Road Bike Steel Tubing and Seatpost Size

#1

Member

Thread Starter

Join Date: Aug 2011

Posts: 39

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Road Bike Steel Tubing and Seatpost Size

Road Bike Steel Tubing and Seatpost Size

Is a 26.8 seatpost meant to fit into 26.8 inside diameter tubing, or is it meant to fit into 27.0 inside diameter tubing ? This will make a difference as to exactly what tube sets my 1950s/60s vintage italian road bike is likely to be built from.

Is a 26.8 seatpost meant to fit into 26.8 inside diameter tubing, or is it meant to fit into 27.0 inside diameter tubing ? This will make a difference as to exactly what tube sets my 1950s/60s vintage italian road bike is likely to be built from.

#2

Decrepit Member

There is usually a 0.2mm difference between the inside diameter of the seat tube and the outside diameter of the seatpost.

27.2mm became the standard seat-post size because most high-end road frames in the 1970s and 1980s were lugged and were almost universally made out of Columbus SL or SLX or Reynolds 531. These seat tubes were 1-1/8” in diameter, or 28.6mm. The single-butted seat tube was 0.9mm thick at the bottom and 0.6mm thick at the top. Well, 2x0.6mm = 1.2mm, which, when subtracted from 28.6mm, yields an I.D. of 27.4mm. However, the tolerance on the wall thickness and roundness of the seat tube made it so that you rarely could fit a 27.4mm post inside, even before brazing. And then, the seat tube always got distorted during brazing, making it even less possible to fit a 27.4mm in there, but a 27.2mm fit nicely. The same goes for why a 27.0mm seat-post was often used on the bigger sizes, which were made out of Columbus SP or SPX, whose seat tubes had 1.0 X 0.7mm wall thicknesses. Because of tolerances, the predicted 27.2mm post (28.6 – 2x0.7 = 27.2mm) never fit, but a 27.0mm fit nicely.

27.2mm became the standard seat-post size because most high-end road frames in the 1970s and 1980s were lugged and were almost universally made out of Columbus SL or SLX or Reynolds 531. These seat tubes were 1-1/8” in diameter, or 28.6mm. The single-butted seat tube was 0.9mm thick at the bottom and 0.6mm thick at the top. Well, 2x0.6mm = 1.2mm, which, when subtracted from 28.6mm, yields an I.D. of 27.4mm. However, the tolerance on the wall thickness and roundness of the seat tube made it so that you rarely could fit a 27.4mm post inside, even before brazing. And then, the seat tube always got distorted during brazing, making it even less possible to fit a 27.4mm in there, but a 27.2mm fit nicely. The same goes for why a 27.0mm seat-post was often used on the bigger sizes, which were made out of Columbus SP or SPX, whose seat tubes had 1.0 X 0.7mm wall thicknesses. Because of tolerances, the predicted 27.2mm post (28.6 – 2x0.7 = 27.2mm) never fit, but a 27.0mm fit nicely.

#3

Junior Member

Join Date: Sep 2011

Location: London, UK

Posts: 8

Bikes: Look KG 221 shimano ultegra / diamant columbus frame (not built up) / O'Brian touring bike (1960's?)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

^ useful answer

#4

Member

Thread Starter

Join Date: Aug 2011

Posts: 39

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Ok thanks for the great answer. This certainly corrects my understanding, I didn't realise that the Seattube thickness was the smaller dimension at the top of the tube. So, that means that a 26.8 seatpost will fit tube with a 0.8 wall at the top (28.6 - 2x0.8 = 27 ID tube). That will reduce the number of possible tubesets.

#5

Decrepit Member

That's right. Often, though, due to heat distortion during brazing the seat tube will still need to be reamed to 26.8 for the seatpost to fit.

#6

Senior Member

Join Date: Sep 2009

Location: EagleRiver AK

Posts: 1,306

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 28 Post(s)

Likes: 0

Liked 60 Times

in

33 Posts

While an unbutted top of the seattube is the norm, some bikes do get built with a seattube that is butted on both ends, resulting for instance in a 26.8mm seatpost on a frame that is 0.6mm in the thin middle of the tube.

#7

Decrepit Member

Originally Posted by Tim Paterek

The seat tube, which can be plain gauge, single butted, or single tier butted, connects the bottom bracket shell with the seat lug. A small number of tube sets come with double-butted seat tubes; do not use them. The fact that seat tubes are single butted allows for the insertion of the seatpost in the thin wall end of the tube without the worry of having to use different diameter seatposts each time a different size frame is built. If the seat tube were double-butted, which is rarely the case, it would be difficult to tell what size seatpost would be necessary. Furthermore, if the seatpost were to be inserted into a double-butted tube, which was cut at a location just before the butt, the seatpost would rock and start to wallow out the top of the seat tube. With a single-butted seat tube, several inches can be cut off and the same size seatpost will still fit.

#8

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,395

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,696 Times

in

2,517 Posts

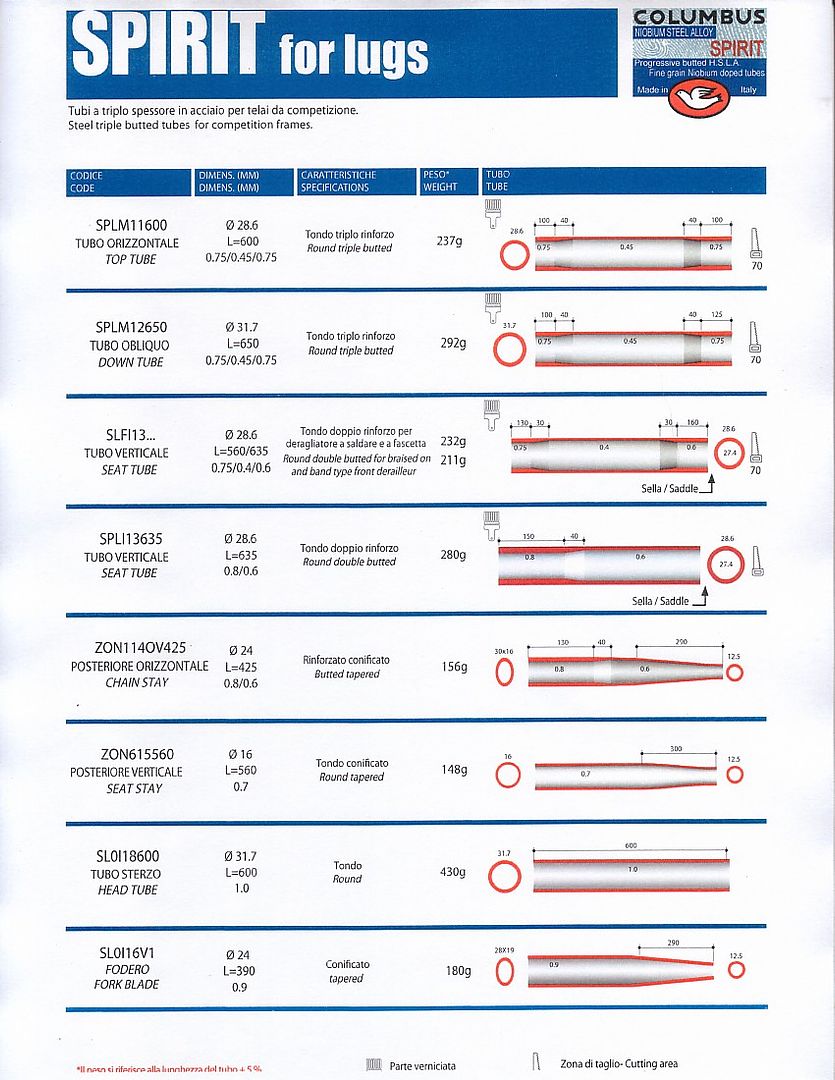

Spirit for lugs features a double butted seat tube. I see nothing wrong with a double butted seat tube it as long as you end up with a standard seat post.

#9

Decrepit Member

It sounds like Paterek's primary objection to double-butted seat tubes is that the builder would have to be very careful in determining where the top transition taper and butt start, and take pains to ensure the butting is long enough so that the top of the tube has a sufficient butt length to support the seatpost without the seatpost bottom wobbling around in the non-butted tube center. This would be particularly problematic in smaller frames where the top of the seat tube might be cut at the very end of the butt or even in the taper. It just doesn't seem worth the potential hassle.

#10

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,395

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,696 Times

in

2,517 Posts

you have that problem with any butted tube, it has to fit the design. I have designed frames with regular butted tubes as seat tubes, you just have to study the specs so you don't end up with the top butting too short. The SFL seat tube has long butts, and there are two different length seat tubes. Not sure what the smallest frame you can make with it is, but I'm pretty sure the normal range is not a problem.

#11

Decrepit Member

It looks like Columbus makes both double-butted and single-butted seat tubes for SFL, and the double-butted tubes come in 560 and 635. The top butt is 160mm and the taper is 30mm, so it looks like you're right. Even a 49cm frame would still leave at least a 9cm top butt.

#12

Member

Thread Starter

Join Date: Aug 2011

Posts: 39

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

This has become an interesting conversation. Well in my case, and the reason for asking the question, is I suspect I probably have tube with the same guage. The frame is from the late 1950s, it has a spring hole in the RD hanger on the Campag dropout. So I will be trying to ID tube that has a 0.8 wall from that era.

#13

Senior Member

Join Date: Feb 2008

Posts: 1,092

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Road Bike Steel Tubing and Seatpost Size

Is a 26.8 seatpost meant to fit into 26.8 inside diameter tubing, or is it meant to fit into 27.0 inside diameter tubing ? This will make a difference as to exactly what tube sets my 1950s/60s vintage italian road bike is likely to be built from.

Is a 26.8 seatpost meant to fit into 26.8 inside diameter tubing, or is it meant to fit into 27.0 inside diameter tubing ? This will make a difference as to exactly what tube sets my 1950s/60s vintage italian road bike is likely to be built from.

Last edited by 753proguy; 09-12-11 at 05:36 PM. Reason: fixed spelling of 'period'

#14

Senior Member

Join Date: Feb 2008

Posts: 1,092

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

FYI, 531 seat tubes were usually 0.5 in the unbutted section, but distortion from brazing meant that with a 28.6 OD, 27.2 was still the typical seat post. Columbus SP, as someone stated, had an unbutted section that was 0.1 thicker than SL (0.7 vs. 0.6 mm), so a 0.2 mm smaller post was typically required (27.0). A lot of 1950s/1960s Italian high-end frames will take a 27.0 seat post, fwiw, whereas the British / American, etc. ones will use a 27.2.

However, the tubing's actual wall thickness could often be a bit more than the spec., and ovality was/is a factor as well, along with whether the frame was properly reamed when new..

And we're talking Imperial-diameter tubing here, Metric (French, Swiss, Spanish, etc. frames, mostly) are another story entirely (subtract 0.6 mm for the typical posts, essentially, so 26.6 and 26.4 for the good tubing).

However, the tubing's actual wall thickness could often be a bit more than the spec., and ovality was/is a factor as well, along with whether the frame was properly reamed when new..

And we're talking Imperial-diameter tubing here, Metric (French, Swiss, Spanish, etc. frames, mostly) are another story entirely (subtract 0.6 mm for the typical posts, essentially, so 26.6 and 26.4 for the good tubing).

#15

Decrepit Member

FYI, 531 seat tubes were usually 0.5 in the unbutted section, but distortion from brazing meant that with a 28.6 OD, 27.2 was still the typical seat post. Columbus SP, as someone stated, had an unbutted section that was 0.1 thicker than SL (0.7 vs. 0.6 mm), so a 0.2 mm smaller post was typically required (27.0). A lot of 1950s/1960s Italian high-end frames will take a 27.0 seat post, fwiw, whereas the British / American, etc. ones will use a 27.2.

However, the tubing's actual wall thickness could often be a bit more than the spec., and ovality was/is a factor as well, along with whether the frame was properly reamed when new..

And we're talking Imperial-diameter tubing here, Metric (French, Swiss, Spanish, etc. frames, mostly) are another story entirely (subtract 0.6 mm for the typical posts, essentially, so 26.6 and 26.4 for the good tubing).

However, the tubing's actual wall thickness could often be a bit more than the spec., and ovality was/is a factor as well, along with whether the frame was properly reamed when new..

And we're talking Imperial-diameter tubing here, Metric (French, Swiss, Spanish, etc. frames, mostly) are another story entirely (subtract 0.6 mm for the typical posts, essentially, so 26.6 and 26.4 for the good tubing).

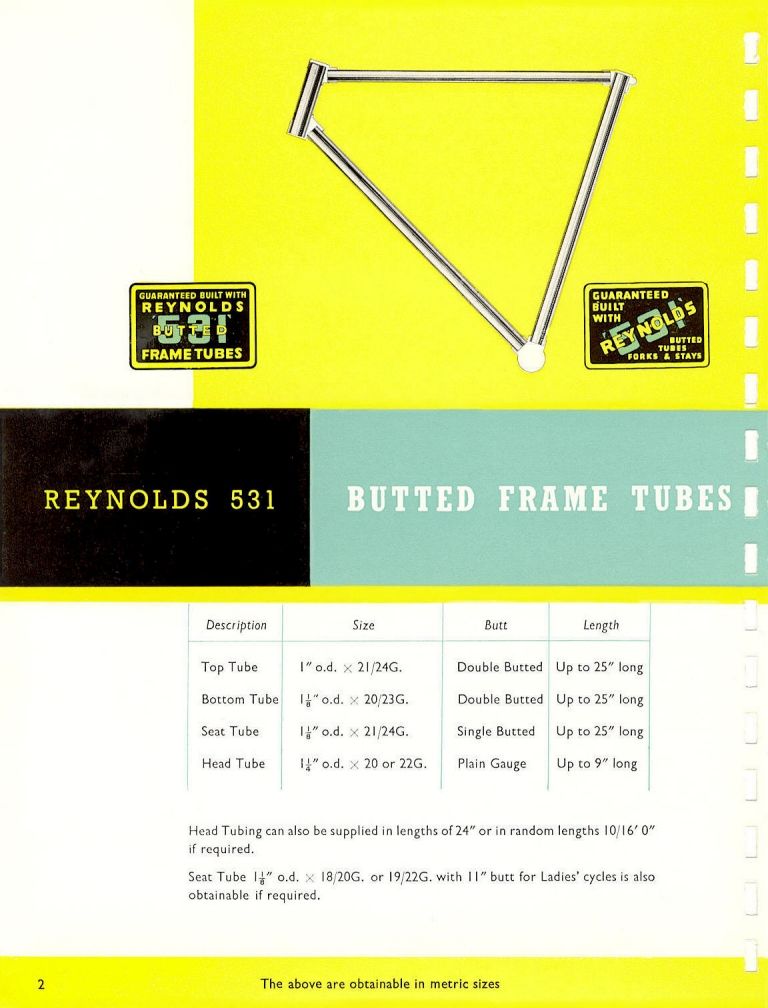

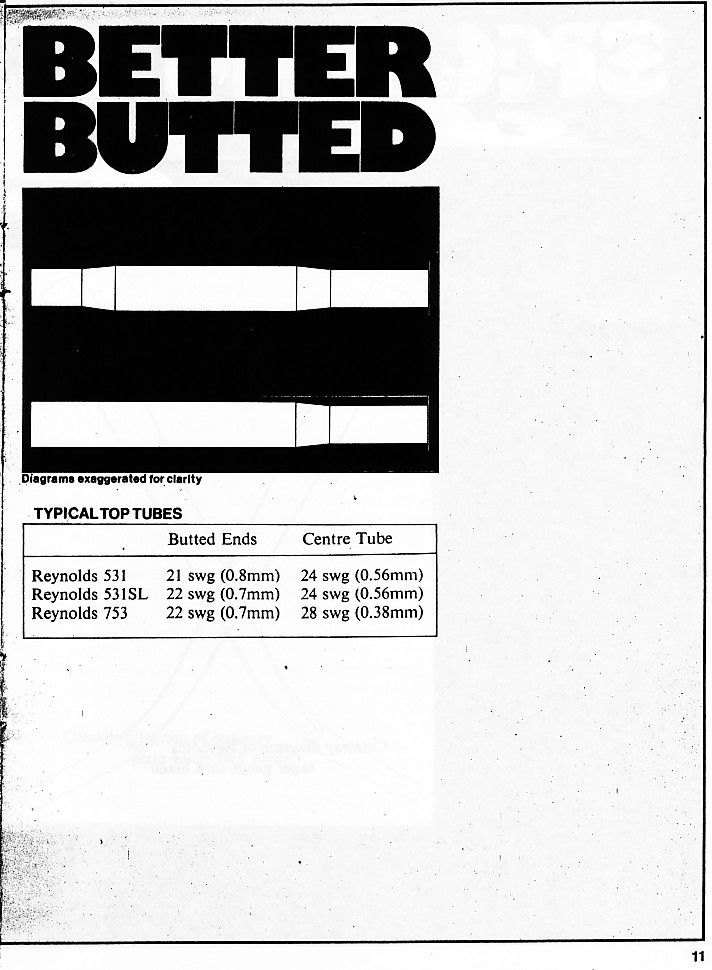

The wall thickness of later variations of 531 (531 SL Speed Stream, 531 Professional, 531 Competion, 531 Special Tourist, 531 BMX, etc.) varied from 0.5mm to 0.8mm in the non-butted end).

Imperial Standard Wire Gauge (SWG) conversion to metric.

Last edited by Scooper; 09-12-11 at 06:49 PM.

#16

Senior Member

Join Date: Feb 2008

Posts: 1,092

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Well, there are catalogs, and then there are real things.

I just went and measured a real butted 531 (28.6 mm OD) seat tube.

It measured 0.81 on the thick end, and 0.51 on the thin end.

I've always seen 'standard' 531 DB tubing referred to as '8/5/8' tubing.

I'll stick with what I said.

I just went and measured a real butted 531 (28.6 mm OD) seat tube.

It measured 0.81 on the thick end, and 0.51 on the thin end.

I've always seen 'standard' 531 DB tubing referred to as '8/5/8' tubing.

I'll stick with what I said.

#17

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,395

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,696 Times

in

2,517 Posts

that's about as close as the guys at Reynolds could make it after having a couple of pints at lunch. It was pretty obvious to me that Reynolds tubes were made by humans, 531 dimensions varied fairly widely.

#18

Senior Member

Join Date: Feb 2008

Posts: 1,092

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

I hear you.

Would that be Watneys Red Barrel?

Actually, though.....

The main reason Reynolds was so successful with 531 for so long is that they were making consistent, high-quality, overheating-tolerant stuff from the git-go (in 1935). Whether others were better at their wall thickness standard deviation numbers by the 1970s, I can't say, but compared to the fiasco that was the early True Temper tubing, I'd say the Reynolds folks had it pretty well nailed. 531 had its 50th anniversary in 1985, and was still going strong for about another 15 years after that. Declining demand finally killed it around 2001 (although Reynolds is willing to make you some, but the catch is you gotta buy 20,000 pounds of it, because that's a minimum run of the correct billet that their steel supplier will produce). Heck, that's only about 4000 sets of tubing. Anyone want to split that up in a group buy? OK, maybe not....

There's a reason why 531 dominated for so long in the marketplace - but I digress.....

Would that be Watneys Red Barrel?

Actually, though.....

The main reason Reynolds was so successful with 531 for so long is that they were making consistent, high-quality, overheating-tolerant stuff from the git-go (in 1935). Whether others were better at their wall thickness standard deviation numbers by the 1970s, I can't say, but compared to the fiasco that was the early True Temper tubing, I'd say the Reynolds folks had it pretty well nailed. 531 had its 50th anniversary in 1985, and was still going strong for about another 15 years after that. Declining demand finally killed it around 2001 (although Reynolds is willing to make you some, but the catch is you gotta buy 20,000 pounds of it, because that's a minimum run of the correct billet that their steel supplier will produce). Heck, that's only about 4000 sets of tubing. Anyone want to split that up in a group buy? OK, maybe not....

There's a reason why 531 dominated for so long in the marketplace - but I digress.....

Last edited by 753proguy; 09-13-11 at 12:13 AM. Reason: Added missing close paren.

#19

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,395

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,696 Times

in

2,517 Posts

well, it might as well have been the only game in town at the high end for a very long time. As far as the dimensions go, I'm just speaking from experience. If you sit down with a pile of '70s 531, which I did many times, some of it will be oversize enough it doesn't easily fit into the lugs. Some of it will be under-size, and some will be just right. It is the luck of the draw. It could really cause you to have a bad day.

It's too bad true temper had a rocky start, the stuff they make now is really some of the nicest tubing I've used.

It's too bad true temper had a rocky start, the stuff they make now is really some of the nicest tubing I've used.

#20

Senior Member

Join Date: Jun 2006

Posts: 20,305

Mentioned: 130 Post(s)

Tagged: 0 Thread(s)

Quoted: 3464 Post(s)

Liked 2,829 Times

in

1,995 Posts

This has become an interesting conversation. Well in my case, and the reason for asking the question, is I suspect I probably have tube with the same guage. The frame is from the late 1950s, it has a spring hole in the RD hanger on the Campag dropout. So I will be trying to ID tube that has a 0.8 wall from that era.

With an unknown Italian frame from the 50's I would start with a 26.8 mm and let the frame tell me otherwise. I have 2 50's Italian bikes bth with 26.8 seat posts, one a steel Campagnolo.

#21

Senior Member

Join Date: Feb 2008

Posts: 1,092

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

well, it might as well have been the only game in town at the high end for a very long time. As far as the dimensions go, I'm just speaking from experience. If you sit down with a pile of '70s 531, which I did many times, some of it will be oversize enough it doesn't easily fit into the lugs. Some of it will be under-size, and some will be just right. It is the luck of the draw. It could really cause you to have a bad day.

It's too bad true temper had a rocky start, the stuff they make now is really some of the nicest tubing I've used.

It's too bad true temper had a rocky start, the stuff they make now is really some of the nicest tubing I've used.

#22

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,395

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,696 Times

in

2,517 Posts

granted, but who knows what the wall thickness was. If the diameter is random, the wall thickness is going to vary.

#23

Senior Member

Join Date: Feb 2008

Posts: 1,092

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Nope. There are two diameters, I.D. and O.D. Diameters and wall thickness are separately-measured characteristics, and one of the keys to 531's success was wall-thickness consistency (vs. the competition at the time). Roundness is another parameter, but that's not involved in this discussion either.

#24

Decrepit Member

With a layperson's understanding of how dies and mandrels are used to make butted tubing, it's difficult for me to believe tubing built to the manufacturer's specifications could have such large variations.

Eventually the dies and mandrels will wear from use and need to be replaced, but when the manufacturer specifies wall thickness in hundredths of a millimeter (like 0.56mm), what is the allowed tolerance? At what point does tubing get rejected because it doesn't meet specs and the tooling get replaced because it has worn too much to produce tubing to spec?

Reynolds 531 tubing was used extensively during WW2 by allied aircraft factories for use in engine mounts and landing gear parts, and I've read enough Air Force military specifications to believe there had to have been strict specifications for the chemical composition and physical properties (UTS, elongation, etc.) as well as dimensions (O.D., I.D., etc.) for the tubing used in building airplane parts.

Any idea what the tolerances for the tubing manufacturers are? I'd have to guess that if one of the manufacturers turned out tubing with tolerances significantly sloppier than the other major manufacturers they'd soon be out of business.

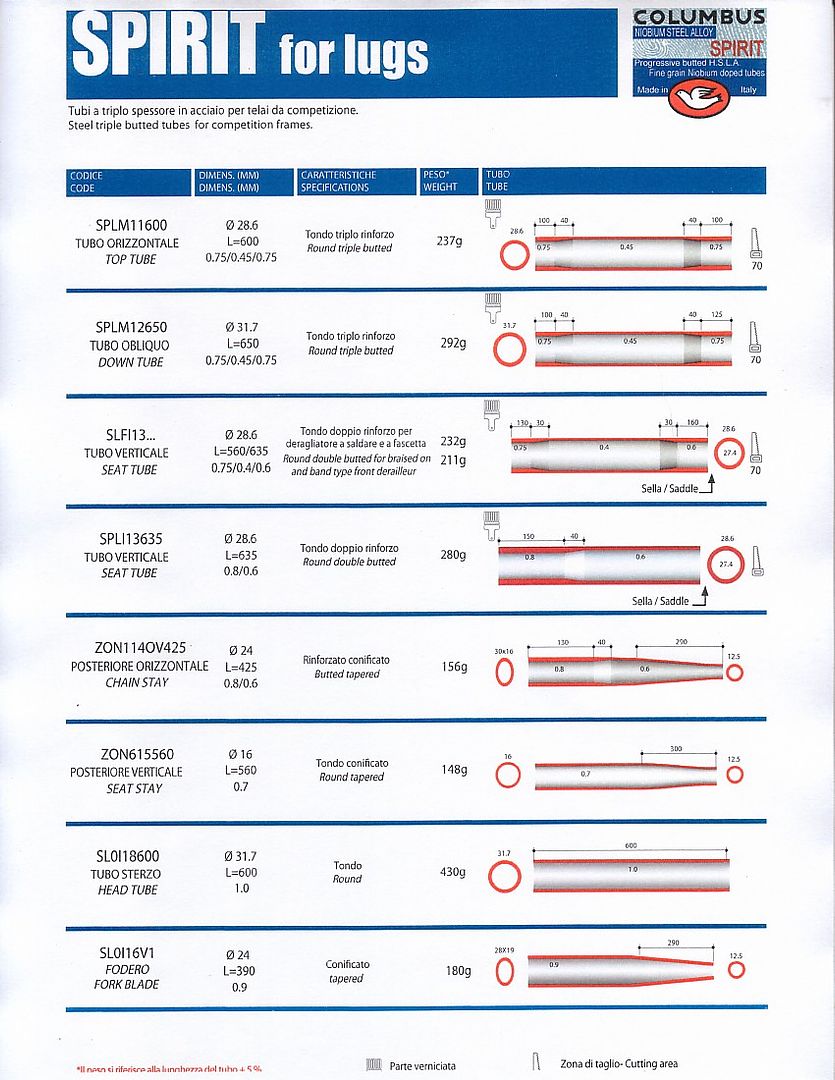

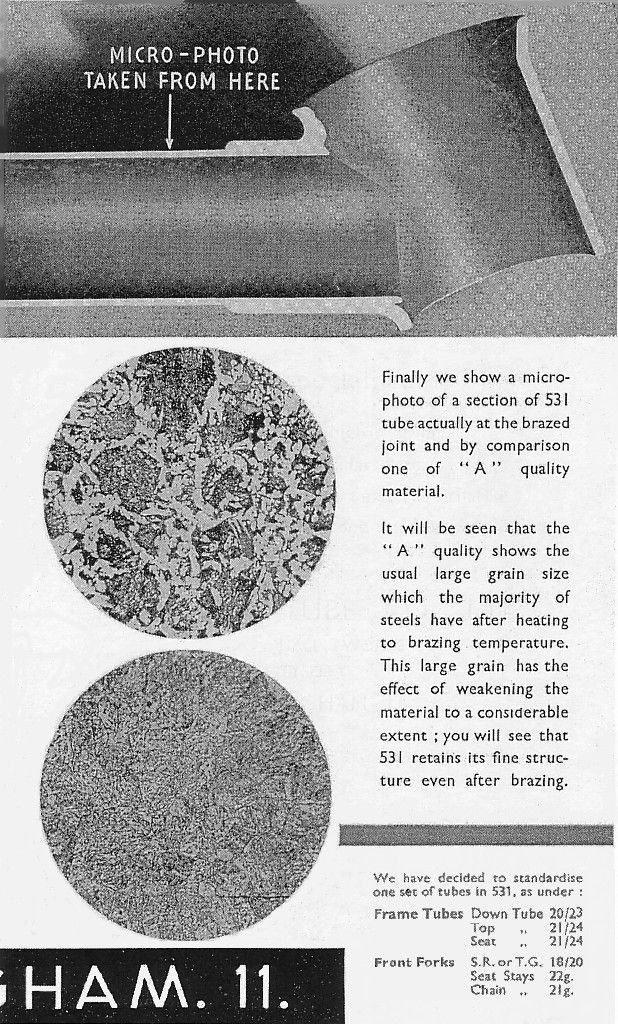

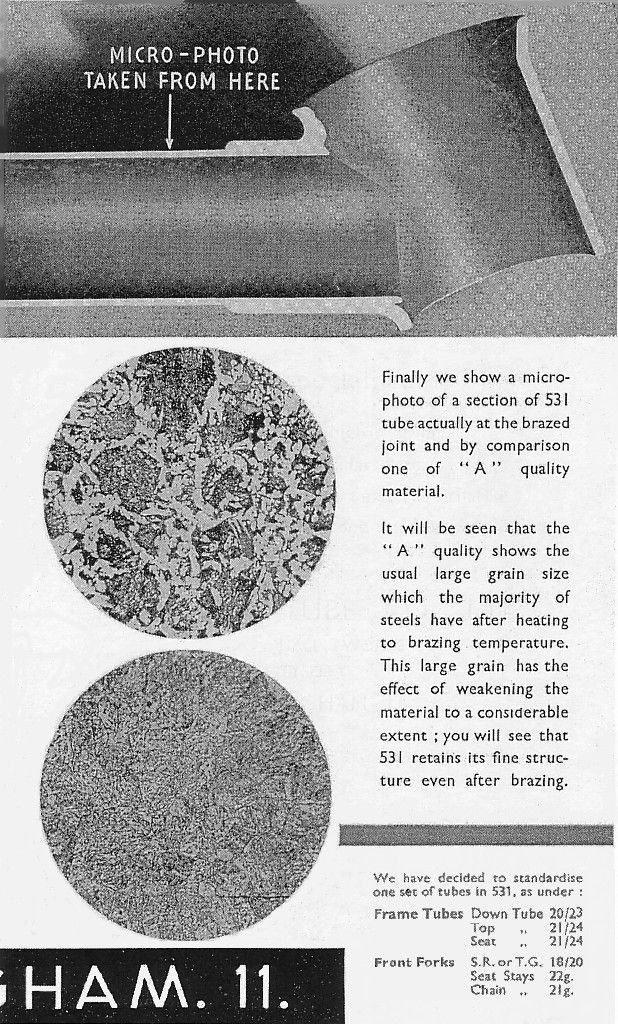

I know the 531 Competition seat tubes had 0.5mm wall thickness at the non-butted end, but I maintain that the standard 531 seat tubes were 0.56mm at the non-butted end from 1935 (see 1936 catalog page below showing 21/24 swg butted seat tube) until the mid-seventies.

Eventually the dies and mandrels will wear from use and need to be replaced, but when the manufacturer specifies wall thickness in hundredths of a millimeter (like 0.56mm), what is the allowed tolerance? At what point does tubing get rejected because it doesn't meet specs and the tooling get replaced because it has worn too much to produce tubing to spec?

Reynolds 531 tubing was used extensively during WW2 by allied aircraft factories for use in engine mounts and landing gear parts, and I've read enough Air Force military specifications to believe there had to have been strict specifications for the chemical composition and physical properties (UTS, elongation, etc.) as well as dimensions (O.D., I.D., etc.) for the tubing used in building airplane parts.

Any idea what the tolerances for the tubing manufacturers are? I'd have to guess that if one of the manufacturers turned out tubing with tolerances significantly sloppier than the other major manufacturers they'd soon be out of business.

I know the 531 Competition seat tubes had 0.5mm wall thickness at the non-butted end, but I maintain that the standard 531 seat tubes were 0.56mm at the non-butted end from 1935 (see 1936 catalog page below showing 21/24 swg butted seat tube) until the mid-seventies.

#25

Senior Member

Join Date: Feb 2008

Posts: 1,092

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

I have no idea what tolerance spec. was on Reynolds' drawing for the wall thickness of a standard-gauge 531 seat tube, nor am I privy to what their tooling replacement schedules were, but I know that they did an excellent job (compared to their competition) of being consistent with wall thickness. Since they were able to consistently make 753 top tubes that were as thin as 0.3 mm (.012 inches!) in the unbutted section, as early as 1975, I'd say they knew their, uh, stuff, in that area.

The 531C designation didn't exist until about 1984. They started calling the tubesets 531C and 531ST then, I think mainly to compete more directly with Columbus SL and SP. Prior to that, they had 531 Special Lightweight, but other than that, in terms of 531, you got 531, which you could custom-order a whole bunch of ways.

I still have some unused 1970s 531, so I went and measured a seat tube, and it measured 0.51 mm. I guess I could go measure 50 of them, and give you the mean and standard deviation if that would help....

Edit: I have the receipt (here somewhere, in some pile or old file...) for the tubing that I measured. I'll see if I can find that to verify the gauge that was ordered for those specific seat tubes.

Update: found the Reynolds Tube Co. Ltd. invoice. 10 December, 1974. Seat tubes are specified as 21/24 Gauge, SB (single butted).

The 531C designation didn't exist until about 1984. They started calling the tubesets 531C and 531ST then, I think mainly to compete more directly with Columbus SL and SP. Prior to that, they had 531 Special Lightweight, but other than that, in terms of 531, you got 531, which you could custom-order a whole bunch of ways.

I still have some unused 1970s 531, so I went and measured a seat tube, and it measured 0.51 mm. I guess I could go measure 50 of them, and give you the mean and standard deviation if that would help....

Edit: I have the receipt (here somewhere, in some pile or old file...) for the tubing that I measured. I'll see if I can find that to verify the gauge that was ordered for those specific seat tubes.

Update: found the Reynolds Tube Co. Ltd. invoice. 10 December, 1974. Seat tubes are specified as 21/24 Gauge, SB (single butted).

Last edited by 753proguy; 09-16-11 at 05:39 PM. Reason: changed "AWG" to "gauge"