I'd suggest a "Matrix". Here's why. Research is pretty convincing (see "The Paradox of Choice: Why More is Less", by Barry Schwartz) that your happiness about your decision starts going down when the number of choices goes up. If you have 3 cheeses on a menu, you can choose one (or even all three!) and be pretty sure you got one of the top three cheeses they offer. If you are offered fifty, and the waiter goes through them verbally one by one, there's no way you can make a choice that you have any certainty over. First, it takes 15 minutes for the cheese list to be read. Second, you can't remember the description of cheese 13 when they're reading cheese 50. So its stressful. This is not speculation: I've been subjected to a 50 cheese list. Felt like saying "uhh, we'll just have the deep fried mozzarella sticks". Point is that a huge range of options is bewildering,and if you are selling you need to zero in on what the customer wants very fast so that you can offer him a limited range that he can feel he's mastered.

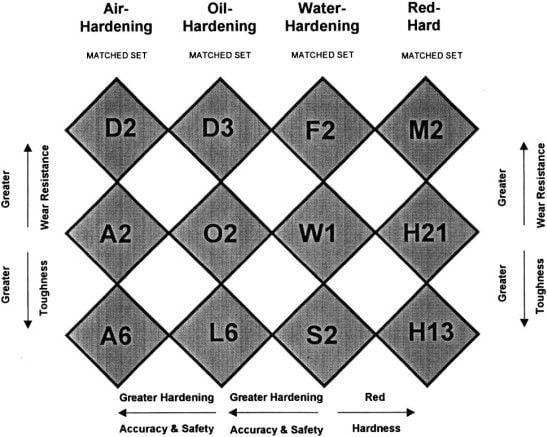

As to a Matrix... There's an example from the tool steel industry. Tool steels are the steels used to cut, stamp, and measure other steels, or that are used in machine tools to give high precision, or durability, or toughness.. As you can imagine, there's like, a zillion types of them. So we have the "50 cheeses" problem. Carpenter Steel makes many of these varieties of tool steels. Back in the 70s, they were probably facing an issue where they couldn't hire and train expert sales guys fast enough. So they created a "Matrix", and published it in a book. Each box of the matrix was a different Carpenter product. The columns were different classes ("Matched Sets") of tool steels. The rows represented durability (hardness) vs toughness (ability absorb shock and to bend but not break when stressed). Carpenter recommended that folks first consider W1 (a steel that you quench with water). If you needed a harder (more wear resistant) steel, use F2 steel. Need something tougher? Use S2. W1, F2, and S2 being different steel alloys. If you needed something that was more dimensionally stable in heat treatment, try O2. The point is, they gave a very simple paradigm for choosing the right tool steel. Engineers and machinists could order what they needed with confidence. And they could rule out a lot of noise. So out of a thousand different steels, you could guide a customer very close to their exact need. And in addition to the matrix (see below), the rest of the book went through each type of steel in the matrix and talked about applications, required heat treating, and technical data.

If you have 60 types of bikes (and there are 1000s online), customers can be bewildered. Salespeople need a rubric like this to allow them to get to the customer's needs fast, and to kill uncertainty. A matrix-like approach allows the salesperson to learn the basic differences faster. In fact, I'd bet that something like this would help wrest some sales back from the web.

Obviously, I consider the Matched Matrix of Carpenter a work of genius. I'd suggest that this might be a good example to try to follow - a matrix of bike models and trim levels. A tool that changes the 60 plus bike choice down to 2 or 3, and gives confidence to the choice made.

Here you are: 99% of tool steel applications in this matrix: