma Stanyan.

Dealing with injury recovery I've changed stems three times to dial fit in, a simple ten minute job w/ threadless, not so much w/ a classic set-up.

-Bandera

The 1 1/8" standard mated to a quality stem & bars makes for a really solid feeling front end on my Soma Stanyan.

Dealing with injury recovery I've changed stems three times to dial fit in, a simple ten minute job w/ threadless, not so much w/ a classic set-up.

-Bandera

#4

Senior Member

Join Date: Sep 2011

Location: Baltimore MD

Posts: 3,331

Bikes: '72 Motobecane Grand Record, '72 Gitane tandem, '72 Raleigh Super Course, '73 Raleigh Gran Sport, '73 Colnago Super, '76 Fiorelli Coppi, '78 Raleigh SBDU Team Pro, '78 Trek 930, '81 Holdsworth Special 650B, '86 Masi GC, ’94 Bridgestone RB-T

Mentioned: 67 Post(s)

Tagged: 0 Thread(s)

Quoted: 786 Post(s)

Liked 517 Times

in

280 Posts

Everyone has their own criteria. For me, it would have to at least 300% stiffer to overcome the disadvantage of being 300% uglier.

__________________

The man who dies with the most toys…is dead. - Rootboy

The man who dies with the most toys…is dead. - Rootboy

#5

Senior Member

Join Date: May 2008

Location: Fredericksburg, Va

Posts: 9,579

Bikes: '65 Frejus TDF, '73 Bottecchia Giro d'Italia, '83 Colnago Superissimo, '84 Trek 610, '84 Trek 760, '88 Pinarello Veneto, '88 De Rosa Pro, '89 Pinarello Montello, '94 Burley Duet, 97 Specialized RockHopper, 2010 Langster, Tern Link D8

Mentioned: 73 Post(s)

Tagged: 0 Thread(s)

Quoted: 1607 Post(s)

Liked 2,214 Times

in

1,103 Posts

I tried a conversion for myself. Unacceptable, period, whatever % metric/goal you want to pick.

__________________

Bikes don't stand alone. They are two tired.

Bikes don't stand alone. They are two tired.

#6

Senior Member

Join Date: Jan 2013

Location: Norman, Oklahoma

Posts: 5,395

Bikes: Too many to list

Mentioned: 36 Post(s)

Tagged: 0 Thread(s)

Quoted: 1765 Post(s)

Liked 1,124 Times

in

746 Posts

I may be one of the ones who has espoused the use of the threadless setups you are talking about.

We have a thread going on our favorite c&v riders, in it i posted a pic of 2 Italian bikes both with quite similar geometry , And using the same handlebar design. (Salsa Bell lap) But one uses standard 26.0 bars and a Technomic stem for comfort, the other uses 31.8 bars and a Thomson MTB stem mated to a threadless adapter- the 26.0 bars with the technomic are 44c and i have 46's mated to the Thomson setup so the wide bars on both do lay down some extra leverage

There is no comparison - i can feel a lot of deflection with the technomic setup when standing, so much so that i feared i was going to tweak the stem if i had to keep standing on a long climb once---- the flip side is the Thomson setup that makes the other bike feel as solid as anything put out by the S Works guys lately

Probably a more fair comparison would not be a Technomic, but maybe a regular 1A stem or a tig welded stem, but i have a box of tig welded stems that are damaged beyond repair also from flex, to include a Cinelli TIG welded track stem that flexed so much the chrome was flaking off in little strips

Rider size, weight and riding style has a lot to do with this though --- im a trackie, and was built like a stereotypical track sprinter of the mid 90's (5'9 210 at the time at <12% bf ) - Leaning hard into the bars and trying to get 12 or 1300 watts or more funneled into the back wheel is hard on equipment

That said, we all used 1" quill stems back then and lived to tell the tale, ----- but a lot of the little short, steep forged NJS Nitto stems are steel, as are the bars, and a lot of Tig welded mtb stems were used on the track then too

My physique has since evolved, thanks to the liberal application of Anheuser Busch products and leisure time, -- so i am not putting out any real power now, but being larger than average causes me to notice differences in stiffness or flexiness ,

That said, i greatly prefer the look of the Technomic equipped bike, and it doesnt get any better than a traditional Cinelli setup, with the deep graceful round drops, - but progress is progress and the new stuff works better. (Edited -- should say --"works better for my needs")

We have a thread going on our favorite c&v riders, in it i posted a pic of 2 Italian bikes both with quite similar geometry , And using the same handlebar design. (Salsa Bell lap) But one uses standard 26.0 bars and a Technomic stem for comfort, the other uses 31.8 bars and a Thomson MTB stem mated to a threadless adapter- the 26.0 bars with the technomic are 44c and i have 46's mated to the Thomson setup so the wide bars on both do lay down some extra leverage

There is no comparison - i can feel a lot of deflection with the technomic setup when standing, so much so that i feared i was going to tweak the stem if i had to keep standing on a long climb once---- the flip side is the Thomson setup that makes the other bike feel as solid as anything put out by the S Works guys lately

Probably a more fair comparison would not be a Technomic, but maybe a regular 1A stem or a tig welded stem, but i have a box of tig welded stems that are damaged beyond repair also from flex, to include a Cinelli TIG welded track stem that flexed so much the chrome was flaking off in little strips

Rider size, weight and riding style has a lot to do with this though --- im a trackie, and was built like a stereotypical track sprinter of the mid 90's (5'9 210 at the time at <12% bf ) - Leaning hard into the bars and trying to get 12 or 1300 watts or more funneled into the back wheel is hard on equipment

That said, we all used 1" quill stems back then and lived to tell the tale, ----- but a lot of the little short, steep forged NJS Nitto stems are steel, as are the bars, and a lot of Tig welded mtb stems were used on the track then too

My physique has since evolved, thanks to the liberal application of Anheuser Busch products and leisure time, -- so i am not putting out any real power now, but being larger than average causes me to notice differences in stiffness or flexiness ,

That said, i greatly prefer the look of the Technomic equipped bike, and it doesnt get any better than a traditional Cinelli setup, with the deep graceful round drops, - but progress is progress and the new stuff works better. (Edited -- should say --"works better for my needs")

Last edited by DMC707; 12-08-16 at 11:46 AM.

#7

Senior Member

Join Date: Jun 2008

Location: E Wa

Posts: 557

Mentioned: 17 Post(s)

Tagged: 0 Thread(s)

Quoted: 110 Post(s)

Likes: 0

Liked 2 Times

in

2 Posts

I definitely notice a difference. Quill stems and 26 bars are considerably more flexible, even in non-sprint circumstances. Of course I weigh 200+ so that likely affects it. I do hate how thick stems look on 28.6 tubes though. FYI my bikes have quill adapters and threadless stems with 31.8 bars.

#8

Pedal to the medal

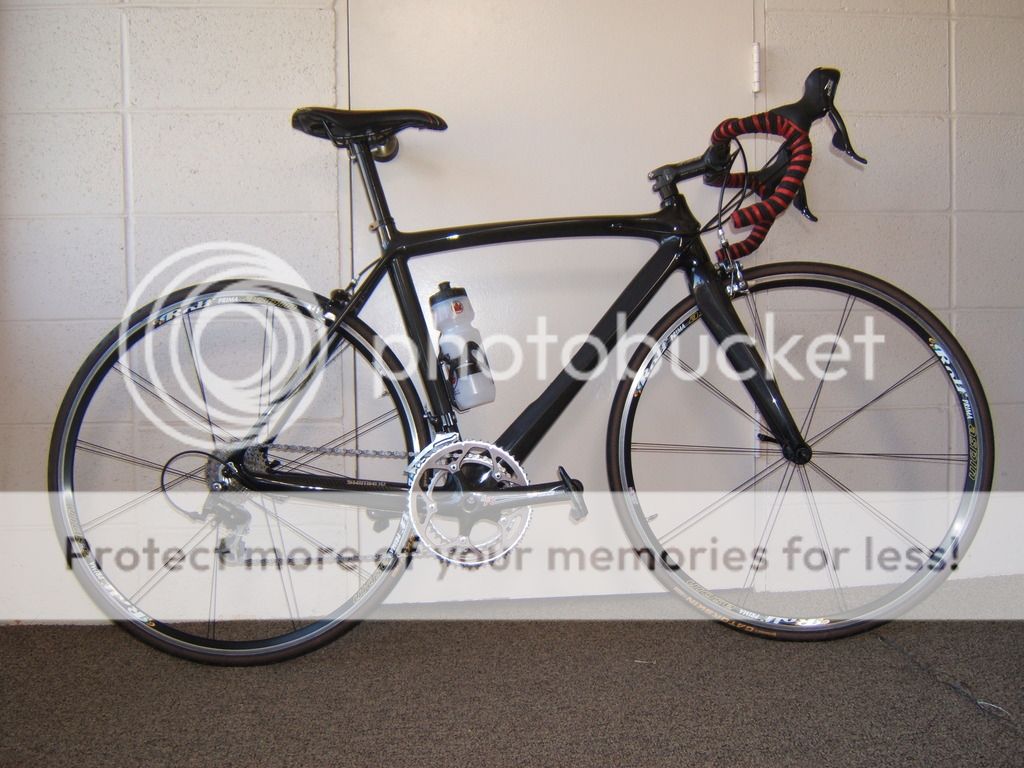

From what I understand the functional advantages of a thread less fork is a stiffer setup due to increased diameters as discussed above, and secondly, the ease of changing a cockpit out when setting new bars, stem, levers, etc.

I was staunchly anti-thread less, that is, until I tried a well setup thread less cockpit on my new Lemond. The wide diameter of the bars makes for a very comfortable setup. Will I be changing all my bikes to threadless? Heck, no. Once a bike is setup, I don't feel the need to change it. However, a new, especially go-fast builds, I would consider going threadless.

I was staunchly anti-thread less, that is, until I tried a well setup thread less cockpit on my new Lemond. The wide diameter of the bars makes for a very comfortable setup. Will I be changing all my bikes to threadless? Heck, no. Once a bike is setup, I don't feel the need to change it. However, a new, especially go-fast builds, I would consider going threadless.

#9

Senior Member

There is also the advantage to the manufacturer in terms of supply chain management: One model of fork works for the full range of frame sizes.

#11

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,892

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4792 Post(s)

Liked 3,918 Times

in

2,548 Posts

155 lb, 6' slow twitch climber here. I have owned one threadless 1" steel steerer'd bike. I see no gain, just bars that are nowhere near as simple to just raise ans lower, something I did many times a season as a racer. Winter miles - up going down as I came into form. Slammed for criteriums, up most of an inch for long races.

I took it for granted I could do this anywhere. (I've even been known to raise them when I was whacked just to get home.) Tools required: a 6 mm hex and something heavy. Crescent wrench, rock or big branch. Skill and attention level required: close to zero. Apply hex to tighten, don't honk on it. Done. (In general, slim quills are a lot easier to eyeball straight then threadless so that's also a plus, esp when you are stupid as happens late in rides.)

My one threadless will get threaded and quilled with a Nitto Pearl when it needs its next HS. I have a near sister bike with threaded and quills (yes, plural; two complete sets of cockpits and calipers. A 5 minute change takes it from a road bike to a climbing specialist. Takes fixed gear riding to new levels. I can do the change after riding myself stupid or just before I head out the door.

Ben

I took it for granted I could do this anywhere. (I've even been known to raise them when I was whacked just to get home.) Tools required: a 6 mm hex and something heavy. Crescent wrench, rock or big branch. Skill and attention level required: close to zero. Apply hex to tighten, don't honk on it. Done. (In general, slim quills are a lot easier to eyeball straight then threadless so that's also a plus, esp when you are stupid as happens late in rides.)

My one threadless will get threaded and quilled with a Nitto Pearl when it needs its next HS. I have a near sister bike with threaded and quills (yes, plural; two complete sets of cockpits and calipers. A 5 minute change takes it from a road bike to a climbing specialist. Takes fixed gear riding to new levels. I can do the change after riding myself stupid or just before I head out the door.

Ben

#12

Senior Member

Join Date: Jul 2006

Location: San Jose (Willow Glen) Ca

Posts: 9,835

Bikes: Kirk Custom JK Special, '84 Team Miyata,(dura ace old school) 80?? SR Semi-Pro 600 Arabesque

Mentioned: 106 Post(s)

Tagged: 0 Thread(s)

Quoted: 2337 Post(s)

Liked 2,813 Times

in

1,536 Posts

+1 and the ability to fine tune height

__________________

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)

#13

Senior Member

Threadless is noticeably more rigid to me. Lighter and stiffer. I prefer it by a large margin. Most threadless stems are ugly, but they don't have to be.

Quills were good enough in the old days. You still are not going to get dropped if you have a quill stem. Obvious advantages are up/down adjustability, sleek look, and easy to align. Steer tubes can sometimes bulge from both corrosion and normal preload IME - in spite of prevailing wisdom. Sliced wedge stem design is superior to the Cinelli conical wedges IMO.

AFA handlebars - I went to 31.8 accidentally on my new bike, because the only bar I found with the bend I wanted in silver only came in 31.8. I'm glad, as it's really nice when climbing, and I'm surrounded by hills. I didn't realize how much my old stem/bars flexed till I got this.

Quills were good enough in the old days. You still are not going to get dropped if you have a quill stem. Obvious advantages are up/down adjustability, sleek look, and easy to align. Steer tubes can sometimes bulge from both corrosion and normal preload IME - in spite of prevailing wisdom. Sliced wedge stem design is superior to the Cinelli conical wedges IMO.

AFA handlebars - I went to 31.8 accidentally on my new bike, because the only bar I found with the bend I wanted in silver only came in 31.8. I'm glad, as it's really nice when climbing, and I'm surrounded by hills. I didn't realize how much my old stem/bars flexed till I got this.

#14

Sunshine

Join Date: Aug 2014

Location: Des Moines, IA

Posts: 16,605

Bikes: '18 class built steel roadbike, '19 Fairlight Secan, '88 Schwinn Premis , Black Mountain Cycles Monstercross V4, '89 Novara Trionfo

Mentioned: 123 Post(s)

Tagged: 0 Thread(s)

Quoted: 10947 Post(s)

Liked 7,474 Times

in

4,181 Posts

The fork on threadless bikes needs to be cut down which adds a step to the build process. Yes, it allows for the same length fork to be selected for 54 or 64cm bikes which lowers the cost of specific inventory, but it also increases the build process.

Is one really that much cheaper than the other so there is a significant savings over time?

#15

Sunshine

Join Date: Aug 2014

Location: Des Moines, IA

Posts: 16,605

Bikes: '18 class built steel roadbike, '19 Fairlight Secan, '88 Schwinn Premis , Black Mountain Cycles Monstercross V4, '89 Novara Trionfo

Mentioned: 123 Post(s)

Tagged: 0 Thread(s)

Quoted: 10947 Post(s)

Liked 7,474 Times

in

4,181 Posts

threadless-

- advantages

- stiffer due to wider diameter materials(i think)

- easier to swap stems

- disadvantages

- not as elegant

- more difficult to adjust height

threaded quill-

- advantages

- easy to adjust height

- elegant

- disadvantages

- difficult to swap stems

- incredibly limited stem angle selection

- flexible

I have threadless quill adapters on 2 bikes for utility over beauty. If quill stems came in a 7degree rise, I would own 2 of them. Unfortunately, almost all were/are limited to -17deg. The rare one that isnt, the Nitto dynamic II, is 65mm from the min insert to the top and seems to only be 110mm or longer. More legit quality angle options back in the day woulda been nice for the secondary market now.

- advantages

- stiffer due to wider diameter materials(i think)

- easier to swap stems

- disadvantages

- not as elegant

- more difficult to adjust height

threaded quill-

- advantages

- easy to adjust height

- elegant

- disadvantages

- difficult to swap stems

- incredibly limited stem angle selection

- flexible

I have threadless quill adapters on 2 bikes for utility over beauty. If quill stems came in a 7degree rise, I would own 2 of them. Unfortunately, almost all were/are limited to -17deg. The rare one that isnt, the Nitto dynamic II, is 65mm from the min insert to the top and seems to only be 110mm or longer. More legit quality angle options back in the day woulda been nice for the secondary market now.

#16

Full Member

I have read this opinion many times and never understand it.

The fork on threadless bikes needs to be cut down which adds a step to the build process. Yes, it allows for the same length fork to be selected for 54 or 64cm bikes which lowers the cost of specific inventory, but it also increases the build process.

Is one really that much cheaper than the other so there is a significant savings over time?

The fork on threadless bikes needs to be cut down which adds a step to the build process. Yes, it allows for the same length fork to be selected for 54 or 64cm bikes which lowers the cost of specific inventory, but it also increases the build process.

Is one really that much cheaper than the other so there is a significant savings over time?

#17

Sunshine

Join Date: Aug 2014

Location: Des Moines, IA

Posts: 16,605

Bikes: '18 class built steel roadbike, '19 Fairlight Secan, '88 Schwinn Premis , Black Mountain Cycles Monstercross V4, '89 Novara Trionfo

Mentioned: 123 Post(s)

Tagged: 0 Thread(s)

Quoted: 10947 Post(s)

Liked 7,474 Times

in

4,181 Posts

#18

Old fart

Join Date: Nov 2004

Location: Appleton WI

Posts: 24,780

Bikes: Several, mostly not name brands.

Mentioned: 153 Post(s)

Tagged: 0 Thread(s)

Quoted: 3583 Post(s)

Liked 3,396 Times

in

1,930 Posts

And the difficulty in swapping stems is not inherent in the quill design. One could use a quill stem with a removable faceplate. It's just that most (but not all) quill stems do not have removable faceplates.

#19

Full Member

#20

Old fart

Join Date: Nov 2004

Location: Appleton WI

Posts: 24,780

Bikes: Several, mostly not name brands.

Mentioned: 153 Post(s)

Tagged: 0 Thread(s)

Quoted: 3583 Post(s)

Liked 3,396 Times

in

1,930 Posts

In most cases it is, but there are times when you may need to cut new threads, e.g. extending the threads on a replacement fork to fit a small frame.

#21

Old fart

Join Date: Nov 2004

Location: Appleton WI

Posts: 24,780

Bikes: Several, mostly not name brands.

Mentioned: 153 Post(s)

Tagged: 0 Thread(s)

Quoted: 3583 Post(s)

Liked 3,396 Times

in

1,930 Posts

#22

Sunshine

Join Date: Aug 2014

Location: Des Moines, IA

Posts: 16,605

Bikes: '18 class built steel roadbike, '19 Fairlight Secan, '88 Schwinn Premis , Black Mountain Cycles Monstercross V4, '89 Novara Trionfo

Mentioned: 123 Post(s)

Tagged: 0 Thread(s)

Quoted: 10947 Post(s)

Liked 7,474 Times

in

4,181 Posts

But if you can fine-tune the height, what advantage does having a wide choice of stem angles offer?

And the difficulty in swapping stems is not inherent in the quill design. One could use a quill stem with a removable faceplate. It's just that most (but not all) quill stems do not have removable faceplates.

And the difficulty in swapping stems is not inherent in the quill design. One could use a quill stem with a removable faceplate. It's just that most (but not all) quill stems do not have removable faceplates.

I have seen a quill stem with removable faceplate, but it was an ugly riser thats new by Sunlite. I used it for a hybrid refurbishment. I havent seen, in person, nice looking quills with a removable faceplate and that'd be neat if they existed.

As for the height adjustment negating the need for different stem angles...well yes that is true, but I would prefer a lower stem with a 0deg rise rather than a tall stem with a -17deg rise. Its why I finally swapped a bike of mine over to a Nitto dynamicII. My stems will never be low and sleek looking, but if I can keep them from being geeky tall, thats a win.

#23

Senior Member

This argument that only one fork size is needed is somewhat overstated IMO.

Manufacturers still need to make multiple frame sizes, and every single tube of a frame has to be cut to different sizes and mitred differently depending on the frame size. That's 8 tubes not including fork blades or bridges. Cutting one more tube (steer tube) is not that big of a deal. Sure, it does save a little bit. 1 of 9...

#24

aka Tom Reingold

Thread Starter

Join Date: Jan 2009

Location: New York, NY, and High Falls, NY, USA

Posts: 40,498

Bikes: 1962 Rudge Sports, 1971 Raleigh Super Course, 1971 Raleigh Pro Track, 1974 Raleigh International, 1975 Viscount Fixie, 1982 McLean, 1996 Lemond (Ti), 2002 Burley Zydeco tandem

Mentioned: 511 Post(s)

Tagged: 0 Thread(s)

Quoted: 7346 Post(s)

Liked 2,453 Times

in

1,430 Posts

The cost of inventory can be high if you have to keep many sizes. This may shift cost from manufacturer to retailer, but it does reduce manufacturing cost.

__________________

Tom Reingold, tom@noglider.com

New York City and High Falls, NY

Blogs: The Experienced Cyclist; noglider's ride blog

“When man invented the bicycle he reached the peak of his attainments.” — Elizabeth West, US author

Please email me rather than PM'ing me. Thanks.

Tom Reingold, tom@noglider.com

New York City and High Falls, NY

Blogs: The Experienced Cyclist; noglider's ride blog

“When man invented the bicycle he reached the peak of his attainments.” — Elizabeth West, US author

Please email me rather than PM'ing me. Thanks.

#25

Senior Member

Can't speak with any authority w/r/t flexibility, but I find myself torn between the aesthetics of quills and the convenience of pop-top threadless. Wish I could combine the two, but my (110 mm) size seems to be AWOL