I have this little Loosy Goosy Atlas 6" lathe, the MK2 version, that I recently got frustrated enough with when the carriage cross slide popped off it's ways as I was trying out a new and more solid tool post. Atlas fans will sadly shake their head because they know that the gibs on the cross slide and the carriage rest slide are plastic, soft and will flex about under pressure . Both of the OEM gibs have cracked off spots where the adjustment bolts seat into half moon pockets. I went on line to my go to machining forum (and elsewhere) and read up. Decided to try making my own, the plastic OEM ones being only .003" thinner then common 1/8" flat stock. So I spent all afternoon between a freezing cold garage where the mill is and the basement where the lathe is (the Atlas 6" weighs only about 90lbs mounted on it's travel board, hence it can go down stairs...). Only had to make one gib a second time

Got to use my recently installed DROs, found out that even with the 110AC power adaptor they don't like the cold, just like a cycle computer. Tomorrow I'll start the reassembly and I'll report back when done and tested. First photo shows the new and the old gib.

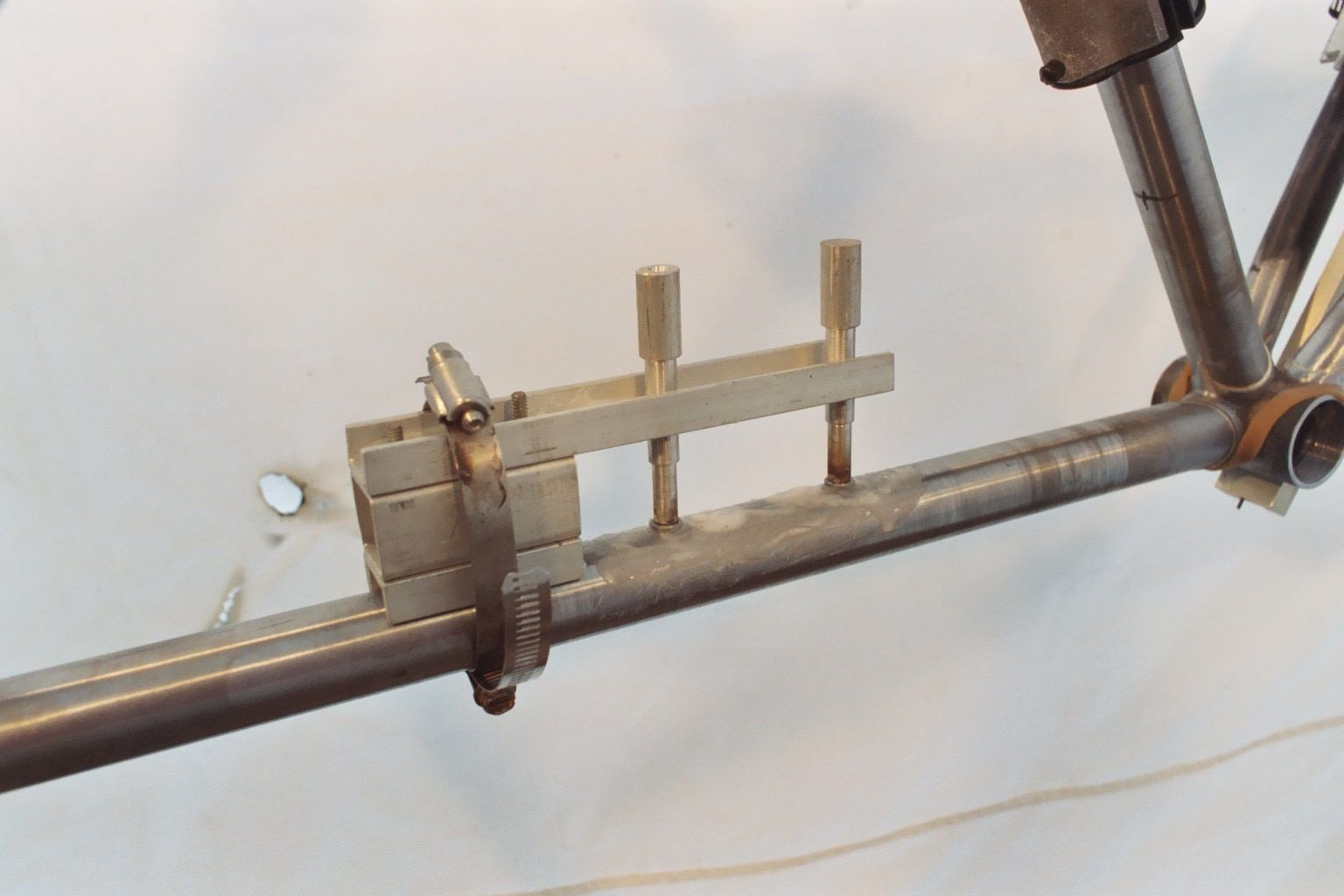

Why is this on a framebuilding forum? Because this is the lathe that I first tried power mitering with. I have a mill vice (w/ vertical travel) for this lathe and would clamp the tube in it with a hole saw in the chuck. Between the coarse teeth and the lathe's slop I bent a couple of tube ends and hole saws and after a few frames moved on in my mitering. I still made little bits and such but the use of the lathe fell off. The other photo is a scan from a shot taken in 1983. IIRC I was turning out one of the water bottle braze on alignment shafts, shown is a last shot years later in use. I have neglected this lathe for the most part for 20+ years, moving it now 5 times over the 40 years I've had it (bought it new). I have a few building tool ideas calling out for a lathe. It's time to revisit and see if I can make it better and become useful again. Andy