Originally Posted by

mpetry912

that is Spoke Service dot CA using the Wheel Fanatyk V2 tensiometer with the digital readout to USB

Not sure if your unit will output a measurement that can be read via USB.

/markp

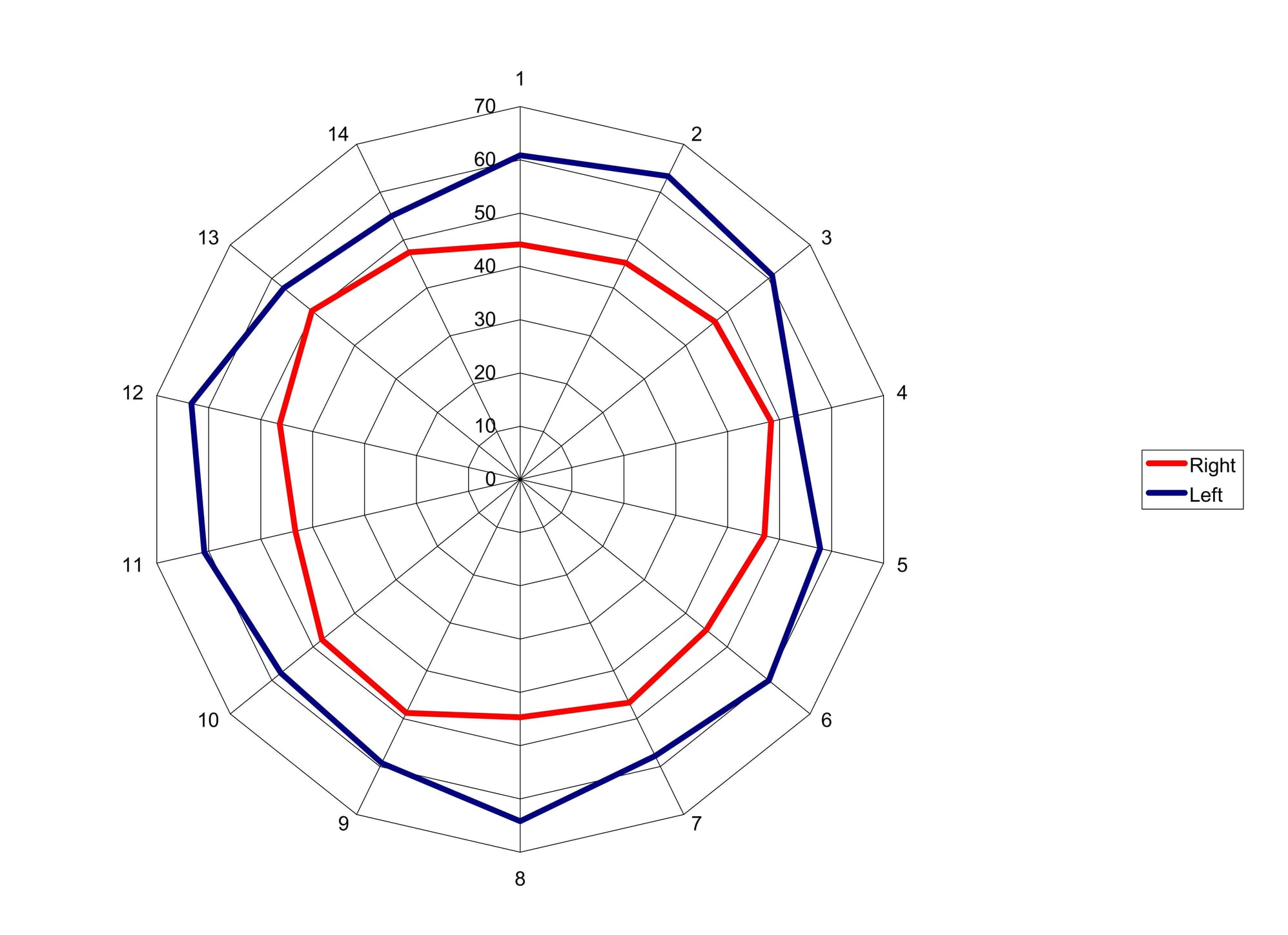

Thanks! I'll look into that at some point but I ended up writing my own thing in Excel. It's obviouly not as polished and looks romper roomish but I like being able to manipulate the data. This is what I'm looking at.

FBinNY

FBinNY I'd like to hear your feedback on this - so far. I saw you mentioned in another thread about maintaining length, this is only my third wheel set build and I'm pretty sure I did that in past builds but regardless did it this time, counting turns. It gave me some sporadic tensions but the wheel looked reasonable for a starting point, I doubt the rim has any give to it so that may amplify the tension differences. Just to see what would happen I started going only by numbers, trying to smooth out the tensions. FWIW this is the front wheel with asymetric carbon rims that feels stiff AF. I wanted to get things semi in order before tensionsioning more. The radial true isn't horrible at ~0.6mm. Lateral true is trash at probably 1.5mm but that I will address later. Spoke tension deviation is 11% on the right and 18% on the left. not good, but at least it's not erratic. I thought that was under control enough to start approaching final tension.

I know this isn't how you build wheels but I'd still like to hear your opinion. Thanks!