Originally Posted by

Jipe

It's a well known issue of this type of design: everything else remaining the same, a bigger ratio between the input rotational speed and output rotational speed (it can be a reduction or multiplication) reduces the efficiency.

No, that is not well known. I don't know it. We are talking about two three speed hubs. In this case, we have three gears involved. The design of both are similar, with the number of teeth in the planet and sun gears differing. As you add more driven gears to the system, inefficiency increases. The inefficiency is mainly due to internal friction. The reason that Rohloff has good relatively good efficiency for the number of gears it has is the high tolerances in its manufacture, use of ball bearings versus roller bearings and bushes in the less costly IGH. Also, it uses light oil, too, versus grease.

This is from

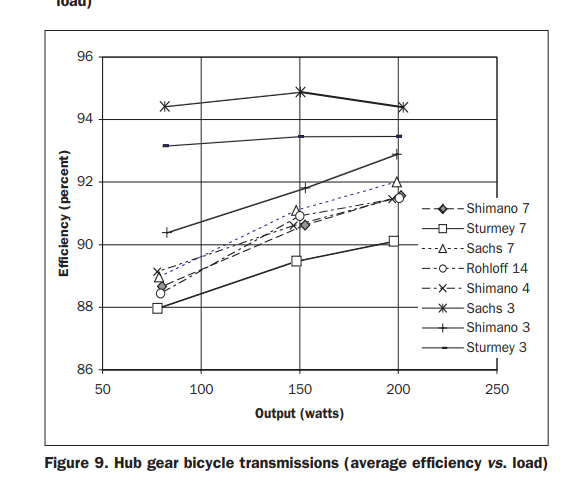

http://ihpva.org/HParchive/PDF/hp52-2001.pdf

International Human Powered Vehicle Association. Note, this is an independent source, not from a manufacturer. As you can see, the three speeds were more efficient than your Rohloff. Though, the Rohloff does well considering how many gears it has.