Originally Posted by

woolwich

Thanks folks for the input and the welcome. I will try and get a photo when the bikes delivered, I was trying to get a little info in advance.

From what I can gather from the bikes age the dropouts will be either a standard steel vertical dropout with mech hanger integrated or a more traditional forward facing sliding drop with hanger. So defo steel and with the dropout and hanger as one piece.

To be more specific I am more after metallurgy advice such as will heat be useful or as unterhausen suggests there will be no benefit.

Cheers

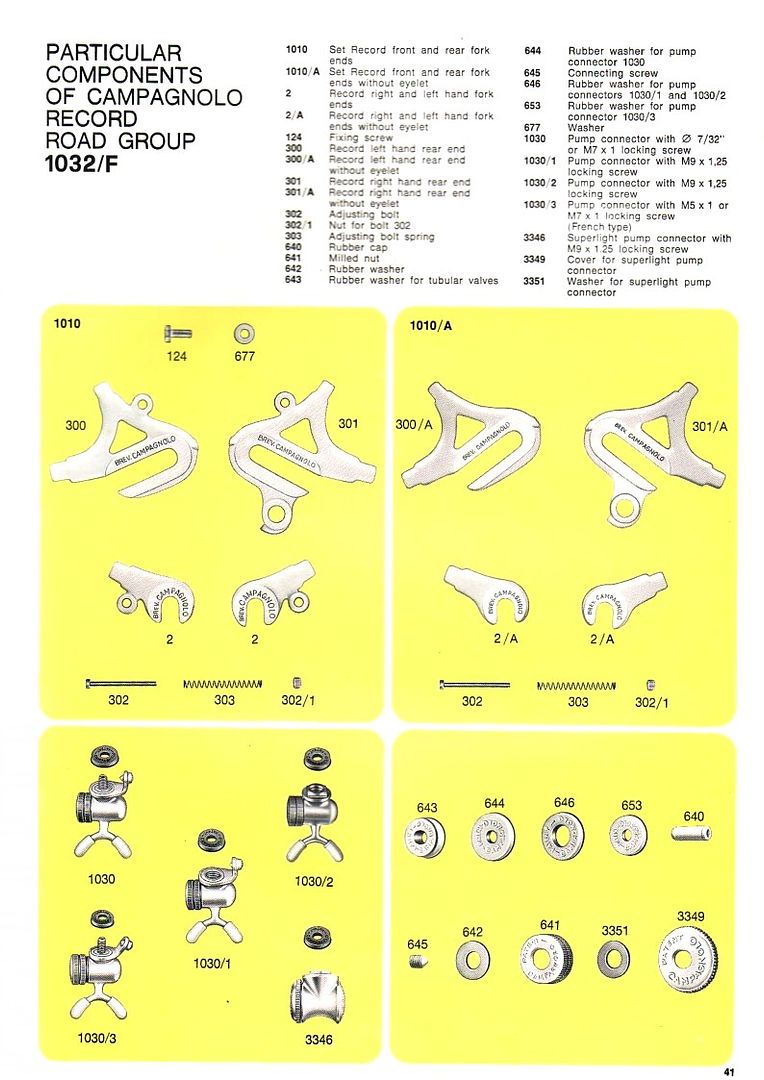

If it's a fairly common dropout like the Campagnolo 1010 or 1010/A (no eyelets), and low temperature silver brazing filler was used, it might be easier and safer to have a framebuilder simply remove the dropout with the bent hanger and replace it with a new one since they are still readily available and are relatively inexpensive.