Idiopathic Bontrager wheel screech

#26

Senior Member

Join Date: Dec 2009

Location: Melbourne, Oz

Posts: 9,547

Bikes: https://weightweenies.starbike.com/forum/viewtopic.php?f=10&t=152015&p=1404231

Mentioned: 15 Post(s)

Tagged: 0 Thread(s)

Quoted: 1529 Post(s)

Liked 718 Times

in

510 Posts

Shhh, Kimmo. If you make posts like this they'll ID you as reactionary. Then they'll come after both of us!

I, too, feel that the older cup and cone angular contact bearings were better: 1) AC gives lateral stiffness, 2) as a result of lateral stiffness, AC bearings wear more slowly, 3) the deep groove radial design means that the inner and outer races are "stacked" and not "nested", meaning that AC hubs can be more compact, 4) the AC hub is held together with the cone nuts and lockwashers - none of the loose pieces held together with the QR and .... o-ring friction!

The only advantage I see to the cartridge approach is that the outer race is easily replaced, which is not so on the older AC bearing wheels. Shops love em I think, because the deep groove radial design wears out every couple years due to higher wear rates from side forces. So it makes for more shop revenue. Sigh.

I, too, feel that the older cup and cone angular contact bearings were better: 1) AC gives lateral stiffness, 2) as a result of lateral stiffness, AC bearings wear more slowly, 3) the deep groove radial design means that the inner and outer races are "stacked" and not "nested", meaning that AC hubs can be more compact, 4) the AC hub is held together with the cone nuts and lockwashers - none of the loose pieces held together with the QR and .... o-ring friction!

The only advantage I see to the cartridge approach is that the outer race is easily replaced, which is not so on the older AC bearing wheels. Shops love em I think, because the deep groove radial design wears out every couple years due to higher wear rates from side forces. So it makes for more shop revenue. Sigh.

Does my head in how so many folks can look at an Ultegra hub or similar, and look at hubs by pretty much anyone except Campy or Shimano (ignoring all the low-end loose-ball stuff like Joytech), and not see that one is fully designed for purpose using all bespoke elements, and the other is a result of the engineers just throwing up their hands and saying 'generic part goes here' when it comes to one of the most important aspects.

#27

The dropped

Join Date: Oct 2018

Location: Columbus, OH

Posts: 2,144

Bikes: Pake C'Mute Touring/Commuter Build, 1989 Kona Cinder Cone, 1995 Trek 5200, 1973 Raleigh Super Course FG, 1960/61 Montgomery Ward Hawthorne "thrift" 3 speed, by Hercules (sold) : 1966 Schwinn Deluxe Racer (sold)

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 1739 Post(s)

Liked 1,014 Times

in

696 Posts

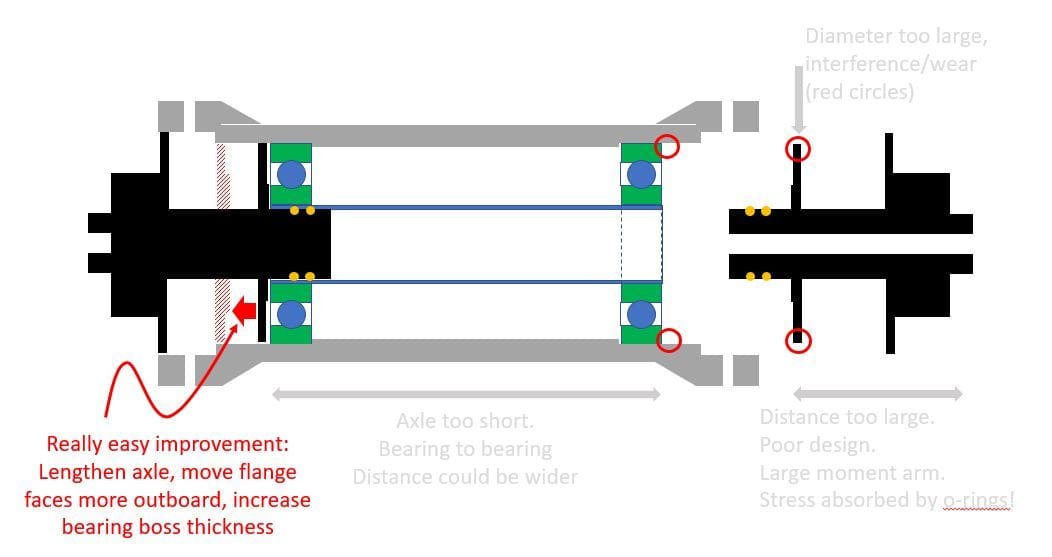

@Kimmo: the engineers involved here were concerned with how to 'cleverly' kill two birds with one stone. I'm sure they saved gobs of money simply because they didn't need to shut down a production line to retool for a longer axle.

#28

Generally bewildered

Thread Starter

Join Date: Aug 2015

Location: Eastern PA, USA

Posts: 3,037

Bikes: 2014 Trek Domane 6.9, 1999 LeMond Zurich, 1978 Schwinn Superior

Mentioned: 20 Post(s)

Tagged: 0 Thread(s)

Quoted: 1152 Post(s)

Liked 341 Times

in

251 Posts

@Kimmo: the engineers involved here were concerned with how to 'cleverly' kill two birds with one stone. I'm sure they saved gobs of money simply because they didn't need to shut down a production line to retool for a longer axle.

Last edited by WizardOfBoz; 10-07-19 at 09:50 AM.

#29

Senior Member

Join Date: May 2019

Location: Bloomington, IN

Posts: 2,951

Bikes: Paramount, Faggin, Ochsner, Ciocc, Basso

Mentioned: 117 Post(s)

Tagged: 0 Thread(s)

Quoted: 1304 Post(s)

Liked 1,913 Times

in

1,143 Posts

Wiz, Kimmo, and Unca,

At what point in the design process, did anyone think about down the line problems that might occur? I'm thinking (just like the last girl I asked out) NEVER! These guys are taught to do the quick and dirty production process, and save the company as many dollars as possible. So post production problems are up to the QA people who will learn how to explain the problem away. Stoopid easy and stoopid simple is the new way of engineering, and don't try to think about the future in this,,, more to come in the next generation... Smiles, MH

At what point in the design process, did anyone think about down the line problems that might occur? I'm thinking (just like the last girl I asked out) NEVER! These guys are taught to do the quick and dirty production process, and save the company as many dollars as possible. So post production problems are up to the QA people who will learn how to explain the problem away. Stoopid easy and stoopid simple is the new way of engineering, and don't try to think about the future in this,,, more to come in the next generation... Smiles, MH

#30

Senior Member

Join Date: Feb 2012

Location: Rochester, NY

Posts: 18,100

Bikes: Stewart S&S coupled sport tourer, Stewart Sunday light, Stewart Commuting, Stewart Touring, Co Motion Tandem, Stewart 3-Spd, Stewart Track, Fuji Finest, Mongoose Tomac ATB, GT Bravado ATB, JCP Folder, Stewart 650B ATB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4212 Post(s)

Liked 3,883 Times

in

2,318 Posts

MH- I was just talking about this aspect of current bike design/manufacturing with a co worker that I will likely end up teaching how to build a frame. The life cycle of a modern bike is less then the industry wants you to believe. Why? Because the marketing side (and one can lump into this the world of magazines, blogs and such that parrot ad spec/hype) are working harder to create a reason to buy the latest/newest with the promise that your Strava status will go up.

We're never going back to the abundance of small replacement parts availability being important or frame resiliency is what makes a frame better Andy

Andy

We're never going back to the abundance of small replacement parts availability being important or frame resiliency is what makes a frame better

Andy

Andy

__________________

AndrewRStewart

AndrewRStewart