Alternative to S&S couplings?

#1

Mike

Thread Starter

Join Date: May 2006

Location: Cayman Islands

Posts: 54

Bikes: Cignal Silverado MTB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Alternative to S&S couplings?

Is there any other way to make a take-apart bicycle frame besides using S&S couplings? Being on a tropical island, by the time I ship my bike to the US, pay customs duty, etc the cost is about $450US, not including the cost of purchasing and installing the couplers. I like my cro-moly frame but it costs me an extra $200 every time I go off-island!

I have been looking at the folding bikes (Brompton, et al) and think their coupling methods are a little crude, but can be easily done by me. Anyone has any good ideas for a simple but solid coupler?

FYI - I have a full machine (lathes, mills, bandsaws, presses) shop along with TIG, MIG and oxy-acetylene torches at my disposal.

My current idea two custom made steel flanges that are brazed or silver soldered to the cut tubes and bolted together in 3 places. I can make a sketch if anyone needs a better diagram. Tubes will insert about 2 inches into each flange. Bolt holes will be threaded for tight, accurate fit as well as use of nylock nuts on protruding threadsfor added security. Holes will be drilled using an indexing fixture. Flange dia will be 1" greater than tube dia. Thickness will be 1/8"( might need more). Bolts will be 5/16 NF Grade 5.

Open to comments, thoughts, other ideas, etc.

Thanks

Mike in

I have been looking at the folding bikes (Brompton, et al) and think their coupling methods are a little crude, but can be easily done by me. Anyone has any good ideas for a simple but solid coupler?

FYI - I have a full machine (lathes, mills, bandsaws, presses) shop along with TIG, MIG and oxy-acetylene torches at my disposal.

My current idea two custom made steel flanges that are brazed or silver soldered to the cut tubes and bolted together in 3 places. I can make a sketch if anyone needs a better diagram. Tubes will insert about 2 inches into each flange. Bolt holes will be threaded for tight, accurate fit as well as use of nylock nuts on protruding threadsfor added security. Holes will be drilled using an indexing fixture. Flange dia will be 1" greater than tube dia. Thickness will be 1/8"( might need more). Bolts will be 5/16 NF Grade 5.

Open to comments, thoughts, other ideas, etc.

Thanks

Mike in

Last edited by mjww; 07-29-06 at 05:41 PM.

#2

Senior Member

Join Date: Mar 2006

Posts: 2,018

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 6 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

I once saw a bike, Sears logo on the side, that had the frame cut in the middle. 2 plates were welded onto the frame ends. It was held together with 2 wingnuts, believe it or not. Not sure if it was a good idea, but I did see it, I sware it is true.

#3

Senior Member

Join Date: Jul 2005

Location: Mid-Atlantic

Posts: 912

Bikes: A bunch

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 6 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Ritchey and Dahon make a breakaway frame that separates at the seattube-toptube joint and at the downtube-bottom-bracket. Very small-volume couplers.

#4

Senior Member

Join Date: Aug 2005

Location: Pittsburgh, PA

Posts: 33,656

Bikes: '96 Litespeed Catalyst, '05 Litespeed Firenze, '06 Litespeed Tuscany, '20 Surly Midnight Special, All are 3x10. It is hilly around here!

Mentioned: 39 Post(s)

Tagged: 0 Thread(s)

Quoted: 2026 Post(s)

Likes: 0

Liked 1,095 Times

in

741 Posts

Bike Friday makes folding/ packable bikes that have a very good reputation. For a full size conventional frame, the S&S couplers are the only proven technology.

Your experimental design sounds interesting but I'm glad you will be doing the testing, not me.

Your experimental design sounds interesting but I'm glad you will be doing the testing, not me.

#5

Decrepit Member

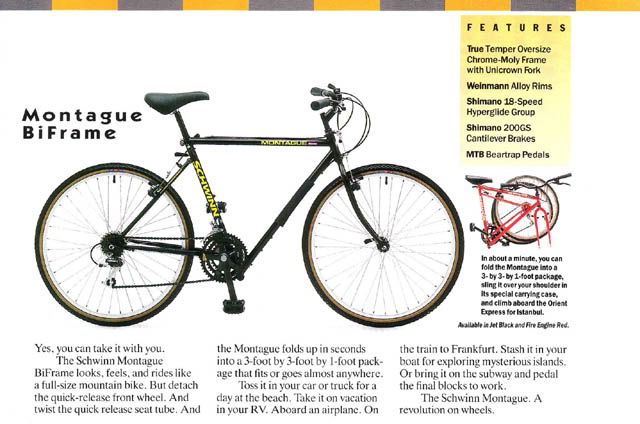

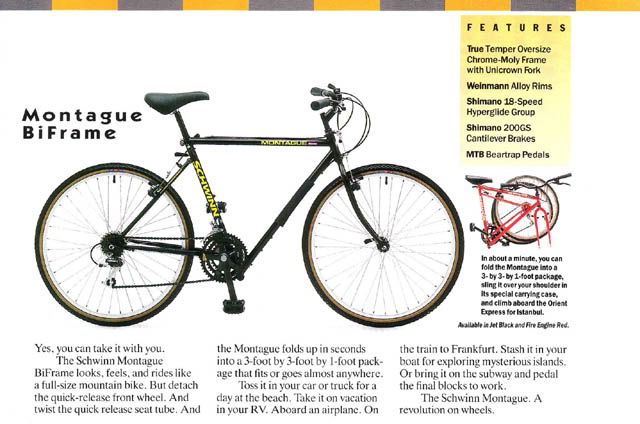

Uhh.. The early 90s Montague M1000 BiFrames are nice and sturdy, fold and unfold quickly, and are reasonably light.

#6

Dilettante

Join Date: Jan 2002

Location: Chicago

Posts: 71

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 2 Times

in

2 Posts

There's the slingshot design, which replaces the bottom tube with a cable under tension. Not only do these fold, the cable provides suspension -- otherwise hard to get on a road bike. However, I don't see the road bike on their web site any more:

https://www.slingshotbikes.com/showro...s/foldtech.cfm

https://www.slingshotbikes.com/showro...s/foldtech.cfm

__________________

--

Oldest bike: 1970 Schwinn Twinn Tanndem

--

Oldest bike: 1970 Schwinn Twinn Tanndem

#7

hunter, gatherer

Join Date: Feb 2005

Posts: 1,183

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

since you have the tools and the will, building your own bike would probably be a good way to go and an interesting experiment too.. i'm sure you'll still have to ship some materials on island though..

unfortunately, S&S won't sell their couplers to builders without adequate liability insurance

I myself have considered building a travelling bike based on the proven and respected frame design of the raleigh twenty.. the bike fridays also use a similar frame, but have a different hinge.

on the twenty, the bike is held together with only two bolts.. the hinge is just two plates in the main tube (similar to what you were thinking)

with the main ('wing') bolt removed, the bike folds by pivoting on the other bolt.. with both bolts out the frame comes apart into two pieces...

here are some pics for clarity:

(i stole one from sheldon brown and the others i dont remember)

unfortunately, S&S won't sell their couplers to builders without adequate liability insurance

I myself have considered building a travelling bike based on the proven and respected frame design of the raleigh twenty.. the bike fridays also use a similar frame, but have a different hinge.

on the twenty, the bike is held together with only two bolts.. the hinge is just two plates in the main tube (similar to what you were thinking)

with the main ('wing') bolt removed, the bike folds by pivoting on the other bolt.. with both bolts out the frame comes apart into two pieces...

here are some pics for clarity:

(i stole one from sheldon brown and the others i dont remember)

#8

Mike

Thread Starter

Join Date: May 2006

Location: Cayman Islands

Posts: 54

Bikes: Cignal Silverado MTB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I myself have considered building a travelling bike based on the proven and respected frame design of the raleigh twenty.. the bike fridays also use a similar frame, but have a different hinge.

Thanks for the detailed photos.

My idea is along the same line but allows greater insertion of the frame tube in the flange. I would rely on the clamping power of 3 bolts at each connection. One 5/16 bolt and nut at correct torque gives close to 1,500 lbs of clamping force. 3 would be way over 4,000 lbs. at each joint.

Another possibility is to machine a clamp that would hold the flange together. Like this "C=" The "c" would be split in two halves and enclapsulate the flanges, the "=". A bit more complicated and not sure if it is any stronger

Somewhere I have a top tube of old cro-moly frame that I think I'll go and test. Make the coupling, braze it on and see how the tube fails when I apply pressure along it.

That should keep me busy for a week or so!

Mike

Thanks for the detailed photos.

My idea is along the same line but allows greater insertion of the frame tube in the flange. I would rely on the clamping power of 3 bolts at each connection. One 5/16 bolt and nut at correct torque gives close to 1,500 lbs of clamping force. 3 would be way over 4,000 lbs. at each joint.

Another possibility is to machine a clamp that would hold the flange together. Like this "C=" The "c" would be split in two halves and enclapsulate the flanges, the "=". A bit more complicated and not sure if it is any stronger

Somewhere I have a top tube of old cro-moly frame that I think I'll go and test. Make the coupling, braze it on and see how the tube fails when I apply pressure along it.

That should keep me busy for a week or so!

Mike

#9

Junior Member

Join Date: Sep 2006

Location: Brooklyn, NY

Posts: 16

Bikes: Road

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Originally Posted by mjww

My current idea two custom made steel flanges that are brazed or silver soldered to the cut tubes and bolted together in 3 places. I can make a sketch if anyone needs a better diagram. Tubes will insert about 2 inches into each flange. Bolt holes will be threaded for tight, accurate fit as well as use of nylock nuts on protruding threadsfor added security. Holes will be drilled using an indexing fixture. Flange dia will be 1" greater than tube dia. Thickness will be 1/8"( might need more). Bolts will be 5/16 NF Grade 5.

Open to comments, thoughts, other ideas, etc.

Thanks

Mike in

Open to comments, thoughts, other ideas, etc.

Thanks

Mike in

I'd like to do the same mechanism but don't know how to solder the bike tubes and don't know anybody in NY to do this work.

Mike, it'd be interesting to know if you implemented you idea, to learn how you did it and see the pics.

Last edited by Vector; 11-16-06 at 09:10 PM.

#10

Senior Member

Have you done the trig on the triangle if you are thinking of a double-triangle frame? A tube inserted into the horizontal top tube by 2" and a tube inserted into a downtube by 2" might make things a little difficult to fit together because they are headed into two different directions. I might be wrong, but it would be worth checking. I think that is one of the reasons why the S&S works so well, that the joining pieces don't have very far to "insert" when they are coupled together.

You might take the principle of the seat tube clamp into your consideration. I have seen pictures of a mini-bicycle that dismantles by undoing similar clamps for the seat and chainstays.

The framebuilding forum might have some better ideas.

EDIT: Just had a look back through my Favs and here is that bike! I must get around to making one just like it one day

You might take the principle of the seat tube clamp into your consideration. I have seen pictures of a mini-bicycle that dismantles by undoing similar clamps for the seat and chainstays.

The framebuilding forum might have some better ideas.

EDIT: Just had a look back through my Favs and here is that bike! I must get around to making one just like it one day

#12

Clever Title Here...

Join Date: Mar 2006

Location: New Joisey

Posts: 134

Bikes: Trek 420, Habanero Custom Team Issue

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

In the recent Excel Sports catalog, I found this Ritchey Break Away "full" size road frame. They have another Ti/Carbon model too. The printed catalog has better detail of the couplers than what the online catalog shows.

#13

Senior Member

Join Date: Mar 2003

Location: Beaufort, South Carolina, USA and surrounding islands.

Posts: 8,521

Bikes: Cannondale R500, Motobecane Messenger

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 11 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

I managed to test ride a Ritchey Break Away while on vacation in Texas. It rode as well as any aluminum framed road bike.

#14

Making a kilometer blurry

Originally Posted by DieselDan

I managed to test ride a Ritchey Break Away while on vacation in Texas. It rode as well as any aluminum framed road bike.

The Ritchey Break-Away technology actually looks like something that could be pretty easily home-brewed with the right set of skills and some well sized tubes.

#15

Senior Member

Join Date: Aug 2005

Location: Pittsburgh, PA

Posts: 33,656

Bikes: '96 Litespeed Catalyst, '05 Litespeed Firenze, '06 Litespeed Tuscany, '20 Surly Midnight Special, All are 3x10. It is hilly around here!

Mentioned: 39 Post(s)

Tagged: 0 Thread(s)

Quoted: 2026 Post(s)

Likes: 0

Liked 1,095 Times

in

741 Posts

Originally Posted by mjww

Is there any other way to make a take-apart bicycle frame besides using S&S couplings? FYI - I have a full machine (lathes, mills, bandsaws, presses) shop along with TIG, MIG and oxy-acetylene torches at my disposal.

#16

Senior Member

Join Date: Feb 2006

Posts: 675

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Have you tried to buy the S&S couplers? You could call around and see if you can get a pair to install yourself. They are listed as $200 add on to a new bike. You should be able to get the bare couplers cheaper than that, or for that price if you can convince them that you can install them.

#17

Senior Member

Join Date: Aug 2005

Location: Pittsburgh, PA

Posts: 33,656

Bikes: '96 Litespeed Catalyst, '05 Litespeed Firenze, '06 Litespeed Tuscany, '20 Surly Midnight Special, All are 3x10. It is hilly around here!

Mentioned: 39 Post(s)

Tagged: 0 Thread(s)

Quoted: 2026 Post(s)

Likes: 0

Liked 1,095 Times

in

741 Posts

Originally Posted by yes

Have you tried to buy the S&S couplers? You could call around and see if you can get a pair to install yourself. They are listed as $200 add on to a new bike. You should be able to get the bare couplers cheaper than that, or for that price if you can convince them that you can install them.

#18

Decrepit Member

I think the biggest reason S&S sells only to qualified frame builders is the very real fear of liability lawsuits if installed by someone who doesn't know what he's doing, and a serious accident results.

#19

Senior Member

Join Date: May 2006

Location: Bootiful Brooklyn, NY

Posts: 2,023

Bikes: GT Edge for the road/Specialized Hopper (well the frame and the bb, everything else is new) for the dirt

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

there are any number of full suspension mountain bikes where the rear triangle is a relatively uncomplicated disengagement from the front...

(OP doesn't say it must be a road bike...)

(OP doesn't say it must be a road bike...)

#20

hunter, gatherer

Join Date: Feb 2005

Posts: 1,183

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

that's correct

to 'qualify' you have to show them proof of your insurance

to 'qualify' you have to show them proof of your insurance

Originally Posted by Scooper

I think the biggest reason S&S sells only to qualified frame builders is the very real fear of liability lawsuits if installed by someone who doesn't know what he's doing, and a serious accident results.

#21

Senior Member

Originally Posted by Hambone

(OP doesn't say it must be a road bike...)

#22

Mike

Thread Starter

Join Date: May 2006

Location: Cayman Islands

Posts: 54

Bikes: Cignal Silverado MTB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Solution found

After about 6 months of testing, I have a solution to the coupler problem. Use the following ideas and pictures at your own risk

It ended up being quite simple. The first test was on wife's Trek mountain bike (where the first 4 pictures came from). Then I did it to my randonneuring bike. My bike has been ridden about 600k with absolutely no movement of the clamps (tested with a micrometer). Feels the same as a non-cut bike. The attached photos are pretty well self explanatory. Nuts and bolts are torqued to specifications and there has been absolutely no movement of the joints, even though the inside surfaces are coated with vaseline as a rust inhibitor. More powder coating will solve that problem.

The two connecting tubes are about 6" long and are cromoly from Aircraft Spruce. Same for the little tubes that the bolts go through. Inside diameter is approximately the same as the outside diameter of the frame tube. Total cost for the connectors was under $20. The two brazed bolts are for a third water cage for anotherwater bottle or an REI cage rocket storage pod for batteries for the lights.

Had the whole thing powdercoated (after my failed paint job). Please disregard the cooler on the front rack. A little test to see the effect of carrying a 9"x9"x6" cube of ice in a cooler as I ride - lots of cold water to drink!

The next step is to build a travel case for it, get/make some cable disconnects, dynamo, etc.

It ended up being quite simple. The first test was on wife's Trek mountain bike (where the first 4 pictures came from). Then I did it to my randonneuring bike. My bike has been ridden about 600k with absolutely no movement of the clamps (tested with a micrometer). Feels the same as a non-cut bike. The attached photos are pretty well self explanatory. Nuts and bolts are torqued to specifications and there has been absolutely no movement of the joints, even though the inside surfaces are coated with vaseline as a rust inhibitor. More powder coating will solve that problem.

The two connecting tubes are about 6" long and are cromoly from Aircraft Spruce. Same for the little tubes that the bolts go through. Inside diameter is approximately the same as the outside diameter of the frame tube. Total cost for the connectors was under $20. The two brazed bolts are for a third water cage for anotherwater bottle or an REI cage rocket storage pod for batteries for the lights.

Had the whole thing powdercoated (after my failed paint job). Please disregard the cooler on the front rack. A little test to see the effect of carrying a 9"x9"x6" cube of ice in a cooler as I ride - lots of cold water to drink!

The next step is to build a travel case for it, get/make some cable disconnects, dynamo, etc.

Last edited by mjww; 07-08-07 at 10:13 AM.

#23

Elitist Troglodyte

Join Date: Jun 2006

Location: Dallas

Posts: 6,925

Bikes: 03 Raleigh Professional (steel)

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 2 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

This seems like a perfect question for the Framebuilders forum!

__________________

Stupidity got us into this mess - why can't it get us out?

- Will Rogers

Stupidity got us into this mess - why can't it get us out?

- Will Rogers

#24

Senior Member

Join Date: May 2006

Location: Bootiful Brooklyn, NY

Posts: 2,023

Bikes: GT Edge for the road/Specialized Hopper (well the frame and the bb, everything else is new) for the dirt

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

really cool. I'm thinking add a little nipple/bump inside the coupling and a dimple in the tube to keep everything aligned. But you said nothing moved so I guess that might be unnecessary.