#1

I was talking to a friend today and he said his Novara was from the eighties and that was when chrome moly was first used in bike frames. My answer was a resounding no and I told him my custom made frame from 1980 was made with Tange No.2 and predates his Tange Infinity frame by years.

So, can the collective wisdom of C&V enlighten me as to when chrome moly tubing was first used in bike frames?

So, can the collective wisdom of C&V enlighten me as to when chrome moly tubing was first used in bike frames?

#2

Pretty sure that 4130 CrMo has been around for at least 70 years, probably longer. Reynolds 531 is not CrMo , it contains Manganese as a main alloy ingredient but it is fairly comparable to CrMo and 531 dates back to the 1930's.

#3

actually 531 is older than the '30s, just didn't see use in bicycle frames until (about) 1928 or so. There certainly were frames made from chromium-molybdenum steel well before "the eighties", plenty of Columbus frames from the '60s (maybe earlier, too) were made of it, certainly some early Schwinns, too .

But it's an interesting trivia question: when was the first use of chrome-moly steel in a bike frame that can be documented.

But it's an interesting trivia question: when was the first use of chrome-moly steel in a bike frame that can be documented.

#4

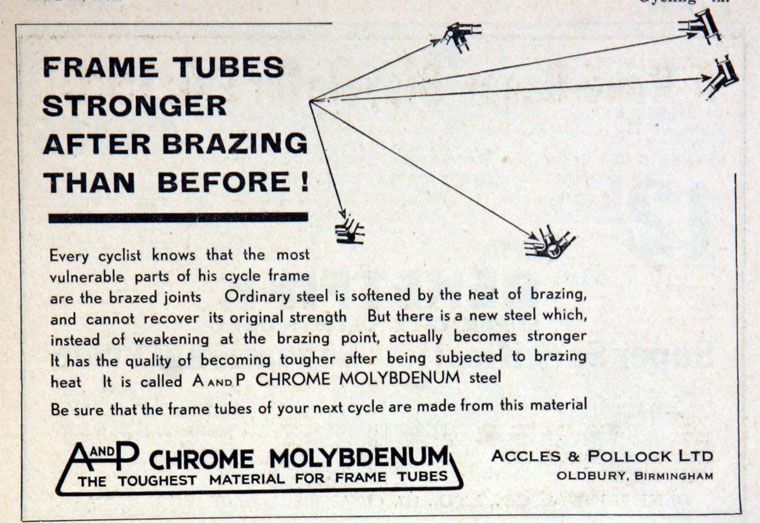

In the thirties, Accles & Pollock chromium-molybdenum tubing was widely used by high end British framebuilders.

This ad is from 1931.

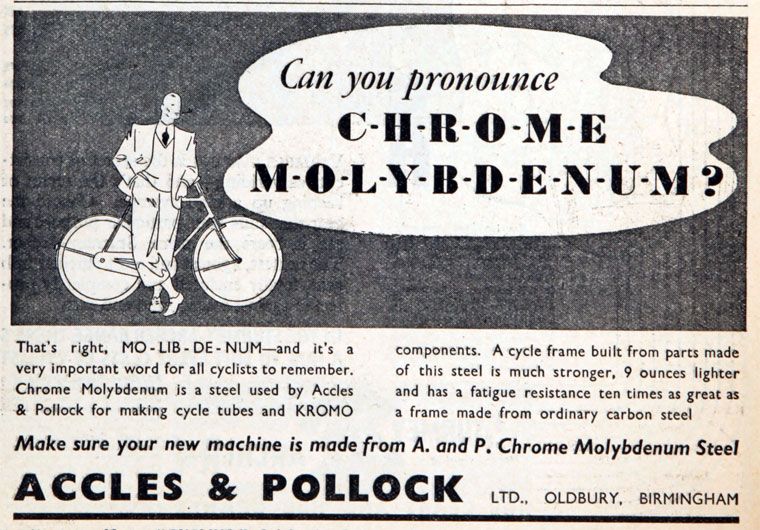

This one for Accles & Pollock "KROMO" brand chromoly is from 1936.

This ad is from 1931.

This one for Accles & Pollock "KROMO" brand chromoly is from 1936.

#5

Reynolds 531 was introduced in 1936, although Reynolds had "H.M." (High Manganese) labeled tubing earlier.

1937 531 catalog cover.

High Manganese (pre-531) decal.

1937 531 catalog cover.

High Manganese (pre-531) decal.

#6

Just as with titanium and carpet fiber bikes over the past 30 years ago, racing bike frames have always been near the forefront of available technical developments. Aside from military aircraft, there are few other common applications that so profoundly benefit from the latest tubing technology and materials as do bikes. I recently read that briefly around 1890, before internal combustions engins became sufficiently powerfull and reliable, track racing bicycles actually held the world speed record as the fastest vehicle, definitly cutting edge tech for the day.

#7

T-Mar , 03-23-13 03:45 AM

Senior Member

T-Mar

Senior Member

close

- Join DateNov 2004

- Posts:23,223

Likes: 0

Liked 3,036 Times

in

1,874 Posts

Quote:

CCM also used it on their Flyer models, starting in 1931 and their Flyte model which was introduced in 1938. It's the earliest CrMo tubeset that I'm aware of.Originally Posted by Scooper

In the thirties, Accles & Pollock chromium-molybdenum tubing was widely used by high end British framebuilders...

#8

T-Mar , 03-23-13 03:55 AM

Senior Member

T-Mar

Senior Member

close

- Join DateNov 2004

- Posts:23,223

Likes: 0

Liked 3,036 Times

in

1,874 Posts

Quote:

I'm pretty sure that the fastest vehicles during that period were steam locomotives. When Mile-A-Minute Murphy did his record breaking ride in 1899, he drafted behind a train.Originally Posted by GrayJay

...I recently read that briefly around 1890, before internal combustions engins became sufficiently powerfull and reliable, track racing bicycles actually held the world speed record as the fastest vehicle, definitly cutting edge tech for the day.

#9

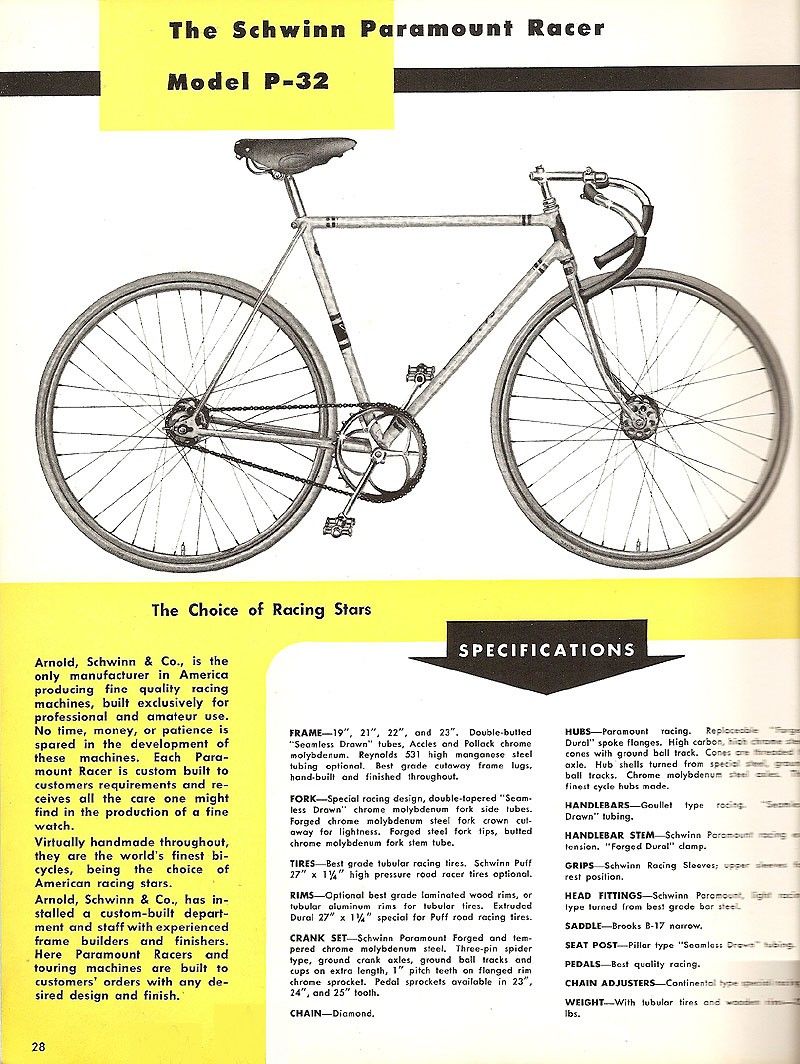

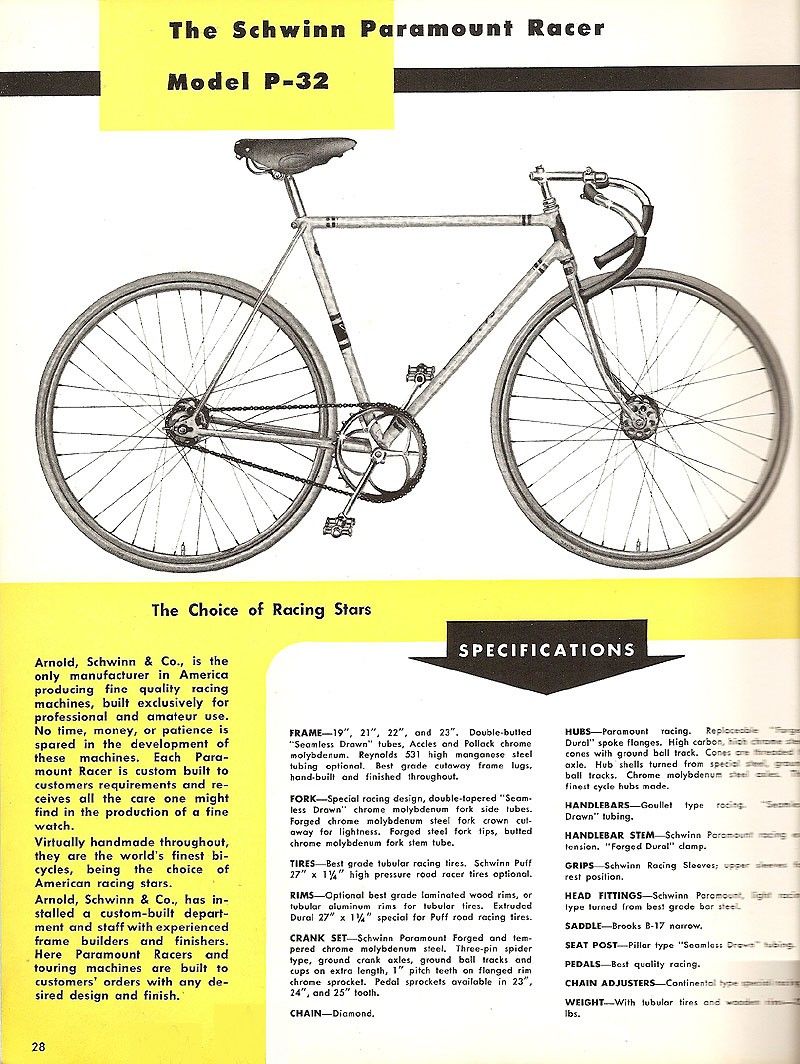

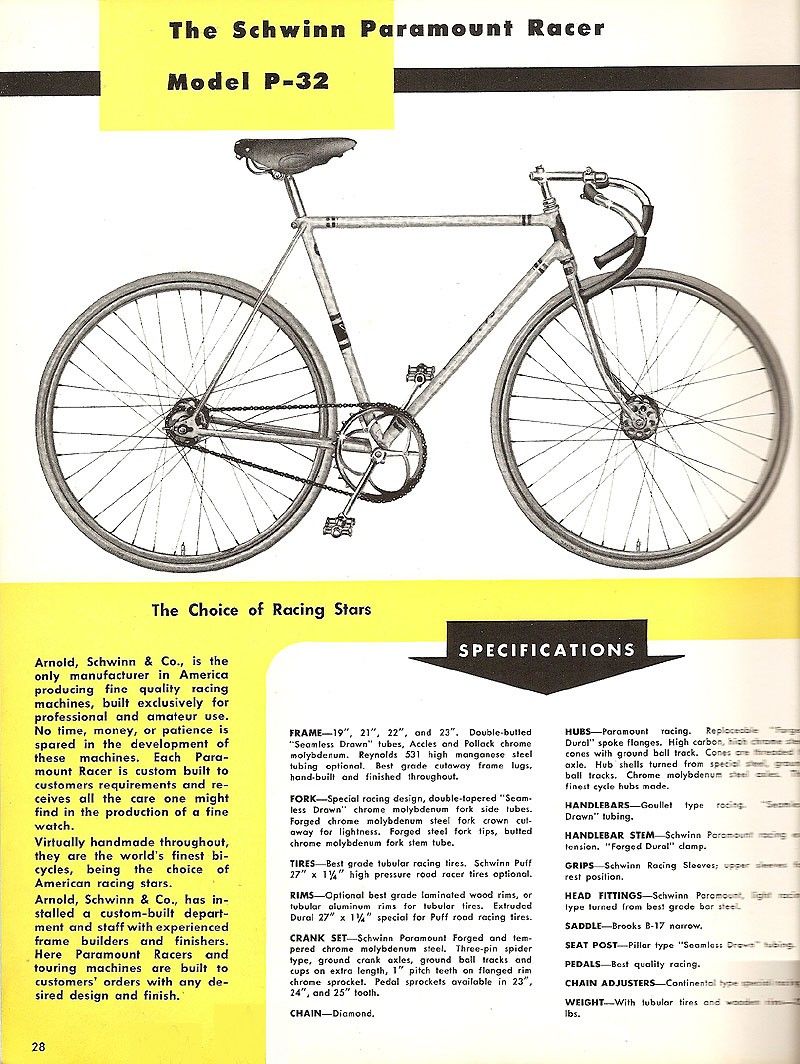

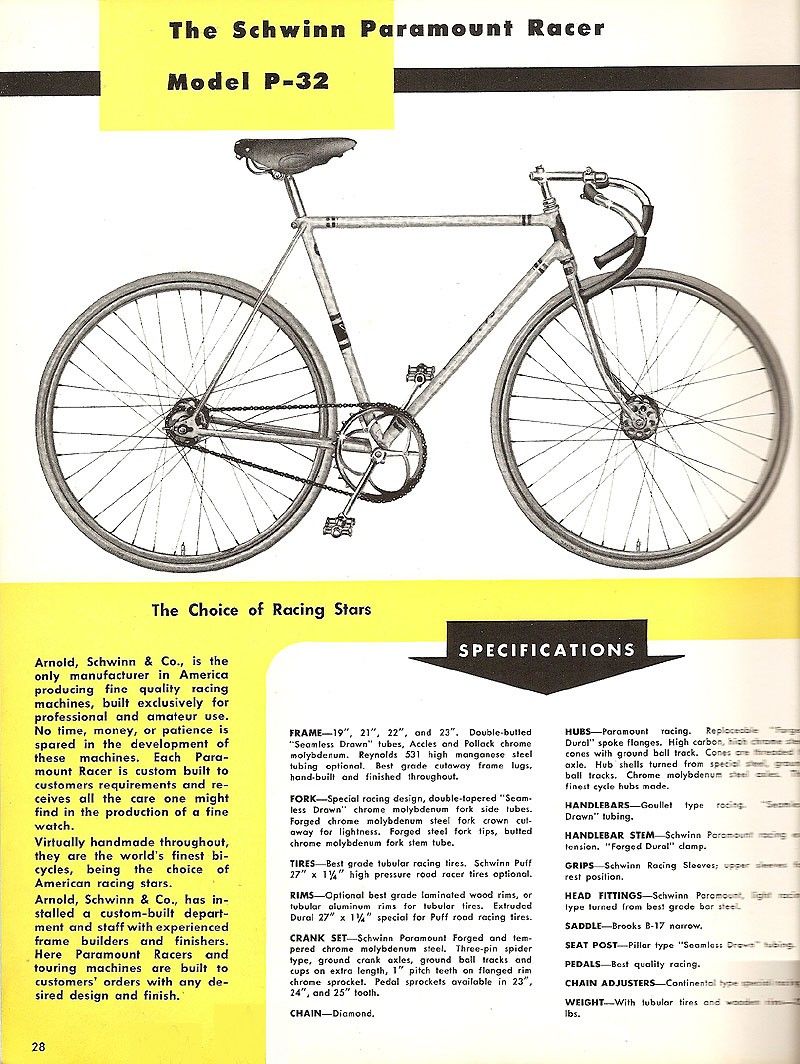

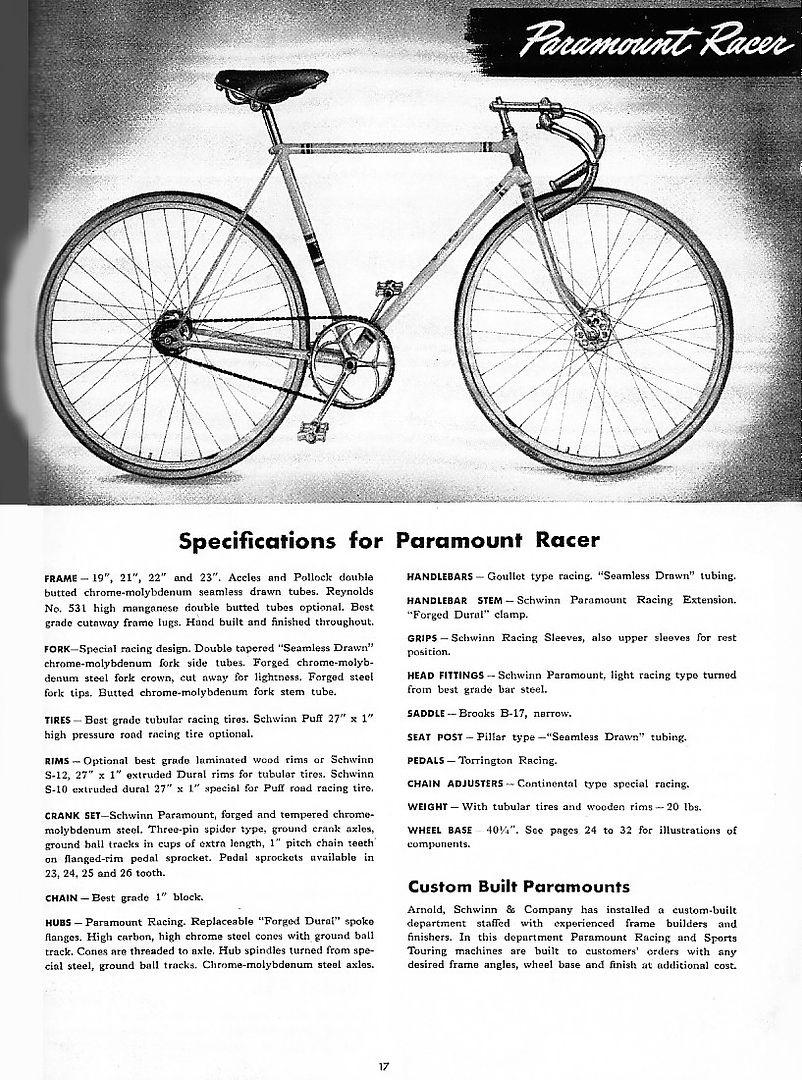

Another little tidbit is that Schwinn offered a choice of Accles & Pollock chromoly or Reynolds 531 tubing in the early post-war Paramounts.

#10

JohnDThompson , 03-23-13 08:55 AM

Old fart

JohnDThompson

Old fart

close

- Join DateNov 2004

- LocationAppleton WI

- Posts:24,784

Liked 3,400 Times

in

1,934 Posts

IIRC, Columbus started out making chrome-moly tubing in the 1920s for the aircraft industry and only later branched out to provide bicycle frame tubing.

#11

Quote:

1937 531 catalog cover.

High Manganese (pre-531) decal.

Stan has corrected me. I mis-read the Reynolds timeline, but there they state that the first 531 tubing was introduced in 1935. They were making butted steel tubing for bicycles, as early as 1902 (or maybe as early as 1898, as that's the date the "Patent Tubing Company Ltd." was formed according to the timeline, but that's not clearly tubing for bicycle frames).Originally Posted by Scooper

Reynolds 531 was introduced in 1936, although Reynolds had "H.M." (High Manganese) labeled tubing earlier.1937 531 catalog cover.

High Manganese (pre-531) decal.

I'd forgotten about Accles and Pollock tubing...how could anyone forget a name like that?

Anyhow, to go back to the OP's question: it would seem that the first use of chrome-moly tubing would have to something made from A&P's Kromo tubing, which was in use for bicycle frames as early as the '30s, including the CCMs that T-Mar mentioned, but an earlier example may come from a UK builder such as Hobbs of Barbican, Thanet or Rattray's "Flying Scot".

At least that's where I'd be looking for the final word in "who's first?".

#12

T-Mar , 03-23-13 10:51 AM

Senior Member

T-Mar

Senior Member

close

- Join DateNov 2004

- Posts:23,223

Likes: 0

Liked 3,036 Times

in

1,874 Posts

Quote:

According to their own literature, Columbus started manufacturing bicycle tubing in 1919. Butted tubesets were introduced in 1930. I haven't seen any literature that specifically mentions when when they started using CrMo. I don't know if they are dancing around the issue or it's just lost in translation. Originally Posted by JohnDThompson

IIRC, Columbus started out making chrome-moly tubing in the 1920s for the aircraft industry and only later branched out to provide bicycle frame tubing.

As for it's use in aircraft, it was not introduced until sometime after the war. During the Great War, most aircraft used wooden frames, with Fokker being the notable exception. They used carbon steels, typically 1010, 1015 and 1018 depending on the year and application.

#13

Sixty Fiver , 03-23-13 10:52 AM

Bicycle Repair Man !!!

Quote:

Prior to internal combustion and improved trains, the fastest vehicle on earth was a tandem bicycle and although I cannot find the reference right now, I believe the distance ridden to test this was 800 miles.Originally Posted by GrayJay

I recently read that briefly around 1890, before internal combustions engins became sufficiently powerfull and reliable, track racing bicycles actually held the world speed record as the fastest vehicle, definitly cutting edge tech for the day.

By the turn of the century passenger trains were able to sustain straight run speeds of 70 mph with average speeds being in the 40's... prior to super heated steam engines the average train plodded along at an average of 20 mph.

#14

Cross Creek , 03-23-13 11:16 AM

Senior Member

An interesting connection is that chromoly steel tubing made superheated steam boilers and turbines possible/safe/reliable (on land and sea). Stainless steel based on chromoly steels did the same for jet engines and later, knives.

#15

uncle uncle , 03-23-13 11:30 AM

Senior Member

uncle uncle

Senior Member

close

- Join DateAug 2010

- Locationsouth kansas america

- Posts:1,910

Liked 234 Times

in

140 Posts

Not to put too fine a point on it, but the info on Reynolds 531 is a bit off topic, since it's steel strengthened with manganese, not chrome molybdenum. To add to the original posters question, why did chromo become so available and affordable in the 1980's? It seems that chromo made inroads to a level of bicycles just a step above entry level. Was it just the competition between the various bicycle companies? Did it become the buzzword for the market at that time, something a novice bicycle purchaser would recognize as a "quality" product?

#16

Quote:

Excellent point there about chromo in frames just above entry level. Originally Posted by uncle uncle

To add to the original posters question, why did chromo become so available and affordable in the 1980's? It seems that chromo made inroads to a level of bicycles just a step above entry level. Was it just the competition between the various bicycle companies? Did it become the buzzword for the market at that time, something a novice bicycle purchaser would recognize as a "quality" product?

Was it only in the 1980s that chromoly became widely used in frames that were less than top of the line? I remember reading about tubing like Columbus SL, Ishiwata and Tange No.2 towards the end of the 70s, but can't remember if they were only in high end frames. Did tube manufacturing technology advance by the mid-70s to bring costs down to a level that it was cost-effective for use in mass-produced frames for a mid-level market?

I have a Fuji Finest with a serial number and other clues such as the fork crown which dates it to 1971. The label on the seatpost says 'Chrome Moly" and I think that at that time the Finest was not the top line Fuji (in their entire line, not just the US market), maybe a step or two down.

Thank you all for for your responses. This is becoming very interesting reading indeed.

#17

Oldpeddaller , 03-23-13 06:35 PM

Senior Member

Quote:

Brilliant!Originally Posted by Scooper

Another little tidbit is that Schwinn offered a choice of Accles & Pollock chromoly or Reynolds 531 tubing in the early post-war Paramounts.

Any chance you could check the original and advise the stated weight of that P32 on the catalogue? - Just interested.

#18

DiegoFrogs , 03-23-13 06:49 PM

Senior Member

I would think that CroMo in lower end bicycles in the late '70s and '80s is probably related to its low cost, high quality production in Japan at the time.

#19

Jeff Wills , 03-23-13 07:17 PM

Insane Bicycle Mechanic

Jeff Wills

Insane Bicycle Mechanic

close

- Join DateMar 2008

- Locationother Vancouver

- Posts:9,837

Liked 704 Times

in

376 Posts

Quote:

In the late '70's, lower-line bikes were lugged hi-tensile steel, with lugged straight-gauge cro-mo one step up. The oddballs of the era were the Schwinn Super Sport/Sports Tourer/Superior, which were fillet-brazed chrome-moly.Originally Posted by DiegoFrogs

I would think that CroMo in lower end bicycles in the late '70s and '80s is probably related to its low cost, high quality production in Japan at the time.

#20

Quote:

Any chance you could check the original and advise the stated weight of that P32 on the catalogue? - Just interested.

"WEIGHT - With tubular tires and wooden rims - 20 lbs." (this illustration is from the 1948 catalog; the color illustration above is from 1950)Originally Posted by Oldpeddaller

Brilliant!Any chance you could check the original and advise the stated weight of that P32 on the catalogue? - Just interested.

#21

Quote:

+1, back then the Japanese makers (BTW, you could get an "American Eagle" AKA Nishiki about then with the same un-named chrome-moly tubing for even less than a Fuji) were in competition to establish market share against the European marques, and offering "quality" tubing to a quality-conscious public was smart. Later on Tange was offered in a #5 tubeset which was heavy, plain-gauge tubing, but at even a lower pricepoint.Originally Posted by DiegoFrogs

I would think that CroMo in lower end bicycles in the late '70s and '80s is probably related to its low cost, high quality production in Japan at the time.

Funny that way back in 1931 A&P were hard at work educating the public as to the quality of their Kromo tubing, and how to pronounce "molybdenum"! Great scans, thanks to Scooper!!

#22

T-Mar , 03-24-13 10:41 AM

Senior Member

T-Mar

Senior Member

close

- Join DateNov 2004

- Posts:23,223

Likes: 0

Liked 3,036 Times

in

1,874 Posts

Quote:

The mid-1980s inroad of chromium-molybdenum into the upper entry level market and lower mid-range market was made possible by the development of reliable welding techniques for tubing. Fabricating the tubes from a flat sheet that was then rolled and welded was far cheaper than drawing a butted, seamless tube. There was a huge inlux of seamed, butted, CrMo tubesets like Tange 900, 1000 and Infinity, Ishiwata's EXO series, Reynolds 501 and Columbus matrix/Cromor. It should be noted that Matrix/Cromor is not a traditional seamed tubeset, in that that it was cold drawn from a seamed blank, but it was cheaper than a seamless tube.Originally Posted by uncle uncle

To add to the original posters question, why did chromo become so available and affordable in the 1980's? It seems that chromo made inroads to a level of bicycles just a step above entry level. Was it just the competition between the various bicycle companies? Did it become the buzzword for the market at that time, something a novice bicycle purchaser would recognize as a "quality" product?

Edit: During the 1970s boom, seamed tubing was considered inferior and there were a number of reported failures. Consequently, high end bicycles used only seamless tubing. However, the reliability of the mid-1980s sets overcame this stigma. When True Temper came onto the scene, all their sets used seamed tubing.

#23

old's'cool , 03-24-13 11:09 AM

curmudgineer

old's'cool

curmudgineer

close

- Join DateDec 2009

- LocationChicago SW burbs

- Posts:4,417

Liked 112 Times

in

70 Posts

Thanks T-Mar, you're a fount of knowledge!

#24

onespeedbiker , 03-24-13 04:21 PM

Retro Grouch

Reynolds butted CrMo (501) came along in the 80's. Pretty much all the large manufactures started building Tig welded 501 frames as the process is much faster than lugs and some say create a stronger weld do to the short heating and cool off times, with the advantage of lighter tubing of the interior butting for medium level bicycles..

#25

Citoyen du Monde , 03-24-13 04:43 PM

Senior Member

I believe that Mannesmann was making Cr-Mo tubing in the 20's already. Columbus used Mannesmann tubing as the basis for most of their tubing. I have had a few bikes with Mannesmann tubing from the 30's-40's that were very light and more than likely Cr-Mo.