Originally Posted by

Robvolz

...as a way to differentiate themselves and their product was to hand-hammer so you knew the product, whether it be a bowl, a light fixture or fenders were hand crafted by people, not machines.

Now, a stamping machine creates the HH look. And no one seems to care what it represented at one time.

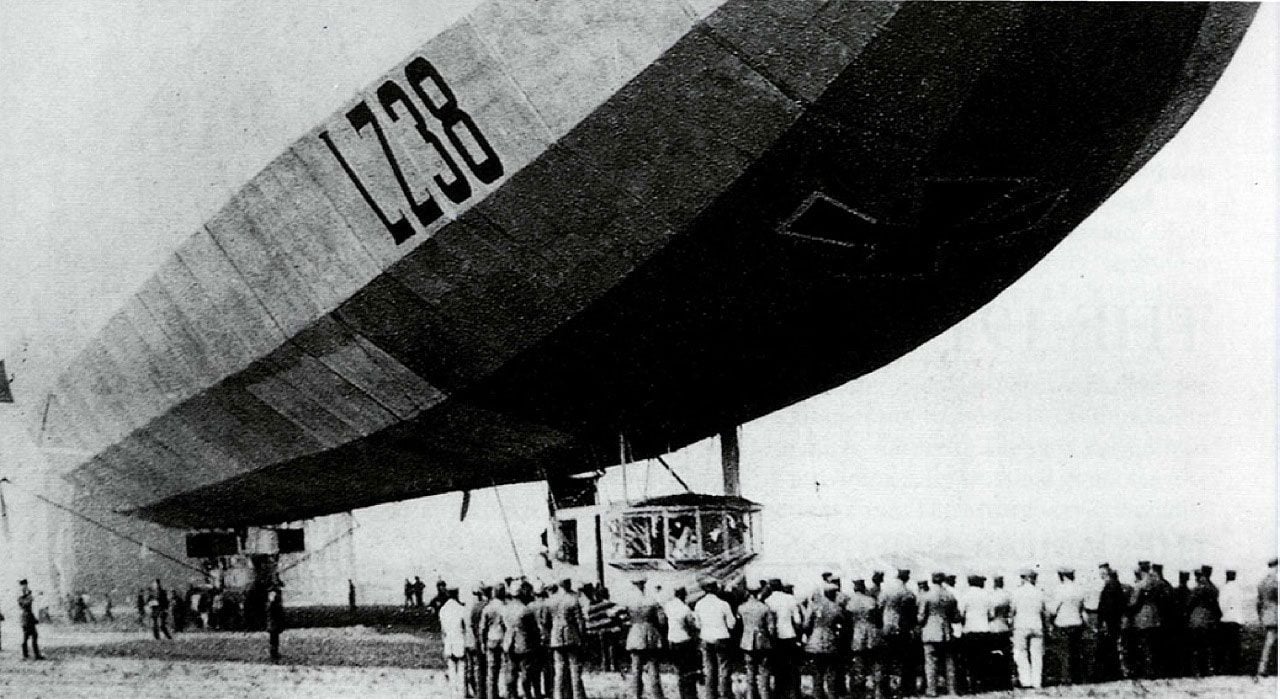

The problem with this is, I just don't think the hand hammered look ever represented hand craft, in bicycle fenders at least. Hammered aluminum bike fenders came out in the '30s or '40s, same time as your streamline toaster. They were always made by machine, as far as I know. The modern ones are reproductions or homages to these, not anything earlier. These '30s and '40s hammered fenders were part of a product lineup that included fluted fenders, smooth fenders, and fenders that had polygonal facets, called "zeppelins" by some because they resembled the Zeppelin's polygonal cross-section. Maybe these Zeppelins would be more amenable to your modernist streamlined aesthetic?

Funny enough, the French company Lefol made a Zeppelin style fender, but possibly because of anti-krautism, they called it "Le Paon" (the peacock).

Originally Posted by

steelbikeguy

Legend says that the first Pro's with hammered rivets were Pro's where the rivets were removed, the leather was subjected to some special treatment to soften it up, and then re-riveted to the saddle frame. To make it look nice, larger rivets were needed to cover the area around the holes (no idea why), and the hammering was needed either to get that large rivet flush with the leather or shaped to match the leather's contours or some other reason.

The first saddles with hammered rivets were "butchered" saddles. It wasn't all about softening the leather, although you could get that done. It was more about customizing. Professionals and other performance-inclined individuals would give a stock saddle (which came with machine-done steel rivets) to someone to butcher. Could be a leatherworker, cobbler, or whatever. This guy would lighten the saddle and give it a custom shape that could be better for the individual who ordered the butchery. The leather would be taken off, the saddle frame possibly altered, the leather chopped and reshaped, and then the whole thing needed to be put back together, which would be done by hand. This is where the hand hammered rivets came in. They were easier to do and possibly better at holding the leather on. And on a small scale like a cobbler's shop or bike shop doing one-off saddle butchery, they didn't cost any more than buying steel rivets and a setting die, which you'd need for steel rivets.

This is my example of a butchered saddle. I think it's from the '50s or so. It started out as a B17, as evidenced by the markings on the leather, so I have placed a stock B17 next to it for scale. The cantle plate shows evidence of being hammered inwards to reduce the width. The leather curls inward under it even without lacing. It is surprisingly comfortable for how it looks. And lighter than any other leather saddle I have, in spite of its steel rails.

So having hand-hammered rivets was a sign of high-performance gear.