Hunt carbon rim exploded while inflating

#101

Senior Member

Join Date: May 2021

Posts: 8,442

Mentioned: 12 Post(s)

Tagged: 0 Thread(s)

Quoted: 4414 Post(s)

Liked 4,867 Times

in

3,012 Posts

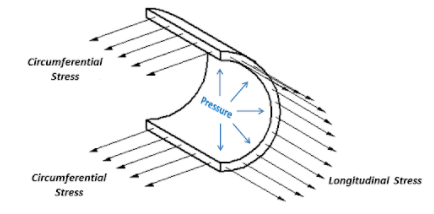

I find this conversation to be very informative as I'd always assumed that 100psi is a 100psi and if that's what a rim is rated for than why would the tire matter. Still not fully getting it as the amount of material in contact with the rim would seem to be the same regardless of the tire size, either way its the same amount of tire contact at the bead as well as the same amount of pressure contained within the system, So is it ultimately a leverage situation? The way the tire expands pushes out on the rim differently effecting how the stress of holding the tire is placed on the rim? Cause I read the amount of area being an issue but I don't see how a larger tire has any more area in contact with the rim. The larger tire has a larger cross section obviously but it would seem to me that there can't be any additional amount air in contact with the rim as the bigger tire does nothing to change the amount of surface area of the rim the tire/tube/air can act upon. How can any size tire with a 100psi apply more pressure than 100psi onto the rim other than by increasing the load on the tire?

So for example if you double the tyre internal surface area, then you double the force acting on the bead at the same pressure. Pressure is just force per unit area.

#102

Advanced Slacker

Join Date: Feb 2017

Posts: 6,210

Bikes: Soma Fog Cutter, Surly Wednesday, Canfielld Tilt

Mentioned: 26 Post(s)

Tagged: 0 Thread(s)

Quoted: 2762 Post(s)

Liked 2,537 Times

in

1,433 Posts

Disclaimer: I did not read past the 1st page of comments.

Just chiming in to say that what Hunt is claiming is true. Higher volume mean more bead stress at the same pressure.

I can see someone who is not so familiar with tubeless making the OP’s error. Being a bit more familiar with this stuff I would not pump a 38mm tire up to 80psi tubeless unless I had some clear documentation that both the tire and rim could handle it. I almost reached to plug my ears and shield my face when I read your opening sentence.

I do think these things need to be more well and explicitly labeled right on the rims, the same way max tire pressure is labeled on tires. It should give max pressure at a few different tire sizes. IF the rims just say “100 psi max” that is misleading , IMO.

Just chiming in to say that what Hunt is claiming is true. Higher volume mean more bead stress at the same pressure.

I can see someone who is not so familiar with tubeless making the OP’s error. Being a bit more familiar with this stuff I would not pump a 38mm tire up to 80psi tubeless unless I had some clear documentation that both the tire and rim could handle it. I almost reached to plug my ears and shield my face when I read your opening sentence.

I do think these things need to be more well and explicitly labeled right on the rims, the same way max tire pressure is labeled on tires. It should give max pressure at a few different tire sizes. IF the rims just say “100 psi max” that is misleading , IMO.

Likes For Kapusta:

#103

Senior Member

Join Date: Sep 2017

Posts: 7,887

Mentioned: 38 Post(s)

Tagged: 0 Thread(s)

Quoted: 6972 Post(s)

Liked 10,968 Times

in

4,692 Posts

"I'm gonna assume a whole bunch of stuff that confirms my uninformed bias."

Likes For Koyote:

#104

climber has-been

Join Date: Dec 2004

Location: Palo Alto, CA

Posts: 7,111

Bikes: Scott Addict R1, Felt Z1

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 3432 Post(s)

Liked 3,567 Times

in

1,793 Posts

I find this conversation to be very informative as I'd always assumed that 100psi is a 100psi and if that's what a rim is rated for than why would the tire matter. Still not fully getting it as the amount of material in contact with the rim would seem to be the same regardless of the tire size, either way its the same amount of tire contact at the bead as well as the same amount of pressure contained within the system...How can any size tire with a 100psi apply more pressure than 100psi onto the rim other than by increasing the load on the tire?

If the tire has a bigger circumference, the "pull away" (circumferential) force will be higher.

Last edited by terrymorse; 12-11-23 at 12:45 PM.

Likes For terrymorse:

#105

Senior Member

Join Date: May 2022

Location: USA - Southwest PA

Posts: 3,098

Bikes: Cannondale - Gary Fisher - Giant - Litespeed - Schwinn Paramount - Schwinn (lugged steel) - Trek OCLV

Mentioned: 6 Post(s)

Tagged: 0 Thread(s)

Quoted: 1400 Post(s)

Liked 1,882 Times

in

1,083 Posts

Alfred Hitchcock warned us about carbon rims

just sayin

#106

Senior Member

Thus, Imo, engineering a rim with at 40 psi (2.76 bar) max pressure is simply fail and a free replacement is justified. - Sadly, replacing the rim with another identical rim is likely to leave you in the same situation, next time around.

#107

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,906

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4806 Post(s)

Liked 3,931 Times

in

2,556 Posts

#108

Newbie

Thread Starter

Well, you should Always adhere the the max pressure of either the rim or the tyre, whichever is higher. HOWever , what good is it your tyre wont seat at the rim max pressure. That seems to be the case in this instance.

Thus, Imo, engineering a rim with at 40 psi (2.76 bar) max pressure is simply fail and a free replacement is justified. - Sadly, replacing the rim with another identical rim is likely to leave you in the same situation, next time around.

Thus, Imo, engineering a rim with at 40 psi (2.76 bar) max pressure is simply fail and a free replacement is justified. - Sadly, replacing the rim with another identical rim is likely to leave you in the same situation, next time around.

The replacement rim did arrive 3 days after I heard from them, will get it rebuilt in a few weeks.

The replacement rim did arrive 3 days after I heard from them, will get it rebuilt in a few weeks.I have definitely learned a good bit on the thread !

Likes For Kbarter:

#109

Senior Member

Join Date: Oct 2014

Location: Portland, OR

Posts: 12,906

Bikes: (2) ti TiCycles, 2007 w/ triple and 2011 fixed, 1979 Peter Mooney, ~1983 Trek 420 now fixed and ~1973 Raleigh Carlton Competition gravel grinder

Mentioned: 129 Post(s)

Tagged: 0 Thread(s)

Quoted: 4806 Post(s)

Liked 3,931 Times

in

2,556 Posts

Well, you should Always adhere the the max pressure of either the rim or the tyre, whichever is higher. HOWever , what good is it your tyre wont seat at the rim max pressure. That seems to be the case in this instance.

Thus, Imo, engineering a rim with at 40 psi (2.76 bar) max pressure is simply fail and a free replacement is justified. - Sadly, replacing the rim with another identical rim is likely to leave you in the same situation, next time around.

Thus, Imo, engineering a rim with at 40 psi (2.76 bar) max pressure is simply fail and a free replacement is justified. - Sadly, replacing the rim with another identical rim is likely to leave you in the same situation, next time around.

Of course, required seating pressure is a function of both the rim and tire. The rim manufacturer has no say in the latter.

Or ... maybe some bright engineer needs to come up with a non-air pressure means of seating tubeless tires; allowing bigger tubeless tires for marginal rims. Perhaps in 20 years, folk will be saying "remember when they use to inflate tubeless tires to insane pressures to seat those beads? All the blown sidewalls and eardrums? Thank God we have our BeadSeater." Or ... ding, ding! You could remove the flanges entirely, make the entire rim a little bigger in diameter to raise up the lower portion to use existing tire sizes, then glue! a tire that's already been sewn or formed into a tube. No rim failures at any pressure. With all the modern adhesives, this should be easy.

#110

climber has-been

Join Date: Dec 2004

Location: Palo Alto, CA

Posts: 7,111

Bikes: Scott Addict R1, Felt Z1

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 3432 Post(s)

Liked 3,567 Times

in

1,793 Posts

Likes For terrymorse:

#111

Senior Member

Join Date: May 2021

Posts: 8,442

Mentioned: 12 Post(s)

Tagged: 0 Thread(s)

Quoted: 4414 Post(s)

Liked 4,867 Times

in

3,012 Posts

Or ... maybe some bright engineer needs to come up with a non-air pressure means of seating tubeless tires; allowing bigger tubeless tires for marginal rims. Perhaps in 20 years, folk will be saying "remember when they use to inflate tubeless tires to insane pressures to seat those beads? All the blown sidewalls and eardrums? Thank God we have our BeadSeater." Or ... ding, ding! You could remove the flanges entirely, make the entire rim a little bigger in diameter to raise up the lower portion to use existing tire sizes, then glue! a tire that's already been sewn or formed into a tube. No rim failures at any pressure. With all the modern adhesives, this should be easy.

https://www.bicyclerollingresistance...oria-air-liner

“The first problem the Air-Liner Road solves is inflating tubeless tires, which can be a real problem with some tires and rim combinations. The Air-Liner solves this problem by making sure the beads are pre-seated and inflating the tire becomes extremely easy.”

Likes For PeteHski:

#112

climber has-been

Join Date: Dec 2004

Location: Palo Alto, CA

Posts: 7,111

Bikes: Scott Addict R1, Felt Z1

Mentioned: 10 Post(s)

Tagged: 0 Thread(s)

Quoted: 3432 Post(s)

Liked 3,567 Times

in

1,793 Posts

I struggle to see how that tire insert would manage to seat a tire bead. It ought to function during installation about the same as a slightly inflated inner tube, which experience shows that it does little to help seat a bead, but it does make it harder to install the tire.

Likes For terrymorse:

#113

Senior Member

Join Date: May 2021

Posts: 8,442

Mentioned: 12 Post(s)

Tagged: 0 Thread(s)

Quoted: 4414 Post(s)

Liked 4,867 Times

in

3,012 Posts

I struggle to see how that tire insert would manage to seat a tire bead. It ought to function during installation about the same as a slightly inflated inner tube, which experience shows that it does little to help seat a bead, but it does make it harder to install the tire.

Likes For Racing Dan:

#115

Senior Member

Well, there's choosing components that work well for their intended use. Manufacturers should be helpful here but there is a long history in bicycling and elsewhere where they aren't. Knowledgeable shops are an asset. So is buyer awareness. I am often wondering "why don't ...". Here, why don't rim manufactures give a biggest recommended tire along with max seating pressure allowable for that rim? (Maybe they do. I haven't done tubeless and have in fact gone away from clincher tires entirely.)

Of course, required seating pressure is a function of both the rim and tire. The rim manufacturer has no say in the latter.

Or ... maybe some bright engineer needs to come up with a non-air pressure means of seating tubeless tires; allowing bigger tubeless tires for marginal rims. Perhaps in 20 years, folk will be saying "remember when they use to inflate tubeless tires to insane pressures to seat those beads? All the blown sidewalls and eardrums? Thank God we have our BeadSeater." Or ... ding, ding! You could remove the flanges entirely, make the entire rim a little bigger in diameter to raise up the lower portion to use existing tire sizes, then glue! a tire that's already been sewn or formed into a tube. No rim failures at any pressure. With all the modern adhesives, this should be easy.

Of course, required seating pressure is a function of both the rim and tire. The rim manufacturer has no say in the latter.

Or ... maybe some bright engineer needs to come up with a non-air pressure means of seating tubeless tires; allowing bigger tubeless tires for marginal rims. Perhaps in 20 years, folk will be saying "remember when they use to inflate tubeless tires to insane pressures to seat those beads? All the blown sidewalls and eardrums? Thank God we have our BeadSeater." Or ... ding, ding! You could remove the flanges entirely, make the entire rim a little bigger in diameter to raise up the lower portion to use existing tire sizes, then glue! a tire that's already been sewn or formed into a tube. No rim failures at any pressure. With all the modern adhesives, this should be easy.

#116

Senior Member

Join Date: Mar 2010

Posts: 1,659

Mentioned: 7 Post(s)

Tagged: 0 Thread(s)

Quoted: 1248 Post(s)

Liked 1,323 Times

in

674 Posts

The incident under consideration involves a circumstance hitherto unencountered, encompassing five pages of documentation and eliciting 115 comments. Noteworthy is the fact that the application of tubeless tires to carbon rims, a practice that has seen widespread adoption, has heretofore demonstrated an absence of notable incidents. It is plausible to posit that the occurrence in question may be an isolated event, and the prevailing consensus suggests the continuation of routine practices. Furthermore, given the unique nature of this specific case, it is conceivable that the tire pressure exceeded the value indicated by the original poster. In light of this analysis, I am inclined to persist in my established approach, affording minimal consideration to this singular occurrence.

Last edited by Atlas Shrugged; 12-11-23 at 07:10 PM.