Rehabilitation of a Dahon speed D7, big play in the hinge

#27

Member

Join Date: May 2015

Location: Lethbridge, Alberta

Posts: 34

Bikes: Breezer Zag8

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 5 Times

in

1 Post

I did remove the grub screw, but the hinge pin wouldn't budge. Considerable force was applied. I opted to shim the hinge instead, ride it for this season, save up my pennies and consider selling the bike in the off-season and buy a new Tern for next season instead.

#28

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Okay. So you have drill the pin ? Mine rotate too into the hinge, is rather "free" to move, and it's really hard to drill... I'll try with a carbide bit.

I've finish to reassemble quickly the bike, first test: it's nice to ride, but if the hinge seems to be tightly closed without load, when I ride the bike the play is always here... So I'll must change the pin and fix the play to ride the bike "safely".

I've finish to reassemble quickly the bike, first test: it's nice to ride, but if the hinge seems to be tightly closed without load, when I ride the bike the play is always here... So I'll must change the pin and fix the play to ride the bike "safely".

#29

Mr. Grenade who likes pie

Join Date: Jun 2015

Location: Terminal City, Canada

Posts: 11

Bikes: Dahon Speed P8

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Okay. So you have drill the pin ? Mine rotate too into the hinge, is rather "free" to move, and it's really hard to drill... I'll try with a carbide bit.

I've finish to reassemble quickly the bike, first test: it's nice to ride, but if the hinge seems to be tightly closed without load, when I ride the bike the play is always here... So I'll must change the pin and fix the play to ride the bike "safely".

I've finish to reassemble quickly the bike, first test: it's nice to ride, but if the hinge seems to be tightly closed without load, when I ride the bike the play is always here... So I'll must change the pin and fix the play to ride the bike "safely".

If you want to drill out the pin, I would find a machine screw/bolt that matches the thread of the original grub screw, and use that to fix the hinge pin in place while you drill from the top. Alternately, if you can't fix it using a screw, you could try folding the bike and using ratchet straps or something between the two halves of the frame to tweak it out of alignment; ie: when the bike is folded, attach one end of a ratchet strap to the bike near the headset, attach the other end somewhere in the rear triangle (or to the downtube, etc), and then tighten up the straps to bend the two halves in opposite directions. This should put some pressure on the pin and hopefully hold it in place while you use a drill (just make sure you have a steady hand).

Otherwise, you could try to bash it out with a hammer (from either end). If you strip the bike, you can probably get access to the top and bottom of the pin relatively easily; I remember there was some mention that the pin didn't want to come out one way, so you may want to try getting it out the other side. The only other suggestion I would have here is to first heat the frame of the bike to get it to expand slightly, then try to rapidly cool the pin (without cooling the frame too much) to hopefully get it to shrink just a bit, then whacking it with a hammer a few times. A can of compressed air with a straw at the end (like the computer keyboard dusters) can be used to do the cooling by inverting it (as it contains a refrigerant). Just make sure to wear protective equipment and do this outdoors, as inhaling the chemicals can be deadly.

#30

Senior Member

Join Date: May 2005

Location: Albany, WA

Posts: 7,393

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Likes: 0

Liked 7 Times

in

6 Posts

The comment that the pin rotates freely makes it puzzling that it simply won't drop out. Maybe there is a ridge in the pin eg at the grub screw location, that requires good alignment of the hinge holes to allow the pin to drop out. Remove the grub screw and fiddle the frame halves until it drops. I have definitely read reports that if the grub screw falls out, sometimes the hinge pin just drops out. On occasion, moisture will corrode the aliminium of the frame, expanding, and tightly clamping down on the pin. In that case, it is almost impossible to get the pin out. But with this freely rotating case, it should virtually drop out, unless the last part of the hole is smaller and preventing the pin from coming out.

#31

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Hello, and thanks for the answers.

@pope face: good idea to block the pin while drilling. For the trick about heat and cold the frame I'm rather unwilling, frames have usualy a heat treatment, and heat it would change significatively the properties of the steel.

The pin is only accessible by one side, if i want to push it by the other side I'll must drill the frame (quite hard to drill and get some risks of weaken it). But if weld a threaded shaft on the pin and pull don't work I guess it must be the best solution (drill a 4.2mm hole and tread it in M5).

@jur: I have try lot of times to shake, swing, hit the top of the hinge,.. But the pin always stay blocked at ~5mm of the end of the hole, even if i have expanded the end of the hole using a dremel.

@pope face: good idea to block the pin while drilling. For the trick about heat and cold the frame I'm rather unwilling, frames have usualy a heat treatment, and heat it would change significatively the properties of the steel.

The pin is only accessible by one side, if i want to push it by the other side I'll must drill the frame (quite hard to drill and get some risks of weaken it). But if weld a threaded shaft on the pin and pull don't work I guess it must be the best solution (drill a 4.2mm hole and tread it in M5).

@jur: I have try lot of times to shake, swing, hit the top of the hinge,.. But the pin always stay blocked at ~5mm of the end of the hole, even if i have expanded the end of the hole using a dremel.

#32

Full Member

Join Date: Apr 2012

Location: Nottingham

Posts: 440

Bikes: Mezzo I4, Trek 1200, Rudge (Montague) BiFrame, Bickerton

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 6 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

As I said on the previous page, using Loctite might sip the pin spinning while you are drilling it out. Take a look at the Loctite Bearing Fit range, 641, 635, 638 etc.. I have successfully milled steel bonded to the machine bed using 641, it doest stick to aluminium very well through. You will need to flush any oil and grease out from between the pin and the bore. Make sure you have good sharp drill bits, cobalt drills will do a better job than HSS.

As for heating, you are unlikely to alter the properties of the steel unless you get it glowing. If the frame is brazed then you will need to take care if using heat.

As for heating, you are unlikely to alter the properties of the steel unless you get it glowing. If the frame is brazed then you will need to take care if using heat.

#33

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Hello (and happy new year), I have some news.

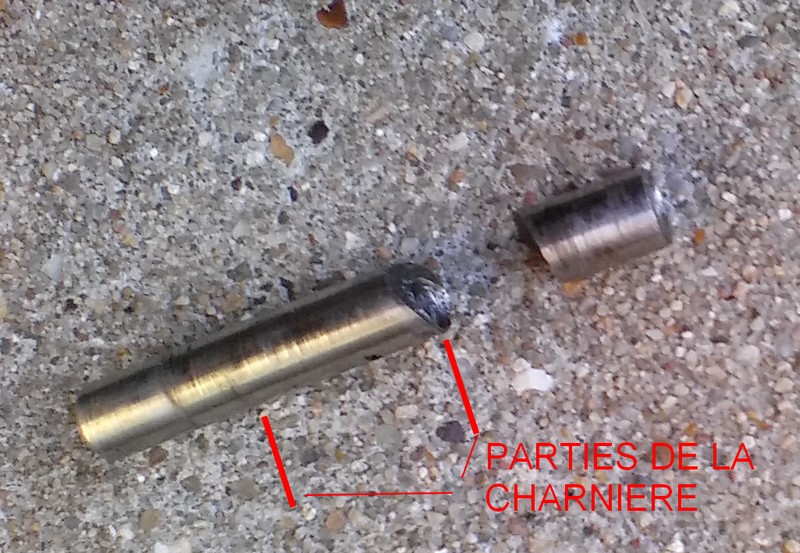

I tried again to drill the axle, but this time with a carbide bit, and it's really more efficient than cobalt bit. During the drilling, the axle went out with the bit, and it was broken in two...

As the other part of axle didn't drop as I tried to shake the frame, I did a little hole on the top of the hinge (as it's a round surface I did a line with a file, use a center drill to begin the drilling, and a 3mm cobalt drill to finish), and push out the rest of the axle. I hope it will not weaken the frame.

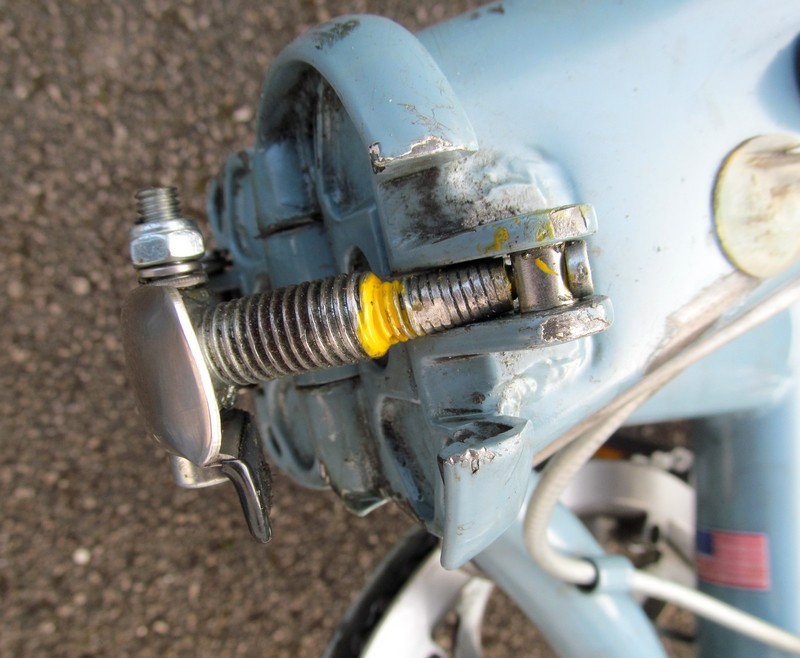

The axle:

The bushings seems to be finally OK, I put a 8mm drill as an axle to test, and the frame has just a little play.

Now I'm looking for a good axle, I think about a long M8 8.8 screw, to keep the threadless portion, or a long cylindrical pin.

Well, thanks for your help, I guess the hardest is done ! I'll post here the news.

! I'll post here the news.

I tried again to drill the axle, but this time with a carbide bit, and it's really more efficient than cobalt bit. During the drilling, the axle went out with the bit, and it was broken in two...

As the other part of axle didn't drop as I tried to shake the frame, I did a little hole on the top of the hinge (as it's a round surface I did a line with a file, use a center drill to begin the drilling, and a 3mm cobalt drill to finish), and push out the rest of the axle. I hope it will not weaken the frame.

The axle:

The bushings seems to be finally OK, I put a 8mm drill as an axle to test, and the frame has just a little play.

Now I'm looking for a good axle, I think about a long M8 8.8 screw, to keep the threadless portion, or a long cylindrical pin.

Well, thanks for your help, I guess the hardest is done

! I'll post here the news.

! I'll post here the news.

#34

Full Member

Join Date: Apr 2012

Location: Nottingham

Posts: 440

Bikes: Mezzo I4, Trek 1200, Rudge (Montague) BiFrame, Bickerton

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 6 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Good result. I am sure you can buy a Dahon replacement pin for the bike. Apply plenty of grease to the new pin and hole before installing it to prevent the pin sticking in the future.

#35

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I could possibly buy a replacement pin effectively, but it would be expenive (I guess) and here I can choose a steel grade with the betters characteristics (hard enough but not too much britle) , to avoid it broke again.

A good 8mm screw had something like 400kg of resistance to shearing, so there is some margin.

The original pin didn't move not cause of rust or something stiky, but cause its inserted tightly in the bushing (no play at all between pin and terminal bushing), but yep I'll put grease, at least to avoid rust.

A good 8mm screw had something like 400kg of resistance to shearing, so there is some margin.

The original pin didn't move not cause of rust or something stiky, but cause its inserted tightly in the bushing (no play at all between pin and terminal bushing), but yep I'll put grease, at least to avoid rust.

#37

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

The pin broke at the level of the bottom of center bushing (an old photo must be more clear)

I guess it's the point where most of the constraints are present, if you visualize the hinge as a vertical lever. With lots of shocks while riding, and the weight of the rider, it would broke. But it must be a defect of the part, looking at the breaking there should be a begining of break.

I guess it's the point where most of the constraints are present, if you visualize the hinge as a vertical lever. With lots of shocks while riding, and the weight of the rider, it would broke. But it must be a defect of the part, looking at the breaking there should be a begining of break.

#39

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

The photo is not really good and the paint have a lot of scratches, but it's a good remark. It would be good to remove the paint around the hinge and the welds, at least around possible cracks (suspect scratches,...).

Last edited by Celika; 01-06-16 at 02:14 PM.

#40

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Hello !

The bike is back on the road ! One year after I bought it .

.

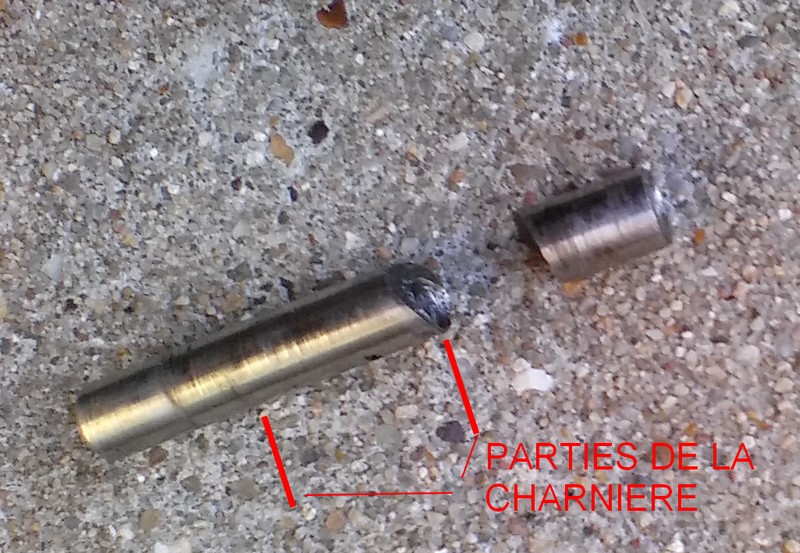

I was looking for a good steel grade rod as my new axle, but as it's a little bit hard to found in a so little diameter, I tried with a "basic" steel (like in DIY stores, not really good but I guess enough strong as I don't go MTB with the bike ). And there is magic, no more play (at least really acceptable). And about the potential crack on the weldings, I've clean it an looked carefully and it seems to be OK.

). And there is magic, no more play (at least really acceptable). And about the potential crack on the weldings, I've clean it an looked carefully and it seems to be OK.

Now I'm rolling along the bike (nice to ride ) to test the resistance of my DIY clamp system, waiting to totaly re-built it better when I'll have a drill press.

) to test the resistance of my DIY clamp system, waiting to totaly re-built it better when I'll have a drill press.

Ugly but really oversize and work well. WARNING: I've made it for myself, I do not recommend to anyone to do it, it could be dangerous.

A little pic with a Prima leather saddle in place of the fatty original:

Pretty rat's style (photo is not zoomed enough to see it) but I love it !

!

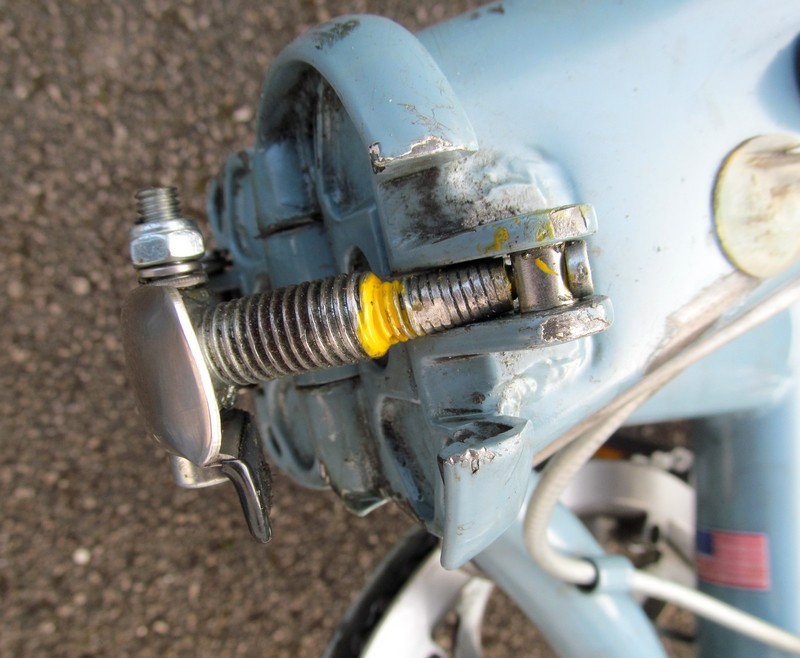

Just a little problem I've seen while I was dismounting and cleaning the stem (about it, rather hard to put it back in place clearly, avoid the operation if you can): the little piece of plastic use as a buffer in the mechanism is broken (crack was on the bottom so I haven't seen it until dismouning)

I've seen it on some pics on the net, do you think it's really dangerous to ride it like that ? I guess to ask the question on the official Dahon forum but I think their answer will be "go to a technician".

Seen it on spare part too, but with shipping it will be almost as expensive than a brand new stem.

Maybe I'll make a new one using some bronze or aluminium (make a part which supports as much efforts with plastic is a strange choice...).

And after all, if the bike always ride nicely in some times I'll go to the best: custom and upgrading ! I'm already planning to make a DIY rear and front derailleur hanger, and put a 8 or 9v group (have some 95' Deore LX in a box, with a 105 front and another road derailleur for the rear) with a road double cranckset. In fact some good, though and cheap old parts.

! I'm already planning to make a DIY rear and front derailleur hanger, and put a 8 or 9v group (have some 95' Deore LX in a box, with a 105 front and another road derailleur for the rear) with a road double cranckset. In fact some good, though and cheap old parts.

I planned to put a dropbar (ideal to compensate the straith position) but looking to the folding mode it would be a great waste of congestion.

Well thanks to have read it, I hope the bike will still ride a long time, and I'll post the mods and upgrade here (even if it's not more "rehabilitation").

Your comments and advices are welcome !

!

The bike is back on the road ! One year after I bought it

.

.I was looking for a good steel grade rod as my new axle, but as it's a little bit hard to found in a so little diameter, I tried with a "basic" steel (like in DIY stores, not really good but I guess enough strong as I don't go MTB with the bike

). And there is magic, no more play (at least really acceptable). And about the potential crack on the weldings, I've clean it an looked carefully and it seems to be OK.

). And there is magic, no more play (at least really acceptable). And about the potential crack on the weldings, I've clean it an looked carefully and it seems to be OK.Now I'm rolling along the bike (nice to ride

) to test the resistance of my DIY clamp system, waiting to totaly re-built it better when I'll have a drill press.

) to test the resistance of my DIY clamp system, waiting to totaly re-built it better when I'll have a drill press.

Ugly but really oversize and work well. WARNING: I've made it for myself, I do not recommend to anyone to do it, it could be dangerous.

A little pic with a Prima leather saddle in place of the fatty original:

Pretty rat's style (photo is not zoomed enough to see it) but I love it

!

!Just a little problem I've seen while I was dismounting and cleaning the stem (about it, rather hard to put it back in place clearly, avoid the operation if you can): the little piece of plastic use as a buffer in the mechanism is broken (crack was on the bottom so I haven't seen it until dismouning)

I've seen it on some pics on the net, do you think it's really dangerous to ride it like that ? I guess to ask the question on the official Dahon forum but I think their answer will be "go to a technician".

Seen it on spare part too, but with shipping it will be almost as expensive than a brand new stem.

Maybe I'll make a new one using some bronze or aluminium (make a part which supports as much efforts with plastic is a strange choice...).

And after all, if the bike always ride nicely in some times I'll go to the best: custom and upgrading

! I'm already planning to make a DIY rear and front derailleur hanger, and put a 8 or 9v group (have some 95' Deore LX in a box, with a 105 front and another road derailleur for the rear) with a road double cranckset. In fact some good, though and cheap old parts.

! I'm already planning to make a DIY rear and front derailleur hanger, and put a 8 or 9v group (have some 95' Deore LX in a box, with a 105 front and another road derailleur for the rear) with a road double cranckset. In fact some good, though and cheap old parts.I planned to put a dropbar (ideal to compensate the straith position) but looking to the folding mode it would be a great waste of congestion.

Well thanks to have read it, I hope the bike will still ride a long time, and I'll post the mods and upgrade here (even if it's not more "rehabilitation").

Your comments and advices are welcome

!

!

#41

Senior Member

Join Date: Sep 2015

Location: NY, NY

Posts: 245

Bikes: Dahon Speed P16 (Upgraded P8)/ 2014 Dahon Vybe c7a / 2015 Trek 7.2fx / 26" Schwinn Ranger

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 49 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I had the same problem when I bought my pre-owned dahon speed p8, took it to my trusted bike shop where i got my everyday dahon vybe d7. The mechanic adjusted the latch and put some locktite into it and told me to not use it for a 24hour period. So after a few months, I think the bike/latch has been holding up pretty good. Almost brand new! Spent money also on it to get it an older 53/39 ultegra crank, a sora fd 2200 and mountain bike shifters.

#42

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Nice idea, I'll clean the plastic, put some epoxy into the crack, and look how it evolves. If your mechanic don't panic about it, it must don't be so serious.

But in the same time, I really think about make a new one more strong, the new material will be more hard so it will speed up the wear of the quick release, unless I put some really thin buffer (<1mm of felt or teflon) between it and the mechanism.

Anyway, even if the quick release wear more quickly, it's still better than an eventual and unexpected opening of the stem if the actual buffer broke...

You used a front derailleur hanger from the web ? And your MTB shifter is OK with the Neos ?

But in the same time, I really think about make a new one more strong, the new material will be more hard so it will speed up the wear of the quick release, unless I put some really thin buffer (<1mm of felt or teflon) between it and the mechanism.

Anyway, even if the quick release wear more quickly, it's still better than an eventual and unexpected opening of the stem if the actual buffer broke...

You used a front derailleur hanger from the web ? And your MTB shifter is OK with the Neos ?

#43

Senior Member

Join Date: May 2005

Location: Albany, WA

Posts: 7,393

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Likes: 0

Liked 7 Times

in

6 Posts

Oh dear another cracked block pic so soon after my rant... I think you should replace that ASAP, that is a safety critical part. Contact Thor, he has spares for those hinge latches. There are other places too. In the interim, *make sure* you *NEVER* ride with a hinge that is not completely solidly fastened, or it may easily break right off. Inspect everything at the hinge for cracks.

#44

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

You talk about this post ?

https://www.bikeforums.net/folding-bi...l#post18597075

I haven't read the forum recently, but it's scary they put this kind of weak design security parts or a new designed bike... Furthermore on the central hinge !

I searched with keywords "dahon plastic hinge" and founded some exemples of cracks, but with "block" as you said I found more cases.

Even with a brand new block, anyway it's a serious design flaw and it could broke again (or at least I wouldn't be totally trusted)... I don't understand why Dahon haven't make a replacement part more strong, or even make a recall of this kind of stem (they have do a recall on some stems but not for this problem I think so).

Yep the part is on the shop, but with shipping to Europe, if I have understand the shipping info, it will cost between 21 and 27$ (include ~20$ shipping), too much for me to a little piece of plastic... Almost the price of a new stem, or at least a used in good shape.

I have a Gitane dealer near to me (Dahon used to say that they deal some Dahon too), maybe thay could have the part cheaper

The DIY replacement part here look rather attractive (but with a curve contact surface, a flat surface don't sound good I think)

https://www.bikeforums.net/folding-bi...ml#post6076731

Unfortunately I don't think the forum member that posted would answer a PM to give his opinion as he just posted 6 messages around 2008...

For the moment, my stem close "normally", a VERY little loose but it seems it's normal according some testimonials on forums (and it's logic regarding to the lenght of the hinge).

https://www.bikeforums.net/folding-bi...l#post18597075

I haven't read the forum recently, but it's scary they put this kind of weak design security parts or a new designed bike... Furthermore on the central hinge !

I searched with keywords "dahon plastic hinge" and founded some exemples of cracks, but with "block" as you said I found more cases.

Even with a brand new block, anyway it's a serious design flaw and it could broke again (or at least I wouldn't be totally trusted)... I don't understand why Dahon haven't make a replacement part more strong, or even make a recall of this kind of stem (they have do a recall on some stems but not for this problem I think so).

Yep the part is on the shop, but with shipping to Europe, if I have understand the shipping info, it will cost between 21 and 27$ (include ~20$ shipping), too much for me to a little piece of plastic... Almost the price of a new stem, or at least a used in good shape.

I have a Gitane dealer near to me (Dahon used to say that they deal some Dahon too), maybe thay could have the part cheaper

The DIY replacement part here look rather attractive (but with a curve contact surface, a flat surface don't sound good I think)

https://www.bikeforums.net/folding-bi...ml#post6076731

Unfortunately I don't think the forum member that posted would answer a PM to give his opinion as he just posted 6 messages around 2008...

For the moment, my stem close "normally", a VERY little loose but it seems it's normal according some testimonials on forums (and it's logic regarding to the lenght of the hinge).

#45

Senior Member

Join Date: Sep 2015

Location: NY, NY

Posts: 245

Bikes: Dahon Speed P16 (Upgraded P8)/ 2014 Dahon Vybe c7a / 2015 Trek 7.2fx / 26" Schwinn Ranger

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 49 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Nice idea, I'll clean the plastic, put some epoxy into the crack, and look how it evolves. If your mechanic don't panic about it, it must don't be so serious.

But in the same time, I really think about make a new one more strong, the new material will be more hard so it will speed up the wear of the quick release, unless I put some really thin buffer (<1mm of felt or teflon) between it and the mechanism.

Anyway, even if the quick release wear more quickly, it's still better than an eventual and unexpected opening of the stem if the actual buffer broke...

You used a front derailleur hanger from the web ? And your MTB shifter is OK with the Neos ?

But in the same time, I really think about make a new one more strong, the new material will be more hard so it will speed up the wear of the quick release, unless I put some really thin buffer (<1mm of felt or teflon) between it and the mechanism.

Anyway, even if the quick release wear more quickly, it's still better than an eventual and unexpected opening of the stem if the actual buffer broke...

You used a front derailleur hanger from the web ? And your MTB shifter is OK with the Neos ?

#46

Senior Member

Join Date: Sep 2014

Posts: 164

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 10 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Great job! I have concern on the main hinge on my folder as well although it's been fine all the time. But good to know how it works and there is a solution if it's not working...

The latch mechanism of both main hinge and handle post are overly complicated and not reliable. Why not Dahon just use simple but much more reliable mechanism like that on Brompton I can't understand.

The latch mechanism of both main hinge and handle post are overly complicated and not reliable. Why not Dahon just use simple but much more reliable mechanism like that on Brompton I can't understand.

#48

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Hi

@zoom: I knew it was a reversed derailleur but doubted about the compatiblity with an usual shifter, tanks for the info .

.

@nz6666: I have a Motobecane progress and a Btwin Bfold 3, with very basic an simple close system (a quick release on a pivot, that's all). This system is more reliable than the one of Dahon, but take more time to fold/unfold the bike.

The solution I've applied on my bike is quite "Mc guyver like" , go to your usual dealer or buy genuine spare parts before think to do something like that if your bike have some play; it will be more safe for you.

, go to your usual dealer or buy genuine spare parts before think to do something like that if your bike have some play; it will be more safe for you.

@thor: thanks for your offer, that's nice, but for the moment I'll try to make the part myself, even if it's not necessarily the best for safety. Mayber later if the DIY don't work properly .

.

Furthermore I've get another Radius stem (rather the same than mine), used, with the same block cracked... Will try to have a correct one with the two.

@zoom: I knew it was a reversed derailleur but doubted about the compatiblity with an usual shifter, tanks for the info

.

.@nz6666: I have a Motobecane progress and a Btwin Bfold 3, with very basic an simple close system (a quick release on a pivot, that's all). This system is more reliable than the one of Dahon, but take more time to fold/unfold the bike.

The solution I've applied on my bike is quite "Mc guyver like"

, go to your usual dealer or buy genuine spare parts before think to do something like that if your bike have some play; it will be more safe for you.

, go to your usual dealer or buy genuine spare parts before think to do something like that if your bike have some play; it will be more safe for you.@thor: thanks for your offer, that's nice, but for the moment I'll try to make the part myself, even if it's not necessarily the best for safety. Mayber later if the DIY don't work properly

.

.Furthermore I've get another Radius stem (rather the same than mine), used, with the same block cracked... Will try to have a correct one with the two.

#49

Senior Member

Thread Starter

Join Date: Apr 2015

Location: High Normandy, France

Posts: 58

Bikes: Raleigh Maverick '15, Dahon Speed D7 ~2007, and a lot :)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 12 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Hello !

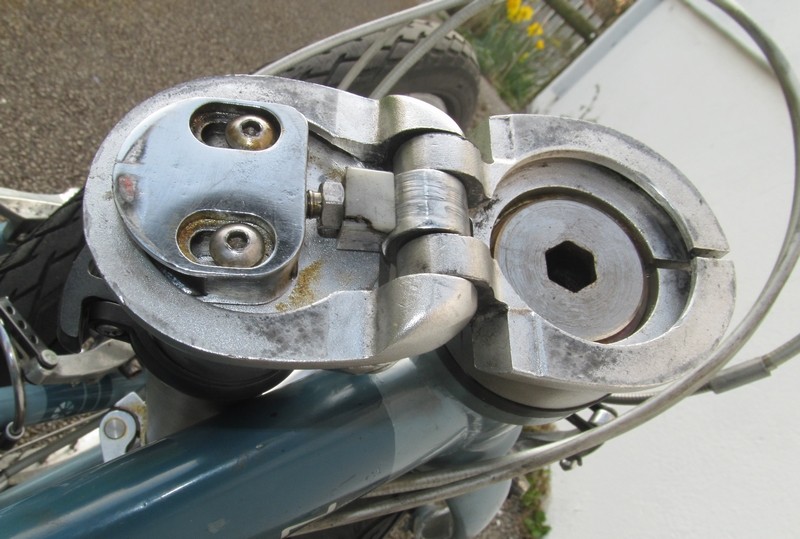

I've work well on my Speed, and there is the result !

I've achieved the main mods I've been expecting:

-Used a modified old steel derailleur hanger to make the bike "standard compatible"

-Get a pair of old LX 8s shifters and rear derailleur, a brand new rear wheel accepting 8 speed (rather cheap but it will work for the moment), and a 11/30 cassette

-A front derailleur modified to fit the 39mm seat tube of the bike, and a FSA vero double crankset (42-52)

-Change the old stem for another, and shorten the adjustable part to have a more lying position

-Made a new one clamp system with 8.8 grade screws, better machined

-Add toe-clip to the genuine pedals

-Seatpost with pump

The front derailleur (I've remake the cable way since the pic):

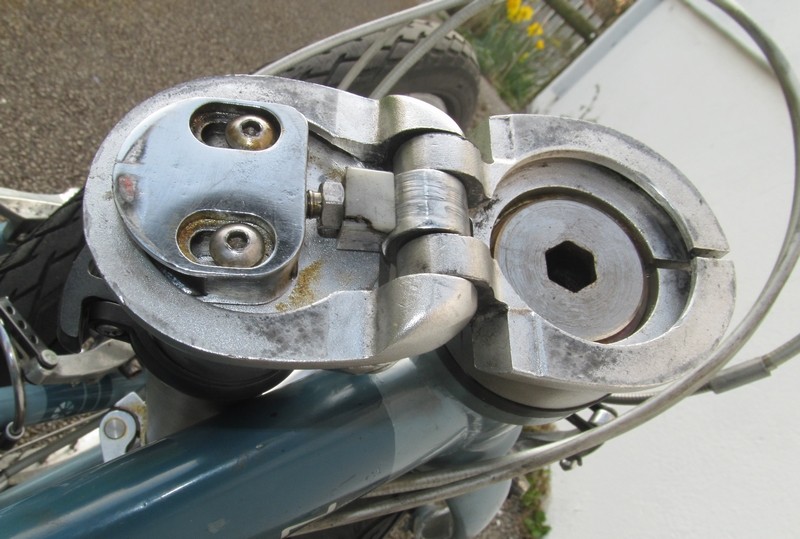

And the little secret, the special key to adjust the hinges, hiden on the handlebar plug (Mcgyver powaaaaaa )

)

The transmission scratch a bit, but on the whole the bike work very well ! I've made some outing and it's quite fast and nice to ride.

! I've made some outing and it's quite fast and nice to ride.

At this point, it wost me in total about 110€ (bike and parts included). But if ever I count the time I spent on it, I could have buy a Speed TR !

!

I've work well on my Speed, and there is the result !

I've achieved the main mods I've been expecting:

-Used a modified old steel derailleur hanger to make the bike "standard compatible"

-Get a pair of old LX 8s shifters and rear derailleur, a brand new rear wheel accepting 8 speed (rather cheap but it will work for the moment), and a 11/30 cassette

-A front derailleur modified to fit the 39mm seat tube of the bike, and a FSA vero double crankset (42-52)

-Change the old stem for another, and shorten the adjustable part to have a more lying position

-Made a new one clamp system with 8.8 grade screws, better machined

-Add toe-clip to the genuine pedals

-Seatpost with pump

The front derailleur (I've remake the cable way since the pic):

And the little secret, the special key to adjust the hinges, hiden on the handlebar plug (Mcgyver powaaaaaa

)

)

The transmission scratch a bit, but on the whole the bike work very well

! I've made some outing and it's quite fast and nice to ride.

! I've made some outing and it's quite fast and nice to ride.At this point, it wost me in total about 110€ (bike and parts included). But if ever I count the time I spent on it, I could have buy a Speed TR

!

!