Common misconceptions about wheels and bike engineering

#26

Bicycling Gnome

Thread Starter

Join Date: Apr 2006

Location: 55.0N 1.59W

Posts: 1,877

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I completely concur with what Jur is saying. The wheel does not derive its strength from upper spokes hanging or lower spokes standing like columns. All the strength of a wheel comes from ALL the spokes together in tension holding the centre in its place. Fine that there is a variation in that tension as the wheel rotates, and it does seem that the lower spokes at BDC may go negative for a moment as the wheel takes them over that position, but others tighten up as the rim distorts microscopical amounts out of round. In the end, all the forces are held in tension by the spokes as a whole.

#27

Senior Member

Join Date: May 2005

Location: Albany, WA

Posts: 7,393

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Likes: 0

Liked 7 Times

in

6 Posts

Check out this youtube clip.. some dudes breaking their back wheels due to overloading... classic collapse at the bottom with the rim kinking up. The rest of the wheel still looks close to normal.

#28

Bicycling Gnome

Thread Starter

Join Date: Apr 2006

Location: 55.0N 1.59W

Posts: 1,877

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Those guys deserve bad things to happen to them. Why didn't they just attack the bikes with a lump hammer? Sheer vandalism of undeserving bicycles.

Glad to see the bast**ds in hospital at the end. They deserve it. Could only be better if they broke their necks.

Glad to see the bast**ds in hospital at the end. They deserve it. Could only be better if they broke their necks.

#29

multimodal commuter

Join Date: Nov 2006

Location: NJ, NYC, LI

Posts: 19,808

Bikes: 1940s Fothergill, 1959 Allegro Special, 1963? Claud Butler Olympic Sprint, Lambert 'Clubman', 1974 Fuji "the Ace", 1976 Holdsworth 650b conversion rando bike, 1983 Trek 720 tourer, 1984 Counterpoint Opus II, 1993 Basso Gap, 2010 Downtube 8h, and...

Mentioned: 584 Post(s)

Tagged: 0 Thread(s)

Quoted: 1908 Post(s)

Liked 574 Times

in

339 Posts

The problem with this analysis is, the spokes are not working discretely - they are all working together. You can't remove a bunch of spokes and still have a working wheel. You might end up with something that may totter uprightly but not a proper, load-bearing wheel. You can't think of spokes as doing individual work, just like you can't think of any other part doing individual work. It's all or nothing.

But to more serious matters... Jur, I'm glad to see you're posting about this stuff today; we've been hearing very worrisome news about the Australian wildfires. I rode my bike through a wildfire once... scary stuff!

#30

Senior Member

Join Date: Dec 2008

Location: Under the Downunder

Posts: 1,014

Bikes: MTBs, BMX, Pocket MTB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I completely concur with what Jur is saying. The wheel does not derive its strength from upper spokes hanging or lower spokes standing like columns. All the strength of a wheel comes from ALL the spokes together in tension holding the centre in its place. Fine that there is a variation in that tension as the wheel rotates, and it does seem that the lower spokes at BDC may go negative for a moment as the wheel takes them over that position, but others tighten up as the rim distorts microscopical amounts out of round. In the end, all the forces are held in tension by the spokes as a whole.

The author's conclusion says, "From these figures, I conclude that it is perfectly reasonable to say that the hub stands on the lower spokes, and that it does not hang from the upper spokes." He then contradicts himself immediately by saying, "It is also wrong to say that the force distributes all around the rim and all the spokes contribute to holding up the hub - over a third of the spokes have an effect that pulls the hub down!"

The fact that a bicycle wheel exists in a state of pre-tension already makes it clear that ALL the spokes work as a whole... BUT only in tension. As loads are exerted on the hub and rim, the pre-loads on each individual spoke vary, some pre-tension increase, some decrease. But a decreased pre-tension is not a compression load... regardless of what the article is suggesting. Even if you can push a rope, there is nothing for the rope (spoke) to push against because of the nipple at its end cannot apply it. And as okie mentioned, even if it was possible the spoke would just bend... and spokes can't break that way.

---

A new thing I've learned and found fascinating is that the test results show that the spokes around 8 and 4 o'clock have increased dramatically in tension and bear the highest loads out of all the spokes. The author concludes that they are pulling the hub down. Instead I agree with what you said EvilV, these spokes are in fact straining like hell to keep that part of the rim from bowing-outwards out of round.

After considering in appreciation all the ideas shared thus far, I still see the top half of the wheel like a suspension bridge, the upper spokes from 10 to 2 o'clock are mainly holding up the hub (tension), the side spokes mainly holding back the rim sides from splaying outwards or ovalizing (tension). The spokes on the lower half of the wheel are mainly holding the circular shape of lower half of the rim (tension) - which is necessary to support the upper half of the wheel. ALL the spokes are working together under tension, to keep the hub in the center of the rim WHILE simultaneously keeping the rim perfectly round.

The test results show that the spokes directly below the hub have negative readings which means the pre-tension here as been reduced, or at the very worst can only lose the pre-tension entirely. They can never bear compression loads.

This is why rims flat-spot instead of go oval when overloaded. This is also why the lower spokes break, not from compression, but the spokes at 4 or 8 o'clock snap from excessive tension.

This is what I find acceptable at this stage, which I also believe can be supported and is in-line with the scientific Finite Element test results from the article. The conclusion of the author on the other hand still eludes me.

.

#31

Bicycling Gnome

Thread Starter

Join Date: Apr 2006

Location: 55.0N 1.59W

Posts: 1,877

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I agree - I can't understand why he thinks the spokes work like columns. Even the most basic look at the way they are arranged - the way the elbow of a loose spoke will just poke right through the hole in the hub when you are threading it in or out and of course the nature of the flanged nipple makes clear that the spokes are never pushing into the hub and always pulling in tension. Thinking about it, I can't see how the spokes tension can go negative either. I think if they went that loose, they would soon break from fatigue. I've had some rear wheel spokes break in both my small wheeled bikes - in both cases from slack tensioning of the wheels by shoddy factory wheel building. Five went in my Merc and six in my Strida copy and both very early in the lives of the bikes. The merc has been great since I replaced them and trued the wheel - nearly three thousand miles since I had a problem with the wheels.

Last edited by EvilV; 02-15-09 at 03:12 AM.

#33

Senior Member

Join Date: Dec 2008

Location: Under the Downunder

Posts: 1,014

Bikes: MTBs, BMX, Pocket MTB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

With smaller wheels that have fewer spokes, every one of them counts critically. So when one spoke is loose the pre-tension becomes uneven more so than a bigger wheel, and I can imagine a particular spoke at the wrong place at the wrong time can be severely taxed and snap.

I've only snapped a spoke once, and that was during an awkward landing on my Giant AC MTB. I actually hear it go "ping" and have always wondered, how on earth can something like that happen?! How can one spoke be singled out like that?... especially when the rest of the wheel and spokes were undamaged. It had snapped at the J-bend and I just put it down to a faulty spoke.

This thread helped me get my head around that. Thanks! It's really made me think... and still thinking... it's a life long journey you know.

it's a life long journey you know.

.

I've only snapped a spoke once, and that was during an awkward landing on my Giant AC MTB. I actually hear it go "ping" and have always wondered, how on earth can something like that happen?! How can one spoke be singled out like that?... especially when the rest of the wheel and spokes were undamaged. It had snapped at the J-bend and I just put it down to a faulty spoke.

This thread helped me get my head around that. Thanks! It's really made me think... and still thinking...

it's a life long journey you know.

it's a life long journey you know.

.

#34

Senior Member

Join Date: Dec 2008

Location: Under the Downunder

Posts: 1,014

Bikes: MTBs, BMX, Pocket MTB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

#35

Bicycling Gnome

Thread Starter

Join Date: Apr 2006

Location: 55.0N 1.59W

Posts: 1,877

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

You mean this bit?

Why do small wheeled bikes seem to steer so quickly. When I last rode my 26" wheeled mountain bike, it felt like a truck on rails as far as steering was concerned. The merc with Brompton geometry steers like a frisky gazelle - after riding even the Strda copy it feels incredibly lively. The idea I used to believe in - that the stability of a pedal cycle is contributed to significantly by gyroscopic forces of the rotating wheels is wrong. There are very tiny gyroscopic forces, but they are as nothing in comparison to others.

All the small wheeled bikes I have ridden - moulton - dahon - merc - brompton - strida copy handle very quickly by comparison to road bikes and mountain bikes with big wheels.

#36

Junior Member

Join Date: Dec 2007

Posts: 11

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I hope I'm not double posting. Wrote a response but seems to have lost it.

Sorry, back to the wheel again. I just looked at the web page, https://www.astounding.org.uk/ian/wheel/, with the load analysis of the bicycle wheel. He has made a critical bad assumption and his analysis is incorrect because of it. He assumes that spokes can carry compression loads. Clearly, this is not the case. His model, for analysis, would be more appropriate for a disk wheel.

A bicycle wheel transfers the load from the hub to the road through two methods. The first is by spoke tension from the hub to the top part of the wheel. There, the load transfers to the rim and places it in compression. The bottom half of the wheel then uses the rim as an arch to carry the load from the top half to the ground. The spokes that aren't working directly in tension to carry the load are used to stabilize the wheel and for propulsion.

So, because the original analysis is based on an incorrect model, the forces in the spokes shown in the diagram should not be used for debate because they are wrong and misleading.

Sorry, back to the wheel again. I just looked at the web page, https://www.astounding.org.uk/ian/wheel/, with the load analysis of the bicycle wheel. He has made a critical bad assumption and his analysis is incorrect because of it. He assumes that spokes can carry compression loads. Clearly, this is not the case. His model, for analysis, would be more appropriate for a disk wheel.

A bicycle wheel transfers the load from the hub to the road through two methods. The first is by spoke tension from the hub to the top part of the wheel. There, the load transfers to the rim and places it in compression. The bottom half of the wheel then uses the rim as an arch to carry the load from the top half to the ground. The spokes that aren't working directly in tension to carry the load are used to stabilize the wheel and for propulsion.

So, because the original analysis is based on an incorrect model, the forces in the spokes shown in the diagram should not be used for debate because they are wrong and misleading.

#37

Senior Member

Join Date: May 2005

Location: Albany, WA

Posts: 7,393

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Likes: 0

Liked 7 Times

in

6 Posts

And the debate rages on...

Okie, you haven't read carefully. The author specifically stated that the spokes are not under compression, that the numerical values are departures from the unloaded state. So, positive values indicate increased tension, negative values indicate a decrease in tension. But at the end, all spokes remain in tension. The results are valid.

Okie, you haven't read carefully. The author specifically stated that the spokes are not under compression, that the numerical values are departures from the unloaded state. So, positive values indicate increased tension, negative values indicate a decrease in tension. But at the end, all spokes remain in tension. The results are valid.

#39

Junior Member

Join Date: Dec 2007

Posts: 11

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I'm sorry, Jur, but I disagree. Here is a quote from the website:

"None of this affects the analysis. If we ignore buckling (or restrain against it), a spoke under tension which is subject to (say) 100N less tension contracts just as much as an unstressed spoke subject to 100N compression (or for that matter a compressive spoke subject to 100N more compression). In the analysis I simply don't tell the computer to let anything buckle, so I can analyse a spoke with compression without worrying that it's really a spoke that started out with a tension and now has less tension,".

Further more, he states:

"Elastic spokes - most of those arguing for hanging from the top spokes at some point start to say "imagine replacing the spokes with elastic...", thus showing that they don't understand statical indeterminatism. Actually, if the rim is made infinitely stiff relative to the spokes (or spokes infinitely elastic) and you define the spokes as all having the same stiffness, the problem is statically determinate, and you can work out the spoke tensions in your head (roughly - not to 5 decimal places). However, I could run an analysis with elastic spokes to demonstrate why this imagining is a bad idea."

Actually, replacing the spokes with elastics is a good idea because that's how they act in real life, albeit as very stiff elastics.

His whole argument is based on the assumption that bicycle spokes can have compression. According to this assumption, if the bicycle wheel was loaded heavily enough, the stresses in the lower half of the wheel would actually change from tension to compression. This cannot happen.

Looking at his results:

"Then, I've split the lift forces into two columns, depending upon whether the spoke force was tensile or compressive. This is to see if the hub hangs from tensile spokes, or stands on compressive ones.

There are 31 tensile spokes. On average they contribute 1.436 N (0.14 kg, just under a third of a pound) each to holding up the hub.

There are 5 compressive spokes. On average they contribute 191.097N (19 kg, just over 42 lbs) each to holding up the hub.

Put it another way - the average compressive spoke contributes 133 times as much lift force as the average tensile spoke."

Here he talks about compressive spokes. There cannot be compressive spokes. The spokes cannot tranfer compression to the rim and would buckle if they could anyways.

Saying that it is not compression but decreasing tension is not correct either. The point is, with his assumptions, he says, imagine the spokes with no tension, carry out the analysis, and then sum the resultant forces with the preload tension forces. This is a good approach but the analysis is flawed. His computations, under no initial spoke tensions, shows compressive forces. This illustrates that his model does not just display decreased tensions but carries compressive loads.

"None of this affects the analysis. If we ignore buckling (or restrain against it), a spoke under tension which is subject to (say) 100N less tension contracts just as much as an unstressed spoke subject to 100N compression (or for that matter a compressive spoke subject to 100N more compression). In the analysis I simply don't tell the computer to let anything buckle, so I can analyse a spoke with compression without worrying that it's really a spoke that started out with a tension and now has less tension,".

Further more, he states:

"Elastic spokes - most of those arguing for hanging from the top spokes at some point start to say "imagine replacing the spokes with elastic...", thus showing that they don't understand statical indeterminatism. Actually, if the rim is made infinitely stiff relative to the spokes (or spokes infinitely elastic) and you define the spokes as all having the same stiffness, the problem is statically determinate, and you can work out the spoke tensions in your head (roughly - not to 5 decimal places). However, I could run an analysis with elastic spokes to demonstrate why this imagining is a bad idea."

Actually, replacing the spokes with elastics is a good idea because that's how they act in real life, albeit as very stiff elastics.

His whole argument is based on the assumption that bicycle spokes can have compression. According to this assumption, if the bicycle wheel was loaded heavily enough, the stresses in the lower half of the wheel would actually change from tension to compression. This cannot happen.

Looking at his results:

"Then, I've split the lift forces into two columns, depending upon whether the spoke force was tensile or compressive. This is to see if the hub hangs from tensile spokes, or stands on compressive ones.

There are 31 tensile spokes. On average they contribute 1.436 N (0.14 kg, just under a third of a pound) each to holding up the hub.

There are 5 compressive spokes. On average they contribute 191.097N (19 kg, just over 42 lbs) each to holding up the hub.

Put it another way - the average compressive spoke contributes 133 times as much lift force as the average tensile spoke."

Here he talks about compressive spokes. There cannot be compressive spokes. The spokes cannot tranfer compression to the rim and would buckle if they could anyways.

Saying that it is not compression but decreasing tension is not correct either. The point is, with his assumptions, he says, imagine the spokes with no tension, carry out the analysis, and then sum the resultant forces with the preload tension forces. This is a good approach but the analysis is flawed. His computations, under no initial spoke tensions, shows compressive forces. This illustrates that his model does not just display decreased tensions but carries compressive loads.

#40

Senior Member

Join Date: May 2005

Location: Albany, WA

Posts: 7,393

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Likes: 0

Liked 7 Times

in

6 Posts

Okie, do you have a detailed analysis and simulation available that corresponds with actual measurements?

Because Jobst Brandt analysis (and the OP's too) match very closely with actual measurements of spoke tension (using strain gauges) of a loaded wheel. So there is no reason whatsoever to doubt the numerical simulation nor the premise that it matters not whether spokes are under pre-compression (such as in a wooden-spoked wheel), no pre-stress at all (such as any plain disc wheel) or under tension (such as a metal wired spoke wheel).

Source https://www-civ.eng.cam.ac.uk/cjb/papers/p20.pdf

You are just confused due to the pre-stressed spokes. The point is, that can safely be ignored. If the spokes wouldn't buckle under load, there would be no reason to tension them up, but since they are wires, they will buckle, so tension is needed to eliminate buckling. And just like many others, you are confused by the idea that tension somehow radically alters wheel theory.

So, unless you can show by measurement and analysis that this idea is wrong, your argument is entirely without merit.

Because Jobst Brandt analysis (and the OP's too) match very closely with actual measurements of spoke tension (using strain gauges) of a loaded wheel. So there is no reason whatsoever to doubt the numerical simulation nor the premise that it matters not whether spokes are under pre-compression (such as in a wooden-spoked wheel), no pre-stress at all (such as any plain disc wheel) or under tension (such as a metal wired spoke wheel).

Originally Posted by Burgoyne and Dilmaghanian

Tests show that the bottom spokes carry virtually all the load by compressive forces, which reduce the tensile prestress set up in the spokes when the wheel was made. The test results are compared with an analysis that considers the spokes as a disk which carries force in one direction only. This is shown to give good agreement, ...

You are just confused due to the pre-stressed spokes. The point is, that can safely be ignored. If the spokes wouldn't buckle under load, there would be no reason to tension them up, but since they are wires, they will buckle, so tension is needed to eliminate buckling. And just like many others, you are confused by the idea that tension somehow radically alters wheel theory.

So, unless you can show by measurement and analysis that this idea is wrong, your argument is entirely without merit.

#41

Junior Member

Join Date: Dec 2007

Posts: 11

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Thank you, Jur for that link. It is very informative. Looking at Fig. 6, showing the strain in the spokes as the wheel is rotated under load, shows that I am wrong. I don't understand totally why yet, but the implications of the diagram are clear. It would seem to me, though, that at least a portion of the load would be carried in tension in the upper spokes. I will have to do more studying.

#42

Junior Member

Join Date: Dec 2007

Posts: 11

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I think I understand it now. Not sure, but I think the decreased tension in the bottom spokes is balanced by an uniform increase in tension in the remaining spokes. At least that's how I interpret the strain diagram. I might be wrong though.

#43

Senior Member

Join Date: May 2005

Location: Albany, WA

Posts: 7,393

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Likes: 0

Liked 7 Times

in

6 Posts

The spoke tension goes through that dip because the rim is deflected inwards locally at the point of load. That local inwards deflection was crucial for my own understanding (and I suspect many others too). Because the general idea was that the wheel assumes some sort of elliptical shape under load which would agree with your argument. But the analysis and measurement showed the surprising result the the rim deflection is local only.

When Jobst Brandt first presented his thesis, he was laughed out of the office:

Originally Posted by Jobst Brandt

My work was published in 1981, at a time when it struck the

engineering fraternity with shock and disbelief. As I have mentioned,

the ME Department at Stanford was polite enough to listen to me,

possibly because I was a graduate of their institution, but that is as

far as it went. Professor Kane, in particular, told me politely that

I was mistaken about the whole concept.

engineering fraternity with shock and disbelief. As I have mentioned,

the ME Department at Stanford was polite enough to listen to me,

possibly because I was a graduate of their institution, but that is as

far as it went. Professor Kane, in particular, told me politely that

I was mistaken about the whole concept.

#44

Senior Member

Join Date: Aug 2008

Posts: 65

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I read that site, and I read Jobst Brandt's book and I believe them both for the most part. I think that the reason that people are so skeptical is the assertion that the wheels "stand" on the bottom spokes. This is kind of a trollish statement and if Jobst wasn't nearly always right about things I think people would write him off as a newsgroup troll. The fact the he's willing to study and measure things that most people only devote idle speculation to gets my respect but I wish he'd be a little more diplomatic about it.

Sure, the bottom few spokes and a small contact patch on the rim experience a great majority of the deflection and change in tension. From "The Bicycle Wheel" though, I get the impression that bike wheels work in spite of this, not because of it. The whole spoke standing business is because rims are vertically compliant and serve mostly to resist compression (along the circumference) and tension (in the nipple holes) from the spokes, not because of anything fundamental about spoked wheels. In the book he says that stiffer rims increase the size of the contact patch. This makes for a less striking finite element analysis picture because it expands the region of "standing" spokes beyond those near the ground. It also improves longevity because it reduces metal fatigue in the spokes (only my impression, I am not a materials scientist and I don't have the book handy).

Sure, the bottom few spokes and a small contact patch on the rim experience a great majority of the deflection and change in tension. From "The Bicycle Wheel" though, I get the impression that bike wheels work in spite of this, not because of it. The whole spoke standing business is because rims are vertically compliant and serve mostly to resist compression (along the circumference) and tension (in the nipple holes) from the spokes, not because of anything fundamental about spoked wheels. In the book he says that stiffer rims increase the size of the contact patch. This makes for a less striking finite element analysis picture because it expands the region of "standing" spokes beyond those near the ground. It also improves longevity because it reduces metal fatigue in the spokes (only my impression, I am not a materials scientist and I don't have the book handy).

Last edited by faffer; 02-15-09 at 09:38 PM.

#45

Senior Member

Join Date: Dec 2006

Location: Southern California

Posts: 930

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Ok jur it took me awhile, but I understand WHY you think the bottom spokes are doing the work. Your logic is that if the top spokes where bearing the load the rim would collapse from the top right? because they would fail from being overloaded right?

But that is precisely why the rims do not collapse from the top. Because the TOP spokes ARE SUPPORTING. rims collapse from the bottom because those spokes are NOT SUPPORTING. The rim will collapse from the WEAKEST point. The bottom.

Also take into account that if spokes are laced radially, that diminishes greatly the bottom spokes ability to support.

But that is precisely why the rims do not collapse from the top. Because the TOP spokes ARE SUPPORTING. rims collapse from the bottom because those spokes are NOT SUPPORTING. The rim will collapse from the WEAKEST point. The bottom.

Also take into account that if spokes are laced radially, that diminishes greatly the bottom spokes ability to support.

#46

Senior Member

Join Date: Dec 2008

Location: Under the Downunder

Posts: 1,014

Bikes: MTBs, BMX, Pocket MTB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I have been studying further the numerical results in the Finite Element Analysis test results from the article, and it still makes sense to me. I do believe that the readings are correct (or at least in relative proportion anyway)... whereby the highest tension loads are at 4 and 8 o'clock.

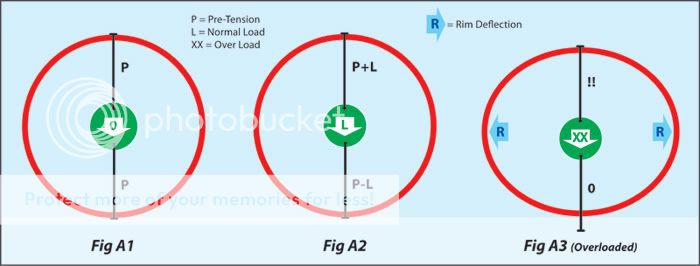

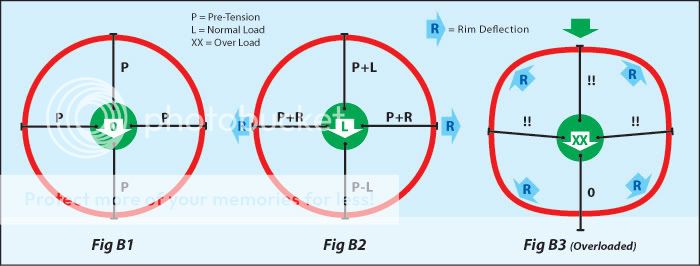

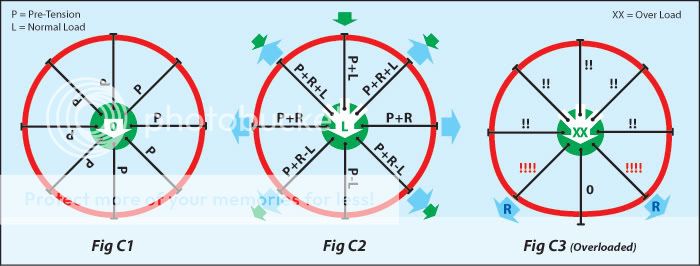

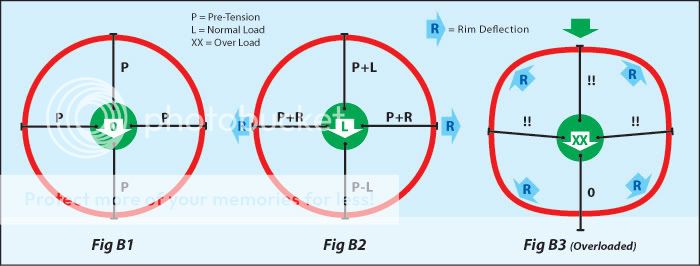

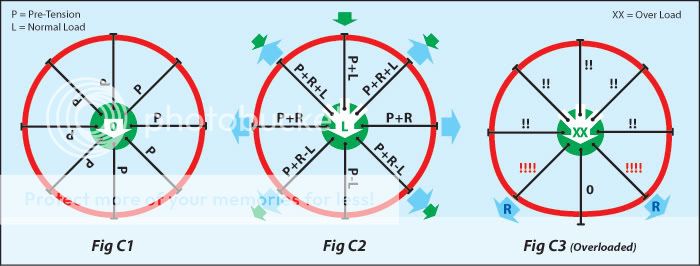

For what it's worth, I have put my deductive reasoning into diagrams to illustrate what I believe is occurring in a spoked wheel. I have simplified the drawings to keep things fundamental, starting with vertical spokes only on Figure A, and followed by progressive steps from there.

In all illustration groups A, B & C...

Fig 1 is always a wheel with equal spoke pre-tension but no hub load;

Fig 2 has a normal load (hub pushing down) but pre-tension on ALL spokes is always present but uneven to some degree; and

Fig 3 is when the wheel is overloaded to the point of rim deformation. The spoke at 6 o'clock has zero tension and cannot bear a compression load. I have exaggerated the rim deflections for clarity.

In order to counter rim ovalization in Fig A3, the next obvious step is to add horizontal spokes...

Fig B3 shows that the horizontal spokes have stopped the rim from ovalizing, but the new tendency now is for the rim to "squarize." In order to counter the rim from squaring, the next obvious step is to add an "X brace" in the form of 4 more spokes...

Finally Fig C3 shows all the spokes at the top half of the wheel are all working together with reasonably even tension to keep the rim from "squaring" while simultaneously keeping the hub suspended. The lower half of the rim is a different story where only two thirds are left in charge of keeping the rim from "squaring" because the spokes directly at the bottom of the hub are no longer contributing and have been relieved of all pre-tension.

Failure would now occur in only one of two ways. If the rim is stronger than the spokes at 4 and 8 o'clock, it's tendency to deflect or "square-up" would snap the spokes. If the rim is weaker, the spokes at 4 and 8 o'clock will hold firm and the rim instead will "flatten" directly beneath the hub... or cave-in completely as seen on those YouTube video links. So slamming into the ground creates a flat-spot, BUT it would actually be the rim (not the ground) that breaks the spokes at 4 and 8 o'clock position.

I do agree with the test data from the article, although the above reasoning is where I respectfully differ at this point in time from the author's conclusion.

.

For what it's worth, I have put my deductive reasoning into diagrams to illustrate what I believe is occurring in a spoked wheel. I have simplified the drawings to keep things fundamental, starting with vertical spokes only on Figure A, and followed by progressive steps from there.

In all illustration groups A, B & C...

Fig 1 is always a wheel with equal spoke pre-tension but no hub load;

Fig 2 has a normal load (hub pushing down) but pre-tension on ALL spokes is always present but uneven to some degree; and

Fig 3 is when the wheel is overloaded to the point of rim deformation. The spoke at 6 o'clock has zero tension and cannot bear a compression load. I have exaggerated the rim deflections for clarity.

In order to counter rim ovalization in Fig A3, the next obvious step is to add horizontal spokes...

Fig B3 shows that the horizontal spokes have stopped the rim from ovalizing, but the new tendency now is for the rim to "squarize." In order to counter the rim from squaring, the next obvious step is to add an "X brace" in the form of 4 more spokes...

Finally Fig C3 shows all the spokes at the top half of the wheel are all working together with reasonably even tension to keep the rim from "squaring" while simultaneously keeping the hub suspended. The lower half of the rim is a different story where only two thirds are left in charge of keeping the rim from "squaring" because the spokes directly at the bottom of the hub are no longer contributing and have been relieved of all pre-tension.

Failure would now occur in only one of two ways. If the rim is stronger than the spokes at 4 and 8 o'clock, it's tendency to deflect or "square-up" would snap the spokes. If the rim is weaker, the spokes at 4 and 8 o'clock will hold firm and the rim instead will "flatten" directly beneath the hub... or cave-in completely as seen on those YouTube video links. So slamming into the ground creates a flat-spot, BUT it would actually be the rim (not the ground) that breaks the spokes at 4 and 8 o'clock position.

I do agree with the test data from the article, although the above reasoning is where I respectfully differ at this point in time from the author's conclusion.

.

#47

Senior Member

Join Date: May 2005

Location: Albany, WA

Posts: 7,393

Mentioned: 16 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Likes: 0

Liked 7 Times

in

6 Posts

I think you are mistaken on a number of points...

1. The analysis is only for relatively small loads. The numbers show that - they are in newtons - so a load of 100kg. No slamming into the ground here.

2. The tensions at 4 and 8o'clock are small beer - not "snapping" tensions at all. They may be for you gross distortion scenario, I don't know, but not for the analysis in the OP. The numbers are merely 3-4kg of weight hanging from a spoke - almost infinitely far from "snapping" tension.

3. Spokes do not snap from excessive tension. For that they are too ductile. No, they snap from metal fatigue due to thousands of times of small bendings to and fro at the spoke elbow as the tension relaxes a bit when the spokes go through BDC. This develops metal fatigue - micro cracks which propagate and eventually the spoke hangs by a thread, so to speak, then only a small amount of excess elbow flexing will make it go, such as when you hit a bump. For a spoke to snap from tension like you are thinking of, it will rip the nipple thread right out before it pulls a neck and finally gives. You can safely put that scenario completely away from you.

1. The analysis is only for relatively small loads. The numbers show that - they are in newtons - so a load of 100kg. No slamming into the ground here.

2. The tensions at 4 and 8o'clock are small beer - not "snapping" tensions at all. They may be for you gross distortion scenario, I don't know, but not for the analysis in the OP. The numbers are merely 3-4kg of weight hanging from a spoke - almost infinitely far from "snapping" tension.

3. Spokes do not snap from excessive tension. For that they are too ductile. No, they snap from metal fatigue due to thousands of times of small bendings to and fro at the spoke elbow as the tension relaxes a bit when the spokes go through BDC. This develops metal fatigue - micro cracks which propagate and eventually the spoke hangs by a thread, so to speak, then only a small amount of excess elbow flexing will make it go, such as when you hit a bump. For a spoke to snap from tension like you are thinking of, it will rip the nipple thread right out before it pulls a neck and finally gives. You can safely put that scenario completely away from you.

Last edited by jur; 02-16-09 at 06:05 AM.

#49

Senior Member

Join Date: Dec 2008

Posts: 1,821

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Also, can a spoke carry significant compression before it buckles or does it basically behave like a string?

Kam

#50

Junior Member

Join Date: Dec 2007

Posts: 11

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Ok, I'm still trying to get my head around this so I started doing though experiments. What if you take a strung archery bow and then push the ends together? The tension in the string will decrease. Now, does the decrease in tension mean the string is taking load in compression or is the bending of the bow carrying the load?