QR-Through Axle Conversion

#1

Junior Member

Thread Starter

Join Date: Jan 2019

Posts: 19

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 3 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

QR-Through Axle Conversion

Hi guys, New to the forum.

Forgive me if this has already been covered, but I've had a good search and couldn't find anything.

I've got a Marin Pine Mountain (steel rigid 27.5+ bike) that I'd like to convert from the uncommon stock Boost QR to a proper through axle front and rear.

This has stemmed from the fact that i want to run some 29er XC wheels for a multi day gravel ride later in the year. My other bikes are all boost through axles so I'd rather keep the same axle standard across the stable.

Now I can TIG weld and don't mind rigging up a frame jig to make sure everything's all lined up properly, but before I get designing and commission a local machine shop to knock up the dropouts, is there any off the shelf units that i'd be able use / modify to fit?

Forgive me if this has already been covered, but I've had a good search and couldn't find anything.

I've got a Marin Pine Mountain (steel rigid 27.5+ bike) that I'd like to convert from the uncommon stock Boost QR to a proper through axle front and rear.

This has stemmed from the fact that i want to run some 29er XC wheels for a multi day gravel ride later in the year. My other bikes are all boost through axles so I'd rather keep the same axle standard across the stable.

Now I can TIG weld and don't mind rigging up a frame jig to make sure everything's all lined up properly, but before I get designing and commission a local machine shop to knock up the dropouts, is there any off the shelf units that i'd be able use / modify to fit?

#2

Banned

If you must ask...

show us your home shop you will do this in... ..

probably better: given Wheels are so much larger, Just buy the bike you want..

probably better: given Wheels are so much larger, Just buy the bike you want..

#3

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,387

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,687 Times

in

2,510 Posts

I looked up that bike on their site, looks like it's aluminum now? on edit: steel, I was fooled by some giant welds. In any event, it had a fairly strange dropout, which didn't look like it could be easily replaceable by anything I'm familiar with. If you post a couple of pictures of the dropouts it would be easier.

Any self-respecting machine shop is going to charge you so much for dropouts that you will be better off selling this frame and getting one that matches your wheels. And that's before any cost to put them on, which is not inconsequential if you want to do a good job.

Any self-respecting machine shop is going to charge you so much for dropouts that you will be better off selling this frame and getting one that matches your wheels. And that's before any cost to put them on, which is not inconsequential if you want to do a good job.

Last edited by unterhausen; 01-10-19 at 06:18 AM.

#5

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,387

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,687 Times

in

2,510 Posts

I was thinking that possibly a Paragon DR 2037 could be retrofitted, but I think the caliper might hit the seat stay and the chainstay on those bikes appear to be really large. A post mount adapter would be needed.

#7

Senior Member

#8

Senior Member

Stupid question: Why not just swap the hub end caps to QR? That conversion usually takes less than 5 minutes on compatible hubs.

#10

Senior Member

Join Date: Aug 2012

Location: Seattle

Posts: 507

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 103 Post(s)

Liked 144 Times

in

88 Posts

I agree with David this is your easy answer. As an example, the SP 15mm TA dynohub comes with a 'inner axle' that just slides into the 15mm axle and then takes a standard QR. Having a machine shop turn inner axles (or end caps) with the 9mm through hole with face and lips to grab the dropouts would be easy/cheaper than cutting, welding and repainting the frame and fork ends.

__________________

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com

#12

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,387

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,687 Times

in

2,510 Posts

I think he has an older bike with boost QR, not the pic that I posted which is TA. However, in the absence of input from the OP, I assumed the dropouts were similar. If the hub is convertible, that would be the best path by far. Rear TA is not much of an advantage on the rear of a hardtail, which is why manufacturers stuck to saving $1 per frame with QR. Now they have come to realize that their customers would prefer TA, so the QR is mostly gone.

#13

Senior Member

Join Date: Aug 2012

Location: Seattle

Posts: 507

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 103 Post(s)

Liked 144 Times

in

88 Posts

[QUOTE=LMCol;20739697

My other bikes are all boost through axles so I'd rather keep the same axle standard across the stable.

[/QUOTE]

First off, I will say I don't know why keeping the same axle standard across bikes would be a goal. The benefits seem extremely small.

But given that goal, what I am (and I think David is) suggesting is the TA wheels when used on the Pine Mtn would be boost TA wheels (that he wants to standardize on) with *adaptors* to use the QR that matches the frame. The sleeve or end caps or whatever machined adaptor bits would need to be removed - thereby converting them back to TA wheels - if those wheels were to be moved to a different TA frame.

For this Pine Mtn frame, those little machined bits would allow a TA wheelset to fit onto a QR frameset with a lot less hassle than replacing dropouts, paint etc.

The caveat is that I don't have all the QR/TA/Boost standards memorized so, if there's a combo that has QR Boost dropouts spaced narrower than TA Boost, then that would be a challenge but, probably not insurmountable with new endcaps.

My other bikes are all boost through axles so I'd rather keep the same axle standard across the stable.

[/QUOTE]

First off, I will say I don't know why keeping the same axle standard across bikes would be a goal. The benefits seem extremely small.

But given that goal, what I am (and I think David is) suggesting is the TA wheels when used on the Pine Mtn would be boost TA wheels (that he wants to standardize on) with *adaptors* to use the QR that matches the frame. The sleeve or end caps or whatever machined adaptor bits would need to be removed - thereby converting them back to TA wheels - if those wheels were to be moved to a different TA frame.

For this Pine Mtn frame, those little machined bits would allow a TA wheelset to fit onto a QR frameset with a lot less hassle than replacing dropouts, paint etc.

The caveat is that I don't have all the QR/TA/Boost standards memorized so, if there's a combo that has QR Boost dropouts spaced narrower than TA Boost, then that would be a challenge but, probably not insurmountable with new endcaps.

__________________

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com

Last edited by duanedr; 01-12-19 at 03:37 AM. Reason: clarity

#14

Junior Member

Thread Starter

Join Date: Jan 2019

Posts: 19

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 3 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Sorry for the late reply. I tried posting pictures, but being a new forum member I'm not allowed until I've got 10 forum posts. The model I have is the red/silver version from either 2016 or 2017.

27.5+ and 29 have roughly the same rolling diameter, so wheelsize shouldn't be an issue. As for the home shop, its just a single garage, but I manage. I could quite easily buy a bike better suited to the job, but where's the fun in that?

They Look nice, thanks for the info.

Very good point, that would be a hell of a lot easier. I guess i'm just looking at excuses to fabricate stuff.

The QR boost uses the same rotor/spoke flange positons as TA Boost, but the actual axle length is shorter (141 vs 148 iirc), which may throw a spanner in the works. I guess it'd make sense to see if there's any wheelsets out there that have swappable cups between the two standards, i just presumed that there wouldn't be any as the QR boost standard is pretty much none-existent.

First off, I will say I don't know why keeping the same axle standard across bikes would be a goal. But given that goal, what I am (and I think David is) suggesting is the TA wheels when used on the Pine Mtn would be boost TA wheels (that he wants to standardize on) with *adaptors* to use the QR required by the frame. The sleeve or end caps or whatever machined adaptor bits would need to be removed if those wheels were to be moved to a different TA frame - thereby converting them back to TA wheels. For this Pine Mtn frame, those little machined bits would allow a TA wheelset to fit onto a QR frameset with a lot less hassle than replacing dropouts, paint etc.

The caveat is that I don't have all the QR/TA/Boost standards memorized so, if there's a combo that has QR Boost dropouts spaced narrower than TA Boost, then that would be a challenge but, probably not insurmountable with new endcaps.

The caveat is that I don't have all the QR/TA/Boost standards memorized so, if there's a combo that has QR Boost dropouts spaced narrower than TA Boost, then that would be a challenge but, probably not insurmountable with new endcaps.

The QR boost uses the same rotor/spoke flange positons as TA Boost, but the actual axle length is shorter (141 vs 148 iirc), which may throw a spanner in the works. I guess it'd make sense to see if there's any wheelsets out there that have swappable cups between the two standards, i just presumed that there wouldn't be any as the QR boost standard is pretty much none-existent.

#15

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,387

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,687 Times

in

2,510 Posts

it really depends on the hub manufacturer. My Salsa came with a convertible hub on the front. Not sure about the rear. Wouldn't surprise me

Someone on mtbr said that industry 9 has conversion axle parts on some of their hubs

Someone on mtbr said that industry 9 has conversion axle parts on some of their hubs

Last edited by unterhausen; 01-12-19 at 05:08 AM.

#16

Senior Member

Join Date: Aug 2012

Location: Seattle

Posts: 507

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 103 Post(s)

Liked 144 Times

in

88 Posts

Ah, totally different question! As with gambling, don't bet more than you are willing to lose.

Replacing the dropouts isn't the hardest thing but you're talking about completely changing the configuration. Also, Through Axles require a pretty high level of precision to work and place the wheel in plane with the frame. This is hard when heating and cooling metals. With vertical/horizontal dropouts, the builder can fix small misalignment in the rear end by filing a bit here, and filling in over there. If a TA rear end isn't dead on when it cools, it doesn't work and you can't really fix it. Experienced builders use TA all the time in steel but, it's probably not the best place for a neophyte to start.

At a minimum, I would find an old steel MTB and try it before I would attempt on a frame I care much about.

Replacing the dropouts isn't the hardest thing but you're talking about completely changing the configuration. Also, Through Axles require a pretty high level of precision to work and place the wheel in plane with the frame. This is hard when heating and cooling metals. With vertical/horizontal dropouts, the builder can fix small misalignment in the rear end by filing a bit here, and filling in over there. If a TA rear end isn't dead on when it cools, it doesn't work and you can't really fix it. Experienced builders use TA all the time in steel but, it's probably not the best place for a neophyte to start.

At a minimum, I would find an old steel MTB and try it before I would attempt on a frame I care much about.

__________________

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com

#17

Senior Member

Join Date: Jan 2013

Location: South Jersey

Posts: 2,262

Mentioned: 18 Post(s)

Tagged: 0 Thread(s)

Quoted: 713 Post(s)

Liked 796 Times

in

473 Posts

If it were me, I'd probably leave it as is. If I were determined to change it to thru axle, I would use the round thru axle dropouts from Paragon. I would use the current axle slot to center the correct size hole saw and cut out a round section of the existing dropout. You can then fixture the new round thru axle dropouts and weld them into the cutouts.

DR2065: Stainless Steel 1-1/2" OD x 1.1" Rear, 12 mm Hub

DR2065: Stainless Steel 1-1/2" OD x 1.1" Rear, 12 mm Hub

#18

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,387

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,687 Times

in

2,510 Posts

I had thought about Breezer style dropout, but didn't think of using parts of the old dropout. That's a good idea. But I agree with Duanedr, don't do it on this bike, mess around with (an)other one(s)

#20

Junior Member

Thread Starter

Join Date: Jan 2019

Posts: 19

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 3 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Right, i can post some images now my post count's up.

Here's the bike in question:

and here's what the dropouts look like.

I've looked at a few options, both jigging the whole rear end up and slotting in a set of larger paragon dropouts including new mech hanger and caliper posts, but that's pretty risky.

I like dsaul's idea with the barrel style dropouts and using the existing ones essentially as a drilling guide. But by going one step further and using the existing dropouts to also constrain the bolt through dropouts in the axial direction, it eliminates another variable.

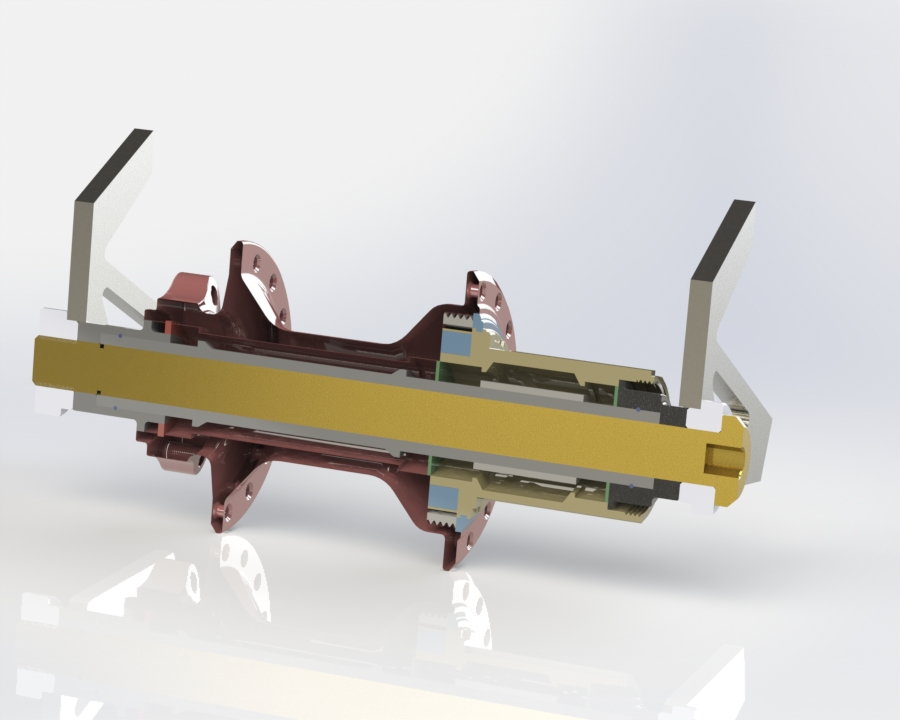

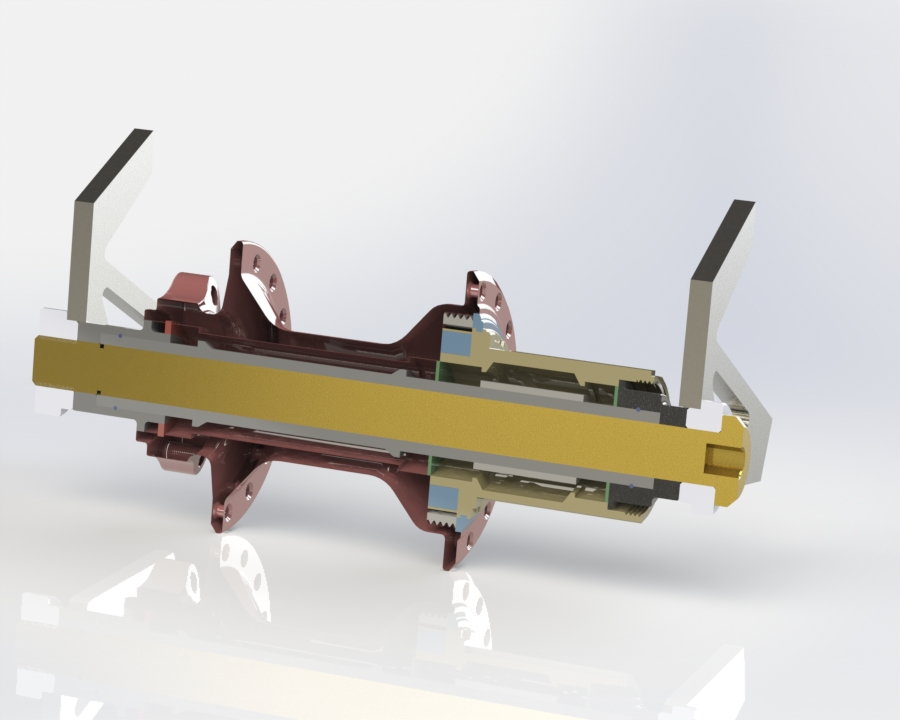

I've mocked the process up in solidworks:

Current 141x9 setup

Trimmed, with boost hub in place (still not 100% whether a hole saw & drilling guide would be better, or just carefully mark and remove material with a die grinder)

New through axle dropouts in place. I can get these knocked up fairly cheaply, super simple turning. Obviously one side is threaded and the other is 12mm through.

And cross section

The dropouts are 5mm thick, I need an additional 3.5mm per side for a boost hub, so my inserts will be inset by 1.5mm.

The only thing i'm concerned about is the mech hanger. It's an integrated design and pretty close to where i'll be cutting and welding, so i'll have to be super careful not to distort it. At least being steel, I can always massage it back into place.

Here's the bike in question:

and here's what the dropouts look like.

I've looked at a few options, both jigging the whole rear end up and slotting in a set of larger paragon dropouts including new mech hanger and caliper posts, but that's pretty risky.

I like dsaul's idea with the barrel style dropouts and using the existing ones essentially as a drilling guide. But by going one step further and using the existing dropouts to also constrain the bolt through dropouts in the axial direction, it eliminates another variable.

I've mocked the process up in solidworks:

Current 141x9 setup

Trimmed, with boost hub in place (still not 100% whether a hole saw & drilling guide would be better, or just carefully mark and remove material with a die grinder)

New through axle dropouts in place. I can get these knocked up fairly cheaply, super simple turning. Obviously one side is threaded and the other is 12mm through.

And cross section

The dropouts are 5mm thick, I need an additional 3.5mm per side for a boost hub, so my inserts will be inset by 1.5mm.

The only thing i'm concerned about is the mech hanger. It's an integrated design and pretty close to where i'll be cutting and welding, so i'll have to be super careful not to distort it. At least being steel, I can always massage it back into place.

#21

Senior Member

Join Date: Aug 2012

Location: Seattle

Posts: 507

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 103 Post(s)

Liked 144 Times

in

88 Posts

With those dropouts, I agree you could probably get away with what you've modeled. I might braze the outer white spacer ring directly to the dropout with Silver or maybe TIG if that's what you've got. I can imagine losing one out on the trail when changing a tire. That would be a bad scenario. If you have the ability to fixture it on a mill and use a hole saw, I agree that might be a good option. I wouldn't worry about the hanger, they can be aligned pretty readily.

I would still try this on something you don't care about tossing away before I cut into a bike a cared about.

Post pics if you take this on!

Post pics if you take this on!

__________________

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com

https://www.flickr.com/photos/54319503@N05/

https://www.draper-cycles.com

#22

Junior Member

Thread Starter

Join Date: Jan 2019

Posts: 19

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 3 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

With those dropouts, I agree you could probably get away with what you've modeled. I might braze the outer white spacer ring directly to the dropout with Silver or maybe TIG if that's what you've got. I can imagine losing one out on the trail when changing a tire. That would be a bad scenario. If you have the ability to fixture it on a mill and use a hole saw, I agree that might be a good option. I wouldn't worry about the hanger, they can be aligned pretty readily.

I would still try this on something you don't care about tossing away before I cut into a bike a cared about.

Post pics if you take this on!

Post pics if you take this on!

I'd love to do the frame mod on a mill, but the only favours I can call in are all CNC mills that don't have the space for a whole frame. I think carefully measured, scribed and fettled by hand might be my best option.

I'll definitely follow up with pics

#23

Junior Member

Thread Starter

Join Date: Jan 2019

Posts: 19

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 3 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I don't suppose anyone knows where i might find a proper detailed writeup of axle standards? i'm finding it impossible to find anything that includes hub cup diameters, axle tolerance classes etc. I've got the the dims of my existing axles and dropouts, but it'd be nice to double check everything with proper specs.

#24

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,387

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,687 Times

in

2,510 Posts

the good news about standards is that everyone can make up their own.

I don't think I have seen any standards, but Paragon machine has STEPS files of some of their dropouts.

I don't think I have seen any standards, but Paragon machine has STEPS files of some of their dropouts.

#25

Senior Member

Join Date: Nov 2014

Location: Eugene, Oregon, USA

Posts: 27,547

Mentioned: 217 Post(s)

Tagged: 0 Thread(s)

Quoted: 18353 Post(s)

Liked 4,502 Times

in

3,346 Posts

Your diagram seems to show slotted dropouts. However, I thought the through axles simply had a hole on the left and a threaded hole on the right.

However, what I might consider is taking your existing rear dropouts and expanding the slots to fit the through axle.

Then welding on caps on the outside for your through axle.

Getting everything aligned perfectly might be a pain (including hole depth to the end of the axles) but you'd end up with a very strong joint with essentially both the slotted dropout PLUS the drilled and threaded through axle.

Your cost would be some scrap metal, and essentially only labor, without any parts to buy. Also less to screw up with frame alignment.

However, what I might consider is taking your existing rear dropouts and expanding the slots to fit the through axle.

Then welding on caps on the outside for your through axle.

Getting everything aligned perfectly might be a pain (including hole depth to the end of the axles) but you'd end up with a very strong joint with essentially both the slotted dropout PLUS the drilled and threaded through axle.

Your cost would be some scrap metal, and essentially only labor, without any parts to buy. Also less to screw up with frame alignment.