The 26 Inch Wheel Flat Earth Society

#101

Senior Member

Come up with a number for psi you find comfortable, and create a complicated formula to get you that result. Easy. Reverse engineering.

#103

Senior Member

Join Date: Aug 2010

Location: Madison, WI

Posts: 11,214

Bikes: 1961 Ideor, 1966 Perfekt 3 Speed AB Hub, 1994 Bridgestone MB-6, 2006 Airnimal Joey, 2009 Thorn Sherpa, 2013 Thorn Nomad MkII, 2015 VO Pass Hunter, 2017 Lynskey Backroad, 2017 Raleigh Gran Prix, 1980s Bianchi Mixte on a trainer. Others are now gone.

Mentioned: 48 Post(s)

Tagged: 0 Thread(s)

Quoted: 3462 Post(s)

Liked 1,468 Times

in

1,145 Posts

I have no clue what the formula would be for the 15 percent tire drop theory, but I am sure someone derived a formula. But that formula would have different pressure in the front because that is based on the weight on each wheel.

https://janheine.wordpress.com/2016/...ure-take-home/

I have at times used numbers similar to the 15 percent tire drop theory for rear wheel when touring with a load, but my front tire always has more pressure than the 15 percent tire drop theory calls for. And riding an unladen bike, I usually run higher pressures than the 15 percent tire drop theory. As I noted above, my front tire would have about 75 to 80 percent as much pressure as in the rear, thus the front would have more than the 15 percent theory.

#104

Jedi Master

Interesting that it does not have a different pressure for each wheel.

I have no clue what the formula would be for the 15 percent tire drop theory, but I am sure someone derived a formula. But that formula would have different pressure in the front because that is based on the weight on each wheel.

https://janheine.wordpress.com/2016/...ure-take-home/

I have at times used numbers similar to the 15 percent tire drop theory for rear wheel when touring with a load, but my front tire always has more pressure than the 15 percent tire drop theory calls for. And riding an unladen bike, I usually run higher pressures than the 15 percent tire drop theory. As I noted above, my front tire would have about 75 to 80 percent as much pressure as in the rear, thus the front would have more than the 15 percent theory.

I have no clue what the formula would be for the 15 percent tire drop theory, but I am sure someone derived a formula. But that formula would have different pressure in the front because that is based on the weight on each wheel.

https://janheine.wordpress.com/2016/...ure-take-home/

I have at times used numbers similar to the 15 percent tire drop theory for rear wheel when touring with a load, but my front tire always has more pressure than the 15 percent tire drop theory calls for. And riding an unladen bike, I usually run higher pressures than the 15 percent tire drop theory. As I noted above, my front tire would have about 75 to 80 percent as much pressure as in the rear, thus the front would have more than the 15 percent theory.

I used to run the front tire lower pressure than the rear, then I pinch flatted the front a couple of times, so I now run them pretty close to the same.

#105

Senior Member

Join Date: Sep 2015

Location: Left Coast, Canada

Posts: 5,126

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 2236 Post(s)

Liked 1,314 Times

in

707 Posts

#106

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,369

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6222 Post(s)

Liked 4,222 Times

in

2,368 Posts

You only considered one point which was the spoke density. I also mentioned the bracing angle. Now I'll admit that the spoke density isn't the biggest factor and the effect it has is slight. However the effect the bracing angle has is not slight. Nor is the strength difference.

As a guess I'd go as far as to say that a 26" wheel is at least 10% more durable than a 700c wheel when other factors are equaled.

As a guess I'd go as far as to say that a 26" wheel is at least 10% more durable than a 700c wheel when other factors are equaled.

On the other hand, if you built the wheels with a Velocity A23 OC hub, the bracing angle would be 6.6°/5.1° which is a smaller bracing angle but it’s more equivalent and makes for a more durable wheel.

And again you address the point which has the least amount of effect, ie. the increased spoke tension. The much larger effect a higher profile rim has is the fact that it has more vertical wall. If you take a steel ruler it's easy to bend one way and completely impossible to the other way. Same thing in effect here. This is like basic engineering stuff. I-beams for crying out loud!

Your ruler analogy is apt. Most of the high profile rims also tend to be rather thin. Your ruler may not bend easily when you push down on it but if you push on it laterally, it bend rather easily. Wheels don’t just work in one direction. Yes they are stiffer but only from in one direction.

I wasn't actually. I was speaking about the fact that wheels work with tensioned spokes. So theoretically you could build a wheel successfully with string only. Though I think it might need a bit more bracing angle than is present in typical bicycle wheels. And the string would need to be kevlar or aramid or some other material which yields very little and allows for crazy high tensions.

Mind you it probably wouldn't be a good wheel but it would be possible.

Ya think?

Mind you it probably wouldn't be a good wheel but it would be possible.

Ya think?

Sigh.......

Ok... So you do realize that the spokes on a bicycle wheel are in tension right? So there isn't any compression happening. We're clear on this? Bicycle spokes do not experience compression. So why would you give an example of a wheel which has compression spokes?

Ok... So you do realize that the spokes on a bicycle wheel are in tension right? So there isn't any compression happening. We're clear on this? Bicycle spokes do not experience compression. So why would you give an example of a wheel which has compression spokes?

Well that's also true. Spoke strength does make a difference but it is still only one part of the puzzle.

Alternatively, lower the number of spoke to a ridiculous number...let’s say 8 paired spoke...and, just to make the test less fair, let’s use those 1.5mm spokes. Would you ride that steel rimmed wheel on a loaded touring bike down a mountain at 50 mph? I wouldn’t ride that wheel across the street.

I get your point but it doesn't work. Rather one should aim for fixing the issue and not just the symptoms.

Want to avoid holes in tubes? Full rubber tires!

Want to avoid high blood pressure? Remove blood! Genious!

Want to avoid broken spokes? Use several different methods in unison to build the most durable yet sensible wheel possible. Component choices, compatibility, build quality and use within the limits of the build all have an effect.

Want to avoid holes in tubes? Full rubber tires!

Want to avoid high blood pressure? Remove blood! Genious!

Want to avoid broken spokes? Use several different methods in unison to build the most durable yet sensible wheel possible. Component choices, compatibility, build quality and use within the limits of the build all have an effect.

My wheels are “sensible”...and strong...and durable. And my wheels are all built with an eye to “component choice, compatibity, build quality” and how the wheel is going to be used. Give me some credit for have a little intelligence. I haven’t found a situation yet where having a heavier rim than what I normally use would be advantageous. If the spokes don’t break and the wheel stays true and round, what more do you think I could do to make the wheel “better”?

As an example of my choices on wheel builds, I built wheels for my fast bike to replace supposedly “better” low spoke count wheels. I used Velocity A23 (not super light rim but it’s not a heavy rim either), Pillar triple butted spokes, White Industry T11 hubs and splined nipples. Do you see anything wrong with those choices? I certainly didn’t and, as an added bonus, the bike went from weighing 22 lbs (10 kg for those with a proper measurement system) to weighing 20 lbs (9 kg) with a what I would consider a far stronger wheel. I’ll take a loss of a kilo of weight off a bike any time and a loss of a kilo of rotating weight is something everyone strives for.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#107

Senior Member

How great an effect do you expect from the bracing angle? How much of a difference is a “huge” difference? Using this calculator using a White Industries MI5 hub and Velocity Dyad in 559mm and 622mm rims, the bracing angles are 8.3°/5° (R/L) for the 559 and 7.4°/4.4°. How much of a difference is significant?

It's hard to say exactly how much is significant without doing some extensive testing. But what is clear is that the bracing angle difference is significant which in turn means that the wheel is much more resistant to sideways loading. What did not surprise me was that the spoke tension difference does not change between sides, because why would it? The angle ratios remain the same.

On the other hand, if you built the wheels with a Velocity A23 OC hub, the bracing angle would be 6.6°/5.1° which is a smaller bracing angle but it’s more equivalent and makes for a more durable wheel.

Also the funny thing about OC rims is that they rely heavily on the rim stiffness charasteristics to work. If your rim had very little torsional stiffness i'd suspect it would not work at all as an OC rim. Which then brings us back to rim stiffness in general.

So the spoke density is unimportant and the spoke tension is unimportant so what is “important”? The bracing angle?

As you should know as a fellow wheelbuilder, it all contributes. Every aspect has an effect and maximizing the durability enhancing sides of those aspects is what builds a strong wheel. Neglect one aspect and the wheel won't implode, but it will be somewhat weaker as a result. Not everyone wants to ride 26" wheels (me being one of them) and so they have to take the durability loss of that aspect. There are also those who prefer a low number of spokes and also prefer them to be extra light. It's all about the compromises you're willing to accept.

Your ruler analogy is apt. Most of the high profile rims also tend to be rather thin. Your ruler may not bend easily when you push down on it but if you push on it laterally, it bend rather easily. Wheels don’t just work in one direction. Yes they are stiffer but only from in one direction.

BUT it needs to be added that IMO the best touring rims are Vee/box section hybrids where you get the vertical stiffness of the high vertical walls as well as the high Vee-section but also the lateral stiffness of the lateral walls present in the rim. Hence, box section. Double wall.

Yea, I “think”. The reason that the Tioga was not such a great wheel is that it depended on the plastic disc for rigidity. Remove the disc and there is nothing there for rigidity. The wheel might be capable of vertical rigidity but the first time you put a lateral load on the rim and the whole thing is going to collapse. Again, the spokes do the work.

Yes, it’s a silly bike but that would be the only way to build with a rim of rubber...by using spokes in compression. But you can’t build with only either. The string would not have any lateral stiffness which is necessary to hold the rim in place. It wouldn’t matter how much tension you put on the strings, without something...like the Tioga’s disc...for them to pull against, the whole thing would fall over.

Yes, it’s a silly bike but that would be the only way to build with a rim of rubber...by using spokes in compression. But you can’t build with only either. The string would not have any lateral stiffness which is necessary to hold the rim in place. It wouldn’t matter how much tension you put on the strings, without something...like the Tioga’s disc...for them to pull against, the whole thing would fall over.

But a very important part of the puzzle. Look at it this way, you could get a steel rim which is the stiffest, strongest rim available. Now pair it with weak spokes like, for example, 1.5mm spokes and built it properly. I doubt that you would end up with a wheel that would be sufficient for a touring load. It would pop spokes more than your local multiplex theater.

Alternatively, lower the number of spoke to a ridiculous number...let’s say 8 paired spoke...and, just to make the test less fair, let’s use those 1.5mm spokes. Would you ride that steel rimmed wheel on a loaded touring bike down a mountain at 50 mph? I wouldn’t ride that wheel across the street.

Alternatively, lower the number of spoke to a ridiculous number...let’s say 8 paired spoke...and, just to make the test less fair, let’s use those 1.5mm spokes. Would you ride that steel rimmed wheel on a loaded touring bike down a mountain at 50 mph? I wouldn’t ride that wheel across the street.

As for lowering the number of spokes to ridiculously low. No, I would not ride that wheel if it had a steel rim. A flexy steel rim would not be able to support the wheel with so few spokes. If it had a really high profile carbon rim reinforced to allow for really high tensions and I'd be allowed to build said wheel I'd use it without load. But since I'm myself pretty heavy that'd be pushing it. But even with a stiff rim, too little spokes causes too much point load (or is it point slack...) to one spoke.

What about it “doesn’t work”? I’ve been building with triple butted spokes for the better part of 20 years. Broken spokes are a thing of the past for me. My first build with triple butted spokes was a mountain bike wheel that was ridden hard off-road for 15 years. The only reason that I had to replace the wheel is because I loaned the bike out and the guy overshifted into the spokes...he “adjusted” the derailer because it wasn’t shifting properly (to him) in the manner that most people “adjust” derailers by messing with the limit screws.

My wheels are “sensible”...and strong...and durable. And my wheels are all built with an eye to “component choice, compatibity, build quality” and how the wheel is going to be used. Give me some credit for have a little intelligence. I haven’t found a situation yet where having a heavier rim than what I normally use would be advantageous. If the spokes don’t break and the wheel stays true and round, what more do you think I could do to make the wheel “better”?

As an example of my choices on wheel builds, I built wheels for my fast bike to replace supposedly “better” low spoke count wheels. I used Velocity A23 (not super light rim but it’s not a heavy rim either), Pillar triple butted spokes, White Industry T11 hubs and splined nipples. Do you see anything wrong with those choices? I certainly didn’t and, as an added bonus, the bike went from weighing 22 lbs (10 kg for those with a proper measurement system) to weighing 20 lbs (9 kg) with a what I would consider a far stronger wheel. I’ll take a loss of a kilo of weight off a bike any time and a loss of a kilo of rotating weight is something everyone strives for.

My wheels are “sensible”...and strong...and durable. And my wheels are all built with an eye to “component choice, compatibity, build quality” and how the wheel is going to be used. Give me some credit for have a little intelligence. I haven’t found a situation yet where having a heavier rim than what I normally use would be advantageous. If the spokes don’t break and the wheel stays true and round, what more do you think I could do to make the wheel “better”?

As an example of my choices on wheel builds, I built wheels for my fast bike to replace supposedly “better” low spoke count wheels. I used Velocity A23 (not super light rim but it’s not a heavy rim either), Pillar triple butted spokes, White Industry T11 hubs and splined nipples. Do you see anything wrong with those choices? I certainly didn’t and, as an added bonus, the bike went from weighing 22 lbs (10 kg for those with a proper measurement system) to weighing 20 lbs (9 kg) with a what I would consider a far stronger wheel. I’ll take a loss of a kilo of weight off a bike any time and a loss of a kilo of rotating weight is something everyone strives for.

Probably the only reason I don't build with velocity is their prohibitively high price in the EU.

That is what I wrote first. But I see you can get the A23 for 60 euros which is around the same price as the DT Swiss TK540. I wonder why Velocity wheels are so expensive in the US...

But I have to say that it will be difficult to move away from the warm embrace of DT Swiss rims because they are just SO EASY TO BUILD! They come laser straight out of the box and have relatively high allowed tensions (at least the TK540 does)

Now I don't question the durability of your wheels. I'm sure they are as close to bombproof as they get. Our methods of building wheels are actually pretty dang similiar.

The only thing we really disagree about is rim interaction in one direction and even then not in general but in point load situations. But I'll test that at some point and make a topic about that.

It'll be fun to start testing all this stuff. I may be wrong (though my logic dictates I'm not. Calculating this stuff should be possible but accounting for all the variables would make one mighty calculation) but if I am it just means I can start using different rims for my builds.

#108

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,369

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 152 Post(s)

Tagged: 1 Thread(s)

Quoted: 6222 Post(s)

Liked 4,222 Times

in

2,368 Posts

It's hard to say exactly how much is significant without doing some extensive testing. But what is clear is that the bracing angle difference is significant which in turn means that the wheel is much more resistant to sideways loading. What did not surprise me was that the spoke tension difference does not change between sides, because why would it? The angle ratios remain the same.

Now while this is something I would absolutely advocate (since OC rims do make wheels strongers as a component choice), isn't this kinda going outside the goalposts?

Also the funny thing about OC rims is that they rely heavily on the rim stiffness charasteristics to work. If your rim had very little torsional stiffness i'd suspect it would not work at all as an OC rim. Which then brings us back to rim stiffness in general.

Also the funny thing about OC rims is that they rely heavily on the rim stiffness charasteristics to work. If your rim had very little torsional stiffness i'd suspect it would not work at all as an OC rim. Which then brings us back to rim stiffness in general.

I also don’t agree that OC rims are any stiffer than a comparable centerline drilled rim. The A23 OC and the A23 are similarly constructed. The advantage of the OC for a dished wheel comes from the more closely equalized spoke tension. Do an apples to apples comparison rather than cheese to chalk one.

I see you've stooped to putting word in my mouth. As some would say: "not cool man!".

As you should know as a fellow wheelbuilder, it all contributes. Every aspect has an effect and maximizing the durability enhancing sides of those aspects is what builds a strong wheel. Neglect one aspect and the wheel won't implode, but it will be somewhat weaker as a result. Not everyone wants to ride 26" wheels (me being one of them) and so they have to take the durability loss of that aspect. There are also those who prefer a low number of spokes and also prefer them to be extra light. It's all about the compromises you're willing to accept.

As you should know as a fellow wheelbuilder, it all contributes. Every aspect has an effect and maximizing the durability enhancing sides of those aspects is what builds a strong wheel. Neglect one aspect and the wheel won't implode, but it will be somewhat weaker as a result. Not everyone wants to ride 26" wheels (me being one of them) and so they have to take the durability loss of that aspect. There are also those who prefer a low number of spokes and also prefer them to be extra light. It's all about the compromises you're willing to accept.

Hence why it's important that the rim is stiff vertically (and as I realized above, also torsionally). Lateral stiffness isn't as important, because that is where the spokes actually do help with the failings of the rim. Lateral stiffness is largely due to the contribution of spokes in both the stiffness as a whole but also in point stiffness (where you would try to bend the wheel in or out in a single point). On the other hand, while spokes are largely responsible for the vertical stiffness of the wheel as a whole they do not contribute at all to vertical point stiffness (such as when the the force inflicted upon the ground is countered by the ground itself and... Man explaining physics simply is kinda tough isn't it. Let's just say the point stiffness counts where the ground is pushing against the wheel)

Also remember that every time any rim hits the bottom of rotation that it is deflected upwards. Making it stiffer decreases the upward deflection but it will still deflect because, as you pointed out, the wheel is in tension and there is nothing to keep the rim from deflecting.

BUT it needs to be added that IMO the best touring rims are Vee/box section hybrids where you get the vertical stiffness of the high vertical walls as well as the high Vee-section but also the lateral stiffness of the lateral walls present in the rim. Hence, box section. Double wall.

But tension is the only think that keeps the wheel from coming apart. There is NO compression in spokes, they cannot handle it. Spokes do have some rigidity, but again it's not compression that's keeping the wheel from coming apart. I also disagree with the notion that the wheel would just fall over. If you do 3X you'd have tension pulling both forwards and back but with the bracing angles also to the sides which would mean the wheel would at least stand. Whether it'd be rideable with conventional bike components.. Well I don't know about that.

But tension is the only think that keeps the wheel from coming apart. There is NO compression in spokes, they cannot handle it. Spokes do have some rigidity, but again it's not compression that's keeping the wheel from coming apart. I also disagree with the notion that the wheel would just fall over. If you do 3X you'd have tension pulling both forwards and back but with the bracing angles also to the sides which would mean the wheel would at least stand. Whether it'd be rideable with conventional bike components.. Well I don't know about that.

But you can't save a bad build with good spokes. The good spokes will be just as prone to failure as the bad spokes if there is a critical compromising factor in the wheelbuild. Granted the Alpine III's are the best out there and those are what I use for my heavy duty wheels, but the 1.5mm double butteds' from DT Swiss aren't exactly bad either. I'm pretty sure you could build a successful touring wheel out of them if you beefed up the other factors, ie. more spokes, smaller wheel diameter, stiffer rim etc etc etc. But no, they aren't good if you're trying to maximize strength and durability. Nor would it be exactly smart to build a touring wheel with such light spokes because the extra spokes aspect would just eat all the weight savings...

As for lowering the number of spokes to ridiculously low. No, I would not ride that wheel if it had a steel rim. A flexy steel rim would not be able to support the wheel with so few spokes. If it had a really high profile carbon rim reinforced to allow for really high tensions and I'd be allowed to build said wheel I'd use it without load. But since I'm myself pretty heavy that'd be pushing it. But even with a stiff rim, too little spokes causes too much point load (or is it point slack...) to one spoke.

As for lowering the number of spokes to ridiculously low. No, I would not ride that wheel if it had a steel rim. A flexy steel rim would not be able to support the wheel with so few spokes. If it had a really high profile carbon rim reinforced to allow for really high tensions and I'd be allowed to build said wheel I'd use it without load. But since I'm myself pretty heavy that'd be pushing it. But even with a stiff rim, too little spokes causes too much point load (or is it point slack...) to one spoke.

My overall point is that people look at a wheel and they see a hub and a rim and that’s all. The spokes are invisible and an afterthought...until the spokes start to break. Then they start looking around for a stronger rim to solve the problem. It’s not the problem they need to solve. More spokes works but stronger spokes works better. Most any rim made in the last 20 years is strong enough for the job. I start every wheel build with the spokes, then I worry about what hub to use and the rim is the last thing I consider and then only is terms of weight.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#109

Senior Member

Sorry but you can’t have it both ways. You can’t say that it hard to say how significant bracing angle differences are and say that bracing angle differences are significant on a 1° level. I’m not saying that the difference isn’t significant only that I don’t know how large a difference is significant.

I need to revisit what I wrote there. I have the flu so I'm not exactly firing with all cylinders at the moment.

It’s not moving the goal posts at all. It kind of shows how the bracing angle is somewhat insignificant without taking other factors into account.

I also don’t agree that OC rims are any stiffer than a comparable centerline drilled rim. The A23 OC and the A23 are similarly constructed. The advantage of the OC for a dished wheel comes from the more closely equalized spoke tension. Do an apples to apples comparison rather than cheese to chalk one.

I didn’t put words in your mouth at all. You are the one who said something is important and then said it isn’t. Yes, I agree that all aspects contribute but some contribute more than others. Nearly every discussion I’ve had about wheels starts with the person looking for a strong rim. The discussion usually ends there too. Yes, rims are important but they aren’t the most important element of the wheel. That’s my point. Most any rim you want to choose is going to work. Not every spoke you choose is going to do the job. Would you honestly ride my steel wheel example above? Although it is an extreme, it’s very similar to what most people think is a “strong” wheel.

Lateral stiffness is the most important parameter. You could build your string wheel and, like I said above, it would probably stand up. Put a lateral load on it and rim will do nothing to stop the wheel from folding over.

Also remember that every time any rim hits the bottom of rotation that it is deflected upwards. Making it stiffer decreases the upward deflection but it will still deflect because, as you pointed out, the wheel is in tension and there is nothing to keep the rim from deflecting.

A string spoked wheel would depend entirely on the rim rigidity. Lace up a set of wheels loosely and go for a ride. The wheel snakebellies as it goes down the road. Loose spoke have just enough rigidity to keep the wheel from folding but only just. Even the vertical rigidity is poor because the rim isn’t under enough tension for the load to be spread around.

But you can’t save a bad build with a stronger rim. That’s my point. Yes, it all works together but you can only beef up the other factors so much. There are limits. And, for each of those parameters that you want to beef up, going with a stronger spoke is going to make them more beefy. I’m not saying, nor have I ever said, to build with poor components. Build with good components but don’t put too much emphasis on parts that don’t have that much of an effect on durability and strength.

All that being said Bontrager straight gauge spokes are made of cheese so no matter how good the build they will not last...

I think you are missing why I choose a steel rim. A steel rim is far from “flexible”. Aluminum is flexible. Steel is 3 times stiffer and a steel rim doesn’t lose that stiffness. My point for choosing a steel rim is that it is stiff, strong and inflexible. It is the ultimate in a “strong” rim. I wouldn’t ride a low spoke steel wheel with light spokes because the spokes would be very prone to breaking. I don’t ride low spoke count wheels for the same reason. I don’t buy into the “the rims are really strong so the wheel is strong” sales pitch. Apparently neither do you.

On the other hand aluminum rims are extruded giving the possibility for pretty wacky shapes. Aluminum extruded in box vee hybrid with double walls and even perhaps tubeless shelves is going to be more stiff than an equivalent steel bent from sheet.

Also 3mm aluminum is stiffer than 1mm of steel even though they weigh the same. Aluminum gains stiffness from thickness (most metals do I think)

As for the strong rim = strong wheel. I don't buy into that either. But it is easier to build a strong wheel with a strong rim than it is with a weak rim.

I actually wouldn't have a problem using low spoke count wheels in road riding if I had owned a road bike that would benefit from such. If I ever do build myself a road bike again I'll probably build some 24/28 spoke wheels with super high carbon rims and aerodynamic spokes. But that's a project for another time.

My overall point is that people look at a wheel and they see a hub and a rim and that’s all. The spokes are invisible and an afterthought...until the spokes start to break. Then they start looking around for a stronger rim to solve the problem. It’s not the problem they need to solve. More spokes works but stronger spokes works better. Most any rim made in the last 20 years is strong enough for the job. I start every wheel build with the spokes, then I worry about what hub to use and the rim is the last thing I consider and then only is terms of weight.

If the rim is too weak then the rim needs to go.

#110

Senior Member

Join Date: Feb 2019

Location: Santa Maria, CA

Posts: 108

Bikes: 1988 Specialized Stumpjumper Monstercross Touring Rig, and a couple of others

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 46 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

In a past life, I worked in the tire industry for a big company that sold medium truck and farm tires. Pressure is relative to load (and inverse to displacement).

I went to the trouble a couple of years back to buy a couple of bathroom scales so I could weigh everyone's wheel weight and percentage that I could find for about a month. Almost everyone has a 40% front, 60% rear bias no matter if it was road or mountain.

I found a chart somewhere for tandems that gave pressures relative to wheel weights, I think mine were 55psi front and 70psi rear on 25x700c tires (I weighed like 235 at the time). Bike handled great and quit beating me up on 200 mile days. Probably rode 8000 miles like that.

After I get the rig all loaded up, I'll find some scales and weigh it. The dead load from the panniers will certainly change the F/R bias.

My Schwalbe Marathoners showed up, They are three times as thick as any other tire I've ever seen and weigh a ton. I understand why they have the reputation for being indestructible. Hopefully if the weather breaks I'll take a test ride on it next week.

I went to the trouble a couple of years back to buy a couple of bathroom scales so I could weigh everyone's wheel weight and percentage that I could find for about a month. Almost everyone has a 40% front, 60% rear bias no matter if it was road or mountain.

I found a chart somewhere for tandems that gave pressures relative to wheel weights, I think mine were 55psi front and 70psi rear on 25x700c tires (I weighed like 235 at the time). Bike handled great and quit beating me up on 200 mile days. Probably rode 8000 miles like that.

After I get the rig all loaded up, I'll find some scales and weigh it. The dead load from the panniers will certainly change the F/R bias.

My Schwalbe Marathoners showed up, They are three times as thick as any other tire I've ever seen and weigh a ton. I understand why they have the reputation for being indestructible. Hopefully if the weather breaks I'll take a test ride on it next week.

#111

Senior Member

Join Date: Sep 2015

Location: Left Coast, Canada

Posts: 5,126

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 2236 Post(s)

Liked 1,314 Times

in

707 Posts

That's why I run them at high pressure. Unlike the current thinking of lower pressures allowing a tire to absorb imperfections rather than deflect off them the Marathon is so thick it isn't molding to much anyway.

#112

Senior Member

Join Date: Feb 2019

Location: Santa Maria, CA

Posts: 108

Bikes: 1988 Specialized Stumpjumper Monstercross Touring Rig, and a couple of others

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 46 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

There is a window of optimum pressure, where outside of it the tire simply rides badly and loses grip while not gaining much in the rolling resistance department. Race car guys knew this for decades before cyclists started paying attention to it, and it was like pulling teeth to get them to stop running 23's at 140psi.

Edit: I have a couple of URLs to post on the subject, but I can't post them till I get ten posts. I'll add them in a later.

Every time I see someone start to debate wheel stiffness or durability, I always start to think they have the pressures too high, not allowing the tire to deflect enough, and transferring unnecessary shock loads into the wheels. Or the rest of the bike. Or the rider. Especially with a 559x47 (26x1.75).

JIMO.

#113

Senior Member

Join Date: Sep 2015

Location: Left Coast, Canada

Posts: 5,126

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 2236 Post(s)

Liked 1,314 Times

in

707 Posts

Well, I just go by how the tires feel when I ride em. I've had them lower and they feel sluggish.. like having to pedal downhill sluggish. I pump em up and they seem to roll a bit faster. I'm not that scientific with tire pressure though. Try them for a while both ways and see what you think. They really aren't like other road bike tires. I also have CST Ciudads 1.5 and Panaracer Paselas 1.75's and they have so much more flex to them. To me the Marathon is a compromise of toughness over rolling resistance and I just want as little contact on pavement as possible.

#114

Senior Member

Join Date: Feb 2019

Location: Santa Maria, CA

Posts: 108

Bikes: 1988 Specialized Stumpjumper Monstercross Touring Rig, and a couple of others

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 46 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Is there a big difference between the Marathons and the Paselas in rolling resistance?

I know theres a bunch of difference between the Conti GP4000 25mm and the Maxxis Rambler 38mm no matter what pressure you put in them.

I know theres a bunch of difference between the Conti GP4000 25mm and the Maxxis Rambler 38mm no matter what pressure you put in them.

#115

Senior Member

Happy, you already know my views are in line with this guy. I think I've mentioned before how especially with commuting similar routes for years, just that little less pressure in tires can make a noticeable difference in harshness going to me and my wheels over rough surfaces, with no difference in ride time over about 10kms.

The kicker is that it's often just that small amount less psi I mean.

The kicker is that it's often just that small amount less psi I mean.

#120

Senior Member

Join Date: Sep 2015

Location: Left Coast, Canada

Posts: 5,126

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 2236 Post(s)

Liked 1,314 Times

in

707 Posts

Go forth and sin no more. Hope they are good pics

Craig, there is definitely a difference between the Marathons and Pasela's in that size, both good and bad. Speed wise the Pasela's are more supple and light and roll much faster. Flat wise the tread on the Pasela's tends to pick up road debris and keep it (I've flatted a couple of times because of that) while the Marathon's shed stuff. The only flat I've had with them was an awkward pinch flat in Moose Jaw when I dropped into a construction hole.

I don't disagree with the harshness of ride and would not argue if it were to be shown otherwise for speed. Most of my touring, other than day rides on other surfaces, for these tires has been major hwy's in Western Canada which are, for the most part, fairly well maintained. On gravel they definitely do bounces and skid off of rocks and would do better at lower pressure. My thoughts are mostly for paved road speed.

I fully admit I don't think too much about the pressure thing. All I know is that I really found the Marathons to be doggish when lower so I default to blow em up mode. I didn't notice this so much when I rode on my own touring with them (assumed speed was a function of loaded weight etc... ) but when I started doing bigger hills and mountain passes as training for another tour I noticed they did not roll downhill very fast, even unloaded. Here's a video coming down the Coquihalla Pass with a buddy on a 29'r suspension bike with big tires treaded tires and he was still pulling ahead of me going downhill all the time. To skip the boring part start at 1:00 in the video.

But all that doesn't mean I don't really like Marathons for what they are. If I were heading out and wanted the toughest tire for no worries, I'd still pick them (though tubeless may change the game there for touring at some point).

Craig, there is definitely a difference between the Marathons and Pasela's in that size, both good and bad. Speed wise the Pasela's are more supple and light and roll much faster. Flat wise the tread on the Pasela's tends to pick up road debris and keep it (I've flatted a couple of times because of that) while the Marathon's shed stuff. The only flat I've had with them was an awkward pinch flat in Moose Jaw when I dropped into a construction hole.

I don't disagree with the harshness of ride and would not argue if it were to be shown otherwise for speed. Most of my touring, other than day rides on other surfaces, for these tires has been major hwy's in Western Canada which are, for the most part, fairly well maintained. On gravel they definitely do bounces and skid off of rocks and would do better at lower pressure. My thoughts are mostly for paved road speed.

I fully admit I don't think too much about the pressure thing. All I know is that I really found the Marathons to be doggish when lower so I default to blow em up mode. I didn't notice this so much when I rode on my own touring with them (assumed speed was a function of loaded weight etc... ) but when I started doing bigger hills and mountain passes as training for another tour I noticed they did not roll downhill very fast, even unloaded. Here's a video coming down the Coquihalla Pass with a buddy on a 29'r suspension bike with big tires treaded tires and he was still pulling ahead of me going downhill all the time. To skip the boring part start at 1:00 in the video.

But all that doesn't mean I don't really like Marathons for what they are. If I were heading out and wanted the toughest tire for no worries, I'd still pick them (though tubeless may change the game there for touring at some point).

Last edited by Happy Feet; 03-03-19 at 11:09 AM.

#121

Senior Member

Join Date: Aug 2010

Location: Madison, WI

Posts: 11,214

Bikes: 1961 Ideor, 1966 Perfekt 3 Speed AB Hub, 1994 Bridgestone MB-6, 2006 Airnimal Joey, 2009 Thorn Sherpa, 2013 Thorn Nomad MkII, 2015 VO Pass Hunter, 2017 Lynskey Backroad, 2017 Raleigh Gran Prix, 1980s Bianchi Mixte on a trainer. Others are now gone.

Mentioned: 48 Post(s)

Tagged: 0 Thread(s)

Quoted: 3462 Post(s)

Liked 1,468 Times

in

1,145 Posts

Within a recommended range, I usually run the higher pressures, not lower in the rear. And I agree that they feel faster that way. But when it comes to the front tire, since I have a lot less weight on it I think running the pressure lower on the front does not hurt anything. And lower pressure should provide better grip, so it may be beneficial.

Above I made a comment that I am repeating here:

Those were 1.5 width (Schwalbe labels that as 40mm on the tire) Marathons. They were the version of Marathons that pre-dated the Greenguard version. (I do not put a lot of miles on my folding bike so still using an older tire.)

I could not feel any loss in speed or increase in rolling resistance by dropping my front presure. But, I did not drop the rear pressure, the rough road problem was my hands and not on my bum. The sprung Brooks Conquest and possibly a very long seatpost on my folding bike allowed me to keep my rear pressures high.

Above, Kingston noted that low pressure in front caused him to have pinch flats, but in this case I had 40mm wide tires and it is really hard to pinch flat that wide a tire.

Above I made a comment that I am repeating here:

...

... , last spring I was on a van supported trip in W Texas where they had a very rough chip seal pavement. First day I had about 55 to 60 in my front 40mm tire and my hands took a beating, my GPS on the handlebars kept acting up too. Then next day I dropped the front pressure to between 40 and 45 psi and that was much better on my hands, the GPS was much happier too.

....

... , last spring I was on a van supported trip in W Texas where they had a very rough chip seal pavement. First day I had about 55 to 60 in my front 40mm tire and my hands took a beating, my GPS on the handlebars kept acting up too. Then next day I dropped the front pressure to between 40 and 45 psi and that was much better on my hands, the GPS was much happier too.

....

I could not feel any loss in speed or increase in rolling resistance by dropping my front presure. But, I did not drop the rear pressure, the rough road problem was my hands and not on my bum. The sprung Brooks Conquest and possibly a very long seatpost on my folding bike allowed me to keep my rear pressures high.

Above, Kingston noted that low pressure in front caused him to have pinch flats, but in this case I had 40mm wide tires and it is really hard to pinch flat that wide a tire.

#122

buy my bikes

Join Date: Jun 2014

Location: Michigan

Posts: 1,803

Bikes: my very own customized GUNNAR CrossHairs

Mentioned: 19 Post(s)

Tagged: 0 Thread(s)

Quoted: 519 Post(s)

Liked 429 Times

in

249 Posts

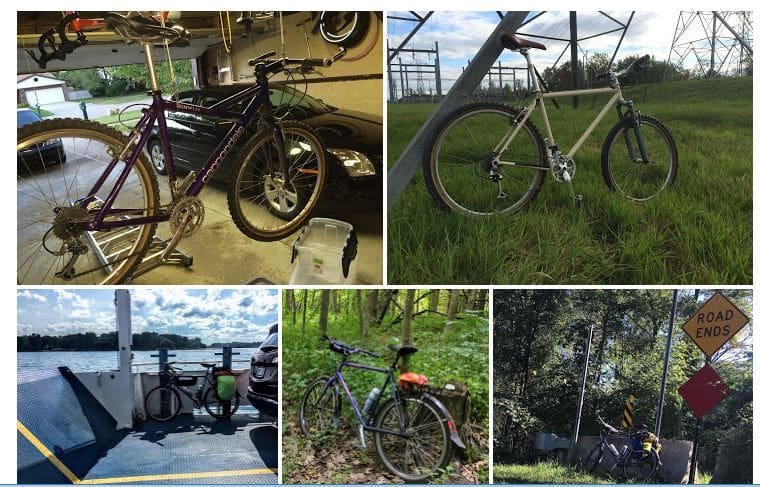

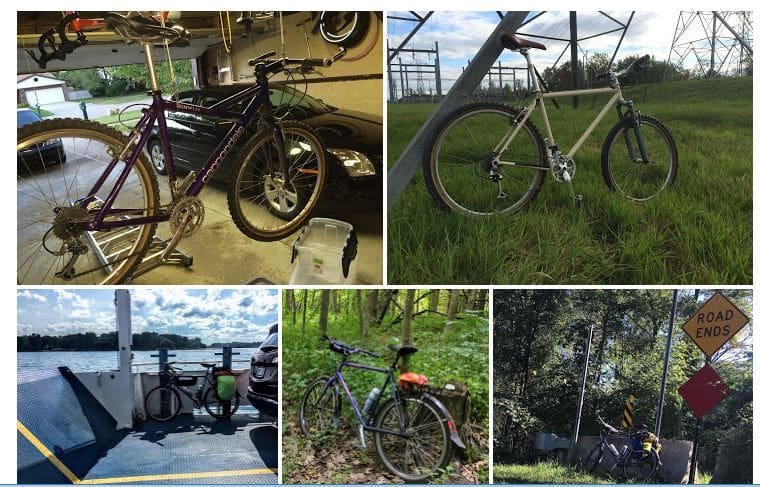

i would like to join. is there an initiation? fee? secret handshake and / or membership card?

#26inchlifestyle

my wheels are round and the earth is flat(ish)

PS: the suspended fork GUNNAR RockHound has been sold & the CANNONDALE now has a rigid fork and new powder coating.

#26inchlifestyle

my wheels are round and the earth is flat(ish)

PS: the suspended fork GUNNAR RockHound has been sold & the CANNONDALE now has a rigid fork and new powder coating.

Last edited by mrv; 03-03-19 at 04:30 PM. Reason: ps

#123

Senior Member

Join Date: Sep 2015

Location: Left Coast, Canada

Posts: 5,126

Mentioned: 24 Post(s)

Tagged: 0 Thread(s)

Quoted: 2236 Post(s)

Liked 1,314 Times

in

707 Posts

Oh... getting in is no problem, Now resigning may be a whole other issue.

Would you like the complimentary plastic spoke protector or the sheepskin seat cover?

Would you like the complimentary plastic spoke protector or the sheepskin seat cover?

#124

What happened?

Join Date: Jun 2007

Location: Around here somewhere

Posts: 7,927

Bikes: 3 Rollfasts, 3 Schwinns, a Shelby and a Higgins Flightliner in a pear tree!

Mentioned: 57 Post(s)

Tagged: 1 Thread(s)

Quoted: 1835 Post(s)

Liked 292 Times

in

255 Posts

My blood pressure is higher if I have to rush it.

__________________

I don't know nothing, and I memorized it in school and got this here paper I'm proud of to show it.