Originally Posted by

jefscolnago

Nothing to do with imagination, except that I imagined why there was more resistance when I tightened the one side up fully while the other side was only just snug, as the instructions dictated. On the campy BB the right side has a flat while the left side does not and it enters into the bike's BB shell. Since they each support the two ends of the bottom bracket, they aren't really independent, are they? And while I may be guilty of having an imagination, I suppose you may be guilty of not having one. I'm just reporting the results I had, which was less resistance when spinning the cranks, no load. But thank you for your concern.

No concern, because it doesn't matter is all. Just setting the record straight. Your perception. But we have to make sure we are talking about a given BB. I presume you are talking about BSA aka threaded BB either Italian or English threaded and Campy UltraTorque cups. If this is what you are talking about, again it doesn't matter what you write.

Spec is to torque each cup on each side. No sequencing. Comports with physics. Cups are independent and separated by solid body aka threaded BB shell.

Maybe you could elaborate about the 'flat you speak of' What flat? Maybe we aren't talking about the same thing. Have a picture? Care to describe in greater detail what parts you are assembling? I have built a ton of Campy bikes.

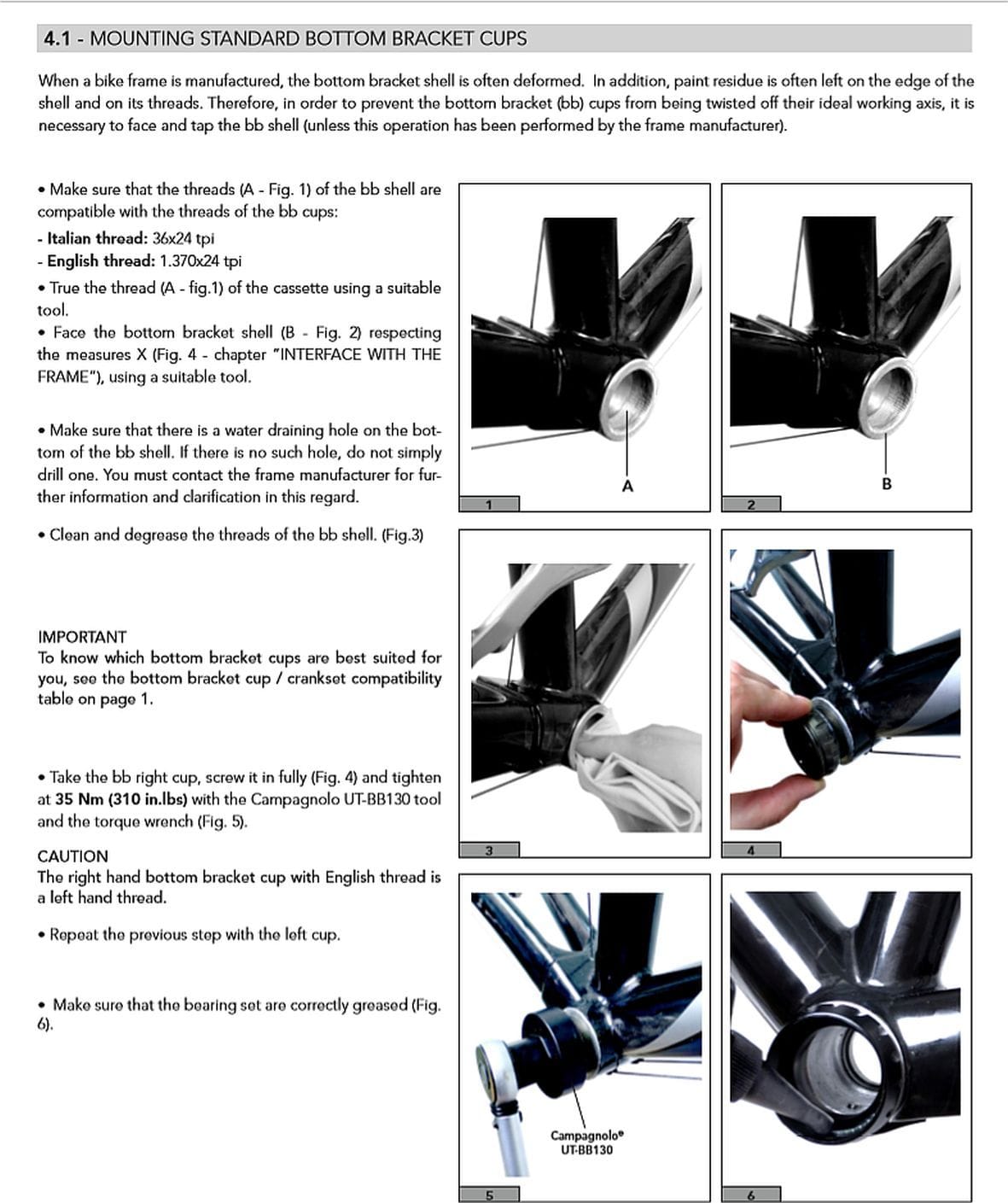

Torque each side to 35 Nm as shown in Campy's technical procedure: