How to remove Campagnolo weird circlip?

#1

Newbie

Thread Starter

How to remove Campagnolo weird circlip?

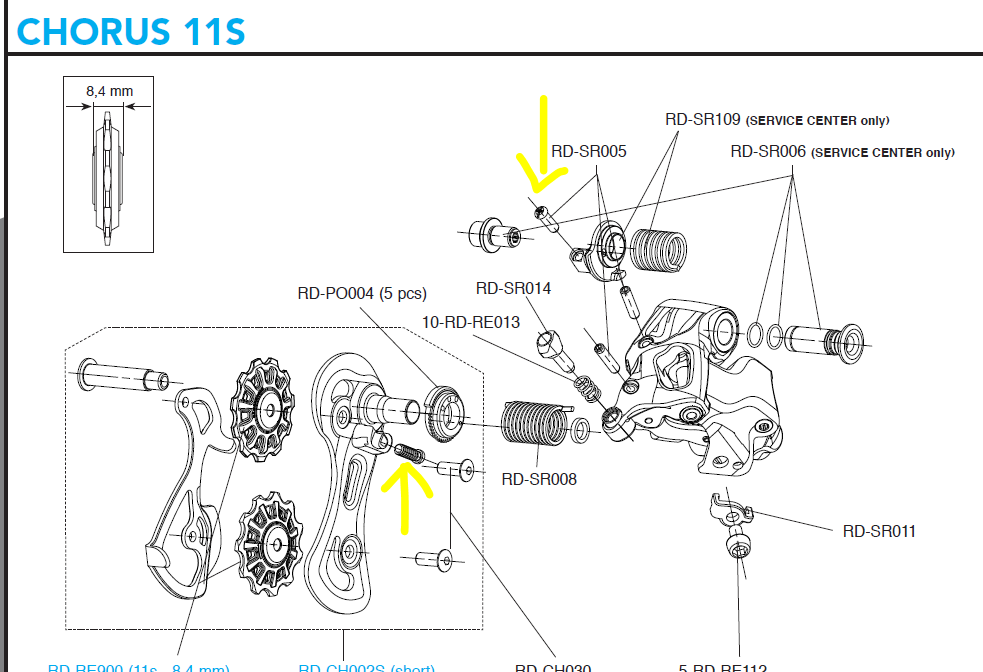

Hi everybody!, I have a very weird circlip on my campagnolo chorus 11v, and dont know how to remove it, its not a classic circlip, here is the picture:

Anybody knows this kind of circlip?

Thanks a lot!!

Anybody knows this kind of circlip?

Thanks a lot!!

#2

Senior Member

Join Date: Jul 2015

Location: NW Oregon

Posts: 2,975

Bikes: !982 Trek 930R Custom, Diamondback ascent with SERIOUS updates, Fuji Team Pro CF and a '09 Comencal Meta 5.5

Mentioned: 15 Post(s)

Tagged: 1 Thread(s)

Quoted: 1299 Post(s)

Liked 739 Times

in

534 Posts

"Service Center Only".. Campy has now chosen to design away it's ease of service.

Apparently the Italian engineers have decided that you are no longer trusted to be a home mechanic.

is there an issue with your derailleur?

Apparently the Italian engineers have decided that you are no longer trusted to be a home mechanic.

is there an issue with your derailleur?

#3

Newbie

Thread Starter

Yes, I need to apply more tension to the spring or replace it. I bought the bicycle second-hand, and it was probably left for a long time with the rear derailleur on the largest cogs, keeping the spring under tension, I know people have removed it (on the forums), but I dont know how its done.

The derailleur its not bad, Im able to use it, but its not 100% perfect as my previous bike (ultegra), I like to have it just perfect!

The derailleur its not bad, Im able to use it, but its not 100% perfect as my previous bike (ultegra), I like to have it just perfect!

#4

Senior Member

Join Date: Feb 2018

Posts: 567

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 241 Post(s)

Liked 232 Times

in

153 Posts

It's a 2 piece snap ring. The upper portion comes off by popping the "ears" towards the thread on the upper pivot bolt, then you can pull the lower portion out.

Is the upper pivot sticking? Some Campag 11 spd RD had issues with the upper pivot sticking if the fixing bolt was over-tightened. Loosen the pivot bolt slightly and it should pivot. I have a Chorus RD on my Ritchey that will stick if the fixing bolt is torqued to the recommended 10 Nm. If it is torqued to 8.5 Nm it works fine, but anything over that and it starts sticking.

Is the upper pivot sticking? Some Campag 11 spd RD had issues with the upper pivot sticking if the fixing bolt was over-tightened. Loosen the pivot bolt slightly and it should pivot. I have a Chorus RD on my Ritchey that will stick if the fixing bolt is torqued to the recommended 10 Nm. If it is torqued to 8.5 Nm it works fine, but anything over that and it starts sticking.

#5

Senior Member

Join Date: Jun 2018

Location: SW Ohio

Posts: 2,397

Mentioned: 93 Post(s)

Tagged: 0 Thread(s)

Quoted: 1104 Post(s)

Liked 1,824 Times

in

878 Posts

One thing to note, the pic you provided isn't of a Campag Chorus 11 RD. They don't have a "B" screw. They have an "H" screw located on the pivot below it. Here is a pic of the H screw, it's located on the lower pivot.

__________________

Last edited by nomadmax; 06-04-23 at 05:22 AM.

#6

I'm good to go!

Join Date: Jul 2017

Location: Mississippi

Posts: 14,984

Bikes: Tarmac Disc Comp Di2 - 2020

Mentioned: 51 Post(s)

Tagged: 0 Thread(s)

Quoted: 6191 Post(s)

Liked 4,807 Times

in

3,316 Posts

Why do you need to increase the tension? If you are using the DR as it's designed to be used, then likely something else is the issue.

If the spring is truly under tensioned, then that would seem like a warranty issue. Springs don't lose tension. Other stuff just gets gummed up or messed up making them less effective. So fix those things first.

If the spring is truly under tensioned, then that would seem like a warranty issue. Springs don't lose tension. Other stuff just gets gummed up or messed up making them less effective. So fix those things first.

#7

Senior Member

Join Date: Apr 2011

Posts: 7,016

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4372 Post(s)

Liked 1,551 Times

in

1,016 Posts

Why do you need to increase the tension? If you are using the DR as it's designed to be used, then likely something else is the issue.

If the spring is truly under tensioned, then that would seem like a warranty issue. Springs don't lose tension. Other stuff just gets gummed up or messed up making them less effective. So fix those things first.

If the spring is truly under tensioned, then that would seem like a warranty issue. Springs don't lose tension. Other stuff just gets gummed up or messed up making them less effective. So fix those things first.

#8

I'm good to go!

Join Date: Jul 2017

Location: Mississippi

Posts: 14,984

Bikes: Tarmac Disc Comp Di2 - 2020

Mentioned: 51 Post(s)

Tagged: 0 Thread(s)

Quoted: 6191 Post(s)

Liked 4,807 Times

in

3,316 Posts

Many seem to think that springs normally lose tension as they age. For the most part I've seen no evidence of such. Other things just get gummed up and require more force. So that is the first thing that should be looked at.

Likes For Iride01:

#9

Senior Member

Join Date: Apr 2011

Posts: 7,016

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4372 Post(s)

Liked 1,551 Times

in

1,016 Posts

I wouldn't expect someone to be using their stuff beyond the design limits. Though I imagine it happens, but it's not the first thing I'd assume just because someone thinks they need to tighten their spring.

Many seem to think that springs normally lose tension as they age. For the most part I've seen no evidence of such. Other things just get gummed up and require more force. So that is the first thing that should be looked at.

Many seem to think that springs normally lose tension as they age. For the most part I've seen no evidence of such. Other things just get gummed up and require more force. So that is the first thing that should be looked at.

People grossly misunderstand what does or does not cause permanent set in springs.

Likes For Kontact:

#10

I'm good to go!

Join Date: Jul 2017

Location: Mississippi

Posts: 14,984

Bikes: Tarmac Disc Comp Di2 - 2020

Mentioned: 51 Post(s)

Tagged: 0 Thread(s)

Quoted: 6191 Post(s)

Liked 4,807 Times

in

3,316 Posts

So you don't think one should ever check for other causes? Just immediately assume it's the spring and nothing else but the spring.

#11

Senior Member

Join Date: Apr 2011

Posts: 7,016

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4372 Post(s)

Liked 1,551 Times

in

1,016 Posts

#13

Newbie

Thread Starter

Before you go too far down the rabbit hole, rotate the clip and verify that there is a second hole to increase pivot spring tension. I've seen newer Campag RDs that don't have that like previous versions. Let me guess, you're having trouble with the top jockey wheel fouling the largest, second to largest, sprockets? First, adjust the H scew to get proper clearance. If that doesn't work, take a link out of the chain to create more tension, that pivot spring isn't worn out or weak.

One thing to note, the pic you provided isn't of a Campag Chorus 11 RD. They don't have a "B" screw. They have an "H" screw located on the pivot below it. Here is a pic of the H screw, it's located on the lower pivot.

One thing to note, the pic you provided isn't of a Campag Chorus 11 RD. They don't have a "B" screw. They have an "H" screw located on the pivot below it. Here is a pic of the H screw, it's located on the lower pivot.

#14

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,696

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5774 Post(s)

Liked 2,571 Times

in

1,423 Posts

BEFORE doing anything, consider whether it's both necessary and possible.

To begin with, springs DO NOT LOSE TENSION when stored under load, so it's highly unlikely that yours has lower strength than a new one would. So, a new spring won't change anything, even if you could find one.

Knowing that, it's rime to try to understand what you problem really is, why, and how to correct it.

To begin with, springs DO NOT LOSE TENSION when stored under load, so it's highly unlikely that yours has lower strength than a new one would. So, a new spring won't change anything, even if you could find one.

Knowing that, it's rime to try to understand what you problem really is, why, and how to correct it.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

Likes For FBinNY:

#15

Senior Member

Join Date: Apr 2011

Posts: 7,016

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4372 Post(s)

Liked 1,551 Times

in

1,016 Posts

#16

Newbie

Thread Starter

BEFORE doing anything, consider whether it's both necessary and possible.

To begin with, springs DO NOT LOSE TENSION when stored under load, so it's highly unlikely that yours has lower strength than a new one would. So, a new spring won't change anything, even if you could find one.

Knowing that, it's rime to try to understand what you problem really is, why, and how to correct it.

To begin with, springs DO NOT LOSE TENSION when stored under load, so it's highly unlikely that yours has lower strength than a new one would. So, a new spring won't change anything, even if you could find one.

Knowing that, it's rime to try to understand what you problem really is, why, and how to correct it.

So with shimano springs they lose tension.

#17

Senior Member

Join Date: Apr 2011

Posts: 7,016

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4372 Post(s)

Liked 1,551 Times

in

1,016 Posts

BEFORE doing anything, consider whether it's both necessary and possible.

To begin with, springs DO NOT LOSE TENSION when stored under load, so it's highly unlikely that yours has lower strength than a new one would. So, a new spring won't change anything, even if you could find one.

Knowing that, it's rime to try to understand what you problem really is, why, and how to correct it.

To begin with, springs DO NOT LOSE TENSION when stored under load, so it's highly unlikely that yours has lower strength than a new one would. So, a new spring won't change anything, even if you could find one.

Knowing that, it's rime to try to understand what you problem really is, why, and how to correct it.

Likes For KerryIrons:

#19

Senior Member

Join Date: Apr 2011

Posts: 7,016

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4372 Post(s)

Liked 1,551 Times

in

1,016 Posts

https://www.thespringstore.com/maxim...mpression.html

#20

Senior Member

Join Date: Mar 2012

Posts: 981

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 506 Post(s)

Likes: 0

Liked 638 Times

in

356 Posts

Yes, they can. I don't know if everyone is just repeating what they heard or left that engineering class early that day. But springs have a working range that can be exceeded.

https://www.thespringstore.com/maxim...mpression.html

https://www.thespringstore.com/maxim...mpression.html

Likes For KerryIrons:

#21

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,696

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5774 Post(s)

Liked 2,571 Times

in

1,423 Posts

Too wrong to ignore

First because the poster is very active and keeps reminding folks of his "credentials", and also because it plays into a commonly accepted myth.

So, first problem is that he's "correcting" something I never said. The OP was worried about a spring being weak because it was stored a long time under load, my post specifically addressed that, and only that (time), consideration, so the "simply not true" simply isn't supported by what follows. I repeat, springs do not weaken by being stored under load. If they did, cars would settle while sitting in driveways, bridges would sag, and so on. This is an old myth and needs to be debunked.

Secondly. Though It's not on point, it's true that a spring can be deformed by overloading. However, that will not change it's spring constant, only the "zero point". In the case of an RD spring with over 10 turns, it would take a staggering amount of distortion (even were it possible) to move that zero point enough to make any noticeable difference.

Third, the post contradicts itself. First he says that springs can deform if overloaded, lists the one way to prevent that. Does he not know that RDs already already meet his preventative condition? EVERY RD has stops to prevent cage rotation beyond a limited arc. They do so the RD won't wind up when the wheel is removed. Those same limits (combined with the spring's design) ensure that it's impossible to overload the spring in normal use. One would have to remove the stops, and manually rotate the cage a few turns with the intent of destroying the spring.

None of this would matter, but my initial "corrected" post was simply intended to help the OP avoid wasting time and money "fixing" something that isn't broken.

-----------------------------

To the OP ---- do not waste your money on the spring, it's fine. There are other places to look, including the possibility of dried lube, or other sources of friction. Also consider that Cage take up is more about chain length and geometry than spring tension. The biggest factor is the position of the idler pulley. At 6 o'clock it's pulling directly back on the chain and does a decent job tensioning it. However with a longish chain and/or a small sprocket combination the idler swings up to 8 o'clock or so where it's pulling almost tangentially to the chain and therefore not adding much tension. So if you want a tighter chain, the first step is to see if your gear combination will allow a shorter chain. Alternatively, take the RD apart, and drill a new spring hole into either the cage or RD body to move the zero point and increasing the tension in the working range.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

Likes For FBinNY:

#22

Senior Member

Join Date: Apr 2011

Posts: 7,016

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4372 Post(s)

Liked 1,551 Times

in

1,016 Posts

Of course they can. When they are pushed beyond their elastic limit they can take a set and be effectively weakened. But that has nothing to do with the case at hand. Derailleur springs will not get weak in normal operation because they never get pushed that far. Storing a derailleur in "high" or "low" position will not affect their springs. The only way age will affect them would be through corrosion.

That coil spring is preloaded, which means that it is well into its elastic range. So I would assume that certain shifts pull the spring briefly past the elastic limit, causing them to deform with time.

That may not have anything to do with the OPs bike, and he has the ability to adjust A tension so it doesn't matter. I just don't think saying that these springs can't be worn is counterproductive to diagnosis.

FBinNY My apologies for not reading your post more carefully.

Likes For Kontact:

#23

I'm good to go!

Join Date: Jul 2017

Location: Mississippi

Posts: 14,984

Bikes: Tarmac Disc Comp Di2 - 2020

Mentioned: 51 Post(s)

Tagged: 0 Thread(s)

Quoted: 6191 Post(s)

Liked 4,807 Times

in

3,316 Posts

Likes For Iride01:

#24

Newbie

Thread Starter

I have seen literally hundreds of Shimano DA and Ultegra RDs on well ridden but cared for road bikes with standard gearing where the B spring is so worn it will allow the upper pulley to rest against the 26t cog with the screw all the way in, despite the fact that the initial installation would only require a few turns to clear.

That coil spring is preloaded, which means that it is well into its elastic range. So I would assume that certain shifts pull the spring briefly past the elastic limit, causing them to deform with time.

That may not have anything to do with the OPs bike, and he has the ability to adjust A tension so it doesn't matter. I just don't think saying that these springs can't be worn is counterproductive to diagnosis.

FBinNY My apologies for not reading your post more carefully.

That coil spring is preloaded, which means that it is well into its elastic range. So I would assume that certain shifts pull the spring briefly past the elastic limit, causing them to deform with time.

That may not have anything to do with the OPs bike, and he has the ability to adjust A tension so it doesn't matter. I just don't think saying that these springs can't be worn is counterproductive to diagnosis.

FBinNY My apologies for not reading your post more carefully.

Because of that previous experience, is why I think that this campy derailleur has the same problem.

#25

Senior Member

Join Date: Apr 2011

Posts: 7,016

Mentioned: 41 Post(s)

Tagged: 0 Thread(s)

Quoted: 4372 Post(s)

Liked 1,551 Times

in

1,016 Posts

Thanks for your reply, thats exactly what happened to an old 105 rear derailleur, I experienced that, and have to repair it by myself by drilling a little hole 2mm apart from the original, was enough to get the proper tension again, and have the derailleur working perfect.

Because of that previous experience, is why I think that this campy derailleur has the same problem.

Because of that previous experience, is why I think that this campy derailleur has the same problem.