Whoops! Left my chain in mineral spirits for (way) too long

#101

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,495

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 153 Post(s)

Tagged: 1 Thread(s)

Quoted: 6295 Post(s)

Liked 4,331 Times

in

2,427 Posts

Chemical bonds always put my head in a fuzz bag even when my brain still worked correctly.

Stress/fatigue cracks and failures and resolution of said failures (from a stricly mechanical point of view) is one of the things I did over the last 40 odd years.

A stress/fatigue failure on an old or very old part, in continuous service, is not unexpected, at least not to the initiated.

Component age is determined by the life cycle designed into that particular item. To increase the life cycle (if that's what the customer wants), a change in materials, a change in manufacturing process or a redesign of the part in question is required.

I have seen parts still in process crack/fail because a needed step was skipped or not deemed necessary the first time around.

"How it's Made" has a segment on bicycle chains,https://www.youtube.com/watch?v=h8j5-dC6_x8, and I am wondering if the chains joejack has were improperly heat treated, or the quenching medium was contaminated? Coluld the cholorinated solvent weaken the molecular bonds at the micro cracks/stresses left over from the manufacturing process, other than turning it into ferric oxide(rust, which I am very familiar with living in Michigan), I don't know, but obviously something is going on.

Stress/fatigue cracks and failures and resolution of said failures (from a stricly mechanical point of view) is one of the things I did over the last 40 odd years.

A stress/fatigue failure on an old or very old part, in continuous service, is not unexpected, at least not to the initiated.

Component age is determined by the life cycle designed into that particular item. To increase the life cycle (if that's what the customer wants), a change in materials, a change in manufacturing process or a redesign of the part in question is required.

I have seen parts still in process crack/fail because a needed step was skipped or not deemed necessary the first time around.

"How it's Made" has a segment on bicycle chains,https://www.youtube.com/watch?v=h8j5-dC6_x8, and I am wondering if the chains joejack has were improperly heat treated, or the quenching medium was contaminated? Coluld the cholorinated solvent weaken the molecular bonds at the micro cracks/stresses left over from the manufacturing process, other than turning it into ferric oxide(rust, which I am very familiar with living in Michigan), I don't know, but obviously something is going on.

A chloride ion in an aqueous media, which the Green Klean mineral spirits appears to be, will do all kinds of funky stuff to metals.

I've started a test tonight to see if I can duplicate the cracking. I won't be using Green Klean spirits but I will be using a 6% solution of sodium chloride in water. This amount of chloride should speed up the process nicely. I'll post results and pictures later.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

#102

Senior Member

Thread Starter

#103

Senior Member

Thread Starter

Science and the truth isn't a popularity contest. Did you start this thread because you wanted to warn others or because you were interested in what caused the chain to crack? Earlier in this thread I stated that I had an Ultegra chain that broke after only 1,100 miles. What would you think if I stated that Ultegra chains were only good for 1,100 miles, or maybe only 10 speed Ultegra chains since mine was a 10 speed chain.

It's not irrelevant! I agree that few cyclists (myself included) would replace their chains with 1/32" of stretch. But I would question why a chain with 4,000 miles had only 1/32" of stretch. About the same stretch that my 1,100 mile Ultegra chain had when it broke (here in Colorado we don't have much of a salt problem). At that rate you should be getting 8,000 miles on a chain before it is worn out; not many cyclists get that kind of mileage. There may have been reasons that your chain didn't show more stretch. Maybe there was still dirt or corrosion inside the rollers that filled some to the space caused by wear. Maybe there is some other explanation like KMC chain is extremely wear resistant or you're using a very good lube.

I don't have a new KMC quick link, but I will donate a new section of Sram 1031 chain if you would like to soak that to compare with your section of KMC X9 chain. Maybe you'll find the Sram chain performs better in corrosive environments. I don't know what the result will be, but after testing you will know. Maybe others will donate sections of other brands too.

Yup.

#104

Senior Member

Thread Starter

If all of the cracks had been towards the exterior of the link I could have believe that my cycling-added stress contributed to the failure. But this oddball crack (which I witnessed only once) seems to indicate that corrosion is randomly attacking the links.

Your final statement is very true. Any little defect in the link gives a spot for the corrosion to start and once it starts it gets worse quickly as the crack gets bigger aided by the existing hoop stress of the riveted pin.

#105

SE Wis

Join Date: Apr 2005

Location: Milwaukee, WI

Posts: 10,560

Bikes: '68 Raleigh Sprite, '02 Raleigh C500, '84 Raleigh Gran Prix, '91 Trek 400, 2013 Novara Randonee, 1990 Trek 970

Mentioned: 40 Post(s)

Tagged: 0 Thread(s)

Quoted: 2756 Post(s)

Liked 3,427 Times

in

2,075 Posts

I'd be sending those pictures to KMC and asking them what happened. Probably a free chain in it too.

#106

Senior Member

Join Date: May 2010

Posts: 461

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

I was very interested to find out that Klean-Strip isn't even pure mineral spirits, but some sort of magic water-based emulsion. Because that's what I've been using, and I don't think it's as effective as good old mineral spirits. Also (and this might be my imagination) it seems to evaporate slower, making it harder to get rid of when I'm done.

So I went to Home Depot and guess what: all they have is Klean-Strip, you can't even get the real thing any more.

So I went to Home Depot and guess what: all they have is Klean-Strip, you can't even get the real thing any more.

#107

Senior Member

Thread Starter

Klean Strip makes normal, non-emulsified odorless mineral spirits. It's what I've switched to using. What you need to avoid is the "green" odorless mineral spirits which has the water added.

#109

Newbie

Join Date: Oct 2007

Location: Boulder, CO

Posts: 39

Bikes: Bella, Masi Gran Corsa Premo, BH cyclocross, Colnago C40, Iron Horse MB

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 6 Times

in

1 Post

Hillrider has posted achieving close to 8000 miles on a chain (well he posted 75000 but I believe that was a typo and should have been 7500). I'm a relatively lightweight guy (160 lbs.) and I'm also a spinner. 80 rpm feels really slow to me. 90-110 is more like it. I don't shift under (much) power and I try to keep my chain lubed (using Chain-L). Summary: I'm pretty light on chains and do decent maintenance. As DaveSSS pointed out, I'm also using a 9 speed chain which is going to offer longer life than a 10 speed chain.

I'll think about doing it myself. I will probably forget about it and I'm not sure I can get the exact solvent you are using. The gremlins in your garage are also part of the equation. I will be glad to send a section of chain if you are interested. Maybe both of us should test it if I have enough.

#110

Senior Member

Join Date: Nov 2011

Posts: 152

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Sorry to resurrect this, but I gotta say, JoeJack, those are the best photos of a mechanical problem I have ever seen on a discussion board. They really got this thread off on the right foot by clearly communicating to us what the exact failure was. Well done.

#111

Senior Member

Join Date: Feb 2011

Posts: 105

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

taking a chain off for cleaning is silly...and a total PITA. I used to do that until I got lazy...and guess what? my chains last just as long as they did before.

just take a clean rag to it (I use old t-shirts)...spin the cranks until the chain doesnt dirty up the rag.

re-apply lube. one drop per link.

wipe off excess lube after a couple hours. I usually wait at least two hours...or overnight.

do this every so often...once a week, every other week...whatever, depending mileage & weather conditions.

works just fine.

just take a clean rag to it (I use old t-shirts)...spin the cranks until the chain doesnt dirty up the rag.

re-apply lube. one drop per link.

wipe off excess lube after a couple hours. I usually wait at least two hours...or overnight.

do this every so often...once a week, every other week...whatever, depending mileage & weather conditions.

works just fine.

#112

Senior Member

Join Date: Nov 2010

Location: River City, OR

Posts: 672

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 9 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

It is the internet after all. Five pages trying to prove that a defective chain isn't really defective?

Been working for lots of people (me included) for many years. If it could ever be proven that the chemical in question was the cause of failure, I'd just quit doing it. Maybe the "green" thing came back to bite you in the butt- as it normally will if not applied properly.

taking a chain off for cleaning is silly...and a total PITA. I used to do that until I got lazy...and guess what? my chains last just as long as they did before

#113

Senior Member

Thread Starter

#114

Senior Member

Join Date: Nov 2011

Posts: 152

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

#115

Senior Member

Join Date: May 2007

Posts: 252

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 4 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

Joejack linked to the following site earlier, but to the galvanic corrosion page. I think the stress corrosion cracking is a better fit for this particular issue. It is NOT a defective chain.

If may not be clear, but the peening process would put a significant radial stress on the side plates, and this stress exists as the chain is laying free on a table top.

As an aside, some years back I did an engineering co-op rotation at an aircraft propeller manufacturer. One of the last steps in aluminum blade processing was to induce a compressive pre-stress in the surface zone of the blade root by a simple rolling process. Even a single hunk of metal, loaded only only modestly by gravity, can be significantly stressed, either by design or accident.

Thanks to Cyccommute for enlightening with the chemical origin for the corrosion.

If may not be clear, but the peening process would put a significant radial stress on the side plates, and this stress exists as the chain is laying free on a table top.

As an aside, some years back I did an engineering co-op rotation at an aircraft propeller manufacturer. One of the last steps in aluminum blade processing was to induce a compressive pre-stress in the surface zone of the blade root by a simple rolling process. Even a single hunk of metal, loaded only only modestly by gravity, can be significantly stressed, either by design or accident.

Thanks to Cyccommute for enlightening with the chemical origin for the corrosion.

#116

Junior Member

Join Date: Sep 2011

Posts: 21

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 0 Times

in

0 Posts

A fatigue failure of the chain would not look like the failure shown here. The crack would propagate through the chain link at the point where the "C" is stamped. this failure is either stress corrosion or hydrogen embrittlement.

Scroll down this link to see that the naysayers are wrong. Clearly a chemical issue here.

https://www.hitachi-metals-techno.com...roller/05.html

Scroll down this link to see that the naysayers are wrong. Clearly a chemical issue here.

https://www.hitachi-metals-techno.com...roller/05.html

#117

Speechless

Join Date: Jun 2011

Location: Central NY

Posts: 8,842

Bikes: Felt Brougham, Lotus Prestige, Cinelli Xperience,

Mentioned: 22 Post(s)

Tagged: 1 Thread(s)

Quoted: 163 Post(s)

Likes: 0

Liked 39 Times

in

16 Posts

I just stumbled on this thread, and was thinking hydrogen embrittlement from the first photos. Chain links are through hardening steels, electro plated, and can be very susceptible. Mineral spirits are hydro-carbons, so if you had an initial issue, the assembly is under constant stress (compression on pin, tension on link), and you provide more fuel for increased loss of strength.

It isn't corrosion, it is a plummet in the base strength of the steel. And as Cyccommute says, the area where waist meets end radius is a large potential stress riser. I have never manufactured bicycle chain, but nine years with industrial roller chain showed me some things. Some old dies used separate waist punch from the blanking punch, so mis-match and stress riser was easy at that point. Even with one piece blankers, that transition point was easy to flub, until we started using wire EDM on all of our blank punches. By design, that area is also weakest point, and planned failure area (smallest cross section in tension), so any stress riser just moves it closer.

Also, chain is a commodity, with a high % of material cost. We had to constantly search for cheapest material, and links had lots of acceptable alternates in strip steel, so we would vary for availability and cost. Different materials would interact in the plating process differently, and hydrogen embrittlement was a large concern. My memory is foggy at this point, but I seem to recollect grades that our metallurgist insisted that we did not plate, but unfortunately, that was awhile ago.

It isn't corrosion, it is a plummet in the base strength of the steel. And as Cyccommute says, the area where waist meets end radius is a large potential stress riser. I have never manufactured bicycle chain, but nine years with industrial roller chain showed me some things. Some old dies used separate waist punch from the blanking punch, so mis-match and stress riser was easy at that point. Even with one piece blankers, that transition point was easy to flub, until we started using wire EDM on all of our blank punches. By design, that area is also weakest point, and planned failure area (smallest cross section in tension), so any stress riser just moves it closer.

Also, chain is a commodity, with a high % of material cost. We had to constantly search for cheapest material, and links had lots of acceptable alternates in strip steel, so we would vary for availability and cost. Different materials would interact in the plating process differently, and hydrogen embrittlement was a large concern. My memory is foggy at this point, but I seem to recollect grades that our metallurgist insisted that we did not plate, but unfortunately, that was awhile ago.

#118

Mad bike riding scientist

Join Date: Nov 2004

Location: Denver, CO

Posts: 27,495

Bikes: Some silver ones, a red one, a black and orange one, and a few titanium ones

Mentioned: 153 Post(s)

Tagged: 1 Thread(s)

Quoted: 6295 Post(s)

Liked 4,331 Times

in

2,427 Posts

The Great Chain Corrosion experiment is finally over! On 23 October, 2011, I placed a piece of chain in a saline solution (~6% sodium chloride). Here's a pictures showing the proportions and the clean chain in the solution

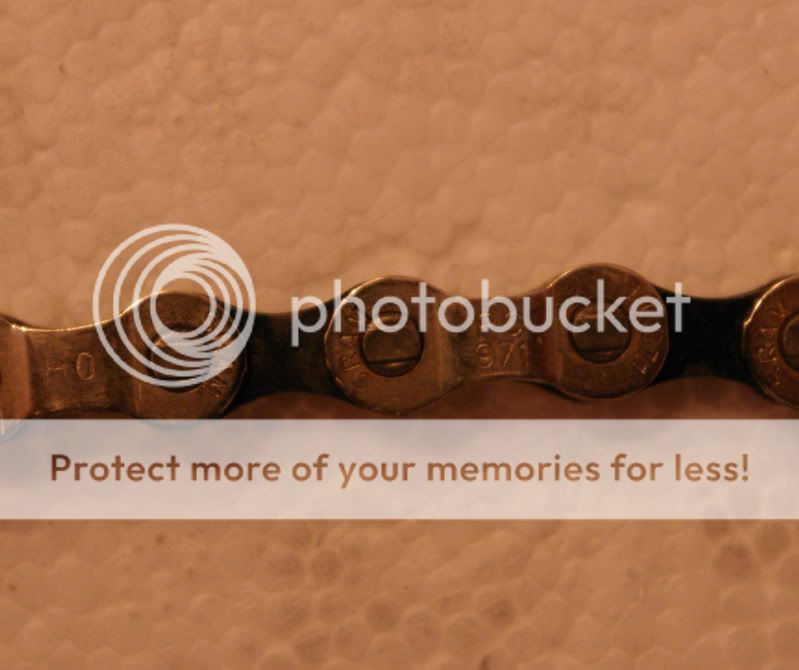

The chain I used was completely free of defects as shown in this picture

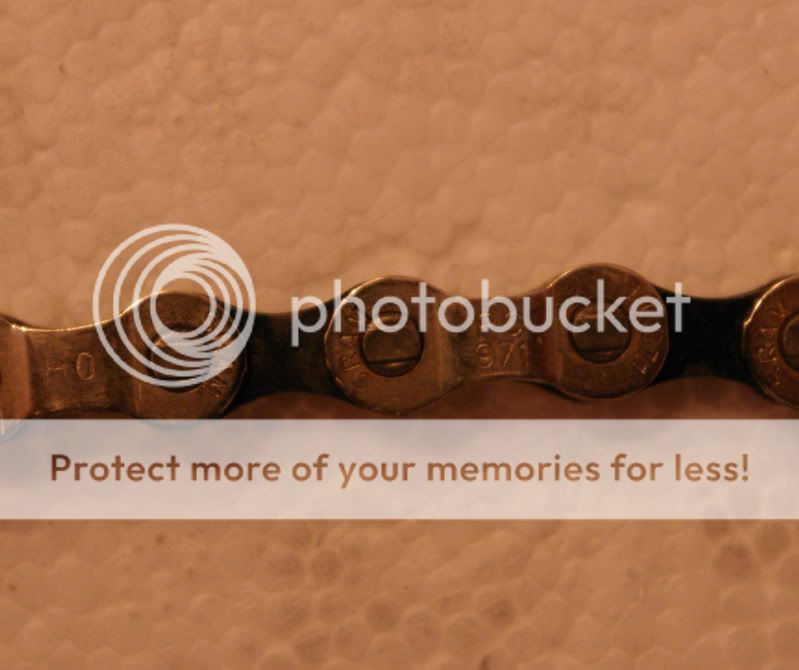

I checked the chain by removing it periodically and inspecting it for the kinds of cracks that JoeJack experienced and, frankly, I was prepared for failure. This morning, 9 December 2011, I checked it again and here's the result:

What the mixture looks like

and the chain

You can clearly see two cracks in the chain that weren't there before I placed the chain in the solution. Both cracks look very much like JoeJack's chain and are in the stamped parts of the chain where I would expect the highest stresses during manufacture of the chain. I'm both amazed that it took so long and astounded that it happened in only 40 days.

My wife will be glad to get the damned jar of rust off her counter. And I think we should all thank her for putting up with my silly bicycle science experiment.

The chain I used was completely free of defects as shown in this picture

I checked the chain by removing it periodically and inspecting it for the kinds of cracks that JoeJack experienced and, frankly, I was prepared for failure. This morning, 9 December 2011, I checked it again and here's the result:

What the mixture looks like

and the chain

You can clearly see two cracks in the chain that weren't there before I placed the chain in the solution. Both cracks look very much like JoeJack's chain and are in the stamped parts of the chain where I would expect the highest stresses during manufacture of the chain. I'm both amazed that it took so long and astounded that it happened in only 40 days.

My wife will be glad to get the damned jar of rust off her counter. And I think we should all thank her for putting up with my silly bicycle science experiment.

__________________

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Stuart Black

Plan Epsilon Around Lake Michigan in the era of Covid

Old School…When It Wasn’t Ancient bikepacking

Gold Fever Three days of dirt in Colorado

Pokin' around the Poconos A cold ride around Lake Erie

Dinosaurs in Colorado A mountain bike guide to the Purgatory Canyon dinosaur trackway

Solo Without Pie. The search for pie in the Midwest.

Picking the Scablands. Washington and Oregon, 2005. Pie and spiders on the Columbia River!

Last edited by cyccommute; 12-09-11 at 11:06 AM.

Likes For cyccommute:

#119

Senior Member

Join Date: Feb 2009

Location: Southwest MO

Posts: 782

Bikes: (2) 1994 Cannondale R900, red, Silver Trek hybrid

Mentioned: 1 Post(s)

Tagged: 0 Thread(s)

Quoted: 69 Post(s)

Liked 4 Times

in

4 Posts

Very interesting.

Is this not related to the failure of the hull of the Titanic? I thought I'd heard that the cold salt water reacted with the steel/iron and that this type of steel/iron was made really brittle in the water. I'm not a chemist, but that's how I recall the story I heard.

Is this not related to the failure of the hull of the Titanic? I thought I'd heard that the cold salt water reacted with the steel/iron and that this type of steel/iron was made really brittle in the water. I'm not a chemist, but that's how I recall the story I heard.

#120

Senior Member

Join Date: Mar 2005

Location: South Florida

Posts: 726

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 2 Times

in

2 Posts

The OP states that the damage was done by mineral spirits. See #1. Correct me if I am wrong but he mentions no other chemicals, salts or concoctions being involved.

Looks like apples and oranges?

Looks like apples and oranges?

Likes For Nerull:

#123

Senior Member

Join Date: Mar 2005

Location: South Florida

Posts: 726

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 1 Post(s)

Likes: 0

Liked 2 Times

in

2 Posts

Nerull,

How about checking #22

Spoke to Roy from Klean Strip, Barr Products Memphis Tn. He said he has never heard of their products damaging steel.

Roy said it was OK to use his name and will accept calls. 1-800 398 3892.

He asked for pictures and any information that he could forward to their engineers/chemists for examination.

There you go. We are not talking about all kinds of other concoctions. We are talking about what the OP originally used.

Want to settle it once and for all, call the manufacturer and ask the question. Send in the proof.

How about checking #22

Spoke to Roy from Klean Strip, Barr Products Memphis Tn. He said he has never heard of their products damaging steel.

Roy said it was OK to use his name and will accept calls. 1-800 398 3892.

He asked for pictures and any information that he could forward to their engineers/chemists for examination.

There you go. We are not talking about all kinds of other concoctions. We are talking about what the OP originally used.

Want to settle it once and for all, call the manufacturer and ask the question. Send in the proof.

#124

Senior Member

Join Date: Apr 2008

Location: A Latvian in Seattle

Posts: 1,020

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 0 Post(s)

Likes: 0

Liked 1 Time

in

1 Post

Thus, we've got a water phase with some kind of salt in it, according to the OP.

#125

Senior Member

Join Date: Sep 2007

Location: Gaseous Cloud around Uranus

Posts: 3,741

Mentioned: 0 Post(s)

Tagged: 0 Thread(s)

Quoted: 38 Post(s)

Likes: 0

Liked 11 Times

in

7 Posts

The cracks appear around the pins,where there is the least amount of room.

My guess is that the salts are re-crystalizing between the pin and side plate and needs more room,so it makes room,much the way loctite works or sorta like making rock candy on a smaller scale.

I'm guessing those cracks would not appear if the fluid was kept moving and crystals couldn't form.

Pull a link apart with just a hole,then put it in a salt solution.....I'm guessing the hole will be fine.

Gotta admit,it is interesting......

My guess is that the salts are re-crystalizing between the pin and side plate and needs more room,so it makes room,much the way loctite works or sorta like making rock candy on a smaller scale.

I'm guessing those cracks would not appear if the fluid was kept moving and crystals couldn't form.

Pull a link apart with just a hole,then put it in a salt solution.....I'm guessing the hole will be fine.

Gotta admit,it is interesting......

Last edited by Booger1; 12-09-11 at 05:47 PM.