Retrofriction: care and feeding

#26

Senior Member

Join Date: Nov 2015

Posts: 4,536

Mentioned: 102 Post(s)

Tagged: 0 Thread(s)

Quoted: 1657 Post(s)

Likes: 0

Liked 858 Times

in

560 Posts

Kontact is correct. They will ghost shift under heavy enough force such as a sprint to clear an intersection or standing to pedal on a slope. Once the levers are dialed in and shift repeatedly and cleanly on the workstand, go for a ride and road test them in a parking lot or on a quiet street. Make sure you have the proper sized screwdriver with you to tighten the fixing screw down.

if your retrofrictions ghost shifts, it l's because your clutch spring or internal barrel are worn out or you overlubricted the internals causing the clutch spring to slip easily.....

Last edited by Chombi1; 04-23-24 at 08:45 AM.

#27

Senior Member

Join Date: Apr 2011

Posts: 7,360

Mentioned: 43 Post(s)

Tagged: 0 Thread(s)

Quoted: 4592 Post(s)

Liked 1,745 Times

in

1,142 Posts

I wanted to address how exactly these things work, because I think this debate about the screw has something to do with how we understand how they work:

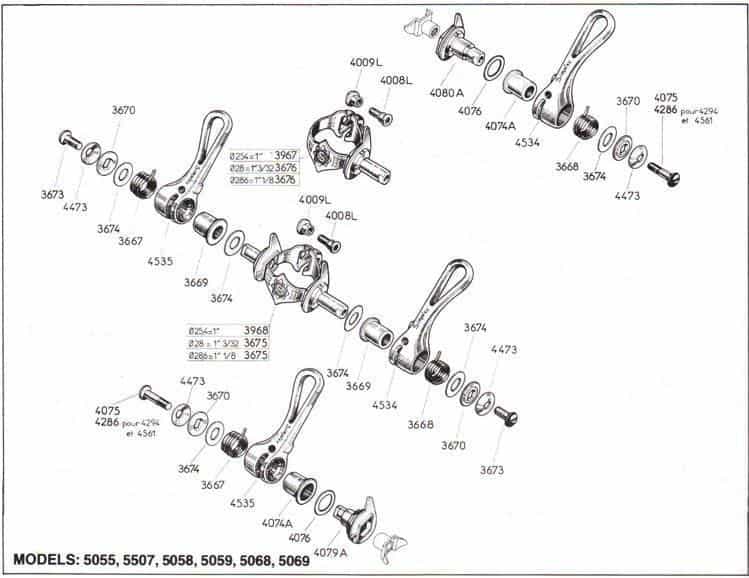

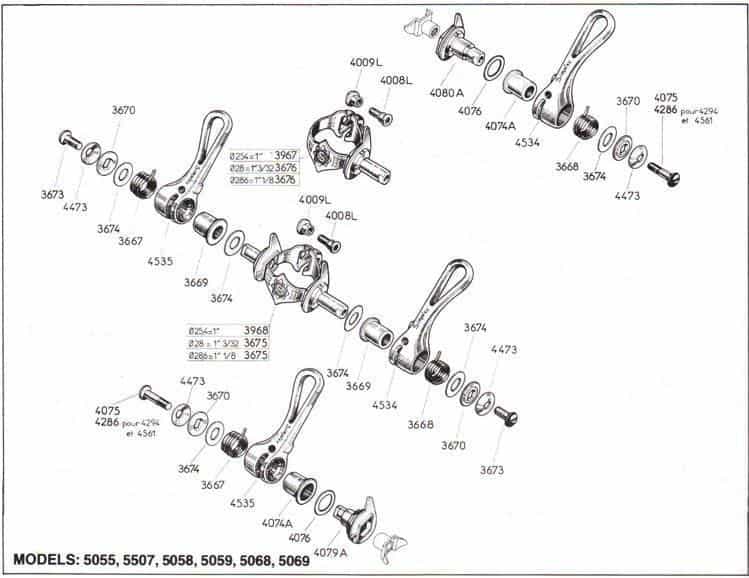

Referring to the shifter in the top of the diagram, we have four parts of real interest:

1. 4080 A - the mounting post that goes over the braze on. This item has a square female base which completely prevents it from rotating.

2. 4074 A - the flared Bushing that slides over the mounting post and is what the clutch spring grips.

3. 4076 - the washer that goes between the mounting post and the flared end of the bushing.

4. 3668 - the clutch spring

What is obvious is that when you pull the lever toward you to downshift on the freewheel, the lever pulls the Spring tip and "unwinds" the Spring, increasing it's inner diameter. This makes the Spring loose on the Bushing, allowing the lever to move without the Bushing moving.

But when the lever is moved forward for an upshift, the Spring inner diameter decreases, and the Spring grips the Bushing.

The Bushing is smooth on the inside and outside. It can turn smoothly under the untensioned Spring, or it can turn on the Post. What prevents it from turning easily on the Post is the mounting screw and washers are pushing it toward the base of the Post. Between them is the 4076 washer.

So the question is: When the lever is pushed forward and the clutch Spring tightens, what is supposed to move? Two possibilities:

1. The Spring moves, but the Bushing does not. In this scenario, the mounting screw has been tightened to the point that the Bushing is locked to the Post. The friction then comes from the tightend spring dragging on the outside of the Bushing to counter the derailleur return spring. Upshifts force the Spring to drag on the Bushing.

2. The Spring locks on to the Bushing, and they move together. In this scenario the mounting screw has been tightened to a moderate setting that allows the bushing to swivel around the post, and the friction resistance to the derailleur return spring comes from the tension of the mounting screw pressuring the outer washers and the inner Washer between the Bushing flange and the Post. In this case the clutch Spring is completely static to the Bushing, and all movement comes from the Bushing slipping past the various washers.

I think #2 is the case, because it explains why the Bushing is smooth on the inside rather than fixed to the Post. It also would prevent a great deal of friction wear to the Bushing from forcing the hardened Spring to push over it in upshifts. This explanation would be why the upshift friction can be varied by the mounting screw tension. The shifter is a pretty normal friction shifter in one direction, and relatively friction free in the other.

#1 is the scenario where mounting screw tension is immaterial to the function of the shifter. It has to be quite tight to make sure the Bushing doesn't slip. This scenario seems like it would wear the Bushing and Spring interface quickly.

Am I missing something?

Referring to the shifter in the top of the diagram, we have four parts of real interest:

1. 4080 A - the mounting post that goes over the braze on. This item has a square female base which completely prevents it from rotating.

2. 4074 A - the flared Bushing that slides over the mounting post and is what the clutch spring grips.

3. 4076 - the washer that goes between the mounting post and the flared end of the bushing.

4. 3668 - the clutch spring

What is obvious is that when you pull the lever toward you to downshift on the freewheel, the lever pulls the Spring tip and "unwinds" the Spring, increasing it's inner diameter. This makes the Spring loose on the Bushing, allowing the lever to move without the Bushing moving.

But when the lever is moved forward for an upshift, the Spring inner diameter decreases, and the Spring grips the Bushing.

The Bushing is smooth on the inside and outside. It can turn smoothly under the untensioned Spring, or it can turn on the Post. What prevents it from turning easily on the Post is the mounting screw and washers are pushing it toward the base of the Post. Between them is the 4076 washer.

So the question is: When the lever is pushed forward and the clutch Spring tightens, what is supposed to move? Two possibilities:

1. The Spring moves, but the Bushing does not. In this scenario, the mounting screw has been tightened to the point that the Bushing is locked to the Post. The friction then comes from the tightend spring dragging on the outside of the Bushing to counter the derailleur return spring. Upshifts force the Spring to drag on the Bushing.

2. The Spring locks on to the Bushing, and they move together. In this scenario the mounting screw has been tightened to a moderate setting that allows the bushing to swivel around the post, and the friction resistance to the derailleur return spring comes from the tension of the mounting screw pressuring the outer washers and the inner Washer between the Bushing flange and the Post. In this case the clutch Spring is completely static to the Bushing, and all movement comes from the Bushing slipping past the various washers.

I think #2 is the case, because it explains why the Bushing is smooth on the inside rather than fixed to the Post. It also would prevent a great deal of friction wear to the Bushing from forcing the hardened Spring to push over it in upshifts. This explanation would be why the upshift friction can be varied by the mounting screw tension. The shifter is a pretty normal friction shifter in one direction, and relatively friction free in the other.

#1 is the scenario where mounting screw tension is immaterial to the function of the shifter. It has to be quite tight to make sure the Bushing doesn't slip. This scenario seems like it would wear the Bushing and Spring interface quickly.

Am I missing something?

#28

Senior Member

Thread Starter

Join Date: Apr 2011

Location: Maryland, USA

Posts: 2,520

Bikes: Drysdale/Gitane/Zeus/Masi/Falcon/Palo Alto/Raleigh/Legnano

Mentioned: 34 Post(s)

Tagged: 0 Thread(s)

Quoted: 1028 Post(s)

Liked 708 Times

in

434 Posts

That's why I don't lubricate the internals of my retrofrictions, I just clean them out periodicslly with WD40 to flush our dust and dirt that might get in them, giving the clutch spring the max ability to grip onto the inner barrel to prevents ghost shifting. I had been installing ajd using Retrofrictions since I discovered them for myself in the early 80's and had enough experience to know them in and out....

if your retrofrictions ghost shifts, it l's because your clutch spring or internal barrel are worn out or you overlubricted the internals causing the clutch spring to slip easily.....

if your retrofrictions ghost shifts, it l's because your clutch spring or internal barrel are worn out or you overlubricted the internals causing the clutch spring to slip easily.....

If the "your clutch spring or internal barrel are worn out", not sure I'd know from a visual inspection, nor what the options are save watching for a replacement set (I think I saw some on For Sale but those are clamp-on and didn't I read they do NOT interchange?)

The bottle of thread locker beckons like it's some controlled substance I'm trying to kick... where's the HotLine I am supposed to call for that particular addition?

__________________

Larry:1958 Drysdale, 1961 Gitane Gran Sport, 1974 Zeus track, 1988 Masi Gran Corsa, 1974 Falcon, 1980 Palo Alto, 1973 Raleigh Gran Sport, 1974 Legnano. Susan: 1976 Windsor Profesional.

Larry:1958 Drysdale, 1961 Gitane Gran Sport, 1974 Zeus track, 1988 Masi Gran Corsa, 1974 Falcon, 1980 Palo Alto, 1973 Raleigh Gran Sport, 1974 Legnano. Susan: 1976 Windsor Profesional.

#30

Full Member

Join Date: Sep 2017

Location: Oklahoma City

Posts: 259

Bikes: 1985 Roberts SLX, Mercian 531, 1984 Torpado SLX,1981/82 Peugeot PSV-10, 1978 Charlie Roberts full touring, 1970 Charlie Roberts 531 road.

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 83 Post(s)

Liked 176 Times

in

69 Posts

Still not thrilled with performance; I have the shifters off the boss and soaking in WD40 (I dunno, leave them in for an hour or so?) and will report back on whether it improves anything.

If the "your clutch spring or internal barrel are worn out", not sure I'd know from a visual inspection, nor what the options are save watching for a replacement set (I think I saw some on For Sale but those are clamp-on and didn't I read they do NOT interchange?)

The bottle of thread locker beckons like it's some controlled substance I'm trying to kick... where's the HotLine I am supposed to call for that particular addition?

If the "your clutch spring or internal barrel are worn out", not sure I'd know from a visual inspection, nor what the options are save watching for a replacement set (I think I saw some on For Sale but those are clamp-on and didn't I read they do NOT interchange?)

The bottle of thread locker beckons like it's some controlled substance I'm trying to kick... where's the HotLine I am supposed to call for that particular addition?

#31

Senior Member

Thread Starter

Join Date: Apr 2011

Location: Maryland, USA

Posts: 2,520

Bikes: Drysdale/Gitane/Zeus/Masi/Falcon/Palo Alto/Raleigh/Legnano

Mentioned: 34 Post(s)

Tagged: 0 Thread(s)

Quoted: 1028 Post(s)

Liked 708 Times

in

434 Posts

I wanted to address how exactly these things work, because I think this debate about the screw has something to do with how we understand how they work:

So the question is: When the lever is pushed forward and the clutch Spring tightens, what is supposed to move? Two possibilities:

1. The Spring moves, but the Bushing does not. In this scenario, the mounting screw has been tightened to the point that the Bushing is locked to the Post. The friction then comes from the tightend spring dragging on the outside of the Bushing to counter the derailleur return spring. Upshifts force the Spring to drag on the Bushing.

2. The Spring locks on to the Bushing, and they move together. In this scenario the mounting screw has been tightened to a moderate setting that allows the bushing to swivel around the post, and the friction resistance to the derailleur return spring comes from the tension of the mounting screw pressuring the outer washers and the inner Washer between the Bushing flange and the Post. In this case the clutch Spring is completely static to the Bushing, and all movement comes from the Bushing slipping past the various washers.

I think #2 is the case, because it explains why the Bushing is smooth on the inside rather than fixed to the Post.

So the question is: When the lever is pushed forward and the clutch Spring tightens, what is supposed to move? Two possibilities:

1. The Spring moves, but the Bushing does not. In this scenario, the mounting screw has been tightened to the point that the Bushing is locked to the Post. The friction then comes from the tightend spring dragging on the outside of the Bushing to counter the derailleur return spring. Upshifts force the Spring to drag on the Bushing.

2. The Spring locks on to the Bushing, and they move together. In this scenario the mounting screw has been tightened to a moderate setting that allows the bushing to swivel around the post, and the friction resistance to the derailleur return spring comes from the tension of the mounting screw pressuring the outer washers and the inner Washer between the Bushing flange and the Post. In this case the clutch Spring is completely static to the Bushing, and all movement comes from the Bushing slipping past the various washers.

I think #2 is the case, because it explains why the Bushing is smooth on the inside rather than fixed to the Post.

Well, having been told not to dismantle, I pulled the assemblies off the frame (and I had already crimped tips on the cables so I did not want to undo that!

Always do those last on a project!) and, at the ends of the cables, dipped into a cup of WD40 and swished. Then I figured, let technology do the work -- put the shifters and WD40 in a very small pesto jar left over from lunch, stuck that in the ultrasonic cleaner balanced on a TV table (bike is in a stand, so too high to reach the floor with the cables in place) and gave everything about 6 minutes. The WD40 discolored but not opaque black. Reassembled, they feel great. On the stand. Without riding the bike.

Always do those last on a project!) and, at the ends of the cables, dipped into a cup of WD40 and swished. Then I figured, let technology do the work -- put the shifters and WD40 in a very small pesto jar left over from lunch, stuck that in the ultrasonic cleaner balanced on a TV table (bike is in a stand, so too high to reach the floor with the cables in place) and gave everything about 6 minutes. The WD40 discolored but not opaque black. Reassembled, they feel great. On the stand. Without riding the bike.The clamp on Do Not interchange with the frame mounted ones, I.e. they’re French after all. Had one of the springs break, they have a little tiny catch on the end, and that can rust and finally break, releasing the pressure, and you are in the smallest cog (of it’s the rear derailleur).

__________________

Larry:1958 Drysdale, 1961 Gitane Gran Sport, 1974 Zeus track, 1988 Masi Gran Corsa, 1974 Falcon, 1980 Palo Alto, 1973 Raleigh Gran Sport, 1974 Legnano. Susan: 1976 Windsor Profesional.

Larry:1958 Drysdale, 1961 Gitane Gran Sport, 1974 Zeus track, 1988 Masi Gran Corsa, 1974 Falcon, 1980 Palo Alto, 1973 Raleigh Gran Sport, 1974 Legnano. Susan: 1976 Windsor Profesional.

Likes For tiger1964:

#32

Full Member

Join Date: Sep 2017

Location: Oklahoma City

Posts: 259

Bikes: 1985 Roberts SLX, Mercian 531, 1984 Torpado SLX,1981/82 Peugeot PSV-10, 1978 Charlie Roberts full touring, 1970 Charlie Roberts 531 road.

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 83 Post(s)

Liked 176 Times

in

69 Posts

Had two sets of braze on shifters overhauled by Wayne Bingham, he replaced the set with the broken spring, as well as another set off eBay.Fr. He might have more springs. Here’s his Facebook page. By now, most people know that I closed my shop Velo Classique at the end of last year. It's now being reborn, although in a very scaled down fashion, as Atelier Velo Classique (that's Classic Bike Workshop in French). It's still a work in progress, but coming together nicely. The veloclassique@gmail address is still active, and the best way to contact me if you'd like to make an appointment, or just want to stay in touch. There is a new webpage in the works too, and there will be postings of things for sale both here and there as all that gets organized.

I want to thank all those that supported Velo Classique while in our two different locations in Purcellville for 14 years. I do miss the shop, but I'm looking forward to what lies ahead too. I have a lot of new ideas, so stay tuned.

I want to thank all those that supported Velo Classique while in our two different locations in Purcellville for 14 years. I do miss the shop, but I'm looking forward to what lies ahead too. I have a lot of new ideas, so stay tuned.

Likes For santa fe 2926:

#33

Full Member

Join Date: Sep 2017

Location: Oklahoma City

Posts: 259

Bikes: 1985 Roberts SLX, Mercian 531, 1984 Torpado SLX,1981/82 Peugeot PSV-10, 1978 Charlie Roberts full touring, 1970 Charlie Roberts 531 road.

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 83 Post(s)

Liked 176 Times

in

69 Posts

https://peugeotcoursepb12.wordpress....-installation/

a good article on the shift levers, mentioning Wayne having replacement springs.

a good article on the shift levers, mentioning Wayne having replacement springs.

#34

Senior Member

Join Date: Apr 2011

Posts: 7,360

Mentioned: 43 Post(s)

Tagged: 0 Thread(s)

Quoted: 4592 Post(s)

Liked 1,745 Times

in

1,142 Posts

Of course, all friction shifters have a washer like that, but those shifters are constantly wiggling them back and forth. The Simplex shifter only ever tries to turn in a single direction, so no wiggling.

Last edited by Kontact; 05-23-24 at 08:02 PM.