lugged apoxy?

#26

Senior Member

Join Date: Jun 2007

Posts: 316

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Excuse my ignorance but is it possible to both braze and epoxy joints or will the heat of brazing destroy the epoxy bond? How about some kind of tig or spot welding along with brazing?

#27

THE Materials Oracle

Join Date: Feb 2006

Location: Finally... home :-)

Posts: 502

Bikes: Univega Alpina 5.1 that became a 5.9, that became a road bike... DMR TrailStar custom build

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Some early glue together frames failed due to corrosion in the joints. Fix was to anodize the lugs before gluing to reduce the galvanic reaction between the parts.

I have friends that had some glue together Trek bikes, with carbon tubes, and these people got a reasonable service life out of the bikes. After a few years there was paint bubbling at some of the joints indicating the start of corrosion. Not good. My understanding is that it's common to use a wrap of fiberglass as an insulator of sort these days. Works well or so it seems; failing joints are not very common despite hundreds of thousands of frames on the road.

I have friends that had some glue together Trek bikes, with carbon tubes, and these people got a reasonable service life out of the bikes. After a few years there was paint bubbling at some of the joints indicating the start of corrosion. Not good. My understanding is that it's common to use a wrap of fiberglass as an insulator of sort these days. Works well or so it seems; failing joints are not very common despite hundreds of thousands of frames on the road.

#28

Banned

Join Date: Aug 2005

Posts: 5,115

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 2 Times

in

1 Post

"Excuse my ignorance but is it possible to both braze and epoxy joints or will the heat of brazing destroy the epoxy bond? How about some kind of tig or spot welding along with brazing?"

It depends on the situation. I can't think of any structure that actually works that way. Brazing occurs at above 800F, which is destructive to most if not all epoxies of small shop variety. Tig welding can be very closely controlled so there probably could be a situation where it could be managed. It would be better to evolve the process so the gluing occurred after the TIG.

I do know of one example, the repair of golf clubs which are socketed together with epoxy. I have seen the extent of the heat occasionally required to separate such joints and it can be spectacular. I had one 3 wood that suffered a broken carbon shaft, and I removed it from the clubhead and reshafted it. It took massive amounts of heat to the point where the residue burn like a roman candle after the shaft was withdrawn. I'm pretty sure on could have tigged in the area of that socket without the shaft failing. That shaft was originally bonded with a post cure phase.

In general, the average shop with the sophistication to do the tig or epoxy work, shouldn't really find itself in this kind of bind...

It depends on the situation. I can't think of any structure that actually works that way. Brazing occurs at above 800F, which is destructive to most if not all epoxies of small shop variety. Tig welding can be very closely controlled so there probably could be a situation where it could be managed. It would be better to evolve the process so the gluing occurred after the TIG.

I do know of one example, the repair of golf clubs which are socketed together with epoxy. I have seen the extent of the heat occasionally required to separate such joints and it can be spectacular. I had one 3 wood that suffered a broken carbon shaft, and I removed it from the clubhead and reshafted it. It took massive amounts of heat to the point where the residue burn like a roman candle after the shaft was withdrawn. I'm pretty sure on could have tigged in the area of that socket without the shaft failing. That shaft was originally bonded with a post cure phase.

In general, the average shop with the sophistication to do the tig or epoxy work, shouldn't really find itself in this kind of bind...

#29

Senior Member

Join Date: Jul 2007

Posts: 84

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Anodizing Before Bonding

I work at a large aerospace company that makes just about every satellite dish in space and it's strictly forbidden to bond to anodize aluminium pieces. I also make exxon grafteks and sometimes substitute the steerer tube with black anodize alum. but mask off where I;m bonding.

#31

THE Materials Oracle

Join Date: Feb 2006

Location: Finally... home :-)

Posts: 502

Bikes: Univega Alpina 5.1 that became a 5.9, that became a road bike... DMR TrailStar custom build

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

I work at a large aerospace company that makes just about every satellite dish in space and it's strictly forbidden to bond to anodize aluminium pieces. I also make exxon grafteks and sometimes substitute the steerer tube with black anodize alum. but mask off where I;m bonding.

You have to remember that most expoxy systems are activated with either acid anhydrides/acyl chlorides or strong Lewis acids, all of which are remarkably corrosive to aluminium, such that they tend to eat straight through even a really deep and solid anodised layer. Once it's in space, there's little in the way of half-decent joint inspection that can be done.

Do you anodise or alochrom parts?

#32

Senior Member

Join Date: Jul 2007

Posts: 84

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

We do an epoxy prep that is airbrushed on and then baked, kept in a controled enviroment, then epoxyed. The exxon graftek frames I build have the primer sprayed inside the lugs before bonding. I do use anodized head tubes at times but make sure theres no anodizing where the lugs are. Maybe the clear coating or sealer they do on the anodizing would affect the epoxy joint?

#33

Mixitup

Join Date: Oct 2005

Posts: 178

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 3 Times

in

2 Posts

The Raleigh Techniums were Epoxy Bonded and there was a lot of engineering of the lugs and the paint that went into this Technology as can be seen in this phamphlet posted a while ago. see thread Edit - there are 2 thumbnails on the link not scanned in order.

The advent of tig welded Alum frames and low cost killed this program

https://www.bikeforums.net/framebuilders/215343-epoxy-bonding.html

I have an 87 and have put many miles on it withloads and it is still going

The advent of tig welded Alum frames and low cost killed this program

https://www.bikeforums.net/framebuilders/215343-epoxy-bonding.html

I have an 87 and have put many miles on it withloads and it is still going

#34

THE Materials Oracle

Join Date: Feb 2006

Location: Finally... home :-)

Posts: 502

Bikes: Univega Alpina 5.1 that became a 5.9, that became a road bike... DMR TrailStar custom build

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

The seal to an anodising is nothign more than a boiling water dunk... It just removes the porosity of the aluimina layer by providing more aluminium hydroxide - that decomposes at room temp back to alumina - to seal it all up. I can't see that making much difference.. Admittedly the surface would have less pore, but it's still pretty fractal, with lots of remaining surface area and roughness...

#35

Senior Member

Join Date: Jul 2007

Posts: 84

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

the way I have seen and done anodizing, the first step is to dip in etch, then rinse, then in the anodizing tank with electricity,rinse, then to a color tank, black or other colors, our company uses blue alot, then to a sealer tank which puts a shiny surface on the part. If you skipped the sealer process, it would be very dull looking. What I'm getting to is that the anodizing is before the color and sealer and what experts tell me, the color and sealer is what doesn't work with epoxy.

#36

THE Materials Oracle

Join Date: Feb 2006

Location: Finally... home :-)

Posts: 502

Bikes: Univega Alpina 5.1 that became a 5.9, that became a road bike... DMR TrailStar custom build

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

the way I have seen and done anodizing, the first step is to dip in etch, then rinse, then in the anodizing tank with electricity,rinse, then to a color tank, black or other colors, our company uses blue alot, then to a sealer tank which puts a shiny surface on the part. If you skipped the sealer process, it would be very dull looking. What I'm getting to is that the anodizing is before the color and sealer and what experts tell me, the color and sealer is what doesn't work with epoxy.

#38

my bike Owns me+my wallet

Join Date: Nov 2006

Location: Sudbury, Ontario

Posts: 709

Bikes: Px-10 singeld, 2007 KHS filte 100

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I Was told that one of the issues In which a layer of fiber glass/some sealant help was, Moisture.. That moisture gets in the joints and rapidly acelerates Corosion. This was in regards to an aluminum frame with aluminum Lugs. How this affects Carbon with stainless lugs, I have no idea, As i have recently been shipped a set of exxon Lugs, Anyone have any Tips in building one, I'll be making a thread when i get them to document the whole build, Buy i'm anxious to get started any tips? and do the exxon lugs HAVE to be chromed, other than style points?

#39

Senior Member

Join Date: Jul 2007

Posts: 84

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Hi, I am the one that sent you the lugs, you can paint the lugs after build, doesn't have to be chromed, although chrome looks really nice, I use hysol 9320 epoxy for gluing, this is what we use to build satellites and space stations. I feel that the moisture problem from years ago is from epoxy shrinkage and that lets moisture in. Todays epoxys don't shrink very much at all so there shouldn't be a problem, especially if you prep the joints well using IPA at the end.

#40

Senior Member

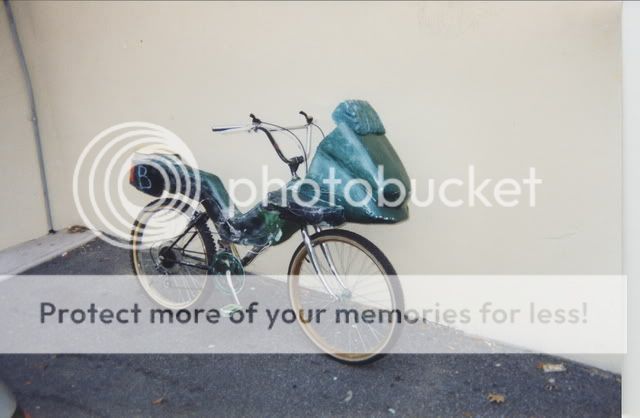

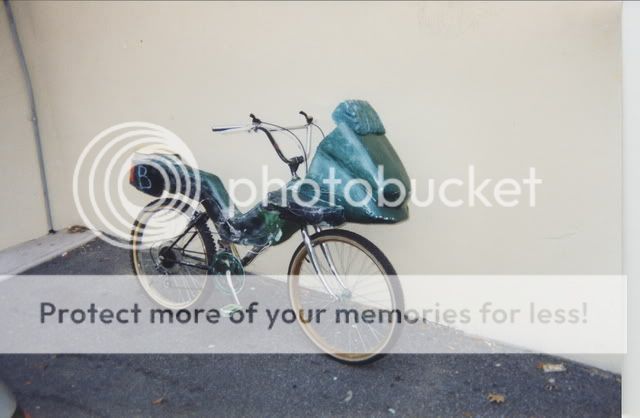

Epoxy?

This bike is made with *polyester resin*, which is more brittle than epoxy. It held together anyway.

Extremely oversized tubing is the key to strength.

I would like to see more bikes like this one. Keep in mind that anything fiberglass can be done in Carbon Fiber.

I used ten layers of fiberglass throughout the construction. Each layer is .030, but I like to say the thickness is a quarter inch.

I am saying that this bike is proof that carbon frame builders are dragging their feet. Composites open up a lot of possibility in design freedom.

But you could wrap steel tubes with fiberglass and in that manner create lugs, and need no welding whatsoever.

This bike is made with *polyester resin*, which is more brittle than epoxy. It held together anyway.

Extremely oversized tubing is the key to strength.

I would like to see more bikes like this one. Keep in mind that anything fiberglass can be done in Carbon Fiber.

I used ten layers of fiberglass throughout the construction. Each layer is .030, but I like to say the thickness is a quarter inch.

I am saying that this bike is proof that carbon frame builders are dragging their feet. Composites open up a lot of possibility in design freedom.

But you could wrap steel tubes with fiberglass and in that manner create lugs, and need no welding whatsoever.