Who has steel plate suitable for making large rear drop-outs for IGH ?

#1

Senior Member

Thread Starter

Join Date: Apr 2010

Location: Elevation 666m Edmonton Canada

Posts: 2,478

Bikes: 2013 Custom SA5w / Rohloff Tourster

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 1236 Post(s)

Liked 318 Times

in

245 Posts

Who has steel plate suitable for making large rear drop-outs for IGH ?

I want rear drop-outs that have zero resemblance to anything pre-formed.

On Friday I found a place to CNC metal for a reasonable cost.

I also got for free some 3/16" "mild steel" ,which is used in construction, that is made to bend before breaking. It is called 836 or A36 and has minimal carbon and other additives, so it seems rather soft.

Does anybody know where I can find something better ? 2 or 3 pieces about 5 inches sq.

Thanks.

On Friday I found a place to CNC metal for a reasonable cost.

I also got for free some 3/16" "mild steel" ,which is used in construction, that is made to bend before breaking. It is called 836 or A36 and has minimal carbon and other additives, so it seems rather soft.

Does anybody know where I can find something better ? 2 or 3 pieces about 5 inches sq.

Thanks.

#2

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,393

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,693 Times

in

2,515 Posts

I would say McMaster-Carr, but they will not ship to you. I don't know if one of the online metals suppliers would ship. I'm not sure if it's worth going to 4130, there are some high carbon steel strips that might work and would be available at any steel supply house.

#3

Bicycle Repair Man !!!

We have a lot of metal suppliers in yeg, lots of fabrication shops will have scrap they would probably give you for free.

#4

Old fart

Join Date: Nov 2004

Location: Appleton WI

Posts: 24,782

Bikes: Several, mostly not name brands.

Mentioned: 153 Post(s)

Tagged: 0 Thread(s)

Quoted: 3587 Post(s)

Liked 3,398 Times

in

1,932 Posts

Mild steel is a good thing for dropouts, as this allows you to align them properly and resist breakage in use.

#5

Senior Member

Thread Starter

Join Date: Apr 2010

Location: Elevation 666m Edmonton Canada

Posts: 2,478

Bikes: 2013 Custom SA5w / Rohloff Tourster

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 1236 Post(s)

Liked 318 Times

in

245 Posts

Thanks for your suggestions. So maybe what i have is OK. Maybe I can cut a piece off and test it.

#6

Decrepit Member

Aircraft Spruce & Specialty sells 9" x 9" 4130 in .125" ($13.25), .190" ($16.25), and .250" ($23.75) thicknesses.

#7

Senior Member

Join Date: Jul 2011

Posts: 2,441

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 33 Post(s)

Likes: 0

Liked 4 Times

in

3 Posts

yeah, in 3/16" I would be going to 4130. And aircraft spruce sells it in Canada out of Brantford airport.

One thing to check is that if they are using a heat cutting process whether that will do anything. Plasma for instance can both burn and harden some metals. Laser? Waterjet should be OK. I am thinking here about using 4130 and heat. I thought 3140 and even heavier metal might be require for a Rohloff type installation since it twists the tab in the slot.

Anyone know a CNC shop in east side Toronto. I contacted a few, and even with the DXF files supplies it would be cheaper to just buy a Sachs.

One thing to check is that if they are using a heat cutting process whether that will do anything. Plasma for instance can both burn and harden some metals. Laser? Waterjet should be OK. I am thinking here about using 4130 and heat. I thought 3140 and even heavier metal might be require for a Rohloff type installation since it twists the tab in the slot.

Anyone know a CNC shop in east side Toronto. I contacted a few, and even with the DXF files supplies it would be cheaper to just buy a Sachs.

#8

Randomhead

Join Date: Aug 2008

Location: Happy Valley, Pennsylvania

Posts: 24,393

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Liked 3,693 Times

in

2,515 Posts

I think you might possibly be unhappy with the lowest grade steel for a dropout if the hubs are nutted. The nuts tend to hog out the dropouts and it gets really hard to make the wheel sit in place.

#9

Full Member

Join Date: Dec 2009

Posts: 495

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 49 Post(s)

Likes: 0

Liked 13 Times

in

12 Posts

Metal Supermarkets. Go there and pick up what you need from the scrap bin. Some of the stores have CNC cutting capability.

Last edited by Canaboo; 10-08-12 at 10:11 PM.

#10

Bicycle Repair Man !!!

Being local I can tell you that in this city, finding the suitable grade and plate is not going to be an issue here.

Could probably scrape up some plate stock at our frame shop as we often have to fabricate new dropouts for bicycles that come in.

Could probably scrape up some plate stock at our frame shop as we often have to fabricate new dropouts for bicycles that come in.

#11

Senior Member

Thread Starter

Join Date: Apr 2010

Location: Elevation 666m Edmonton Canada

Posts: 2,478

Bikes: 2013 Custom SA5w / Rohloff Tourster

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 1236 Post(s)

Liked 318 Times

in

245 Posts

Metal supermarket said they never had 3/16 and only the tubes are 4130.

If I could choose, I would make it 7/32 thick.

If I could choose, I would make it 7/32 thick.

#16

Decrepit Member

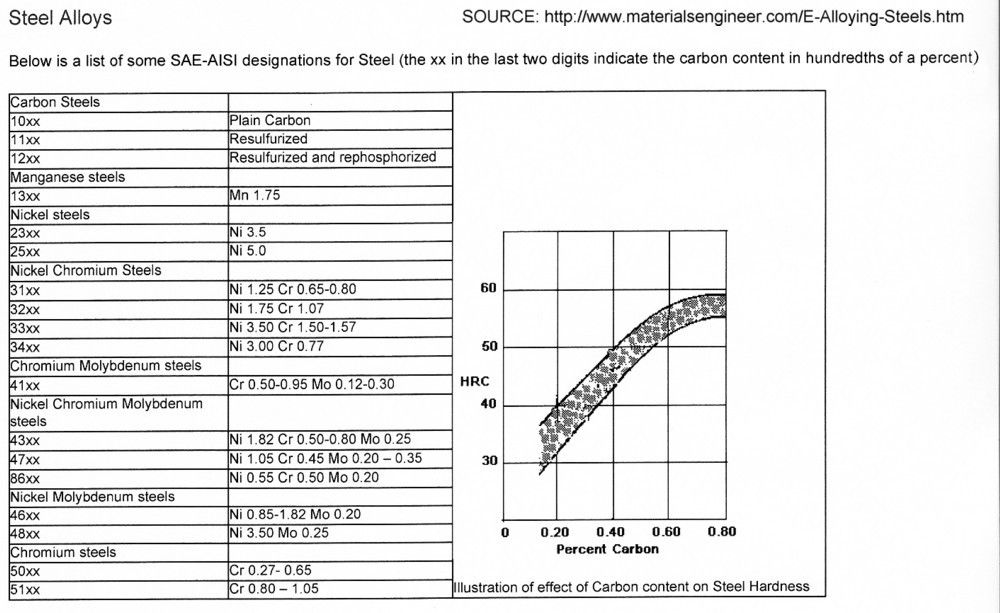

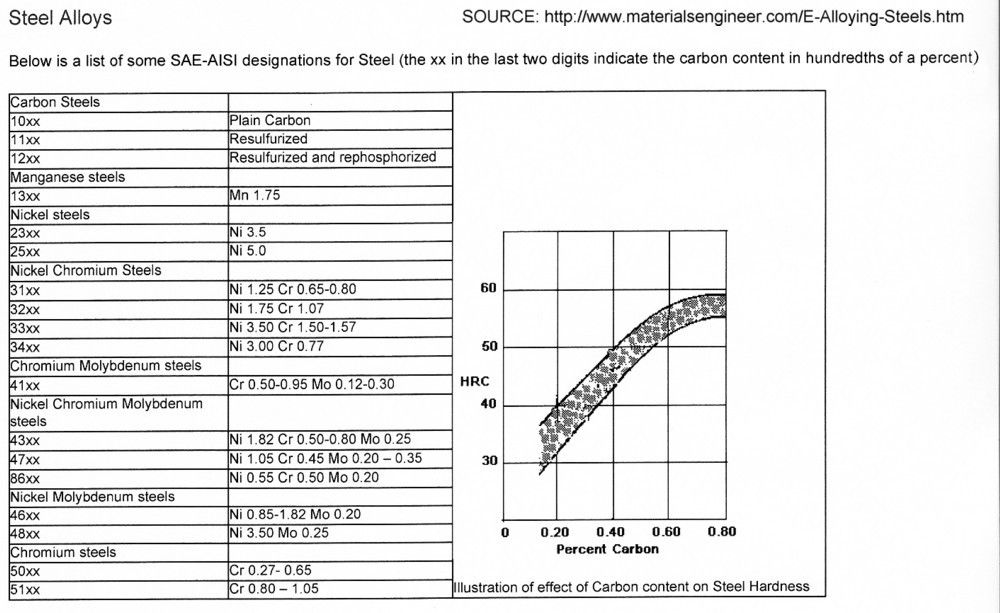

4140 has a higher percentage of carbon than 4130, and is a little harder. The last two digits in the SAE-AISI designation indicate the carbon content in hundredths of a percent.

Alloying of Steels

Alloying of Steels

#17

Senior Member

Aircraft Spruce & Specialty sells 9" x 9" 4130 in .125" ($13.25), .190" ($16.25), and .250" ($23.75) thicknesses.

#18

Framebuilder

Join Date: Dec 2007

Posts: 570

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 8 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Taking a wild guess here, I'm thinking you don't build bikes.

Thread

Thread Starter

Forum

Replies

Last Post

Pukeskywalker

Road Cycling

6

03-23-10 08:49 PM