Design direction for first framebuild

#1

Newbie

Thread Starter

Design direction for first framebuild

Hey everyone,

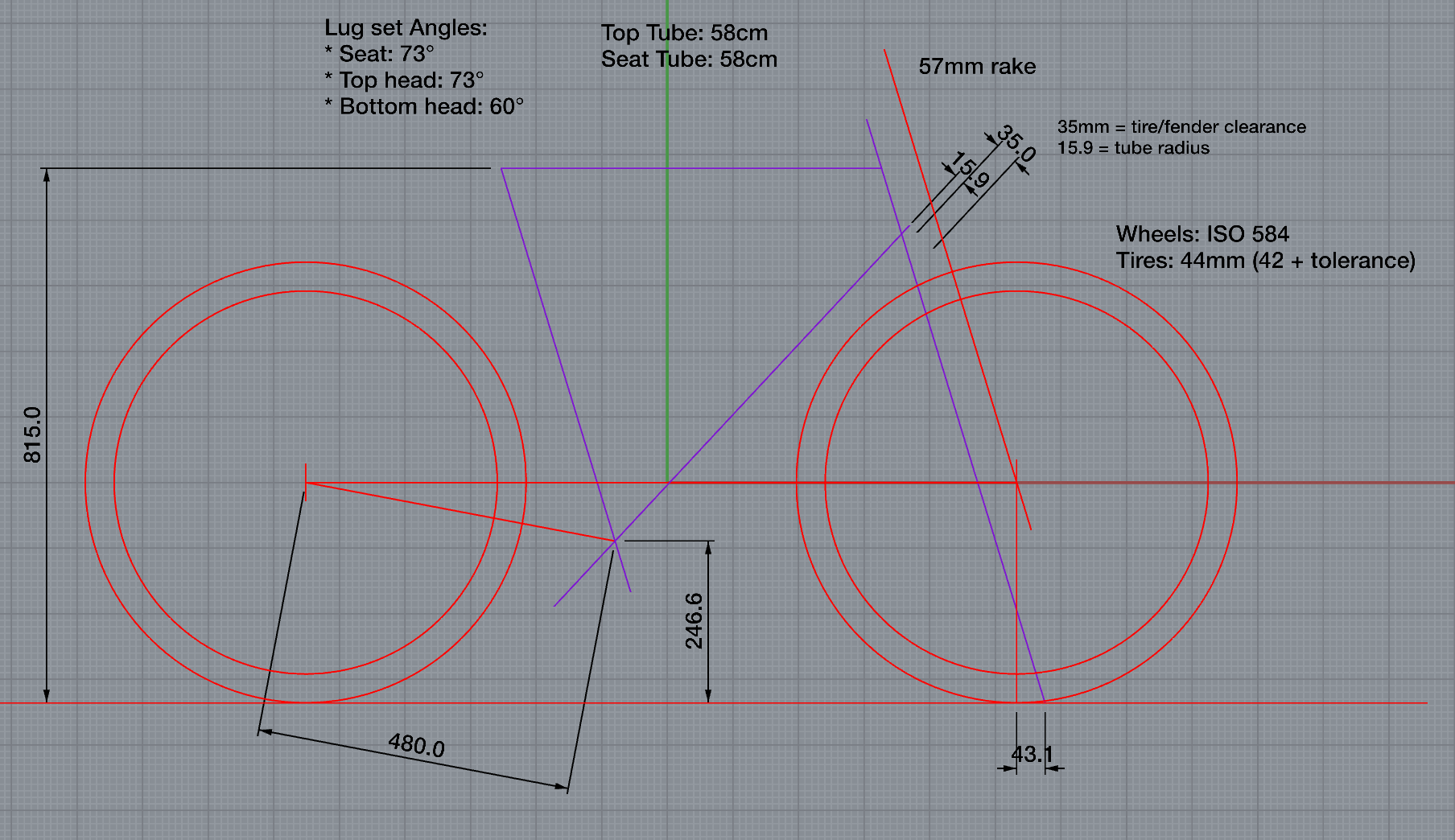

I took some brazing classes at my local maker space and am considering building my first frame. I have a basic understanding of frame geometry and have started playing around with frame design in CAD. I was hoping to shortcut some of the trial and error by getting some advice here. The goal is to keep it simple, so let me know if I'm trying to do too much the first time out. I'm working off pdf's of Richard Talbot's book and the Paterek Manual, but they mostly stick to general principles. Here's the brief:

I took some brazing classes at my local maker space and am considering building my first frame. I have a basic understanding of frame geometry and have started playing around with frame design in CAD. I was hoping to shortcut some of the trial and error by getting some advice here. The goal is to keep it simple, so let me know if I'm trying to do too much the first time out. I'm working off pdf's of Richard Talbot's book and the Paterek Manual, but they mostly stick to general principles. Here's the brief:

- Off the shelf lugs, with a lugged BB for ease of construction

- widest tires possible, 48-55mm

- fenders

- Single speed city bike

- Swept back bars, porteur or north road style

- comfortable, stable handling. shock absorption from bad roads. somewhat-upright posture

- prefer a low BB if possible to make it easy to put a foot down at intersections & stability

- carry groceries, commuting

#2

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,387

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,687 Times

in

2,510 Posts

I think you should consider going with 40mm tires max. That's plenty big enough for most bad roads and you can get them to fit between the typical oval chain stays without going to s-bend chain stays. It also relieves you of pressure for worrying about chain ring clearance. Fiddling around with fitting big tires on a lugged bike is something to do later in your career. Certainly no earlier than your second frame. I'm not sure why the seat tube line on your drawing is going behind the bb, that's not going to happen with a lugged bb shell. Maybe I'm misunderstanding what that line signifies. You don't need 50mm for fender clearance. 30mm should be fine. I usually go with 25. It does tend to mysteriously shrink somehow

If you want to put a front load on this bike, 45mm rake isn't enough. Probably want to go with at least 55mm. Are you building a fork? All my road/all road bikes have front loading. Even if you are going to have panniers on the rear, you want to balance them out with a front load.

I don't usually care too much about chain stay length. I'm a little surprised that it's still a thing since we got rid of most of the obsessions from the '70s, like high bottom brackets, no rake, and steep angles. If you are going to put rear panniers on the bike, long chainstays are a good idea anyway, for heel clearance.

If you want to put a front load on this bike, 45mm rake isn't enough. Probably want to go with at least 55mm. Are you building a fork? All my road/all road bikes have front loading. Even if you are going to have panniers on the rear, you want to balance them out with a front load.

I don't usually care too much about chain stay length. I'm a little surprised that it's still a thing since we got rid of most of the obsessions from the '70s, like high bottom brackets, no rake, and steep angles. If you are going to put rear panniers on the bike, long chainstays are a good idea anyway, for heel clearance.

Last edited by unterhausen; 03-31-23 at 08:45 AM.

#3

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,056

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4195 Post(s)

Liked 3,837 Times

in

2,295 Posts

Do you know if the seat set back will match other bikes you have found to fit well? For an upright and swept back handle bar 73* is steep for a seat angle. I agree with Eric's comments on tire profiles and the rapidly increasing efforts to fit them past about 42mm wide ones. The BB is quite high, perhaps you like that but I wouldn't. For a wide tired bike I think 73* head angle is a bit much too. Andy

__________________

AndrewRStewart

AndrewRStewart

Likes For Andrew R Stewart:

#4

framebuilder

Your design is not right for North Road handlebars. The steepest allowable seat angle should only be 71º or even less. Otherwise you will seat uncomfortably forward without your body being balanced over the pedals. The transportation frames we make in Ukraine have 71º seat and head angles. They are parallel for convenience. A 58 cm top tube is about right. I would lower the BB height to only 260 cm (if using 170 mm cranks). Of course with your fat tires that might make the seat tube/down tube angle on your socketed BB shell a bit challenging. When you draw it out or use CAD you might find that makes a BB drop of 90mm or more.

Likes For Doug Fattic:

#5

Newbie

Thread Starter

Do you know if the seat set back will match other bikes you have found to fit well? For an upright and swept back handle bar 73* is steep for a seat angle. I agree with Eric's comments on tire profiles and the rapidly increasing efforts to fit them past about 42mm wide ones. The BB is quite high, perhaps you like that but I wouldn't. For a wide tired bike I think 73* head angle is a bit much too. Andy

With swept back bars, is it necessary to use a short top tube + long stem combo to keep the grip area near or in front of the steering axis to avoid excess twitchiness? I have this combination currently on a bike with relatively slack angles and it handles stable, though plenty of dutch bikes and english 3 speeds have very short stems and seem to handle fine. Or maybe head angles and rake numbers are more controlling?

Likes For harrier6:

#6

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,892

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4792 Post(s)

Liked 3,918 Times

in

2,548 Posts

Dick Talbot! Clubmate of mine at NEBC about a half million years ago. Somewhere I have his old Campy pedals, 19k miles to me, freshly re-built with perfect bearings. They now have twice the mileage. Was writing the book at that time.

Likes For 79pmooney:

#7

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,387

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,687 Times

in

2,510 Posts

The effect of stem length on handling is overblown. For a more modern example of people using short stems, just look at a high-end mountain bike. Pacenti even sells a bar/stem combo where the handlebars are inset for the steerer. Also, for engineers, if you do a moment balance, you will find that the stem length isn't significant until the wheel is turned further than normal. I think the mtb designers are doing this to allow a longer top tube so you're less likely to go over the bars. I think that in general, you want a longer top tube for an upright bar bike just so you aren't quite so upright.

#8

Senior Member

Join Date: Dec 2019

Posts: 954

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 321 Post(s)

Liked 263 Times

in

212 Posts

A chainstay length of 440 is enough to avoid dreaded pannier foot-slap in my experience. If you want very fat tyres you could also consider 26" wheels. But they don't need to be so fat. Agree with others who have said much better not to get involved with super-tight CS clearances on a first build.

#9

framebuilder

harrier6, I became very interested in the design of upright riding bicycles when we started our Ukraine Bicycle Project over 20 years ago. I used as an example of what we wanted to supply to pastors (sometimes wearing a suit and tie) the Dutch style of transportation bicycles with upright handlebars, IGHs and an enclosed chain case. In fact I brought one back from Holland to study its design as well as a number of Dutch catalogs that give frame geometry dimensions. Then I made some prototypes to make sure what we did worked well. In fact I made a frame with 72 parallel angles and that is when I fully realized a swallower seat angle was required. I mistakenly thought steeper angles might make them a bit sportier. In the upright position the cyclist's body rotates back and as a result their butt obviously goes back too. On the frame with a 72º seat angle, I was constantly bothered by wanting my butt to go further back but I couldn't because the seat angle placed it too far forward.

My interest in riding bikes with North Road handlebars continued and evolved by making some frames with light tubing for trail riding and longer trips than just to get groceries. The one I made for myself was a brazing example for my framebuilding class students. I also made one for my wife with really light tubing. Some good cyclists as they age like upright riding.

I'm attaching 3 pictures. The first one shows prototypes I have made since 2000 to test the design I still keep in the shop for personal and student use. The 2nd picture shows 2 bikes I made for my wife and I to ride on bike trails. The 3rd picture is of a frame designed last week for upright handlebars waiting to be brazed as an example to my student on how brazing should be done. The design on this frame has 71º parallel angles. The BB drop is 85 for 700C by 35 tires. The top tube slopes 2 degrees so I don't have to blacksmith 73º lugs to fit 71º angles. I recommend you design your frame similarly. The top tube has an effective top tube length of 58cm. Its actually length is shorter of course because it is not level.

The bicycle 3rd from the front has been to Ukraine and back to show the XB3 company in Kharkiv what we were wanting them to make.

These are the bikes by wife and I use for riding bike trails.

This is a transportation style of frame to be brazed this week as an example for my student to video. The fixture was laser cut out of stainless in Ukraine.

My interest in riding bikes with North Road handlebars continued and evolved by making some frames with light tubing for trail riding and longer trips than just to get groceries. The one I made for myself was a brazing example for my framebuilding class students. I also made one for my wife with really light tubing. Some good cyclists as they age like upright riding.

I'm attaching 3 pictures. The first one shows prototypes I have made since 2000 to test the design I still keep in the shop for personal and student use. The 2nd picture shows 2 bikes I made for my wife and I to ride on bike trails. The 3rd picture is of a frame designed last week for upright handlebars waiting to be brazed as an example to my student on how brazing should be done. The design on this frame has 71º parallel angles. The BB drop is 85 for 700C by 35 tires. The top tube slopes 2 degrees so I don't have to blacksmith 73º lugs to fit 71º angles. I recommend you design your frame similarly. The top tube has an effective top tube length of 58cm. Its actually length is shorter of course because it is not level.

The bicycle 3rd from the front has been to Ukraine and back to show the XB3 company in Kharkiv what we were wanting them to make.

These are the bikes by wife and I use for riding bike trails.

This is a transportation style of frame to be brazed this week as an example for my student to video. The fixture was laser cut out of stainless in Ukraine.

Likes For Doug Fattic:

#10

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,985

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1172 Post(s)

Liked 2,567 Times

in

1,072 Posts

#11

Newbie

Thread Starter

Thanks Doug, that was very insightful. 71 deg sounds like a reasonable position, as I'm not going for the bolt-upright Dutch position (and the various disadvantages that come with it) where 65 deg seat tubes are not unheard of. And I wasn't going to ask in the interest of keeping the thread on the subject of frame geometry and handling, but you answered the question I was asking myself about how to make off the shelf 73 deg lugs work for my purposes. I vaguely remember one of my books describing lug bending and manipulation, but I never would have thought of your solution. It seems more appropriate in this situation as well.

#12

framebuilder

And now a word about seat angles and frame design. I quit making frames for racers by the mid 80's. Those looking to buy a steel custom frame are now mostly recreational cyclists. How they position themselves on a bicycle is different than someone looking to go as fast as possible. For the former, there is the need to balance aerodynamic and biomechanical efficiency with some comfort while recreational cyclists put much more emphasis on comfort. And by comfort I mean raising the handlebars so they are around level with the seat (easier to see down the road) and correspondingly move the seat back to unweight pressure on their hands. They want their body weight balanced over their pedals. Now in order to ovoid massive toe overlap the head angle needs to relax at the same time.

I design a frame around a person's bicycle position established on a fitting bike where that position is not restricted by their current frame geometry. This results in a seat angle much more likely to be more relaxed than 73º. That is a standard only because of the industry's insistence on using 700C wheels and avoiding toe overlap. And our history of making go fast bicycles instead of something more suitable for normal riders.

With North Road handlebars, the placement of the rider's hands are much closer to their body and as a result (besides needing a seat angle 71º or less) it also requires a longer top tube and stem so their hands are not too close to the body. In general terms, that can be 2 or 3 centimeters longer than what they might use on their standard road bike.

I design a frame around a person's bicycle position established on a fitting bike where that position is not restricted by their current frame geometry. This results in a seat angle much more likely to be more relaxed than 73º. That is a standard only because of the industry's insistence on using 700C wheels and avoiding toe overlap. And our history of making go fast bicycles instead of something more suitable for normal riders.

With North Road handlebars, the placement of the rider's hands are much closer to their body and as a result (besides needing a seat angle 71º or less) it also requires a longer top tube and stem so their hands are not too close to the body. In general terms, that can be 2 or 3 centimeters longer than what they might use on their standard road bike.

#13

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,056

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4195 Post(s)

Liked 3,837 Times

in

2,295 Posts

I'll add that shifting one's hips rearwards (slacker seat tube angle for a more upright position) adds weight to the rear tire/wheel. I might add a bit to the chainstay length to compensate. Andy

__________________

AndrewRStewart

AndrewRStewart

#14

Senior Member

Join Date: Jul 2006

Location: San Jose (Willow Glen) Ca

Posts: 9,835

Bikes: Kirk Custom JK Special, '84 Team Miyata,(dura ace old school) 80?? SR Semi-Pro 600 Arabesque

Mentioned: 106 Post(s)

Tagged: 0 Thread(s)

Quoted: 2337 Post(s)

Liked 2,813 Times

in

1,536 Posts

harrier6, I became very interested in the design of upright riding bicycles when we started our Ukraine Bicycle Project over 20 years ago. I used as an example of what we wanted to supply to pastors (sometimes wearing a suit and tie) the Dutch style of transportation bicycles with upright handlebars, IGHs and an enclosed chain case. In fact I brought one back from Holland to study its design as well as a number of Dutch catalogs that give frame geometry dimensions. Then I made some prototypes to make sure what we did worked well. In fact I made a frame with 72 parallel angles and that is when I fully realized a swallower seat angle was required. I mistakenly thought steeper angles might make them a bit sportier. In the upright position the cyclist's body rotates back and as a result their butt obviously goes back too. On the frame with a 72º seat angle, I was constantly bothered by wanting my butt to go further back but I couldn't because the seat angle placed it too far forward.

My interest in riding bikes with North Road handlebars continued and evolved by making some frames with light tubing for trail riding and longer trips than just to get groceries. The one I made for myself was a brazing example for my framebuilding class students. I also made one for my wife with really light tubing. Some good cyclists as they age like upright riding.

I'm attaching 3 pictures. The first one shows prototypes I have made since 2000 to test the design I still keep in the shop for personal and student use. The 2nd picture shows 2 bikes I made for my wife and I to ride on bike trails. The 3rd picture is of a frame designed last week for upright handlebars waiting to be brazed as an example to my student on how brazing should be done. The design on this frame has 71º parallel angles. The BB drop is 85 for 700C by 35 tires. The top tube slopes 2 degrees so I don't have to blacksmith 73º lugs to fit 71º angles. I recommend you design your frame similarly. The top tube has an effective top tube length of 58cm. Its actually length is shorter of course because it is not level.

The bicycle 3rd from the front has been to Ukraine and back to show the XB3 company in Kharkiv what we were wanting them to make.

These are the bikes by wife and I use for riding bike trails.

This is a transportation style of frame to be brazed this week as an example for my student to video. The fixture was laser cut out of stainless in Ukraine.

My interest in riding bikes with North Road handlebars continued and evolved by making some frames with light tubing for trail riding and longer trips than just to get groceries. The one I made for myself was a brazing example for my framebuilding class students. I also made one for my wife with really light tubing. Some good cyclists as they age like upright riding.

I'm attaching 3 pictures. The first one shows prototypes I have made since 2000 to test the design I still keep in the shop for personal and student use. The 2nd picture shows 2 bikes I made for my wife and I to ride on bike trails. The 3rd picture is of a frame designed last week for upright handlebars waiting to be brazed as an example to my student on how brazing should be done. The design on this frame has 71º parallel angles. The BB drop is 85 for 700C by 35 tires. The top tube slopes 2 degrees so I don't have to blacksmith 73º lugs to fit 71º angles. I recommend you design your frame similarly. The top tube has an effective top tube length of 58cm. Its actually length is shorter of course because it is not level.

The bicycle 3rd from the front has been to Ukraine and back to show the XB3 company in Kharkiv what we were wanting them to make.

These are the bikes by wife and I use for riding bike trails.

This is a transportation style of frame to be brazed this week as an example for my student to video. The fixture was laser cut out of stainless in Ukraine.

__________________

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)

Life is too short not to ride the best bike you have, as much as you can

(looking for Torpado Super light frame/fork or for Raleigh International frame fork 58cm)

#15

The Wheezing Geezer

Join Date: Oct 2021

Location: Española, NM

Posts: 1,044

Bikes: 1976 Fredo Speciale, Jamis Citizen 1, Ellis-Briggs FAVORI, Rivendell Clem Smith Jr.

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 411 Post(s)

Liked 899 Times

in

441 Posts

In your drawings, your front wheel is attached to a perfectly straight fork, whereas most fork blades are curved, or straight but angled forward at the crown (ugh...)

Not sure if that might be misleading you about front tire clearance, or not. I agree with shallower angles for your use. 73° parallel was very popular for '70s racing bikes.

Not sure if that might be misleading you about front tire clearance, or not. I agree with shallower angles for your use. 73° parallel was very popular for '70s racing bikes.

#16

framebuilder

On my wife's light weight trail riding bike were some classic lugs I had in inventory from years ago. They had little heart shaped cutouts already stamped into the lugs.

Last edited by Doug Fattic; 04-06-23 at 02:35 PM.

#17

Newbie