Greasing Bolts vs Not Greasing — Questions, Evidence?

#51

Senior Member

Join Date: Jun 2008

Location: Vancouver, BC

Posts: 9,201

Mentioned: 11 Post(s)

Tagged: 0 Thread(s)

Quoted: 1186 Post(s)

Liked 289 Times

in

177 Posts

Lugnuts are subject to becoming loose as the wheel rolls for miles and miles and miles; lugnuts are treated so as not to rust, which doesn't always work. If you lube a lug nut you can only lube the threaded area and make sure you don't get any lube on the mating surfaces of nut and the lughole, if that happens you won't be able to torque the nuts down correctly and the nuts could loosen up over many miles. Due to the difficulty of trying to ensure that no lube gets on the two surfaces it's just better not lube them at all. Just do as your manufacture recommends, they don't want to be sued so they know what's best to do.

#52

Tortoise Wins by a Hare!

Join Date: Feb 2006

Location: Looney Tunes, IL

Posts: 7,398

Bikes: Wabi Special FG, Raleigh Roper, Nashbar AL-1, Miyata One Hundred, '70 Schwinn Lemonator and More!!

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 1549 Post(s)

Liked 941 Times

in

504 Posts

I like to put a light amount of grease or anti-seize compound on almost any fastener... even auto lug nuts.  Never had anything work loose, freeze up, or strip threads.

Never had anything work loose, freeze up, or strip threads.

You all can, and should, look up the manufacture specs for every fastener you ever put a wrench on.

Never had anything work loose, freeze up, or strip threads.

Never had anything work loose, freeze up, or strip threads.You all can, and should, look up the manufacture specs for every fastener you ever put a wrench on.

#53

Advocatus Diaboli

Join Date: Feb 2015

Location: Wherever I am

Posts: 8,631

Bikes: Merlin Cyrene, Nashbar steel CX

Mentioned: 14 Post(s)

Tagged: 1 Thread(s)

Quoted: 4729 Post(s)

Liked 1,531 Times

in

1,002 Posts

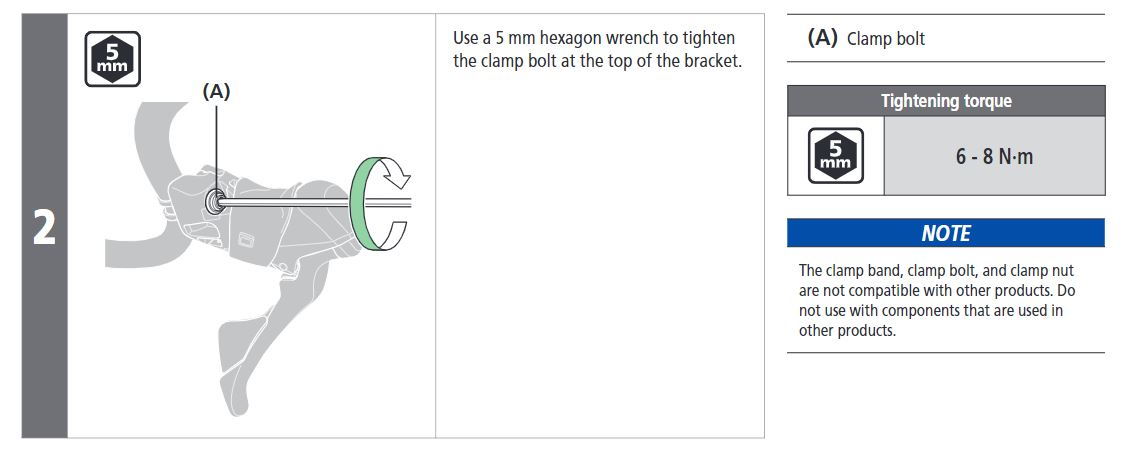

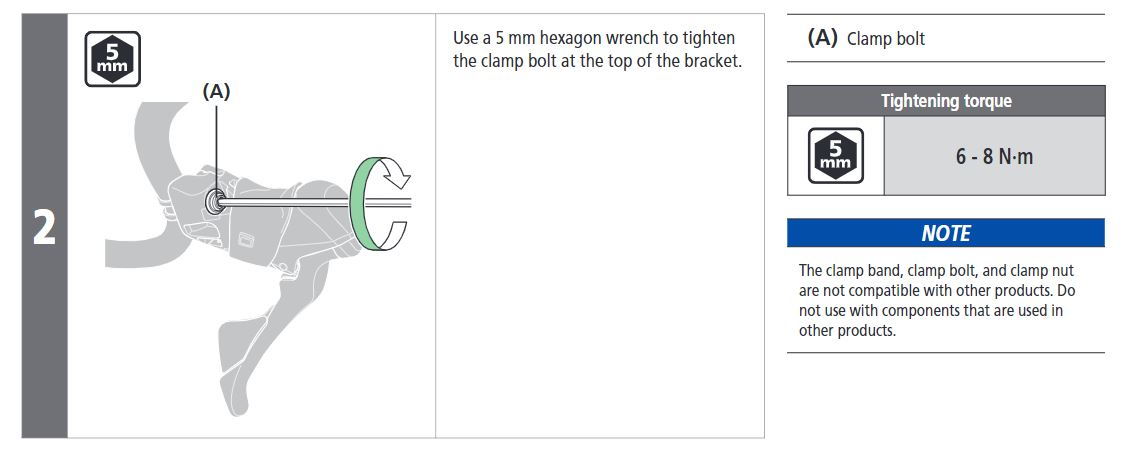

Here's a couple random snippets out of Shimano's dealer manual for ultegra brakes. Note that (to the point of this thread's OP) there's no indication of greased or dry. Shimano gives a tightening range. And, Shimano provides a helpful warning

#54

Tortoise Wins by a Hare!

Join Date: Feb 2006

Location: Looney Tunes, IL

Posts: 7,398

Bikes: Wabi Special FG, Raleigh Roper, Nashbar AL-1, Miyata One Hundred, '70 Schwinn Lemonator and More!!

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 1549 Post(s)

Liked 941 Times

in

504 Posts

However, as seems to be case usually, the specs are often either maximums or ranges for the bolt itself, and don't tell you the spec for whatever is being clamped by that component.

Here's a couple random snippets out of Shimano's dealer manual for ultegra brakes. Note that (to the point of this thread's OP) there's no indication of greased or dry. Shimano gives a tightening range. And, Shimano provides a helpful warning

Here's a couple random snippets out of Shimano's dealer manual for ultegra brakes. Note that (to the point of this thread's OP) there's no indication of greased or dry. Shimano gives a tightening range. And, Shimano provides a helpful warning

#55

Senior Member

Join Date: Feb 2019

Location: Indiana

Posts: 592

Bikes: 1984 Fuji Club, Suntour ARX; 2013 Lynskey Peloton, mostly 105 with Ultegra rear derailleur, Enve 2.0 fork; 2020 Masi Giramondo 700c, full Deore with TRP dual piston mech disk brakes

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 324 Post(s)

Liked 81 Times

in

71 Posts

#56

Georgia Traveler

Lots of varying opinions on this topic. Personally I use peanut butter on everything threaded on my bike and I have never had an issue (except with ants.) Believe me, I have a degree in Germanic Languages and Literature and know what I am talking about. Plus, I stayed in a Holiday Inn Express last night.

#57

Tortoise Wins by a Hare!

Join Date: Feb 2006

Location: Looney Tunes, IL

Posts: 7,398

Bikes: Wabi Special FG, Raleigh Roper, Nashbar AL-1, Miyata One Hundred, '70 Schwinn Lemonator and More!!

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 1549 Post(s)

Liked 941 Times

in

504 Posts

Lots of varying opinions on this topic. Personally I use peanut butter on everything threaded on my bike and I have never had an issue (except with ants.) Believe me, I have a degree in Germanic Languages and Literature and know what I am talking about. Plus, I stayed in a Holiday Inn Express last night.

As a side benefit, as long as you carry a mini tool you'll always have bonk recovery insurance on your rides.

#58

Senior Member

I had been taught by some bike mechanics to grease bolts and other threads on bikes. But recently I read a thread on a Corvette forum about whether or not to grease lug nut threads. The most popular opinion was to use grease. But it emerged, with much better evidence, that you shouldn't grease — they should be left dry and clean. The better evidence came from engineers and manufacturers.

So I am wondering what Shimano, for example, has to say. Or Campy.

And are torque specs meant for greased or ungreased? (It turned out that overtorqueing is a real issue with greased lug nuts, leading to different types of weakening and failures. The torque specs are for dry threads.)

And are some but not all threads on bikes meant to be greased?

Does this apply to all bikes, all manufacturers, and all vintages?

So I am wondering what Shimano, for example, has to say. Or Campy.

And are torque specs meant for greased or ungreased? (It turned out that overtorqueing is a real issue with greased lug nuts, leading to different types of weakening and failures. The torque specs are for dry threads.)

And are some but not all threads on bikes meant to be greased?

Does this apply to all bikes, all manufacturers, and all vintages?

S

#59

fixed at birth

Join Date: Mar 2007

Posts: 2

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I had been taught by some bike mechanics to grease bolts and other threads on bikes. But recently I read a thread on a Corvette forum about whether or not to grease lug nut threads. The most popular opinion was to use grease. But it emerged, with much better evidence, that you shouldn't grease — they should be left dry and clean. The better evidence came from engineers and manufacturers.

So I am wondering what Shimano, for example, has to say. Or Campy.

And are torque specs meant for greased or ungreased? (It turned out that overtorqueing is a real issue with greased lug nuts, leading to different types of weakening and failures. The torque specs are for dry threads.)

And are some but not all threads on bikes meant to be greased?

Does this apply to all bikes, all manufacturers, and all vintages?

So I am wondering what Shimano, for example, has to say. Or Campy.

And are torque specs meant for greased or ungreased? (It turned out that overtorqueing is a real issue with greased lug nuts, leading to different types of weakening and failures. The torque specs are for dry threads.)

And are some but not all threads on bikes meant to be greased?

Does this apply to all bikes, all manufacturers, and all vintages?

#60

Senior Member

Join Date: Feb 2019

Location: Indiana

Posts: 592

Bikes: 1984 Fuji Club, Suntour ARX; 2013 Lynskey Peloton, mostly 105 with Ultegra rear derailleur, Enve 2.0 fork; 2020 Masi Giramondo 700c, full Deore with TRP dual piston mech disk brakes

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 324 Post(s)

Liked 81 Times

in

71 Posts

All one needs to do is google this: "should car wheel nuts be greased" and start reading, but more importantly read your owners manual.

#61

73SchwinnWV

Join Date: Jan 2019

Posts: 7

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 2 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I had been taught by some bike mechanics to grease bolts and other threads on bikes. But recently I read a thread on a Corvette forum about whether or not to grease lug nut threads. The most popular opinion was to use grease. But it emerged, with much better evidence, that you shouldn't grease — they should be left dry and clean. The better evidence came from engineers and manufacturers.

So I am wondering what Shimano, for example, has to say. Or Campy.

And are torque specs meant for greased or ungreased? (It turned out that overtorqueing is a real issue with greased lug nuts, leading to different types of weakening and failures. The torque specs are for dry threads.)

And are some but not all threads on bikes meant to be greased?

Does this apply to all bikes, all manufacturers, and all vintages?

So I am wondering what Shimano, for example, has to say. Or Campy.

And are torque specs meant for greased or ungreased? (It turned out that overtorqueing is a real issue with greased lug nuts, leading to different types of weakening and failures. The torque specs are for dry threads.)

And are some but not all threads on bikes meant to be greased?

Does this apply to all bikes, all manufacturers, and all vintages?

Be careful freelancing assembly when riding your bike in traffic or high speed.

If no direction for assembly communicate with manufacturer. Otherwise, rely on engineering data for size, material, and application.

Don't forget to use a calibrated or verified torque wrench. Manufacturing data will tell you proper storage and warm up.

#62

Senior Member

Need to go with manufacturer data. As default, all fasteners clean and dry. If manufacturer says otherwise then do that. Example: electronic fuel controller on an F16 is mounted on the P&W motor. Hugh vibration and heat. Fuel is routed through it to cool the circuit cards. All fasteners are greased and torqued in steps, sequence, even running torque before final torque. Some as low as 4 inch/oz. The manufacturer and AF tech data demand it be assembled that way.

Be careful freelancing assembly when riding your bike in traffic or high speed.

If no direction for assembly communicate with manufacturer. Otherwise, rely on engineering data for size, material, and application.

Don't forget to use a calibrated or verified torque wrench. Manufacturing data will tell you proper storage and warm up.

Be careful freelancing assembly when riding your bike in traffic or high speed.

If no direction for assembly communicate with manufacturer. Otherwise, rely on engineering data for size, material, and application.

Don't forget to use a calibrated or verified torque wrench. Manufacturing data will tell you proper storage and warm up.

#63

Senior Member

Come on, everyone knows you tighten those little buggers until the cover makes a slight cracking sound, then back off half a turn.

#64

Senior Member

Everyone's an expert. Not. I'm a mechanical engineer and even I am not the best expert, but I understand the ones who are, which are, *fastener engineers*, the ones that design (engineer, with calculations and computer modeling) threaded (and other) fasteners and connections. Here's the scoop. I wrote this after seeing on a very well-respected bike repair shop's website, advocating grease and oil on threads:

"Each bolt and nut (threaded part example: pedal) is lubricated (oil for bolts 5mm and smaller, grease for bolts 6mm and larger) to allow the proper torque to be reached and prevent corrosion. Counterintuitively, lube allows a bolt to be torqued easier and stay tight better than a dry bolt." (my note: INCORRECT)

Threaded fasteners (bolts and nuts) are designed assuming clean, dry bolts (and new surface finish on threads); regular lube (oil or grease) does reduce the coefficient of friction and increases clamping load over spec. Do not do that. But a dry thread can cause corrosion and even galling (especially with softer stainless steel fasteners). I am not advocating a dry bolt. But the wrong lube can cause over-torquing beyond spec. HOWEVER, "Anti-seize" thread lube does not. It specifically contains extremely fine malleable metal powder to counteract the effect of the greasy medium that contains it. Besides lubing, it also counteracts galling much better than grease or oil. Oh and instead of a dry press fit on square taper bottom brackets, anti-seize there will prevent corrosion and ease disassembly without affecting function or causing an excessive press. The gray anti-seize contains aluminum, copper, and graphite and is rated for the range of -80 to 1600F. The copper anti-seize uses all copper and is rated for -30 to 1800F. Since I'm not operating in the arctic, I prefer the copper as it's easier to see and also is electrically and thermally conductive, it's superb for things like antenna and spark plug threads (especially important in an aluminum engine head), and most especially bolts on the exhaust system. The good part about anti-seize is that the bottle comes with a brush applicator, very convenient. The bad part is the stuff is messy, you don't want it on your clothes (unless you want to look like an aircraft mechanic, they use it everywhere). I think copper anti-seize on a black shop apron looks especially cool, but that's just me.

Some *auto racing* bolt manufacturers do advocate super-lube greases on their bolts, but those bolts are ultra-high-strength (above grade 8), and need the lube to achieve above-normal preload tensions to prevent things like head gasket failures on engines running 4 atmospheres of turbo boost.

The aforementioned bike shop also said:

"Thread locker and grease are not mutually exclusive. Bolts with factory applied threadlocker (baked on) should still be lubricated!" (my note: INCORRECT)

In order for the threadlocker adhesive to be effective to increase release torque above "clean and dry", it must adhere to both the bolt and the threaded hole. Any lubricant prevents a bond at one or both of the surfaces. Standard practice at my last company (military application) for threadlocked joints was clean both threads with acetone, dry, and apply threadlocker. I know, every bike mechanic has differing opinions, but if you talk to a fastener engineer (those are the folks that know the most about this stuff), they will confirm the above. (One of my college roomies, in the Air Force, went through the "NASA high reliability soldering course". I thought I knew how to solder. I didn't. Specialized knowledge. Not obvious, looks simple.)

After communicating the above to the head mechanic and owner of said bike shop, he got all huffy, saying all of the following (as though I was advocating dry threads, I was not, I just said that anti-seize accomplishes all; lubes the thread, seals out water, prevents corrosion and galling, AND does not change the coefficient of friction like grease and oil does):

"Tongue in cheek:

Regarding lug nuts and studs, try to avoid lube and leave them dry, but if there are severe corrosion issues, I will use a small amount of anti-seize on the threads, but not on the outside nut taper (which is why the "small amount" so that doesn't get pushed down to the taper area when threading the nut on). Lug nuts are a special case as there are radial dynamic forces in play ***for lug-piloted wheels***, the wheel moves on the studs like a small male gear inside a larger ring gear (the term is hypocylic fretting precession). On small vehicles, the lug nut taper will compress upon meeting the matching taper in the wheel, to keep the lug nut tight. On larger trucks, this does not work, thus the lugs on the left side of the vehicle are left-hand threaded, so that the relative motion tries to tighten them. Also, having a precision center hub interface or dowel pins between the wheel and hub, also reduce the tendency for lug nuts to come off.

"Each bolt and nut (threaded part example: pedal) is lubricated (oil for bolts 5mm and smaller, grease for bolts 6mm and larger) to allow the proper torque to be reached and prevent corrosion. Counterintuitively, lube allows a bolt to be torqued easier and stay tight better than a dry bolt." (my note: INCORRECT)

Threaded fasteners (bolts and nuts) are designed assuming clean, dry bolts (and new surface finish on threads); regular lube (oil or grease) does reduce the coefficient of friction and increases clamping load over spec. Do not do that. But a dry thread can cause corrosion and even galling (especially with softer stainless steel fasteners). I am not advocating a dry bolt. But the wrong lube can cause over-torquing beyond spec. HOWEVER, "Anti-seize" thread lube does not. It specifically contains extremely fine malleable metal powder to counteract the effect of the greasy medium that contains it. Besides lubing, it also counteracts galling much better than grease or oil. Oh and instead of a dry press fit on square taper bottom brackets, anti-seize there will prevent corrosion and ease disassembly without affecting function or causing an excessive press. The gray anti-seize contains aluminum, copper, and graphite and is rated for the range of -80 to 1600F. The copper anti-seize uses all copper and is rated for -30 to 1800F. Since I'm not operating in the arctic, I prefer the copper as it's easier to see and also is electrically and thermally conductive, it's superb for things like antenna and spark plug threads (especially important in an aluminum engine head), and most especially bolts on the exhaust system. The good part about anti-seize is that the bottle comes with a brush applicator, very convenient. The bad part is the stuff is messy, you don't want it on your clothes (unless you want to look like an aircraft mechanic, they use it everywhere). I think copper anti-seize on a black shop apron looks especially cool, but that's just me.

Some *auto racing* bolt manufacturers do advocate super-lube greases on their bolts, but those bolts are ultra-high-strength (above grade 8), and need the lube to achieve above-normal preload tensions to prevent things like head gasket failures on engines running 4 atmospheres of turbo boost.

The aforementioned bike shop also said:

"Thread locker and grease are not mutually exclusive. Bolts with factory applied threadlocker (baked on) should still be lubricated!" (my note: INCORRECT)

In order for the threadlocker adhesive to be effective to increase release torque above "clean and dry", it must adhere to both the bolt and the threaded hole. Any lubricant prevents a bond at one or both of the surfaces. Standard practice at my last company (military application) for threadlocked joints was clean both threads with acetone, dry, and apply threadlocker. I know, every bike mechanic has differing opinions, but if you talk to a fastener engineer (those are the folks that know the most about this stuff), they will confirm the above. (One of my college roomies, in the Air Force, went through the "NASA high reliability soldering course". I thought I knew how to solder. I didn't. Specialized knowledge. Not obvious, looks simple.)

After communicating the above to the head mechanic and owner of said bike shop, he got all huffy, saying all of the following (as though I was advocating dry threads, I was not, I just said that anti-seize accomplishes all; lubes the thread, seals out water, prevents corrosion and galling, AND does not change the coefficient of friction like grease and oil does):

"Tongue in cheek:

Oh, not this age-old argument!

Let's just say that we agreed to disagree.

Typical Engineer telling the poor mechanics how to do it "right". Bicycles are different you see. Comparing them to airplanes is silly. Bicycles are the lowest position on the totem pole of life. They get left outside, uncared for in the weather, etc. Also, most bicycle bolts do not have special coatings to facilitate assembly. On modern bikes most bolts now have backed on blue thread locker (sometimes it is red, green, white or yellow). It is put there by lawyers. Interestingly, somoe bike components also come with grease on the threads. Lube is also particularly important under the bolt or nut head. My less than 5 greater than 6mm rule is to make it easy and quick to work. time=money. Also with oil, you do not need to completely remove the nut or bolt. So I say this to you, You are wrong! Experience trumps book learning. I have 35 years 40 hours a week full time bicycle mechanic experience. I, daily, see the results of no lube or loc-tite only. Corrosion, stuck bolts, etc. Square taper BB spindles are a press fit and should NEVER have lube. They don't need to be cleaned off with acetone, but no lube on the tapers. I have never seen an actual stuck crank on a square spindle. If it is "stuck" the cause is something else, like not lubing the crank extractor threads and bottoming the tool before removal, or super weak melt forged aluminum. BTW, we have both copper and silver anti-seize in the shop at each bench. Silver for stainless steel, copper for titanium."

Let's just say that we agreed to disagree.

Regarding lug nuts and studs, try to avoid lube and leave them dry, but if there are severe corrosion issues, I will use a small amount of anti-seize on the threads, but not on the outside nut taper (which is why the "small amount" so that doesn't get pushed down to the taper area when threading the nut on). Lug nuts are a special case as there are radial dynamic forces in play ***for lug-piloted wheels***, the wheel moves on the studs like a small male gear inside a larger ring gear (the term is hypocylic fretting precession). On small vehicles, the lug nut taper will compress upon meeting the matching taper in the wheel, to keep the lug nut tight. On larger trucks, this does not work, thus the lugs on the left side of the vehicle are left-hand threaded, so that the relative motion tries to tighten them. Also, having a precision center hub interface or dowel pins between the wheel and hub, also reduce the tendency for lug nuts to come off.

Last edited by Duragrouch; 02-26-19 at 07:27 PM.

#65

Senior Member

Lots of varying opinions on this topic. Personally I use peanut butter on everything threaded on my bike and I have never had an issue (except with ants.) Believe me, I have a degree in Germanic Languages and Literature and know what I am talking about. Plus, I stayed in a Holiday Inn Express last night.

#66

Senior Member

Or, you could use anti-seize to prevent seizing. Lube is not anti-seize. WD-40 is not lube. Something is not WD-40.

#68

Senior Member

Join Date: Feb 2019

Location: Indiana

Posts: 592

Bikes: 1984 Fuji Club, Suntour ARX; 2013 Lynskey Peloton, mostly 105 with Ultegra rear derailleur, Enve 2.0 fork; 2020 Masi Giramondo 700c, full Deore with TRP dual piston mech disk brakes

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 324 Post(s)

Liked 81 Times

in

71 Posts

#69

Senior Member

Ok another myth busting moment, WD40 IS A LUBE, read: https://www.wd40.com/cool-stuff/myths-legends-fun-facts

In a pinch, WD-40 can act as lube. I have used it as such when nothing else was available. But it is far from ideal as a lube. Now, I am not one to tout very specialized lubricants, like spending $10 for a small tube of bike chain lube. That's just slick marketing. There are so many fantastic lubes around now at much lower prices. One is automatic transmission fluid, great lube, cheap. I would chose that because I know it's designed for severe use, and is the right viscosity for chain lube in all temperatures, especially synthetic ATF. But now engine oils have gotten down to 0 (zero) weight, which is also the right viscosity, and is designed for high-pressure point contact, so also makes a good bicycle chain lube (and even when thicker, oil was always the lubricant on engine timing chains).

#70

Senior Member

Grease and oil CAN increase the bolt tension/clamping force for a given tightening torque spec, and thus exceed strength limitations for the bolt or what it is clamping, and thus break stuff.

#71

Senior Member

Join Date: Feb 2011

Location: NW Peloponnese, Greece

Posts: 548

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 112 Post(s)

Likes: 0

Liked 25 Times

in

22 Posts

1. Most likely seatpost

2. I used the stem spec because the handlebar was aluminium

3. I meant the derailleur and break wire tightening bolts

I make sure the threads are clean, and don't use any grease on torqued bolts.

If I remember there is a special compound used in industry where you are suppose to applied to threads before torquing.

#72

Senior Member

Thread Starter

Join Date: Feb 2019

Posts: 198

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 92 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Everyone's an expert. Not. I'm a mechanical engineer and even I am not the best expert, but I understand the ones who are, which are, *fastener engineers*, the ones that design (engineer, with calculations and computer modeling) threaded (and other) fasteners and connections. Here's the scoop. I wrote this after seeing on a very well-respected bike repair shop's website, advocating grease and oil on threads:

"Each bolt and nut (threaded part example: pedal) is lubricated (oil for bolts 5mm and smaller, grease for bolts 6mm and larger) to allow the proper torque to be reached and prevent corrosion. Counterintuitively, lube allows a bolt to be torqued easier and stay tight better than a dry bolt." (my note: INCORRECT)

Threaded fasteners (bolts and nuts) are designed assuming clean, dry bolts (and new surface finish on threads); regular lube (oil or grease) does reduce the coefficient of friction and increases clamping load over spec. Do not do that. But a dry thread can cause corrosion and even galling (especially with softer stainless steel fasteners). I am not advocating a dry bolt. But the wrong lube can cause over-torquing beyond spec. HOWEVER, "Anti-seize" thread lube does not. It specifically contains extremely fine malleable metal powder to counteract the effect of the greasy medium that contains it. Besides lubing, it also counteracts galling much better than grease or oil. Oh and instead of a dry press fit on square taper bottom brackets, anti-seize there will prevent corrosion and ease disassembly without affecting function or causing an excessive press. The gray anti-seize contains aluminum, copper, and graphite and is rated for the range of -80 to 1600F. The copper anti-seize uses all copper and is rated for -30 to 1800F. Since I'm not operating in the arctic, I prefer the copper as it's easier to see and also is electrically and thermally conductive, it's superb for things like antenna and spark plug threads (especially important in an aluminum engine head), and most especially bolts on the exhaust system. The good part about anti-seize is that the bottle comes with a brush applicator, very convenient. The bad part is the stuff is messy, you don't want it on your clothes (unless you want to look like an aircraft mechanic, they use it everywhere). I think copper anti-seize on a black shop apron looks especially cool, but that's just me.

Some *auto racing* bolt manufacturers do advocate super-lube greases on their bolts, but those bolts are ultra-high-strength (above grade 8), and need the lube to achieve above-normal preload tensions to prevent things like head gasket failures on engines running 4 atmospheres of turbo boost.

The aforementioned bike shop also said:

"Thread locker and grease are not mutually exclusive. Bolts with factory applied threadlocker (baked on) should still be lubricated!" (my note: INCORRECT)

In order for the threadlocker adhesive to be effective to increase release torque above "clean and dry", it must adhere to both the bolt and the threaded hole. Any lubricant prevents a bond at one or both of the surfaces. Standard practice at my last company (military application) for threadlocked joints was clean both threads with acetone, dry, and apply threadlocker. I know, every bike mechanic has differing opinions, but if you talk to a fastener engineer (those are the folks that know the most about this stuff), they will confirm the above. (One of my college roomies, in the Air Force, went through the "NASA high reliability soldering course". I thought I knew how to solder. I didn't. Specialized knowledge. Not obvious, looks simple.)

After communicating the above to the head mechanic and owner of said bike shop, he got all huffy, saying all of the following (as though I was advocating dry threads, I was not, I just said that anti-seize accomplishes all; lubes the thread, seals out water, prevents corrosion and galling, AND does not change the coefficient of friction like grease and oil does):

"Tongue in cheek:

Regarding lug nuts and studs, try to avoid lube and leave them dry, but if there are severe corrosion issues, I will use a small amount of anti-seize on the threads, but not on the outside nut taper (which is why the "small amount" so that doesn't get pushed down to the taper area when threading the nut on). Lug nuts are a special case as there are radial dynamic forces in play ***for lug-piloted wheels***, the wheel moves on the studs like a small male gear inside a larger ring gear (the term is hypocylic fretting precession). On small vehicles, the lug nut taper will compress upon meeting the matching taper in the wheel, to keep the lug nut tight. On larger trucks, this does not work, thus the lugs on the left side of the vehicle are left-hand threaded, so that the relative motion tries to tighten them. Also, having a precision center hub interface or dowel pins between the wheel and hub, also reduce the tendency for lug nuts to come off.

"Each bolt and nut (threaded part example: pedal) is lubricated (oil for bolts 5mm and smaller, grease for bolts 6mm and larger) to allow the proper torque to be reached and prevent corrosion. Counterintuitively, lube allows a bolt to be torqued easier and stay tight better than a dry bolt." (my note: INCORRECT)

Threaded fasteners (bolts and nuts) are designed assuming clean, dry bolts (and new surface finish on threads); regular lube (oil or grease) does reduce the coefficient of friction and increases clamping load over spec. Do not do that. But a dry thread can cause corrosion and even galling (especially with softer stainless steel fasteners). I am not advocating a dry bolt. But the wrong lube can cause over-torquing beyond spec. HOWEVER, "Anti-seize" thread lube does not. It specifically contains extremely fine malleable metal powder to counteract the effect of the greasy medium that contains it. Besides lubing, it also counteracts galling much better than grease or oil. Oh and instead of a dry press fit on square taper bottom brackets, anti-seize there will prevent corrosion and ease disassembly without affecting function or causing an excessive press. The gray anti-seize contains aluminum, copper, and graphite and is rated for the range of -80 to 1600F. The copper anti-seize uses all copper and is rated for -30 to 1800F. Since I'm not operating in the arctic, I prefer the copper as it's easier to see and also is electrically and thermally conductive, it's superb for things like antenna and spark plug threads (especially important in an aluminum engine head), and most especially bolts on the exhaust system. The good part about anti-seize is that the bottle comes with a brush applicator, very convenient. The bad part is the stuff is messy, you don't want it on your clothes (unless you want to look like an aircraft mechanic, they use it everywhere). I think copper anti-seize on a black shop apron looks especially cool, but that's just me.

Some *auto racing* bolt manufacturers do advocate super-lube greases on their bolts, but those bolts are ultra-high-strength (above grade 8), and need the lube to achieve above-normal preload tensions to prevent things like head gasket failures on engines running 4 atmospheres of turbo boost.

The aforementioned bike shop also said:

"Thread locker and grease are not mutually exclusive. Bolts with factory applied threadlocker (baked on) should still be lubricated!" (my note: INCORRECT)

In order for the threadlocker adhesive to be effective to increase release torque above "clean and dry", it must adhere to both the bolt and the threaded hole. Any lubricant prevents a bond at one or both of the surfaces. Standard practice at my last company (military application) for threadlocked joints was clean both threads with acetone, dry, and apply threadlocker. I know, every bike mechanic has differing opinions, but if you talk to a fastener engineer (those are the folks that know the most about this stuff), they will confirm the above. (One of my college roomies, in the Air Force, went through the "NASA high reliability soldering course". I thought I knew how to solder. I didn't. Specialized knowledge. Not obvious, looks simple.)

After communicating the above to the head mechanic and owner of said bike shop, he got all huffy, saying all of the following (as though I was advocating dry threads, I was not, I just said that anti-seize accomplishes all; lubes the thread, seals out water, prevents corrosion and galling, AND does not change the coefficient of friction like grease and oil does):

"Tongue in cheek:

Oh, not this age-old argument!

Let's just say that we agreed to disagree.

Typical Engineer telling the poor mechanics how to do it "right". Bicycles are different you see. Comparing them to airplanes is silly. Bicycles are the lowest position on the totem pole of life. They get left outside, uncared for in the weather, etc. Also, most bicycle bolts do not have special coatings to facilitate assembly. On modern bikes most bolts now have backed on blue thread locker (sometimes it is red, green, white or yellow). It is put there by lawyers. Interestingly, somoe bike components also come with grease on the threads. Lube is also particularly important under the bolt or nut head. My less than 5 greater than 6mm rule is to make it easy and quick to work. time=money. Also with oil, you do not need to completely remove the nut or bolt. So I say this to you, You are wrong! Experience trumps book learning. I have 35 years 40 hours a week full time bicycle mechanic experience. I, daily, see the results of no lube or loc-tite only. Corrosion, stuck bolts, etc. Square taper BB spindles are a press fit and should NEVER have lube. They don't need to be cleaned off with acetone, but no lube on the tapers. I have never seen an actual stuck crank on a square spindle. If it is "stuck" the cause is something else, like not lubing the crank extractor threads and bottoming the tool before removal, or super weak melt forged aluminum. BTW, we have both copper and silver anti-seize in the shop at each bench. Silver for stainless steel, copper for titanium."

Let's just say that we agreed to disagree.

Regarding lug nuts and studs, try to avoid lube and leave them dry, but if there are severe corrosion issues, I will use a small amount of anti-seize on the threads, but not on the outside nut taper (which is why the "small amount" so that doesn't get pushed down to the taper area when threading the nut on). Lug nuts are a special case as there are radial dynamic forces in play ***for lug-piloted wheels***, the wheel moves on the studs like a small male gear inside a larger ring gear (the term is hypocylic fretting precession). On small vehicles, the lug nut taper will compress upon meeting the matching taper in the wheel, to keep the lug nut tight. On larger trucks, this does not work, thus the lugs on the left side of the vehicle are left-hand threaded, so that the relative motion tries to tighten them. Also, having a precision center hub interface or dowel pins between the wheel and hub, also reduce the tendency for lug nuts to come off.

Some people just seem to have more of an engineering mindset and engineering perspectives.

Would anti-seize be appropriate for all threads found on bikes? If there are exceptions, what if anything should be used instead?

Would threadlocker be better in some cases?

#73

Senior Member

I wanted to express my appreciation for this. Interesting stuff. It's what I was hoping to find with the original post.

Some people just seem to have more of an engineering mindset and engineering perspectives.

Would anti-seize be appropriate for all threads found on bikes? If there are exceptions, what if anything should be used instead?

Would threadlocker be better in some cases?

Some people just seem to have more of an engineering mindset and engineering perspectives.

Would anti-seize be appropriate for all threads found on bikes? If there are exceptions, what if anything should be used instead?

Would threadlocker be better in some cases?

Anti-seize is appropriate for all threads that do not use threadlocking adhesive, nor any with Nylock style nuts (read below), as it might damage the nylon. For metal-to-metal threaded interfaces, even if not needed, it does no harm. Notably, it seals out water and prevents corrosion, whereas using grease to do the same thing will change the torque/tension relationship. However, in areas adjacent to bearings, be careful that the anti-seize compound does not get on the bearings (internally), as the metal particles in it would be very bad for the bearings.

Threadlocker: Most threads on the bike are designed to be "self-locking", in other words, the static friction of the threaded joint, once torqued to specification, exceeds any operating forces wanting to cause the threaded part to unscrew. Note: A "finer" thread helps this (in English threads, higher number of threads per inch (TPI), in Metric, smaller pitch length), this represents a "shallower ramp angle" when analogizing threads with an inclined ramp. Also, some parts have a left-hand thread to also counteract unlocking forces. A "Nylock" nut with nylon insert, and also nuts that are "crimped" to be tight on the bolt threads, are both "prevailing torque nuts", those features meant to help the nut self-lock. Some car parts have a special nut that is just a tiny bit off in thread pitch in order to self-lock. In cases with a free-running (normal) threaded interface, a threadlocking adhesive will provide more resistance to coming undone. Most frequent applications are on bolts and nuts where you cannot tighten them fully as that would impede function. Example: Handle bolts on multi-tools like a Leatherman: Fully tightening would make the handles hard to open, looser torque with dry threads and the bolts constantly come loose, so they use threadlocker adhesive. To disassemble, heat bolt with soldering iron and unscrew while hot. Another example: Bike brake levers, the handle pivot bolt. Too tight and the handle won't release. Usually no thread locker there, but rather a Nylock nut. Another way to lock a loose thread is a cotter pin like on car wheel bearings, or multiple nuts tightened against each other like the wheel bearing cone and lock nut on bicycle wheel bearings (without "cartridge" bearings).

Bonus info!: Most "lock washers" use some design that "cuts" into the underside of the nut or bolt. I had an early Dahon folder with a crank bolt that wouldn't stay tight with normal lockwashers. I ended up using a Nord-Lock, I ran across them in my last job in defense applications, very cool: Two washers against each other with friction outer surfaces, and with the internal mating surface a series of wedges (at a steeper ramp angle than the bolt thread) such that, if the bolt tries to unscrew, the wedges make the washers expand away from each other, tightening the joint. With a Nord-Lock, the crank never came undone again unless I was wrenching on it.

Last edited by Duragrouch; 03-05-19 at 02:31 PM.

#74

Advocatus Diaboli

Join Date: Feb 2015

Location: Wherever I am

Posts: 8,631

Bikes: Merlin Cyrene, Nashbar steel CX

Mentioned: 14 Post(s)

Tagged: 1 Thread(s)

Quoted: 4729 Post(s)

Liked 1,531 Times

in

1,002 Posts

Anti-seize is appropriate for all threads that do not use threadlocking adhesive, nor any with Nylock style nuts (read below), as it might damage the nylon. For metal-to-metal threaded interfaces, even if not needed, it does no harm. Notably, it seals out water and prevents corrosion, whereas using grease to do the same thing will change the torque/tension relationship. However, in areas adjacent to bearings, be careful that the anti-seize compound does not get on the bearings (internally), as the metal particles in it would be very bad for the bearings.

.

.

#75

Senior Member

The rate of speed a bolt is tightened reduces the resulting friction of the threads and therefore changes the resulting clamping force for a given torque applied, what is the suggested tightening speed of bolts? Temperature plays a role as well, even more so with dissimilar metals. How far does someone want to go with this.

https://books.google.com/books?id=GE...torque&f=false

https://books.google.com/books?id=GE...torque&f=false

Last edited by u235; 03-05-19 at 07:36 PM.