I'm no Ti expert or guru, but here's my take based on the materials data sheets and what I've read in various framebuilders forums. Take this for the $.02 it's worth.

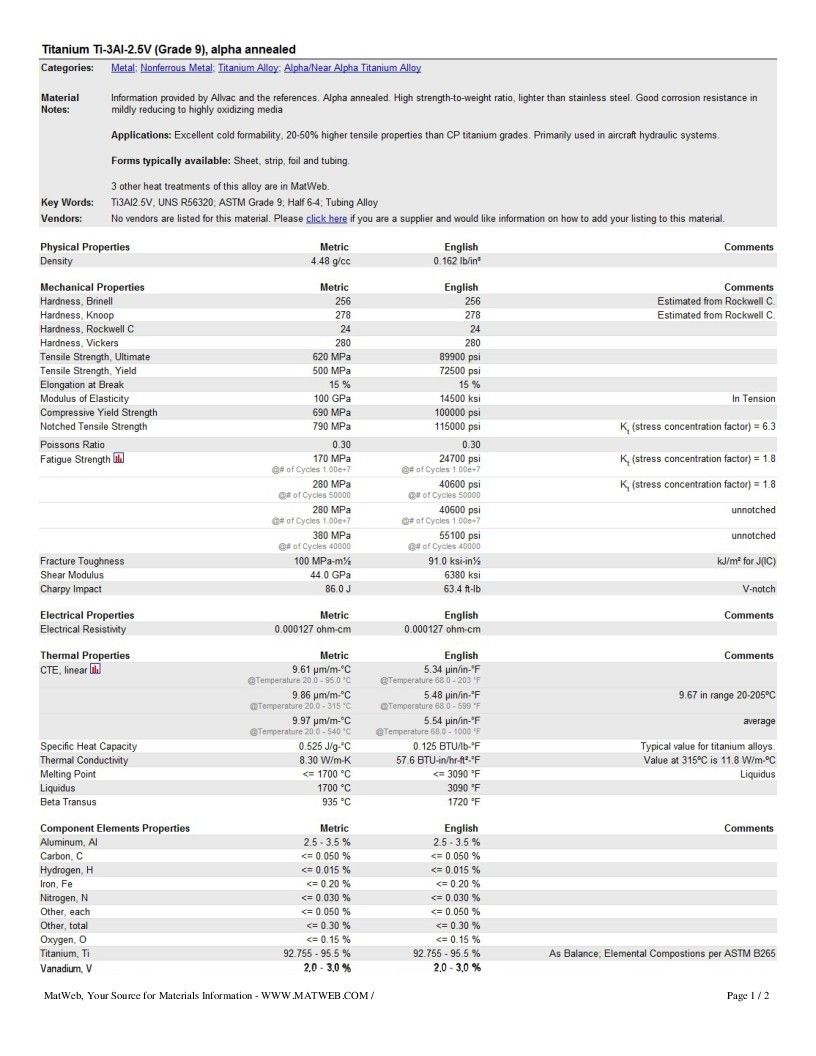

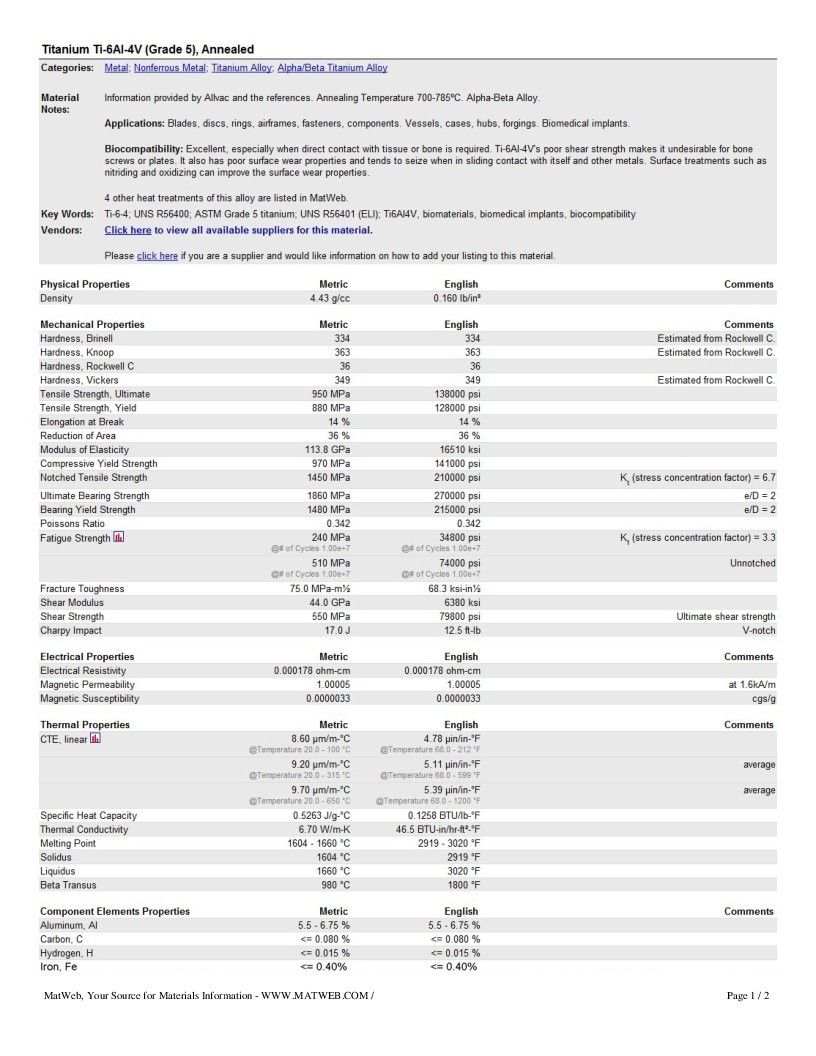

3Al-2.5V has a "stiffness" modulus (E) of 100 GPa, while 6Al-4V has a "stiffness" modulus (E) of 113.8 GPa, so the latter is about 14% stiffer, but frankly the wall thickness and diameters of the tubes are going to have a much greater effect of the frame stiffness than the alloy.

The density of both 3Al-2.5V and 6Al-4V is close to the same. 3Al-2.5V has a density of 4.48 g/cc, while 6Al-4V has a density of 4.43 g/cc, so 6Al-4V weighs a hair less for the same volume of material.

There is a significant difference in ultimate tensile strength (UTS) and yield strength (YS) between the two. 3Al-2.5V UTS=620 MPa and YS=500 MPa. 6Al-4V UTS=970 MPa and YS=880 MPa, so 6Al-4V is about 50% stronger than 3Al-2.5V.

Hardness (Brinell) for 3Al-2.5V is 256, while 6Al-4V is 334.

I believe most builders who work with titanium will tell you that 3Al-2.5V is easier to work with.

There are trade-offs, but if I were considering a Ti frame I would go with 3Al-2.5V personally.