Spoke Tension - which TM-1 reading?

#1

Full Member

Thread Starter

Spoke Tension - which TM-1 reading?

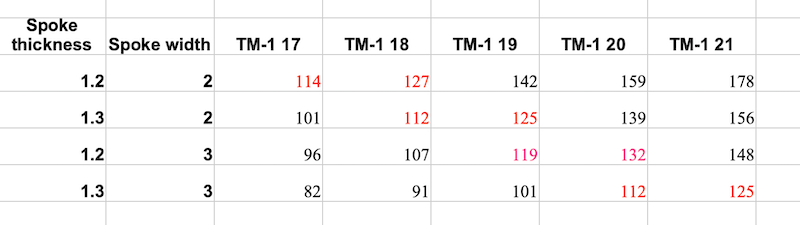

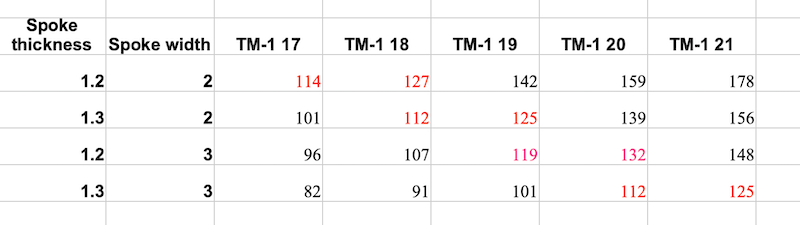

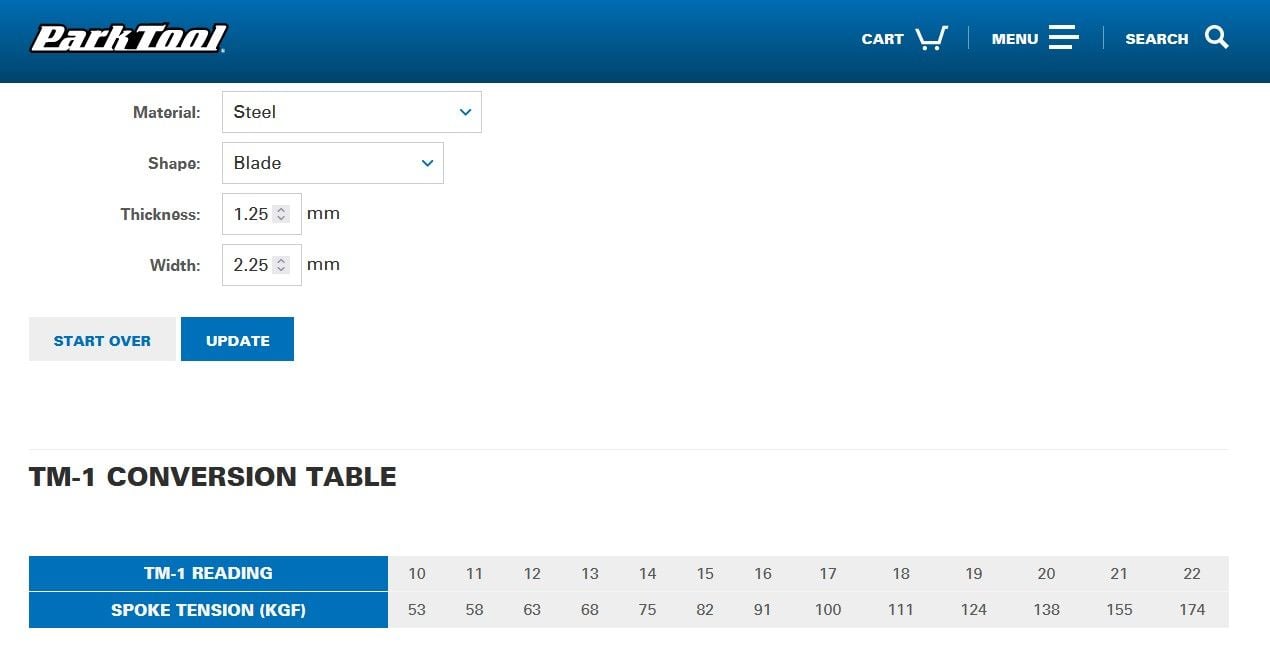

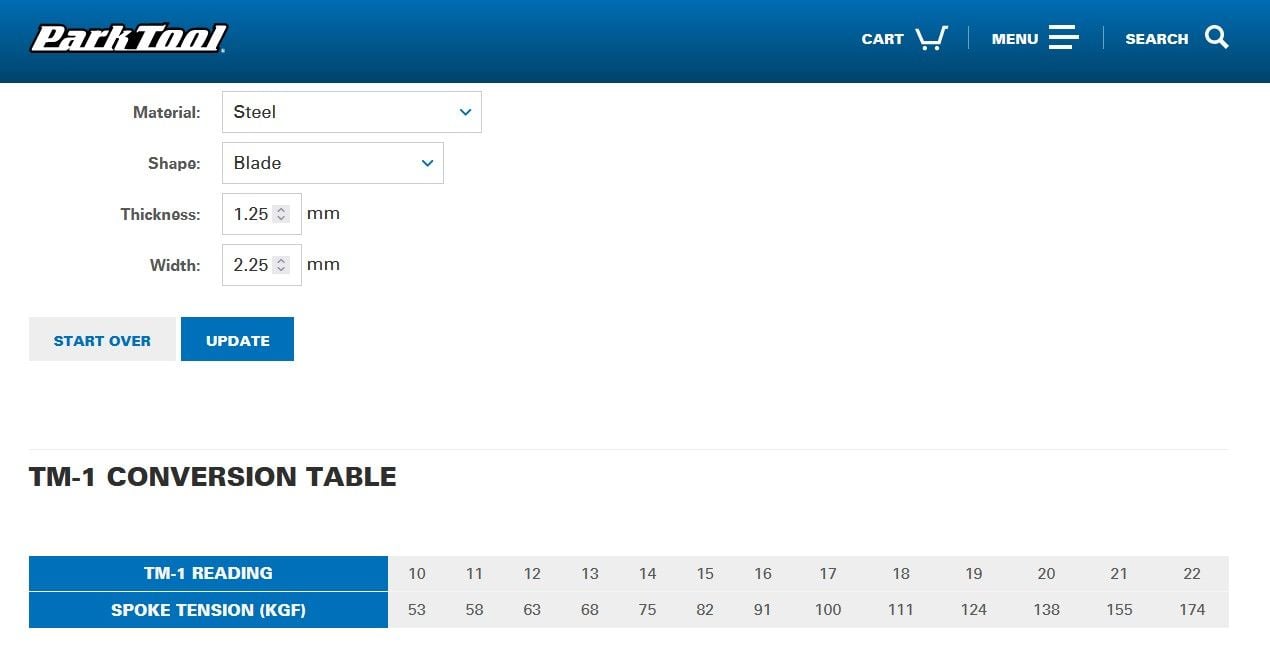

I'm rebuilding a wheel and don't know which Park Tool TM-1 reading to use for tensioning. The spokes are Sapim CX-Sprint with dimensions 1.25mm thickness x 2.25mm width. The rim is a Velocity Cliffhanger which specifies maximum tension of 120 kgf. I used the Park Tool wheel tension app online which maybe needless to say does not have the exact spoke dimensions. Plugging in 4 options I got these numbers (screenshot of spreadsheet). Which would you use? Thoughts/suggestions appreciated.

#2

Wheelman

Join Date: Aug 2021

Location: Putney, London UK

Posts: 854

Bikes: 1982 Holdsworth Avanti (531), 1961 Holdsworth Cyclone

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 298 Post(s)

Liked 682 Times

in

345 Posts

Hiya,

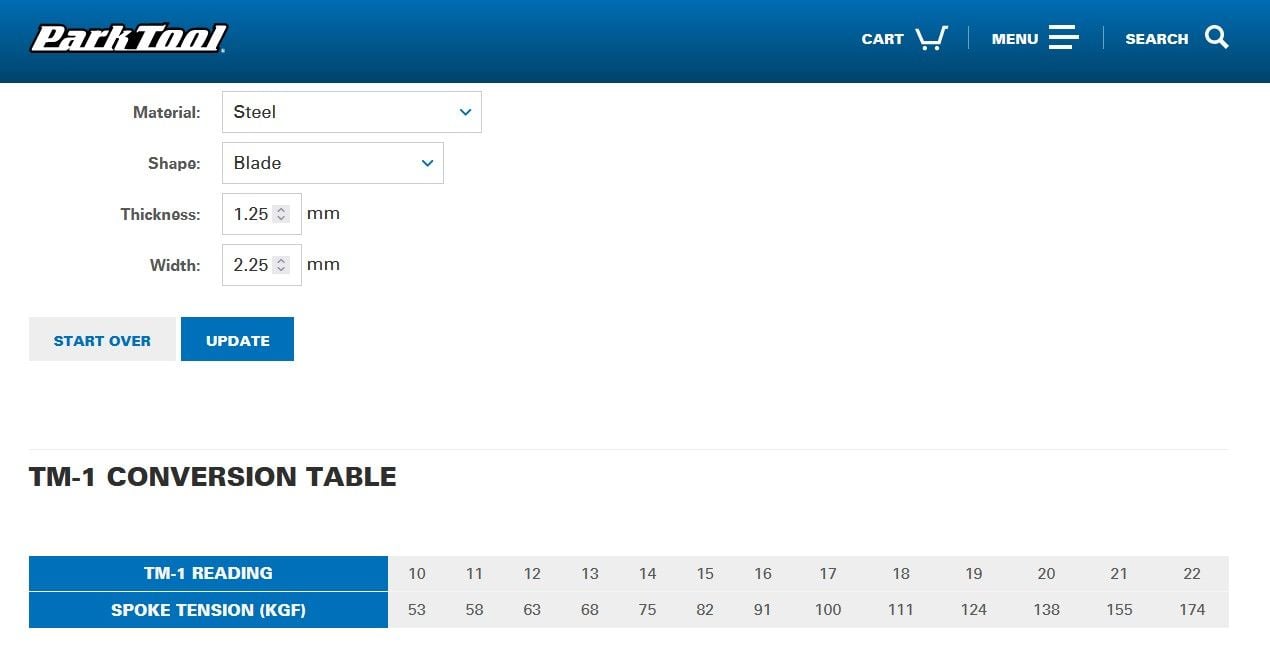

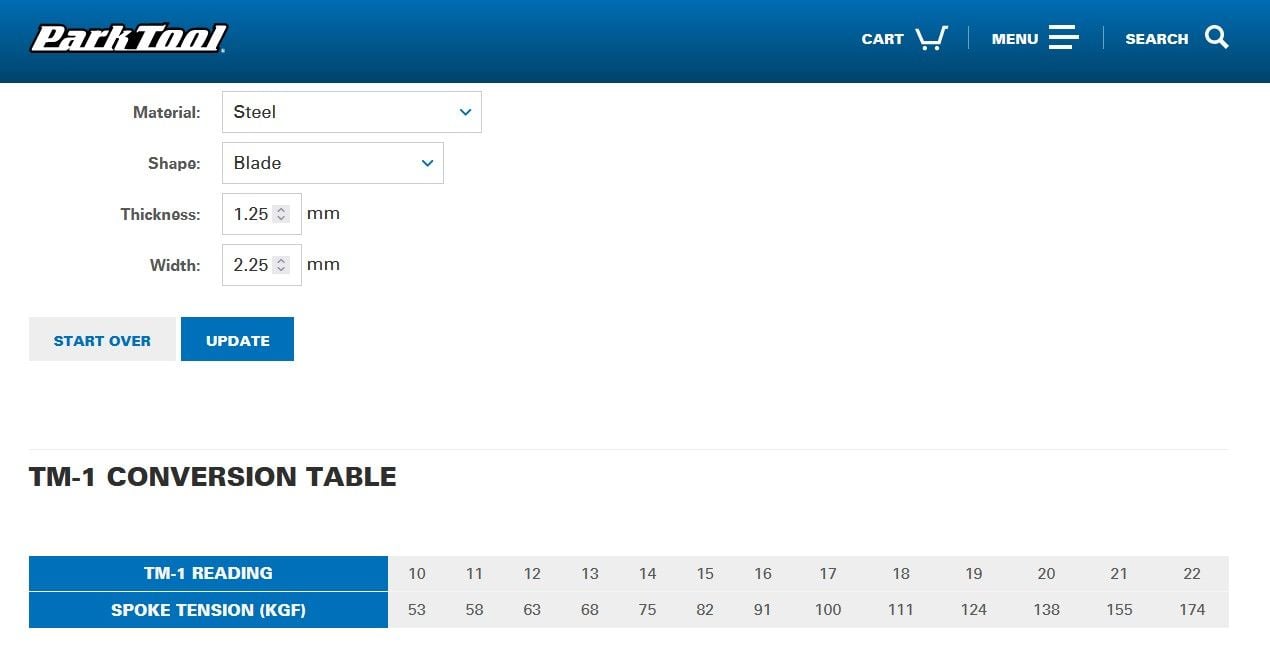

I just fired up the Park Tool app https://www.parktool.com/en-us/wta

and that does let you put in the measurements you want.

(It highlight the values in red but then does it anyway)

That table doesn't match the values in their published table at https://www.parktool.com/assets/doc/...conv-table.pdf

So I'm going to assume they calculated it on the fly.

If you need the equation based on those values I could do that.

Edit: To be clear you have to type '1.25' and '2.25' into Park Tool, it's not on the selecter.

I just fired up the Park Tool app https://www.parktool.com/en-us/wta

and that does let you put in the measurements you want.

(It highlight the values in red but then does it anyway)

That table doesn't match the values in their published table at https://www.parktool.com/assets/doc/...conv-table.pdf

So I'm going to assume they calculated it on the fly.

If you need the equation based on those values I could do that.

Edit: To be clear you have to type '1.25' and '2.25' into Park Tool, it's not on the selecter.

Last edited by Aardwolf; 12-07-23 at 09:20 AM.

Likes For Aardwolf:

#3

Senior Member

Join Date: Apr 2011

Posts: 7,173

Mentioned: 42 Post(s)

Tagged: 0 Thread(s)

Quoted: 4475 Post(s)

Liked 1,615 Times

in

1,061 Posts

Don't use max tensions unless your rim only has 20 spokes.

#4

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,827

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5845 Post(s)

Liked 2,678 Times

in

1,493 Posts

+1

Don't fall into the "tension is good, more is better, most is best" trap. Increasing tension beyond what's needed does nothing to strengthen or stiffen a wheel. The only thing it does is increase dead load stress on the rim.

The rim's published max tension isn't a goal, it's a limit and it's best to stay well below that unless something like low spoke count, or minimum NDS tension on a dished wheel force you to go high.

Proper spoke tension is mainly a function of spoke gauge and for what you're using 105kgf should be more than enough.

Don't fall into the "tension is good, more is better, most is best" trap. Increasing tension beyond what's needed does nothing to strengthen or stiffen a wheel. The only thing it does is increase dead load stress on the rim.

The rim's published max tension isn't a goal, it's a limit and it's best to stay well below that unless something like low spoke count, or minimum NDS tension on a dished wheel force you to go high.

Proper spoke tension is mainly a function of spoke gauge and for what you're using 105kgf should be more than enough.

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

#5

Full Member

Thread Starter

I'm not an expert at this by any means so no agenda. Just looking to get this wheel built with the safest option. It's a tandem so a heavy bike. The rim was failing fast so I'm just replacing that. I measured tension on the drive side of the wheel and it was 20-21 with the TM-1 tool. I thought that seemed high but ???

+1

Don't fall into the "tension is good, more is better, most is best" trap. Increasing tension beyond what's needed does nothing to strengthen or stiffen a wheel. The only thing it does is increase dead load stress on the rim.

The rim's published max tension isn't a goal, it's a limit and it's best to stay well below that unless something like low spoke count, or minimum NDS tension on a dished wheel force you to go high.

Proper spoke tension is mainly a function of spoke gauge and for what you're using 105kgf should be more than enough.

Don't fall into the "tension is good, more is better, most is best" trap. Increasing tension beyond what's needed does nothing to strengthen or stiffen a wheel. The only thing it does is increase dead load stress on the rim.

The rim's published max tension isn't a goal, it's a limit and it's best to stay well below that unless something like low spoke count, or minimum NDS tension on a dished wheel force you to go high.

Proper spoke tension is mainly a function of spoke gauge and for what you're using 105kgf should be more than enough.

#6

Full Member

Thread Starter

OK, getting that too. When I enter the second digit it highlights the dimension number red so assumed it wouldn't work. Thanks.

Hiya,

I just fired up the Park Tool app https://www.parktool.com/en-us/wta

and that does let you put in the measurements you want.

(It highlight the values in red but then does it anyway)

That table doesn't match the values in their published table at https://www.parktool.com/assets/doc/...conv-table.pdf

So I'm going to assume they calculated it on the fly.

If you need the equation based on those values I could do that.

I just fired up the Park Tool app https://www.parktool.com/en-us/wta

and that does let you put in the measurements you want.

(It highlight the values in red but then does it anyway)

That table doesn't match the values in their published table at https://www.parktool.com/assets/doc/...conv-table.pdf

So I'm going to assume they calculated it on the fly.

If you need the equation based on those values I could do that.

#7

jsallen

I suggest checking against musical pitch as described at https://www.sheldonbrown.com/spoke-pitch.html. The musical pitch is independent of spoke gauge, because it depends in the same way on spoke gauge and tension. The pitch recommended is for 1/3 the yield strength of steel spokes, which is good and tight while allowing for the increase in tension due to torque and lateral loading. If the rim can't manage this tension, then use lighter spokes.

Last edited by jsallen; 12-07-23 at 09:33 AM.

#8

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,827

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5845 Post(s)

Liked 2,678 Times

in

1,493 Posts

The prior rim's failure is a major clue. Discounting crash damage and other outside factors, the main cause of rim failure is excess spoke tension.

The fact it's a high load argues for staying well below max tension, keeping dead load lower and leaving more room for the dynamic load.

Either way here's a hint that will help for this and similar situations. Learn how to use interpolation to find answers when you lack specific data points.

The fact it's a high load argues for staying well below max tension, keeping dead load lower and leaving more room for the dynamic load.

Either way here's a hint that will help for this and similar situations. Learn how to use interpolation to find answers when you lack specific data points.

Last edited by FBinNY; 12-07-23 at 09:39 AM.

#9

Full Member

Thread Starter

I'd be interested in the equation if it's not too much trouble.

Hiya,

That table doesn't match the values in their published table at https://www.parktool.com/assets/doc/...conv-table.pdf

So I'm going to assume they calculated it on the fly.

If you need the equation based on those values I could do that.

Edit: To be clear you have to type '1.25' and '2.25' into Park Tool, it's not on the selecter.

That table doesn't match the values in their published table at https://www.parktool.com/assets/doc/...conv-table.pdf

So I'm going to assume they calculated it on the fly.

If you need the equation based on those values I could do that.

Edit: To be clear you have to type '1.25' and '2.25' into Park Tool, it's not on the selecter.

#10

Full Member

Thread Starter

Yes, that was my concern. The front wheel has identical components without rim failure. The rear rim is cracking at most of the spoke holes spoke holes but there is far more weight in the back as it is an electric tandem where the motor and battery weight - and stoker, obviously - are located.

#11

Full Member

Thread Starter

I can't rely on my ability to hear pitch - way beyond my pay grade. But worth a read.

I suggest checking against musical pitch as described at https://www.sheldonbrown.com/spoke-pitch.html. The musical pitch is independent of spoke gauge, because it depends in the same way on spoke gauge and tension. The pitch recommended is for 1/3 the yield strength of steel spokes, which is good and tight while allowing for the increase in tension due to torque and lateral loading. If the rim can't manage this tension, then use lighter spokes.

#12

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,827

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5845 Post(s)

Liked 2,678 Times

in

1,493 Posts

Yes, that was my concern. The front wheel has identical components without rim failure. The rear rim is cracking at most of the spoke holes spoke holes but there is far more weight in the back as it is an electric tandem where the motor and battery weight - and stoker, obviously - are located.

For your spokes that's somewhere near 60kgf. Use the ratio of left and right CTF distances to estimate corresponding DS tension. That should leave you a range below the rim's limit, and you want to aim for the lower third.

Another way is to use the front wheel as a guide. You know that's OK, so try to stay close to that if possible.

Since this is all rule of thumb work, and you lack a basis for precise calculations, there's no need to obsess over a precise tension measurement.

BTW given the application and your inexperience, why are you using flat blade spokes, instead of typical DB spokes?

Last edited by FBinNY; 12-07-23 at 09:55 AM.

#13

Wheelman

Join Date: Aug 2021

Location: Putney, London UK

Posts: 854

Bikes: 1982 Holdsworth Avanti (531), 1961 Holdsworth Cyclone

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 298 Post(s)

Liked 682 Times

in

345 Posts

Ok I was bored, and the alternative was something I can ignore for a bit.

If you put (for example) 10.5 as a reading into the PT app it will give the Kgf to 2 decimal places.

Exponential fit using R statistics package, R squared value is 0.99999.

If you put (for example) 10.5 as a reading into the PT app it will give the Kgf to 2 decimal places.

Exponential fit using R statistics package, R squared value is 0.99999.

Likes For Aardwolf:

#14

Full Member

Thread Starter

I'm replacing only the rim and reusing the spokes and hub that came wheel.

I like numbers because they give me something concrete to work to. I took a wheel building class long ago and, as I remember it, we were taught to focus on the DS tensioning: lateral, radial and dish truing would bring in the NDS tension to where it needed to be. We only measured the NDS spokes to verify that they were tensioned about the same relative to themselves.

I like numbers because they give me something concrete to work to. I took a wheel building class long ago and, as I remember it, we were taught to focus on the DS tensioning: lateral, radial and dish truing would bring in the NDS tension to where it needed to be. We only measured the NDS spokes to verify that they were tensioned about the same relative to themselves.

#15

Full Member

Thread Starter

Nice graph (and equation). Looks like I'll be aiming for 20 on the TM-1. Or consider 19 and check the wheel at every ride to make sure spokes are not loosening. thanks for the help.

#17

Senior Member

Join Date: Dec 2010

Location: northern Deep South

Posts: 8,930

Bikes: Fuji Touring, Novara Randonee

Mentioned: 36 Post(s)

Tagged: 0 Thread(s)

Quoted: 2612 Post(s)

Liked 1,956 Times

in

1,226 Posts

#18

Wheelman

Join Date: Aug 2021

Location: Putney, London UK

Posts: 854

Bikes: 1982 Holdsworth Avanti (531), 1961 Holdsworth Cyclone

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 298 Post(s)

Liked 682 Times

in

345 Posts

I added the extra digits to show it was calculated (using the formula in reverse).

I read my cheapo meter to about 1 decimal,

with the intention of being roughly right most of the time and the error averaging out.

Of course that's after I calibrate it, and I tap the meter on the spokes until the reading stops changing.

But more importantly the meter is only used to check maximum tension and to even out tension.

The final determining factor is is the wheel true enough.

#19

Wheelman

Join Date: Aug 2021

Location: Putney, London UK

Posts: 854

Bikes: 1982 Holdsworth Avanti (531), 1961 Holdsworth Cyclone

Mentioned: 4 Post(s)

Tagged: 0 Thread(s)

Quoted: 298 Post(s)

Liked 682 Times

in

345 Posts

If the rim is specced at max 120kg you really want to be max 120 ish.

So in practise that's probably going to be average 110 and + or - 10% for truing.

I run Mavic tubular rims (36h) specced at 90kg max, a few spokes are towards 100kg.

But those are very old rims that need a lot of truing.

No problems after 2k miles.

So in practise that's probably going to be average 110 and + or - 10% for truing.

I run Mavic tubular rims (36h) specced at 90kg max, a few spokes are towards 100kg.

But those are very old rims that need a lot of truing.

No problems after 2k miles.

Likes For Aardwolf:

#20

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,827

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5845 Post(s)

Liked 2,678 Times

in

1,493 Posts

The rim's published limit is 120kgf, WHY would you opt to shoot for that, leaving ZERO margin for error? Doubly so since the prior rim clearly showed it failed from excess tension. So, what do you hope to gain by bringing tensions up to the rim's absolute limit?

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

Last edited by FBinNY; 12-07-23 at 03:16 PM.

#21

Full Member

Thread Starter

OK, yet another data point that I am truly losing it. 😫

If the rim is specced at max 120kg you really want to be max 120 ish.

So in practise that's probably going to be average 110 and + or - 10% for truing.

I run Mavic tubular rims (36h) specced at 90kg max, a few spokes are towards 100kg.

But those are very old rims that need a lot of truing.

No problems after 2k miles.

So in practise that's probably going to be average 110 and + or - 10% for truing.

I run Mavic tubular rims (36h) specced at 90kg max, a few spokes are towards 100kg.

But those are very old rims that need a lot of truing.

No problems after 2k miles.

#22

Full Member

Thread Starter

It was a brain poo - let's just say I spent the last day enduring a rather unpleasant medical procedure - so, hey, why not rebuild a wheel? Uggghhhh.

When you last visited the Grand Canyon, did you consistently walk to the very edge of the cliffs?

The rim's published limit is 120kgf, WHY would you opt to shoot for that, leaving ZERO margin for error. Doubly so since the prior rim clearly showed it failed from excess tension. So, what do you hope to gain by bringing tensions up to the rim's absolute limit?

The rim's published limit is 120kgf, WHY would you opt to shoot for that, leaving ZERO margin for error. Doubly so since the prior rim clearly showed it failed from excess tension. So, what do you hope to gain by bringing tensions up to the rim's absolute limit?

#23

Senior Member

Join Date: Apr 2009

Location: New Rochelle, NY

Posts: 38,827

Bikes: too many bikes from 1967 10s (5x2)Frejus to a Sumitomo Ti/Chorus aluminum 10s (10x2), plus one non-susp mtn bike I use as my commuter

Mentioned: 140 Post(s)

Tagged: 1 Thread(s)

Quoted: 5845 Post(s)

Liked 2,678 Times

in

1,493 Posts

No sweat. Hopefully the procedure went well, and you'll be fine by morning. Wait till then, and read the entire thread (not too long) think about it while enjoying your AM coffee.and

__________________

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

FB

Chain-L site

An ounce of diagnosis is worth a pound of cure.

Just because I'm tired of arguing, doesn't mean you're right.

“One accurate measurement is worth a thousand expert opinions” - Adm Grace Murray Hopper - USN

WARNING, I'm from New York. Thin skinned people should maintain safe distance.

Last edited by FBinNY; 12-08-23 at 01:19 PM.

Likes For FBinNY:

#24

Senior Member

Join Date: Dec 2010

Location: northern Deep South

Posts: 8,930

Bikes: Fuji Touring, Novara Randonee

Mentioned: 36 Post(s)

Tagged: 0 Thread(s)

Quoted: 2612 Post(s)

Liked 1,956 Times

in

1,226 Posts

As a clydesdale myself, most of the wheel failures I've seen come from spoke tension that's too low. Either the cyclic stress kills it at the head, or the low stress leads to a nipple coming unscrewed.

Now FB makes a good point, perhaps it's not ideal to tiptoe right at the edge of the tension specification of the rim. So I'll back off perhaps 10% from the max, and aim for that. But if a spoke or two goes high, even a TM notch above spec, I don't sweat it. I figure the safety factors and margins engineered into the rim should cover those exceedances.

How's that working out? Well, I've had a couple failures. One was hitting a ridge in a road (it was like a small curb) at speed. It looked like a tar stripe after an overnight rain. The other was when I dropped a suitcase on a bike in the back of a car. I can't really blame wheel build for either of those "failures," so I'll keep on with what I've been doing.

Now FB makes a good point, perhaps it's not ideal to tiptoe right at the edge of the tension specification of the rim. So I'll back off perhaps 10% from the max, and aim for that. But if a spoke or two goes high, even a TM notch above spec, I don't sweat it. I figure the safety factors and margins engineered into the rim should cover those exceedances.

How's that working out? Well, I've had a couple failures. One was hitting a ridge in a road (it was like a small curb) at speed. It looked like a tar stripe after an overnight rain. The other was when I dropped a suitcase on a bike in the back of a car. I can't really blame wheel build for either of those "failures," so I'll keep on with what I've been doing.

#25

Senior Member

Join Date: Apr 2011

Posts: 7,173

Mentioned: 42 Post(s)

Tagged: 0 Thread(s)

Quoted: 4475 Post(s)

Liked 1,615 Times

in

1,061 Posts

I'm not an expert at this by any means so no agenda. Just looking to get this wheel built with the safest option. It's a tandem so a heavy bike. The rim was failing fast so I'm just replacing that. I measured tension on the drive side of the wheel and it was 20-21 with the TM-1 tool. I thought that seemed high but ???

With high spoke counts you need to get the individual spoke tension on the minimum side so you don't overwhelm the rim total tension limit.

You may need to decrease the front wheel tension before that rim also fails, rather than match its tension.

I do not agree with using pitch to build a wheel of unfamiliar format or by someone new to wheel building. Figure out the tension range for these spokes, put that range between 20 to 48 spokes and then match your spoke count to a place on that range.