View Poll Results: Do you retighten the bolts?

Voters: 64. You may not vote on this poll

Poll: tightening crank bolts after mounting arms

#26

Senior Member

Join Date: Jun 2013

Location: 700 Ft. above sea level.

Posts: 3,254

Bikes: More than there were awhile ago.

Mentioned: 22 Post(s)

Tagged: 0 Thread(s)

Quoted: 638 Post(s)

Liked 1,294 Times

in

612 Posts

While rare, beam type wrenches CAN go out of calibration and I have experienced it. I loaned out my beam type that came with the Craftsman toolset I got for HS graduation in 1973 once and only once, it came back with the needle noticably off zero. A casual hobbyist might not notice if the needle was off, it's usually caused by misuse or improper storage. However, judging by your previous posts I think I'm safe in assuming you are not a "casual hobbyist" and neither misuse nor store yours improperly.

I only have clickers now, I was doing mostly automotive work then so I replaced my beam type with a clicker as there were situations where seeing the wrench while torquing was next to if not totally impossible. As I needed wrenches of other ranges I bought more clickers. Now if I was to purchase a wrench strictly for bicycle work where I have it on a stand and can position it wherever I needed I would definitely go with beam type BUT.... as I have a few hundred dollars invested in the ones I already have from my motorcycle and vintage car days they'll "have to do do".

I only have clickers now, I was doing mostly automotive work then so I replaced my beam type with a clicker as there were situations where seeing the wrench while torquing was next to if not totally impossible. As I needed wrenches of other ranges I bought more clickers. Now if I was to purchase a wrench strictly for bicycle work where I have it on a stand and can position it wherever I needed I would definitely go with beam type BUT.... as I have a few hundred dollars invested in the ones I already have from my motorcycle and vintage car days they'll "have to do do".

__________________

".....distasteful and easily triggered."

".....distasteful and easily triggered."

#27

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,368

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6220 Post(s)

Liked 4,221 Times

in

2,367 Posts

On the few I own personally (like 2) I torque them to 35 ft-lb (~45Nm) and never touch them. Never had one come loose.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old SchoolÖWhen It Wasnít Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old SchoolÖWhen It Wasnít Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Likes For cyccommute:

#28

Ride, Wrench, Swap, Race

Join Date: Jan 2010

Location: Northern California

Posts: 9,194

Bikes: Cheltenham-Pedersen racer, Boulder F/S Paris-Roubaix, Varsity racer, '52 Christophe, '62 Continental, '92 Merckx, '75 Limongi, '76 Presto, '72 Gitane SC, '71 Schwinn SS, etc.

Mentioned: 132 Post(s)

Tagged: 0 Thread(s)

Quoted: 1565 Post(s)

Liked 1,296 Times

in

866 Posts

Best is to strictly adhere to the crank maker's prescribed (non-?)lubrication of tapers, washers and threads, ...and of course their torque specification.

I seldom use a torque wrench on square-taper crank bolts, but will re-tighten once after simply jumping on the pedals back and forth one time to effect forward/reverse torsion on the square tapered press-fit.

With nutted spindles (having coarser, larger-diameter threads made of relatively brittle material), I use a bit less torque on the nuts, but will repeat the tightening and jumping on the pedals three times so as to prevent the crankarms loosening. Using Loctite on nutted spindle studs is also a great idea, supplementing the toothed, directional scalloping on the nut's integral washer face.

I've had a crankarm loosen during a short CX race, so I use Loctite on all crank bolt threads for racing off road.

Off-road riding/racing incurs much greater torsion on the tapered interface, leading to greater chances of the bolt losing tension.

Heavier riders incur relatively larger spindle torsion under all riding conditions, so also may benefit more from use of Loctite on crank bolt threads.

I seldom use a torque wrench on square-taper crank bolts, but will re-tighten once after simply jumping on the pedals back and forth one time to effect forward/reverse torsion on the square tapered press-fit.

With nutted spindles (having coarser, larger-diameter threads made of relatively brittle material), I use a bit less torque on the nuts, but will repeat the tightening and jumping on the pedals three times so as to prevent the crankarms loosening. Using Loctite on nutted spindle studs is also a great idea, supplementing the toothed, directional scalloping on the nut's integral washer face.

I've had a crankarm loosen during a short CX race, so I use Loctite on all crank bolt threads for racing off road.

Off-road riding/racing incurs much greater torsion on the tapered interface, leading to greater chances of the bolt losing tension.

Heavier riders incur relatively larger spindle torsion under all riding conditions, so also may benefit more from use of Loctite on crank bolt threads.

#29

ambulatory senior

Join Date: Dec 2016

Location: Peoria Il

Posts: 5,998

Bikes: Austro Daimler modified by Gugie! Raleigh Professional and lots of other bikes.

Mentioned: 76 Post(s)

Tagged: 0 Thread(s)

Quoted: 1955 Post(s)

Liked 3,661 Times

in

1,679 Posts

Working in a bike shop with torque wrenches I was quite surprised at how tight crank bolts are supposed to be. Mine are put on tighter nowadays. Rarely recheck though.

Likes For 52telecaster:

#30

Junior Member

I think that the crank bolt torque settings are dependent on whether the bottom bracket axle is greased or not, and also whether the crank bolts are greased, or not.

I recall reading that for Campy (Nuovo) Record cranksets, the instructions said to degrease the tapers and the crank bolts, and install the crankset with no lubrication on those surfaces.

Campy's 11/1996 installation instructions for the crankset states: "Remove any possible traces of grease from bottom bracket spindle tapers before installing cranks." Also shown is the crank arm torque spec is 32-38 newton-meters (23.6 - 28 foot pounds). The BB bolts, as supplied by Campy, are dry and have a bit of painted-on locktite which adds to retention friction.

A Campagnolo supplied 1994 (bicycle) owner's manual also states to check the tightness of the crank after the first ride. The manual also states to "carefully clean the crank aperture" before reinstalling the cranks. The same 32-38 N-m torque spec is shown here, also.

Phil Wood's current instructions fo their "square taper bottom bracket" say to follow the manufacturer's instructions. However, Phil Wood also says to grease the BB axle tapers with Phil Wood grease before installing the crankset (https://cdn.shopify.com/s/files/1/03...s_V1.2.pdf?354).

What I do for crank installation:

I'm using a Phil Wood BB on all of my (3) bikes. I choose to oil the BB axle tapers; I put on a couple drops of Phil Wood oil, rub it around, and then finger-wipe off the excess. I also oil the crank arm bolts. I then install the crankset and torque down the BB bolts using either a Campy 15mm BB wrench, or another wrench of similar length. After the crank arms are installed, I then remove the BB axle bolts, clean them, and I also wipe clean (with Qtips) the axle threads. I then reinstall the bolts and torque them down by hand. I don't have a torque wrench.

My intention is to have a smooth installation and minimize any sticking or galling of the surfaces.

After crankset installation, my first ride is at moderate pace on relatively flat ground: I don't want to stomp on the cranks and possibly distort the tapers (if that's possible). On that first ride, I check the crank arm (ie, BB) bolts several times. To tighten the bolts, I just firmly lean on the end of the wrench. On my last crankset installation (only a couple of days ago) the cranks seemed to settle in and the bolts stopped loosening up after about an hour of riding. I'll check the bolts again on the second ride, but I usually find that after the cranks have seated, the bolts usually stay put.

I recall reading that for Campy (Nuovo) Record cranksets, the instructions said to degrease the tapers and the crank bolts, and install the crankset with no lubrication on those surfaces.

Campy's 11/1996 installation instructions for the crankset states: "Remove any possible traces of grease from bottom bracket spindle tapers before installing cranks." Also shown is the crank arm torque spec is 32-38 newton-meters (23.6 - 28 foot pounds). The BB bolts, as supplied by Campy, are dry and have a bit of painted-on locktite which adds to retention friction.

A Campagnolo supplied 1994 (bicycle) owner's manual also states to check the tightness of the crank after the first ride. The manual also states to "carefully clean the crank aperture" before reinstalling the cranks. The same 32-38 N-m torque spec is shown here, also.

Phil Wood's current instructions fo their "square taper bottom bracket" say to follow the manufacturer's instructions. However, Phil Wood also says to grease the BB axle tapers with Phil Wood grease before installing the crankset (https://cdn.shopify.com/s/files/1/03...s_V1.2.pdf?354).

What I do for crank installation:

I'm using a Phil Wood BB on all of my (3) bikes. I choose to oil the BB axle tapers; I put on a couple drops of Phil Wood oil, rub it around, and then finger-wipe off the excess. I also oil the crank arm bolts. I then install the crankset and torque down the BB bolts using either a Campy 15mm BB wrench, or another wrench of similar length. After the crank arms are installed, I then remove the BB axle bolts, clean them, and I also wipe clean (with Qtips) the axle threads. I then reinstall the bolts and torque them down by hand. I don't have a torque wrench.

My intention is to have a smooth installation and minimize any sticking or galling of the surfaces.

After crankset installation, my first ride is at moderate pace on relatively flat ground: I don't want to stomp on the cranks and possibly distort the tapers (if that's possible). On that first ride, I check the crank arm (ie, BB) bolts several times. To tighten the bolts, I just firmly lean on the end of the wrench. On my last crankset installation (only a couple of days ago) the cranks seemed to settle in and the bolts stopped loosening up after about an hour of riding. I'll check the bolts again on the second ride, but I usually find that after the cranks have seated, the bolts usually stay put.

#31

Senior Member

Join Date: Jun 2006

Posts: 20,305

Mentioned: 130 Post(s)

Tagged: 0 Thread(s)

Quoted: 3464 Post(s)

Liked 2,831 Times

in

1,997 Posts

I don't retighten, don't even check, because I've never seen a need to. Never had one come loose. I'm not saying this is advice for others, but it has worked for me.

I think I tighten them tighter initially than most people do though. I don't know, since I've never used a torque wrench, but I'll bet I'm overtightening according to the manufacturer's spec. I don't use a tommy bar or cheater, just the normal 6 or 7" long wrench, but with close to all my might. I figger if a peanut butter wrench was good enough for Tullio, it's good enough for me.

This has never split or wallowed a crank for me, despite my use of <gasp> grease on the tapers. My chainline comes out OK, though I'll admit I never measured it with a micrometer. If I had to guess I'd say my cranks might go on a half-mm further than at recommended torque, but I'm OK with that. I like low-Q.

Maybe this would cause problems on a cheap/weak crank, like I dunno, Maxy? I have stuck with better brands like Campy Record, Dura-Ace, Stronglight 93/99, TA Pro, Mavic, Specialized. I have broken 3 cranks, two TA and one Campy, but not at the square taper. Twice as many TA cranks as Campy probably because I used TA on MTBs versus road only on Campy. Maybe TA cranks are weaker as well, I dunno, but the MTB abuse could be enough to explain it. I raced Norba Expert class (hard pedaling) and competed in Observed Trials (hard knocks).

I frequently took the cranks off for cleaning just because it's easier than cleaning in-place when they're grimy, so some of my cranks have been off and back on many times.

Mark B

I think I tighten them tighter initially than most people do though. I don't know, since I've never used a torque wrench, but I'll bet I'm overtightening according to the manufacturer's spec. I don't use a tommy bar or cheater, just the normal 6 or 7" long wrench, but with close to all my might. I figger if a peanut butter wrench was good enough for Tullio, it's good enough for me.

This has never split or wallowed a crank for me, despite my use of <gasp> grease on the tapers. My chainline comes out OK, though I'll admit I never measured it with a micrometer. If I had to guess I'd say my cranks might go on a half-mm further than at recommended torque, but I'm OK with that. I like low-Q.

Maybe this would cause problems on a cheap/weak crank, like I dunno, Maxy? I have stuck with better brands like Campy Record, Dura-Ace, Stronglight 93/99, TA Pro, Mavic, Specialized. I have broken 3 cranks, two TA and one Campy, but not at the square taper. Twice as many TA cranks as Campy probably because I used TA on MTBs versus road only on Campy. Maybe TA cranks are weaker as well, I dunno, but the MTB abuse could be enough to explain it. I raced Norba Expert class (hard pedaling) and competed in Observed Trials (hard knocks).

I frequently took the cranks off for cleaning just because it's easier than cleaning in-place when they're grimy, so some of my cranks have been off and back on many times.

Mark B

I did not read prior to Mark's post about lubricating the spindle taper... I will attempt to remove any assembly grease from the taper with my fingers. No rag, but only the most thin veil of lubricant, where the spindle appears dry basically.

grease them up and you will need to re-torque.

I have used a torque wrench once, as a comparison to what I do. A positive confirmation.

#32

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

I have heard a bit of lore repeated over the years, that the oil you get on your finger by rubbing your nose, then aplied to the spindle, is the right amount of lubrication. But any lube means lubed! You're also getting moisture off your nose, so I wouldn't actually recommend this method. Though I can't say from personal experience, it sounds wrong to me to intentionally put water in that interface.

grease them up and you will need to re-torque.

This argument is evergreen, and it will never be settled, but I just want people to know that there is controversy, with experts on both sides. I know for a fact that both dry and greased tapers can work reliably when done by an experienced mechanic. I'm not trying to win anyone over to my "side", I know my anecdotes aren't data and I haven't proven anything. But neither have the dry tapers people ó most of whom are using grease whether they know it or not!

Mark B

Likes For bulgie:

#33

Iím a little Surly

Join Date: Jan 2010

Location: Near the district

Posts: 2,422

Bikes: Two Cross Checks, a Karate Monkey, a Disc Trucker, and a VO Randonneur

Mentioned: 5 Post(s)

Tagged: 0 Thread(s)

Quoted: 699 Post(s)

Liked 1,294 Times

in

647 Posts

I donít re-check and Iíve not had one come loose

#34

Full Member

Join Date: Apr 2010

Location: '16 StumpJ, Salsa Mukluk, Soulcycles SS, Dean Colonel HT, BMC FourstrokeTrail, Dean Torres CX, Santana Visa Tandem, Trek T2000 Tandem, Cupertino MTB Tandem, FreeAgent26"Xtracycle, Dirt Drop Dingle, Jamis Dragon Dingle, Airborne Skyhag SS, SSDean Cols

Posts: 219

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 70 Post(s)

Liked 116 Times

in

61 Posts

Related, how far does a typical square taper move inboard as it is mounted in contact with the spindle until seated at proper torque?

Does that distance vary between different cranks?

And how does that relate to torque?

The result does affect chain line, especially on single speeds.

Does that distance vary between different cranks?

And how does that relate to torque?

The result does affect chain line, especially on single speeds.

#35

Full Member

Join Date: Dec 2012

Location: North Seattle

Posts: 387

Bikes: Davidson í81

Mentioned: 2 Post(s)

Tagged: 0 Thread(s)

Quoted: 120 Post(s)

Liked 229 Times

in

121 Posts

I use grease and make them really tight the first time (1/2Ē drive ratchet, I donít own a peanut butter wrench and donít want one). I donít re-torque, donít even check, and always stand ďgoofy footedĒ on the pedals (itís what feels normal to me).

Have never had a crank I installed come loose.

Iíve seen it happen to friends, in every instance on modern low end Shimano MTB cranks assembled by a bike shop (owners should have checked apparently).

Have never had a crank I installed come loose.

Iíve seen it happen to friends, in every instance on modern low end Shimano MTB cranks assembled by a bike shop (owners should have checked apparently).

Last edited by C9H13N; 01-16-23 at 01:18 AM.

#36

Senior Member

Join Date: Feb 2020

Posts: 2,820

Mentioned: 49 Post(s)

Tagged: 0 Thread(s)

Quoted: 1106 Post(s)

Likes: 0

Liked 1,328 Times

in

784 Posts

Related, how far does a typical square taper move inboard as it is mounted in contact with the spindle until seated at proper torque?

Does that distance vary between different cranks?

And how does that relate to torque?

The result does affect chain line, especially on single speeds.

Does that distance vary between different cranks?

And how does that relate to torque?

The result does affect chain line, especially on single speeds.

Likes For oneclick:

#37

Senior Member

Join Date: Jun 2006

Posts: 20,305

Mentioned: 130 Post(s)

Tagged: 0 Thread(s)

Quoted: 3464 Post(s)

Liked 2,831 Times

in

1,997 Posts

Related, how far does a typical square taper move inboard as it is mounted in contact with the spindle until seated at proper torque?

Does that distance vary between different cranks?

And how does that relate to torque?

The result does affect chain line, especially on single speeds.

Does that distance vary between different cranks?

And how does that relate to torque?

The result does affect chain line, especially on single speeds.

a taper fit depends on the engagement friction, why sabotage the design?

#38

Senior Member

Join Date: Jun 2006

Posts: 20,305

Mentioned: 130 Post(s)

Tagged: 0 Thread(s)

Quoted: 3464 Post(s)

Liked 2,831 Times

in

1,997 Posts

I use grease and make them really tight the first time (1/2Ē drive ratchet, I donít own a peanut butter wrench and donít want one). I donít re-torque, donít even check, and always stand ďgoofy footedĒ on the pedals (itís what feels normal to me).

Have never had a crank I installed come loose.

Iíve seen it happen to friends, in every instance on modern low end Shimano MTB cranks assembled by a bike shop (owners should have checked apparently).

Have never had a crank I installed come loose.

Iíve seen it happen to friends, in every instance on modern low end Shimano MTB cranks assembled by a bike shop (owners should have checked apparently).

#39

Senior Member

Join Date: Nov 2005

Location: NW Ohio

Posts: 3,421

Bikes: 1984 Miyata 310, 1986 Schwinn Sierra, 2011 Jamis Quest, 1980 Peugeot TH8 Tandem, 1992 Performance Parabola, 1987 Ross Mt. Hood, 1988 Schwinn LeTour, 1988 Trek 400T, 1981 Fuji S12-S LTD, 197? FW Evans

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 533 Post(s)

Liked 1,007 Times

in

516 Posts

The Park Tool chart I have recommends 305-435 inch-pounds. My 3/8 torque wrench only goes to 250 inch-pounds, so that is what I use. Whenever I am tightening a crank, 250 inch-pounds feels like I should be worried about breaking something, so that is probably as tight as anybody would make it if they were not using a torque wrench. I do not recheck the cranks after riding and they are still tight when I take them apart later. I have a 1/2 inch torque wrench, but it starts at 25 foot-pounds(300 in-lbs.), so I question the accuracy that close to the bottom of the scale. I wipe the grease off the spindle with a rag, but I'm not using a solvent so there may be some residue.

#40

Senior Member

Join Date: Oct 2009

Posts: 1,104

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 288 Post(s)

Liked 330 Times

in

160 Posts

I lightly grease the spindle, use about 3/4 of my very manly, very virile strength on the bolt, take a ride somewhere, and then re-tighten. The bolt usually moves a snug.

I suspect I donít use the prescribed torque in the bolt, and my bet is that the prescribed force is excessive for safety concerns or something similar. Never had a problem.

My best guess would be that a torque wrench is a tool that belongs to a Monkee.

I suspect I donít use the prescribed torque in the bolt, and my bet is that the prescribed force is excessive for safety concerns or something similar. Never had a problem.

My best guess would be that a torque wrench is a tool that belongs to a Monkee.

#41

Senior Member

Join Date: Nov 2010

Posts: 3,504

Mentioned: 9 Post(s)

Tagged: 0 Thread(s)

Quoted: 586 Post(s)

Liked 612 Times

in

447 Posts

Sugino has a recommendation that bolts should be tightened with a regular wrench first. Then, after tightened, a torque wrench is used to ensure proper installation specs. They have more details here:

https://www.suginoltd.co.jp/us/pdf/T...nChart(EN).pdf

https://www.suginoltd.co.jp/us/pdf/T...nChart(EN).pdf

Likes For TugaDude:

#42

Senior Member

Join Date: Jan 2005

Location: Baltimore, MD

Posts: 5,380

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 2487 Post(s)

Liked 2,956 Times

in

1,679 Posts

Sugino has a recommendation that bolts should be tightened with a regular wrench first. Then, after tightened, a torque wrench is used to ensure proper installation specs. They have more details here:

https://www.suginoltd.co.jp/us/pdf/T...nChart(EN).pdf

https://www.suginoltd.co.jp/us/pdf/T...nChart(EN).pdf

From that page: crank axle bolt---40 to 50 Newton meters (29.5 to 36.9 foot-pounds, or 354 to 442 inch-pounds); crank axle nut---40 nm.

Likes For Trakhak:

#43

Senior Member

Join Date: Jan 2005

Location: Baltimore, MD

Posts: 5,380

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 2487 Post(s)

Liked 2,956 Times

in

1,679 Posts

I've always just tightened once... until..

There was the time when I bought a Phil titanium BB to use on a Campy Record crankset. i.e. the classic late 70's/early 80's Nuovo or Super Record crankset. I thought I'd replace the Campy BB with a lighter Phil BB. I contacted Phil to be sure that the axle taper was suited for the Campy, and they assured me it was. I installed it as typical, and did a few rides. Unfortunately, I was in the middle of a ride when I discovered that one (or both?) arms were a bit loose! I was close to one of the LBSs, and they snugged the bolts up. No issues after that.

There was the time when I bought a Phil titanium BB to use on a Campy Record crankset. i.e. the classic late 70's/early 80's Nuovo or Super Record crankset. I thought I'd replace the Campy BB with a lighter Phil BB. I contacted Phil to be sure that the axle taper was suited for the Campy, and they assured me it was. I installed it as typical, and did a few rides. Unfortunately, I was in the middle of a ride when I discovered that one (or both?) arms were a bit loose! I was close to one of the LBSs, and they snugged the bolts up. No issues after that.

In other words, the torque required to keep the assembly correctly tight (once the proper installation torque has been reached with the steel bolt) is lower than that specified for initial assembly.

#44

Senior Member

Join Date: Feb 2008

Location: Peoria, IL

Posts: 4,478

Mentioned: 86 Post(s)

Tagged: 0 Thread(s)

Quoted: 1829 Post(s)

Liked 3,376 Times

in

1,580 Posts

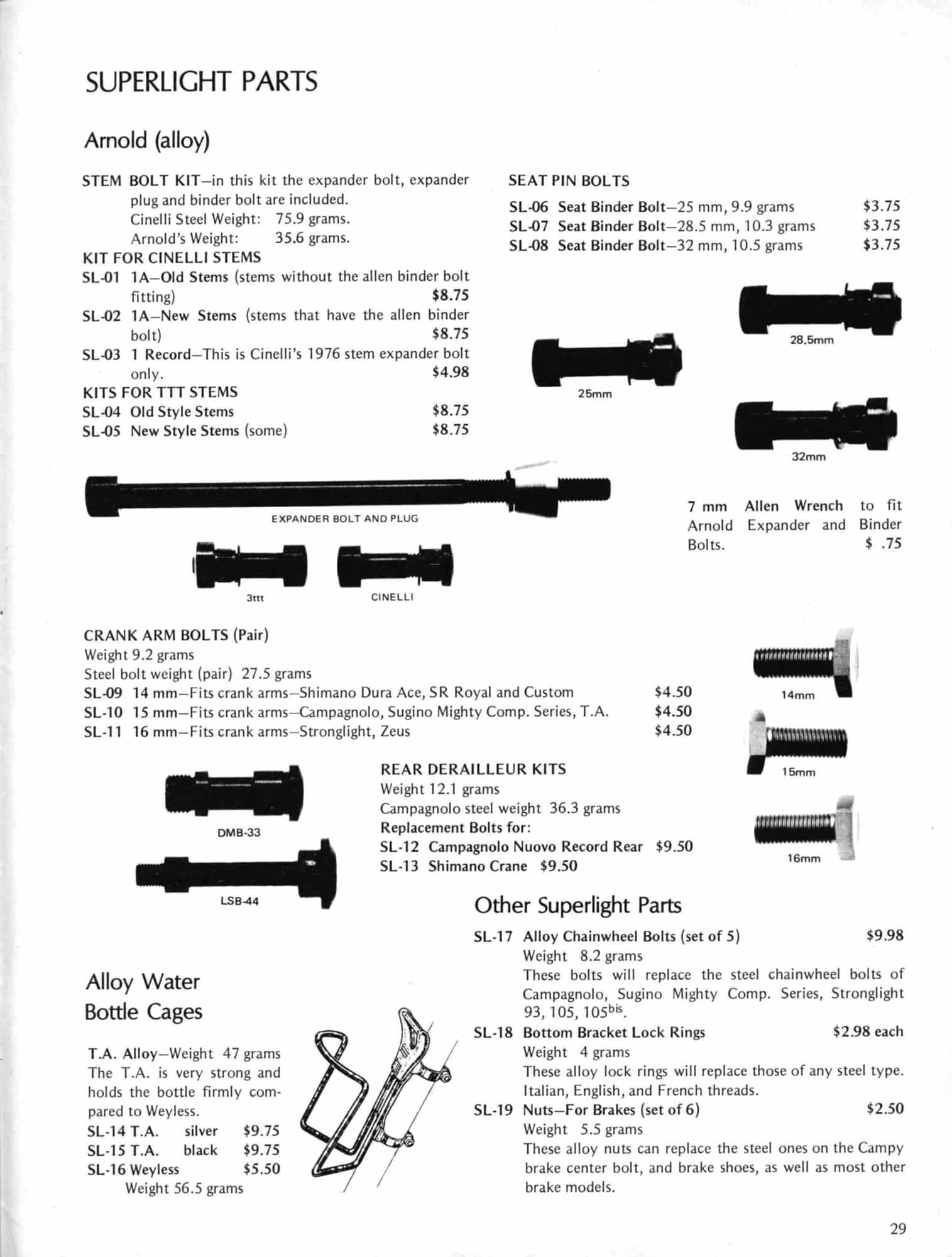

The mention of titanium bike parts brought to mind a tip concerning titanium bolts (and aluminum bolts, such as Cinelli 1R stem bolts). To install a lighter (and weaker) bolt while avoiding failure of the bolt during assembly or out on the road, use a steel bolt to tighten the fitting to the torque spec and then remove the steel bolt and install the lower-strength bolt.

In other words, the torque required to keep the assembly correctly tight (once the proper installation torque has been reached with the steel bolt) is lower than that specified for initial assembly.

In other words, the torque required to keep the assembly correctly tight (once the proper installation torque has been reached with the steel bolt) is lower than that specified for initial assembly.

I do recall some of the lightweight bolt kits, like Arnold, and have heard the recommendation to use steel bolts when forcing the cranks onto the axle.

The Palo Alto bike shop catalog listed a wide selection of aluminum bolts and parts....

A friend gave me some of his vintage bits, including some Cinelli style stem bolts that he had made. Really impressive, both in weight and craftsmanship. I can't imagine being brave enough to trust your teeth and face to an aluminum stem bolt, though. I think I sold one or two to a friend building up a weight weenie bike, and may still have one or two sets.

Steve in Peoria

#45

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,906

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4806 Post(s)

Liked 3,932 Times

in

2,557 Posts

With my Phil titanium BB, no titanium bolts were included, so no chance to try this technique... and I'm not sure that I would use them anyway.

I do recall some of the lightweight bolt kits, like Arnold, and have heard the recommendation to use steel bolts when forcing the cranks onto the axle.

The Palo Alto bike shop catalog listed a wide selection of aluminum bolts and parts....

A friend gave me some of his vintage bits, including some Cinelli style stem bolts that he had made. Really impressive, both in weight and craftsmanship. I can't imagine being brave enough to trust your teeth and face to an aluminum stem bolt, though. I think I sold one or two to a friend building up a weight weenie bike, and may still have one or two sets.

Steve in Peoria

I do recall some of the lightweight bolt kits, like Arnold, and have heard the recommendation to use steel bolts when forcing the cranks onto the axle.

The Palo Alto bike shop catalog listed a wide selection of aluminum bolts and parts....

A friend gave me some of his vintage bits, including some Cinelli style stem bolts that he had made. Really impressive, both in weight and craftsmanship. I can't imagine being brave enough to trust your teeth and face to an aluminum stem bolt, though. I think I sold one or two to a friend building up a weight weenie bike, and may still have one or two sets.

Steve in Peoria

#46

Paramount Fan

Join Date: Dec 2006

Location: Vermont

Posts: 293

Bikes: Paramounts, Raleigh Pros, Colnago, DeRosa, Gios, Masis, Pinarello, R. Sachs, Look, D. Moulton, Witcomb, Motobecane, Bianchis, Fat City, Frejus, Follis, Waterford, Litespeed, d'Autremont, others, mostly '70s-'80s

Mentioned: 3 Post(s)

Tagged: 0 Thread(s)

Quoted: 123 Post(s)

Liked 240 Times

in

133 Posts

Then you are using grease on your tapers! Unless you degrease with solvent or detergent, any grease means greased tapers. Even a thick wad of grease gets squished out until there is only the thinnest of films, so your method is just the same as the thick wad of grease method, other than the thick wad making more of a mess.

I have heard a bit of lore repeated over the years, that the oil you get on your finger by rubbing your nose, then aplied to the spindle, is the right amount of lubrication. But any lube means lubed! You're also getting moisture off your nose, so I wouldn't actually recommend this method. Though I can't say from personal experience, it sounds wrong to me to intentionally put water in that interface.

OK, but when will that happen? Hasn't happened yet, but I've only been doing this for 50 years, and like they say, "past performance is no guarantee of future results".

This argument is evergreen, and it will never be settled, but I just want people to know that there is controversy, with experts on both sides. I know for a fact that both dry and greased tapers can work reliably when done by an experienced mechanic. I'm not trying to win anyone over to my "side", I know my anecdotes aren't data and I haven't proven anything. But neither have the dry tapers people ó most of whom are using grease whether they know it or not!

Mark B

I have heard a bit of lore repeated over the years, that the oil you get on your finger by rubbing your nose, then aplied to the spindle, is the right amount of lubrication. But any lube means lubed! You're also getting moisture off your nose, so I wouldn't actually recommend this method. Though I can't say from personal experience, it sounds wrong to me to intentionally put water in that interface.

OK, but when will that happen? Hasn't happened yet, but I've only been doing this for 50 years, and like they say, "past performance is no guarantee of future results".

This argument is evergreen, and it will never be settled, but I just want people to know that there is controversy, with experts on both sides. I know for a fact that both dry and greased tapers can work reliably when done by an experienced mechanic. I'm not trying to win anyone over to my "side", I know my anecdotes aren't data and I haven't proven anything. But neither have the dry tapers people ó most of whom are using grease whether they know it or not!

Mark B

What I wonder is what are considered correct tightening torques for vintage cranksets. I don't recall ever seeing a published spec from most manufacturers of vintage cranks -- did Stronglight even consider torque spec a thing? I'm in the dark even for a Campy Nuovo Record torque spec, and I'm a bit leery of anyone else's "educated guess" as being more authoritative than that for which I have developed a feel using my trusty peanut butter wrench. If I knew manufacturers' torque specs, I would use them. I'm often surprised when doing automotive work how much more I turn a bolt when I torque it after I thought I had already gotten pretty close with a regular wrench.

I did have the misfortune a few years ago of having a Campy left arm work loose on a ride. I'm am quite sure I installed it the same as I have been doing for decades, but the crank had a long, unknown history before I got it. I have read much of what Jobst wrote on the subject over the years and now clean the threads and apply Blue Loctite. If the bolt never loosens up the arm will never develop play. As these aluminum parts age I expect they get even more susceptible to cracking, and I think overtightening and/or re-tightening is not a wise strategy.

#47

aka: Dr. Cannondale

Join Date: Jul 2009

Posts: 7,735

Mentioned: 234 Post(s)

Tagged: 0 Thread(s)

Quoted: 2155 Post(s)

Liked 3,406 Times

in

1,206 Posts

Likes For rccardr:

#48

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

I have seen cracks in an Arnold Industries crank fixing bolts, the gold-anodized ones. Seen two that cracked, both in the head in a way that didn't cause the shaft of the bolt to break. Just sorta like one-third of the hex starting to come off, what would that be called, a chordal crack maybe? Anyway a mellow failure mode, the bikes stayed rideable with the crack there. One was installed by me so I know for sure it was torqued with a steel bolt first. The alu bolt cracked from just maintaining the crank on the spindle. So it can happen.

That didn't stop me from using alu crank bolts though, too much of a weight-weenie. On my wife's bike anyway. She likes having a light bike and accepts there are some compromises. Me, I'm fat, so obsessing about the weight of crank bolts is not something I indulge in anymore. But back in my racing days, sure.

Mark B

#49

Senior Member

Join Date: Jan 2005

Location: Baltimore, MD

Posts: 5,380

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 2487 Post(s)

Liked 2,956 Times

in

1,679 Posts

I knew only a couple of guys who used Cinelli stems with the aluminum stem bolt. One of the two was on a ride when the bolt snapped---without warning, of course. He managed to stay upright long enough to come to a safe stop, to his own surprise.

Among earlier generations of (European) pros, proper use of aluminum bolts might have been common knowledge, especially for the team mechanics.

Last edited by Trakhak; 01-16-23 at 05:07 PM.

Likes For Trakhak:

#50

blahblahblah chrome moly

Join Date: Apr 2009

Location: Seattle

Posts: 1,994

Mentioned: 92 Post(s)

Tagged: 0 Thread(s)

Quoted: 1181 Post(s)

Liked 2,576 Times

in

1,076 Posts

I used to do a no-hands track stand pretty well, but I always steererd with the bars until stopped, then sat up to do the no-hands thing. Coming to a stop without handlebars might be tricky.

Phil Anderson told the story of a pro who pulled his stem clean out of the steerer, in the middle of a tightly-packed pro peloton. Nobody fell down! I think he attributed the stem coming out to the cone having been tightened too low in a small frame, into the taper where the butt begins. Then any little slippage causes the stem to become completely loose. Not from the bolt breaking.

EDIT: Ah I see you edited yours, the guy did not fall over, so I take back what I said about him not being good at riding no hands!

Mark B